air condition MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 707 of 909

ON-BOARD DIAGNOSTIC

M–77

M

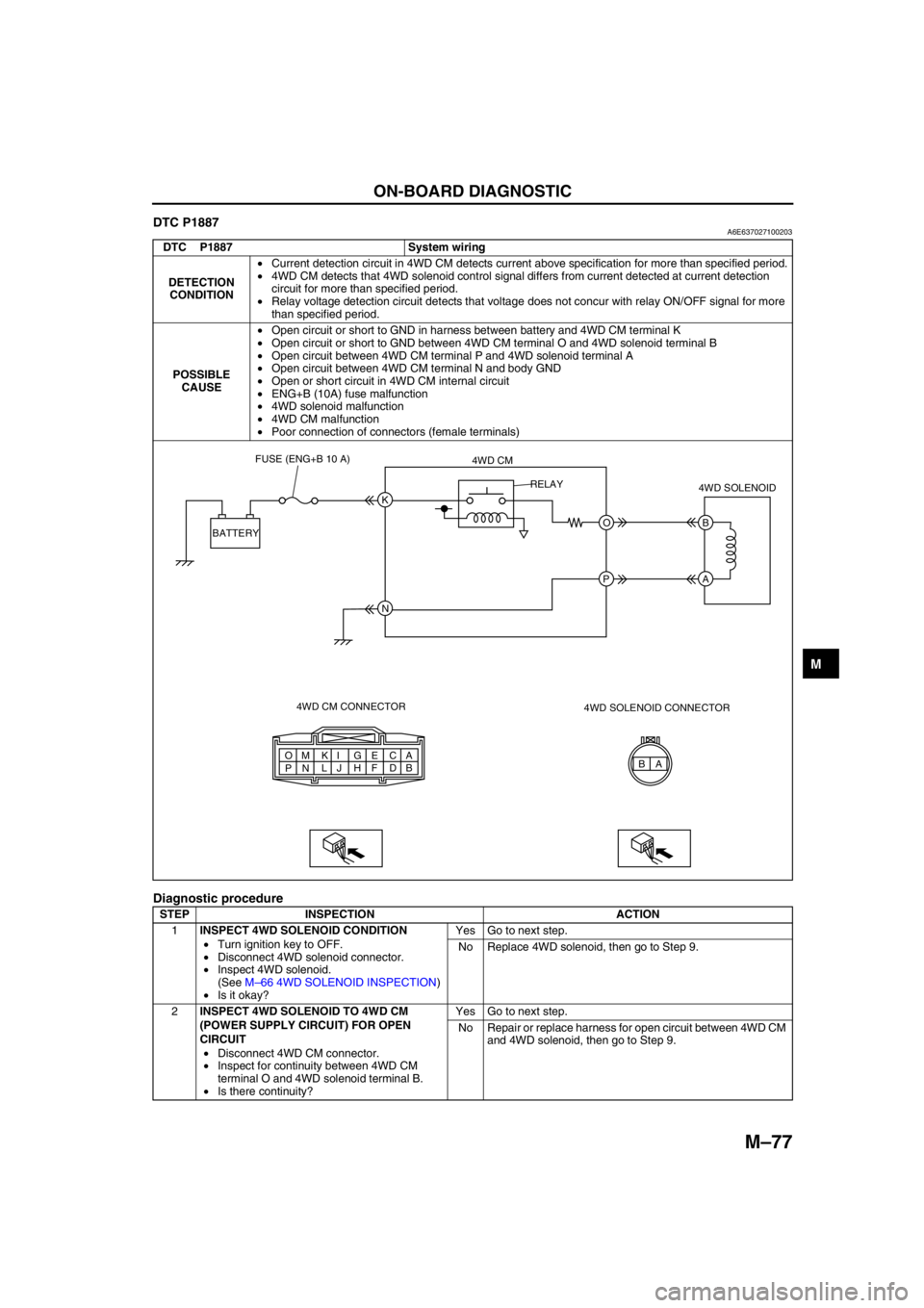

DTC P1887A6E637027100203

Diagnostic procedure

DTC P1887 System wiring

DETECTION

CONDITION•Current detection circuit in 4WD CM detects current above specification for more than specified period.

•4WD CM detects that 4WD solenoid control signal differs from current detected at current detection

circuit for more than specified period.

•Relay voltage detection circuit detects that voltage does not concur with relay ON/OFF signal for more

than specified period.

POSSIBLE

CAUSE•Open circuit or short to GND in harness between battery and 4WD CM terminal K

•Open circuit or short to GND between 4WD CM terminal O and 4WD solenoid terminal B

•Open circuit between 4WD CM terminal P and 4WD solenoid terminal A

•Open circuit between 4WD CM terminal N and body GND

•Open or short circuit in 4WD CM internal circuit

•ENG+B (10A) fuse malfunction

•4WD solenoid malfunction

•4WD CM malfunction

•Poor connection of connectors (female terminals)

STEP INSPECTION ACTION

1INSPECT 4WD SOLENOID CONDITION

•Turn ignition key to OFF.

•Disconnect 4WD solenoid connector.

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is it okay?Yes Go to next step.

No Replace 4WD solenoid, then go to Step 9.

2INSPECT 4WD SOLENOID TO 4WD CM

(POWER SUPPLY CIRCUIT) FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector.

•Inspect for continuity between 4WD CM

terminal O and 4WD solenoid terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and 4WD solenoid, then go to Step 9.

A A

B C

D E

F G

H I

J K

L M

N O

PB K

O B

A

N P BATTERYFUSE (ENG+B 10 A)

4WD CM

4WD CM CONNECTOR4WD SOLENOID

4WD SOLENOID CONNECTOR RELAY

Page 708 of 909

M–78

ON-BOARD DIAGNOSTIC

End Of Sie

3INSPECT 4WD SOLENOID TO 4WD CM

(POWER SUPPLY CIRCUIT) FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal O and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and 4WD solenoid, then go to Step 9.

No Go to next step.

4INSPECT 4WD SOLENOID TO 4WD CM

(GROUND CIRCUIT) FOR OPEN CIRCUIT

•Inspect for continuity between 4WD CM

terminal P and 4WD solenoid terminal A.

•Is there continuity?Yes Replace 4WD CM, then go to next step.

No Repair or replace harness for open circuit between 4WD CM

and 4WD solenoid, then go to Step 9.

5INSPECT 4WD CM POWER SUPPLY CIRCUIT

FOR OPEN CIRCUIT

•Measure voltage between 4WD CM terminal

K and ground.

•Is voltage B+?Yes Replace 4WD CM, then go to Step 9.

No Go to next step.

6INSPECT 4WD CM TO BATTERY FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector and battery

positive terminal.

•Inspect for continuity between 4WD CM

terminal K and battery positive terminal.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and battery positive terminal, then go to Step 9.

7INSPECT 4WD CM TO BATTERY FOR SHORT

TO GROUND

•Inspect for continuity between 4WD CM

terminal K and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and battery positive terminal, then go to Step 9.

No Replace 4WD CM, then go to step 9.

8INSPECT FUSE CONDITION

•Turn ignition key to OFF.

•Is ENG+B fuse (10A) okay?Yes Go to next step.

No Replace fuse, then go to Step 9.

9VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

(See M–76 Clearing DTCs Procedures)

•Drive vehicle.

•Is the same DTC present?Yes Replace 4WD CM, then go to next step.

No Go to next step.

10VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 709 of 909

ON-BOARD DIAGNOSTIC

M–79

M

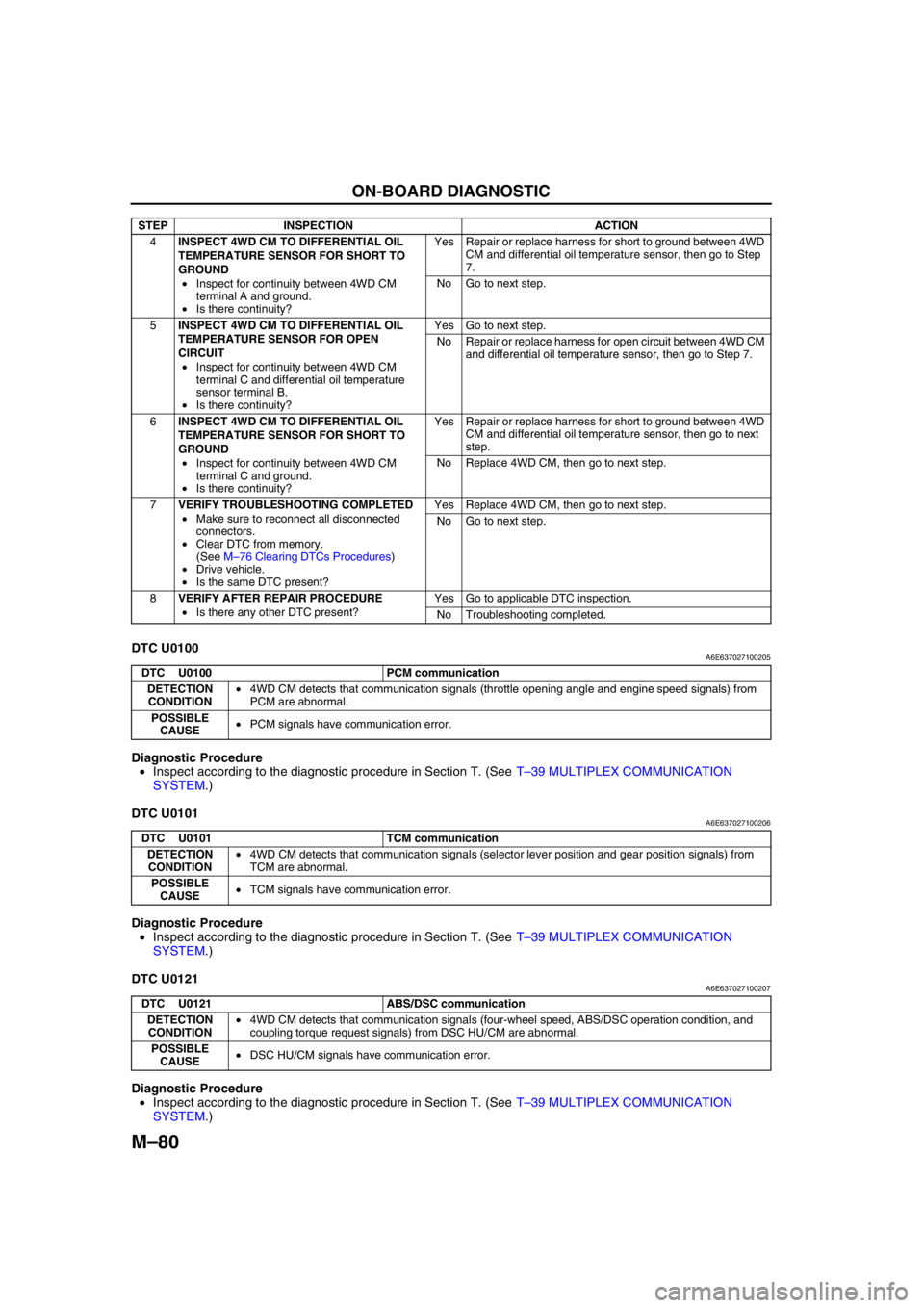

DTC P1888A6E637027100204

Diagnostic procedure

DTC P1888 Differential oil temperature sensor

DETECTION

CONDITION•Differential oil temperature sensor voltage monitor circuit detects abnormal input voltage.

POSSIBLE

CAUSE•Open circuit, or short to battery or GND between 4WD CM terminal A and differential oil temperature

sensor terminal A

•Open circuit or short to battery between 4WD CM terminal C and differential oil temperature sensor

terminal B

•Differential oil temperature sensor malfunction

•4WD CM malfunction

•Poor connection of connectors (female terminals)

STEP INSPECTION ACTION

1INSPECT DIFFERENTIAL OIL

TEMPERATURE SENSOR CONDITION

•Turn ignition key to OFF.

•Disconnect differential oil temperature

sensor connector.

•Is it okay?Yes Go to next step.

No Replace differential oil temperature sensor, then go to Step

7.

2INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector.

•Inspect for continuity between 4WD CM

terminal A and differential oil temperature

sensor terminal A.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and differential oil temperature sensor, then go to Step 7.

3INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

POWER

•Inspect voltage between 4WD CM terminal A

and ground.

•Is voltage B+?Yes Repair or replace harness for short to power between 4WD

CM and differential oil temperature sensor, then go to Step

7.

No Go to next step.

A B A

B C

D E

F G

H I

J K

L M

N O

PA

C A

B

4WD CM CONNECTOR4WD CM

DIFFERENTIAL OIL

TEMPERATURE SENSOR

DIFFERENTIAL OIL TEMPERATURE

SENSOR CONNECTOR

Page 710 of 909

M–80

ON-BOARD DIAGNOSTIC

End Of Sie

DTC U0100A6E637027100205

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

DTC U0101A6E637027100206

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

DTC U0121A6E637027100207

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

4INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal A and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and differential oil temperature sensor, then go to Step

7.

No Go to next step.

5INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR OPEN

CIRCUIT

•Inspect for continuity between 4WD CM

terminal C and differential oil temperature

sensor terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and differential oil temperature sensor, then go to Step 7.

6INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal C and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and differential oil temperature sensor, then go to next

step.

No Replace 4WD CM, then go to next step.

7VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

(See M–76 Clearing DTCs Procedures)

•Drive vehicle.

•Is the same DTC present?Yes Replace 4WD CM, then go to next step.

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC U0100 PCM communication

DETECTION

CONDITION•4WD CM detects that communication signals (throttle opening angle and engine speed signals) from

PCM are abnormal.

POSSIBLE

CAUSE•PCM signals have communication error.

DTC U0101 TCM communication

DETECTION

CONDITION•4WD CM detects that communication signals (selector lever position and gear position signals) from

TCM are abnormal.

POSSIBLE

CAUSE•TCM signals have communication error.

DTC U0121 ABS/DSC communication

DETECTION

CONDITION•4WD CM detects that communication signals (four-wheel speed, ABS/DSC operation condition, and

coupling torque request signals) from DSC HU/CM are abnormal.

POSSIBLE

CAUSE•DSC HU/CM signals have communication error.

Page 712 of 909

M–82

TROUBLESHOOTING

FOREWORDA6E638027100202

End Of Sie

SYMPTOM TROUBLESHOOTINGA6E638027100203•Verify the symptoms, and perform troubleshooting according to the appropriate number.

End Of Sie

NO.1 FREQUENT FRONT WHEEL SLIPA6E638027100204

Warning

•During simulation driving, vehicle stability may decrease extremely and cause an accident. Be

sure to perform the simulation test driving in a safe area.

Malfunction vehicle delivered

Questionnaire

Verify malfunction symptoms

Symptom troubleshooting

Verify that malfunctions have been repaired

Troubleshooting completedConfirm all customer problems using a questionnaire.

Confirm malfunction on actual vehicle.

DTC inspection

Inspect for DTCs using WDS or equivalent.

Perform applicable troubleshooting inspection according to

diagnostic index.

A6E63802001

No. Symptom Description

1 Frequent front wheel slip Front wheels slip frequently during acceleration on low-friction road.

2

Tight corner braking effectBrakes seem to be applied during tight cornering while driving very

slowly on paved road.

3 Abnormal noise and/or vibration from

coupling unitThere is abnormal noise and/or vibration from coupling unit during

driving.

1 Frequent front wheel slip

[TROUBLESHOOTING HINTS]

•Tire traction performance is extremely poor for given road friction. (4WD system is normal.)

•Improper wheel alignment (4WD system is normal.)

•Rear differential oil temperature is extremely high (Fail-safe condition)

•Differential oil temperature sensor malfunction (Fail-safe condition)

•Compare slip frequency with another vehicle of the same model (under the same road conditions and tire traction

performance).

•Replace tires with others of the same model and perform test under the same road conditions to determine if the

malfunction was caused by tire traction performance.

•Coupling component malfunction

•4WD solenoid malfunction

Page 714 of 909

M–84

TROUBLESHOOTING

End Of Sie

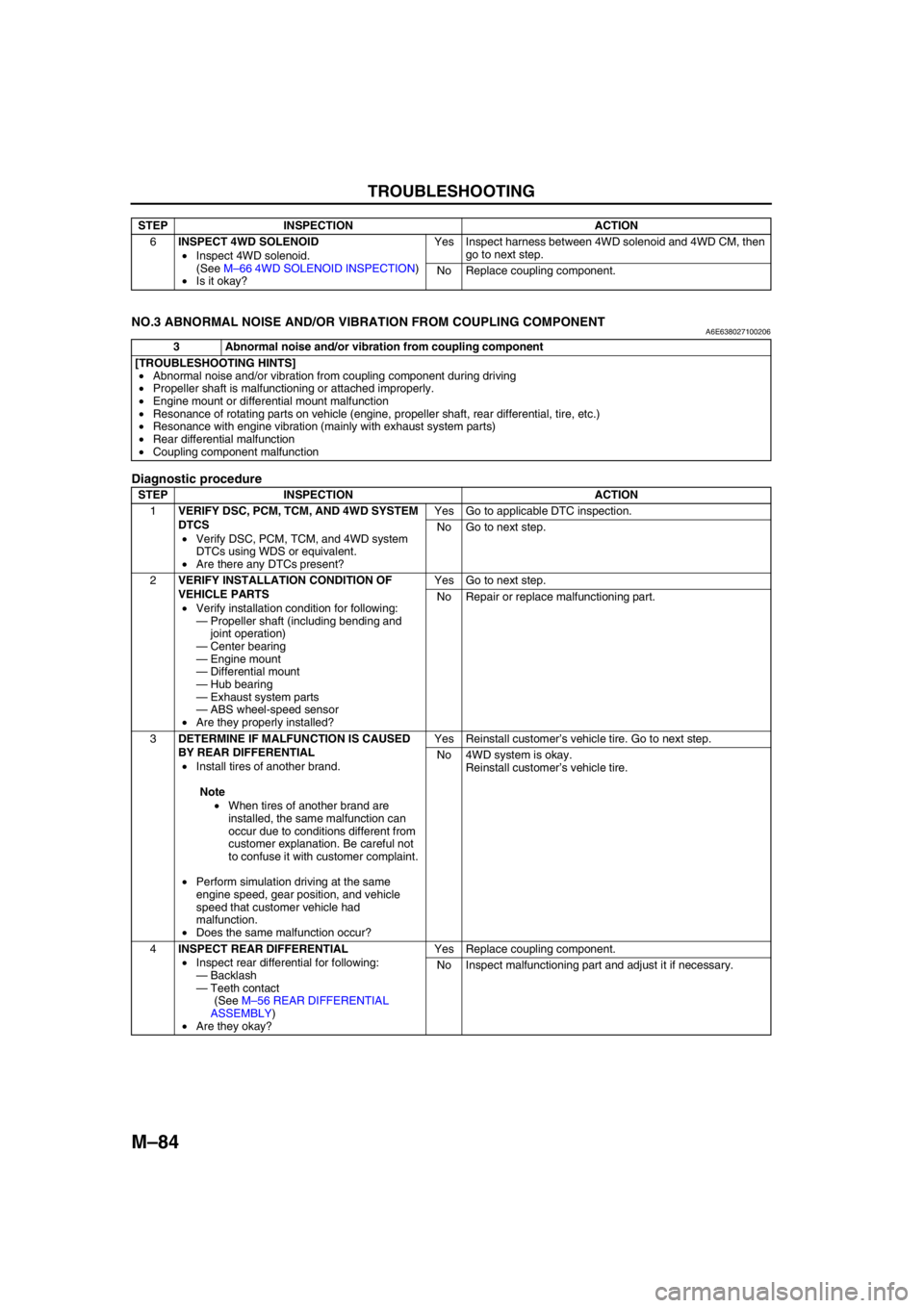

NO.3 ABNORMAL NOISE AND/OR VIBRATION FROM COUPLING COMPONENTA6E638027100206

Diagnostic procedure

End Of Sie

6INSPECT 4WD SOLENOID

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is it okay?Yes Inspect harness between 4WD solenoid and 4WD CM, then

go to next step.

No Replace coupling component. STEP INSPECTION ACTION

3 Abnormal noise and/or vibration from coupling component

[TROUBLESHOOTING HINTS]

•Abnormal noise and/or vibration from coupling component during driving

•Propeller shaft is malfunctioning or attached improperly.

•Engine mount or differential mount malfunction

•Resonance of rotating parts on vehicle (engine, propeller shaft, rear differential, tire, etc.)

•Resonance with engine vibration (mainly with exhaust system parts)

•Rear differential malfunction

•Coupling component malfunction

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCS

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY INSTALLATION CONDITION OF

VEHICLE PARTS

•Verify installation condition for following:

—Propeller shaft (including bending and

joint operation)

—Center bearing

—Engine mount

—Differential mount

—Hub bearing

—Exhaust system parts

—ABS wheel-speed sensor

•Are they properly installed?Yes Go to next step.

No Repair or replace malfunctioning part.

3DETERMINE IF MALFUNCTION IS CAUSED

BY REAR DIFFERENTIAL

•Install tires of another brand.

Note

•When tires of another brand are

installed, the same malfunction can

occur due to conditions different from

customer explanation. Be careful not

to confuse it with customer complaint.

•Perform simulation driving at the same

engine speed, gear position, and vehicle

speed that customer vehicle had

malfunction.

•Does the same malfunction occur?Yes Reinstall customer’s vehicle tire. Go to next step.

No 4WD system is okay.

Reinstall customer’s vehicle tire.

4INSPECT REAR DIFFERENTIAL

•Inspect rear differential for following:

—Backlash

—Teeth contact

(See M–56 REAR DIFFERENTIAL

ASSEMBLY)

•Are they okay?Yes Replace coupling component.

No Inspect malfunctioning part and adjust it if necessary.

Page 762 of 909

ON-BOARD DIAGNOSTIC

P–29

PEnd Of Sie

DTC U2511A6E697067650204

Diagnostic procedure

•Follow inspection procedures for CAN. (See T–39 MULTIPLEX COMMUNICATION SYSTEM.)

End Of Sie

3INSPECT FORWARD-G SENSOR PART

SIGNAL CIRCUIT FOR OPEN CIRCUIT

•Inspect continuity between DSC HU/CM

terminal V (harness side) and combine

sensor terminal A (harness side).

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between DSC

HU/CM terminal V and combine sensor terminal A, then go

to Step 8.

4INSPECT FORWARD-G SENSOR PART

SIGNAL CIRCUIT FOR SHORT TO GROUND

•Turn ignition key to OFF.

•Inspect continuity between DSC HU/CM

terminal V (harness side) and ground.

•Is there continuity?Yes Repair or replace harness for short to ground circuit

between DSC HU/CM terminal V and combine sensor

terminal A, then go to Step 8.

No Go to next step.

5INSPECT DIAGNOSIS SIGNAL CIRCUIT FOR

SHORT FOR OPEN CIRCUIT

•Turn ignition key to OFF.

•Inspect continuity between DSC HU/CM

terminal S (harness side) and combine

sensor terminal F.

•Is there continuity?Yes Repair or replace harness for open circuit between DSC

HU/CM terminal S and combine sensor terminal F, then go

to Step 8.

No Go to next step.

6INSPECT DIAGNOSIS SIGNAL CIRCUIT FOR

SHORT TO GROUND

•Turn ignition key to OFF.

•Inspect continuity between DSC HU/CM

terminal S (harness side) and ground.

•Is there continuity?Yes Repair or replace harness for short to ground circuit

between DSC HU/CM terminal S and combine sensor

terminal F, then go to Step 8.

No Go to next step.

7INSPECT COMBINE SENSOR

•Inspect combine sensor.

•Is it okay?Yes Go to next step.

No Replace combine sensor, then go to next step.

8VERIFY TROUBLESHOOTING COMPLETED

•Clear DTC from memory.

•Is same DTC present?Yes Replace DSC HU/CM, then go to next step.

No Go to next step.

9VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC U2511 CAN communication

DETECTION

CONDITION•Detects that the communication signals from 4WD CM is abnormal.

POSSIBLE

CAUSE•4WD CM signals have communication error.

Page 815 of 909

T–4

MULTIPLEX COMMUNICATION SYSTEM

SYSTEM WIRING DIAGRAMA6E811155430203

.

End Of SieCAN SIGNAL-CHARTA6E811155430204

OUT: Output (sends signal)

IN: Input (receives signal)

1

2

67

3

8

4

5

ROAF AG

HG

2M2J2W

2X

9

10

CAN_L

CAN_H

A6E81111102

1PCM

2 DSC HU/CM (with DSC)

3 ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

4 Data link connector-2

5 Instrument cluster

6 TCM (JA5AX-EL)7 4WD control module (4WD)

8Twist pair

9 2R (except MZR-CD (RF Turbo))

39 (MZR-CD (RF Turbo))

10 2U (except MZR-CD (RF Turbo))

13 (MZR-CD (RF Turbo))

SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Accelerator pedal position

(MZR-CD (RF Turbo))OUT IN IN–IN

Air induction type OUT–IN––

ATF temperature IN OUT–––

AT warning light conditions

(JA5AX-EL)IN OUT––IN

Battery reconnection

(except MZR-CD (RF

Turbo))OUT IN–––

Brake system configuration

(EBD/ABS/TCS/DSC)IN–OUT–IN

Brake system

statusABS IN–OUT––

EBD/ABS/

TCS/DSC––OUT IN IN

Brake system warning light

conditions (brake fluid level

sensor)––IN–OUT

Country OUT–IN––

Coupling torque (with

DSC)––IN OUT–

Coupling torque request

(with DSC)––OUT IN–

Page 864 of 909

U–1

U

UHEATER AND AIR CONDITIONER SYSTEMS

OUTLINE................................................................ U-2

OUTLINE OF CONSTRUCTION.......................... U-2

FEATURES .......................................................... U-2

SPECIFICATIONS ............................................... U-2

CONTROL SYSTEM............................................... U-6

WATER HEATER SYSTEM................................. U-6

OUTLINE................................................................ U-7

SUPPLEMENTAL SERVICE INFORMATION .....U-7

LOCATION INDEX.................................................U-8

BASIC SYSTEM................................................... U-8

CONTROL SYSTEM ............................................ U-9

BASIC SYSTEM................................................... U-10

A/C UNIT REMOVAL/INSTALLATION...............U-10

A/C COMPRESSOR

REMOVAL/INSTALLATION ............................U-11

CONDENSER REMOVAL/INSTALLATION ....... U-12

REFRIGERANT LINES

REMOVAL/INSTALLATION ............................U-13

CONTROL SYSTEM............................................. U-15

WATER HEATER UNIT

REMOVAL/INSTALLATION ............................U-15

FUEL PUMP (WATER HEATER SYSTEM)

INSPECTION .................................................. U-16

CLIMATE CONTROL UNIT INSPECTION.........U-16

ON-BOARD DIAGNOSTIC...................................U-22

FOREWORD ......................................................U-22

DTC TABLE ................................................... U-22-2

PID/DATA MONITOR AND RECORD ........... U-22-2

DTC B1317 .................................................... U-22-3

DTC B1318 ........................................................ U-23

DTC B1342, B2463, B2537, B2538, B2547 ....... U-23

DTC B2449, B2450 ............................................ U-24

DTC B2451, B2452 ............................................ U-24

DTC B2453, B2454 ............................................ U-25

DTC B2548 ........................................................ U-25

TROUBLESHOOTING.......................................... U-26

FOREWORD ......................................................U-26

TROUBLESHOOTING INDEX ...........................U-26 FEATURES

SERVICE

Page 865 of 909

U–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E850201038201•The construction and operation of the air conditioner system is essentially carried over from that of the previous

Mazda6 (GG) model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E850201038202Improved Comfort

•The water heater system has been adopted. (For MZR-CD (RF Turbo) European (L.H.D.) specs.)

End Of Sie

SPECIFICATIONSA6E850201038203Manual Air Conditioner

OUTLINE

ItemSpecification

L3, L8, LF MZR-CD (RF Turbo)

Heating capacity (kW {kcal/h}) 4.400 {3,784}4.400 {3,784} (L.H.D.)

5.120 {4,403} (R.H.D.)

Airflow volume

(during heater operation)Blower motor

(m

3/h)310 (L.H.D.)

300 (R.H.D.)

Electricity consumption

(during heater operation)Blower motor (W) 184

Cooling capacity (kW {kcal/h}) 4.200 {3,612}

Airflow volume (during air

conditioner operation)Blower motor

(m

3/h)460

Electricity consumption

(during air conditioner

operation)Blower motor (W) 225

Magnetic clutch (W) 46 45

Fan type Blower motor Sirocco fan

RefrigerantType R-134a

Regular amount

(approximate quantity)470 {16.6} (L.H.D.)

430 {15.2} (R.H.D.)

(g {oz})

A/C compressorType Vane-rotary

Discharge capacity

120 {120, 4.06}

(ml {cc, fl oz})

Max. allowable speed

6,400

(rpm)

Lube

oilType ATMOS GU10

Sealed volume

(approximate quantity)

120 {120, 4.06} 150 {150, 5.07}

(ml {cc, fl oz})

Magnetic clutch clearance

0.3—0.5 {0.012—0.019}

(mm {in})

CondenserType Multiflow (sub-cooling type)

Radiated heat (kW {kcal/h})4.69 {4,030}: European (L.H.D.) specs.

5.96 {5,130}: European (U.K.), GCC specs.

Receiver/drier

capacity(ml {cc, fl oz}) 190 {190, 6.42}

Desiccant Synthetic zeolite

Expansion valve Type Block type

Evaporator Type Double-tank drawn cup