air condition MAZDA 6 2002 Suplement Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 304 of 909

F2–152

ON-BOARD DIAGNOSTIC

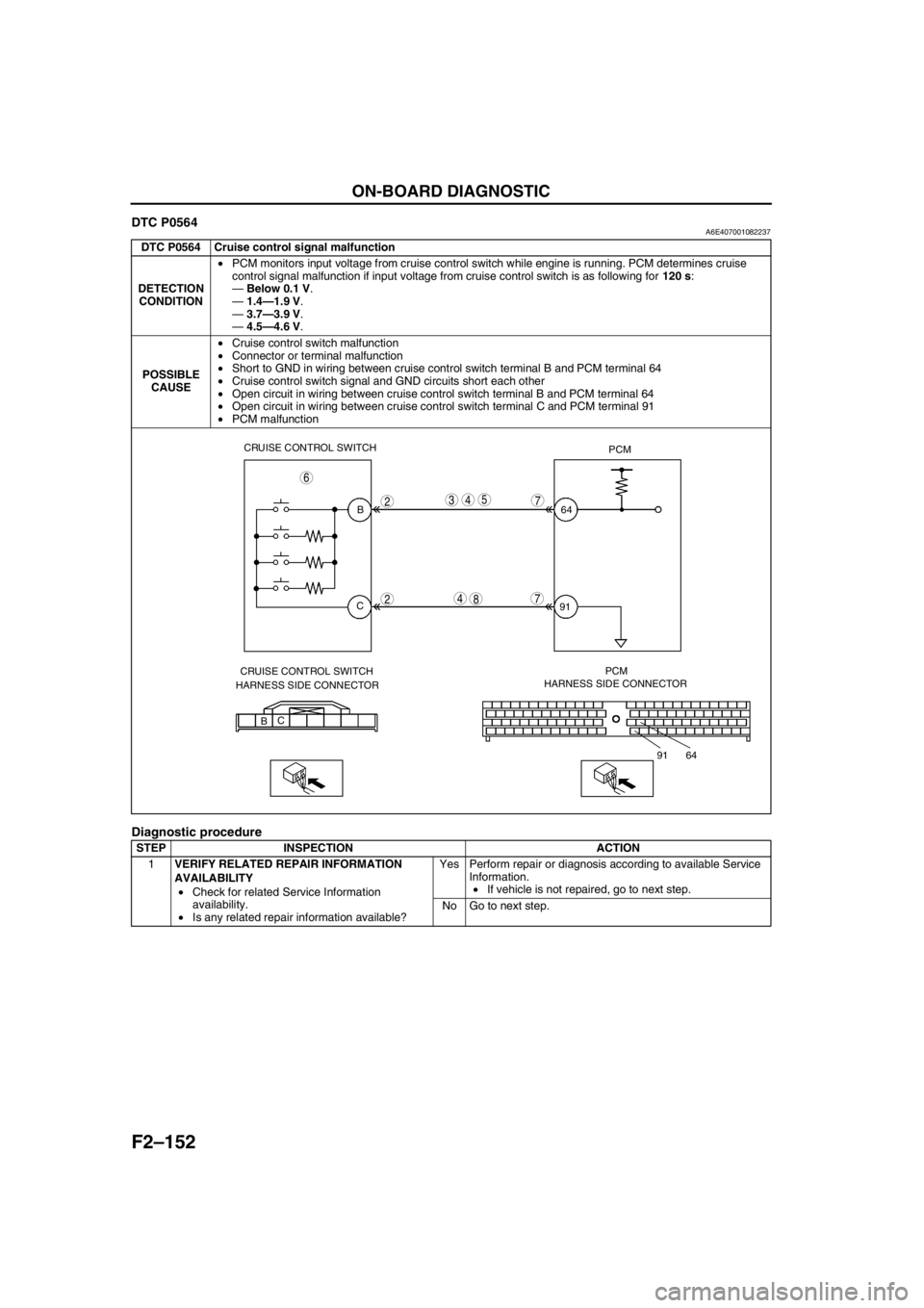

DTC P0564A6E407001082237

Diagnostic procedure

DTC P0564 Cruise control signal malfunction

DETECTION

CONDITION•PCM monitors input voltage from cruise control switch while engine is running. PCM determines cruise

control signal malfunction if input voltage from cruise control switch is as following for 120 s:

—Below 0.1 V.

—1.4—1.9 V.

—3.7—3.9 V.

—4.5—4.6 V.

POSSIBLE

CAUSE•Cruise control switch malfunction

•Connector or terminal malfunction

•Short to GND in wiring between cruise control switch terminal B and PCM terminal 64

•Cruise control switch signal and GND circuits short each other

•Open circuit in wiring between cruise control switch terminal B and PCM terminal 64

•Open circuit in wiring between cruise control switch terminal C and PCM terminal 91

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

CRUISE CONTROL SWITCH

PCM

B

C64

91

CRUISE CONTROL SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

BC

64 91

2

2

543

4

7

6

78

Page 306 of 909

F2–154

ON-BOARD DIAGNOSTIC

DTC P0602A6E407001082238

Diagnostic procedure

End Of Sie

DTC P0602 PCM programming error

DETECTION

CONDITION•No configuration data in PCM

Note

•If “PCM CONFIGURATION” is successful, the PCM stored DTC P0602 and illuminates the MIL

(System i s normal). Clear the DTC P0602 using WDS or equivalent after “PCM CONFIGURATION”.

•MIL goes off after three drive cycles with no failure (DTCs remain in PCM).

POSSIBLE

CAUSE•Complete configuration has not been completed.

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Perform “PCM Configuration Procedure”, then go to next

step.

(See F2–68 PCM CONFIGURATION)

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2VERIFY TROUBLESHOOTING OF DTC P0602

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

3VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 307 of 909

ON-BOARD DIAGNOSTIC

F2–155

F2

DTC P0606A6E407001082239

Diagnostic procedure

End Of Sie

DTC P0610A6E407001082240

Diagnostic procedure

End Of Sie

DTC P0606 PCM malfunction

DETECTION

CONDITION•PCM does not read DTC from output devices.

POSSIBLE

CAUSE•PCM internal malfunction

STEP INSPECTION ACTION

1

––Replace PCM.

(See F2–64 PCM REMOVAL/INSTALLATION)

DTC P0610 Control module vehicle options error

DETECTION

CONDITION•PCM data configuration error

POSSIBLE

CAUSE•Configuration procedure has not been completed

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Perform “PCM Configuration Procedure”, then go to next

step.

(See F2–68 PCM CONFIGURATION)

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2VERIFY TROUBLESHOOTING OF DTC P0610

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

3VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 312 of 909

F2–160

ON-BOARD DIAGNOSTIC

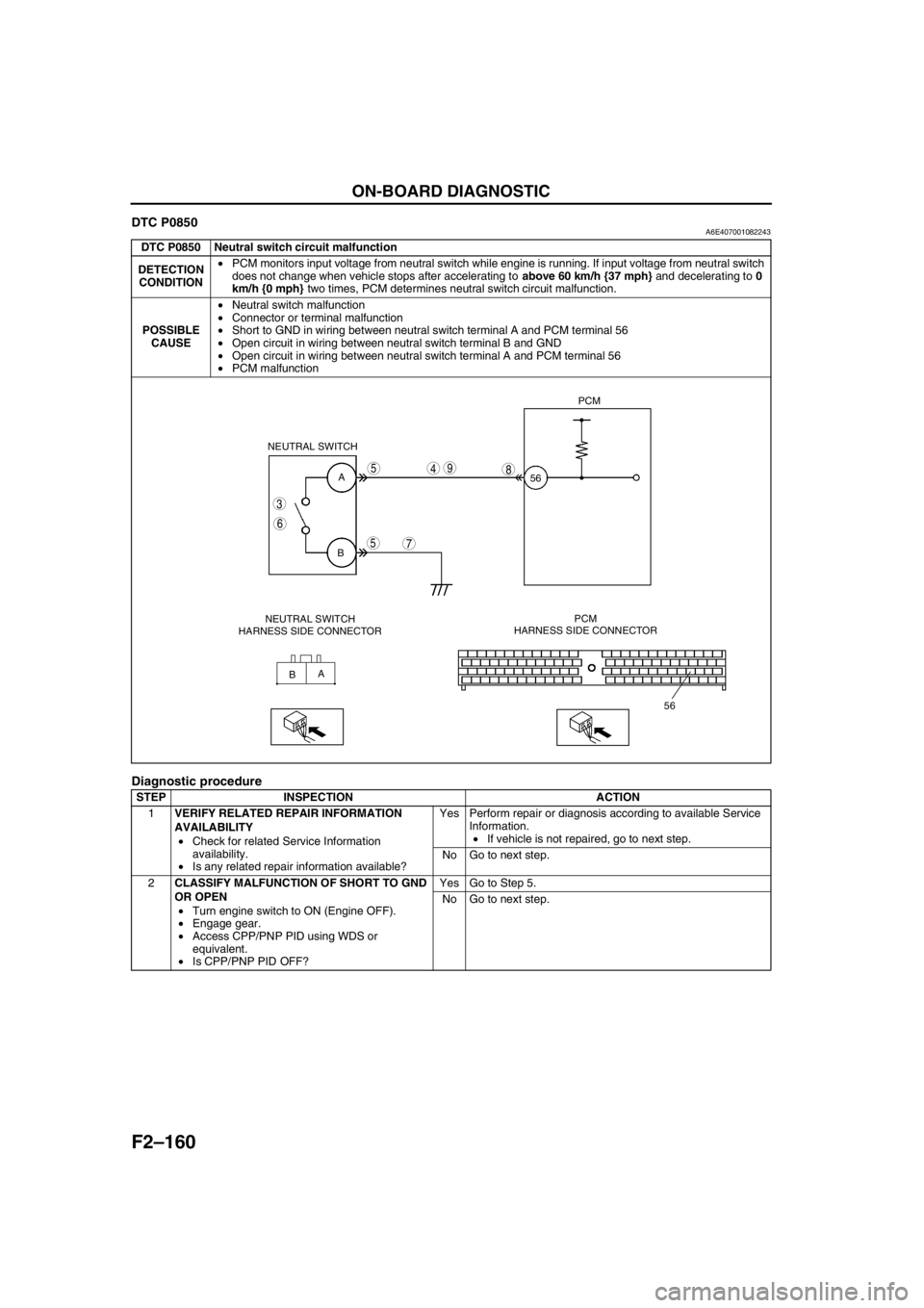

DTC P0850A6E407001082243

Diagnostic procedure

DTC P0850 Neutral switch circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from neutral switch while engine is running. If input voltage from neutral switch

does not change when vehicle stops after accelerating to above 60 km/h {37 mph} and decelerating to 0

km/h {0 mph} two times, PCM determines neutral switch circuit malfunction.

POSSIBLE

CAUSE•Neutral switch malfunction

•Connector or terminal malfunction

•Short to GND in wiring between neutral switch terminal A and PCM terminal 56

•Open circuit in wiring between neutral switch terminal B and GND

•Open circuit in wiring between neutral switch terminal A and PCM terminal 56

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2CLASSIFY MALFUNCTION OF SHORT TO GND

OR OPEN

•Turn engine switch to ON (Engine OFF).

•Engage gear.

•Access CPP/PNP PID using WDS or

equivalent.

•Is CPP/PNP PID OFF?Yes Go to Step 5.

No Go to next step.

A

B

A

B NEUTRAL SWITCH

56PCM

56

3

6

5

5

7

498

NEUTRAL SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 314 of 909

F2–162

ON-BOARD DIAGNOSTIC

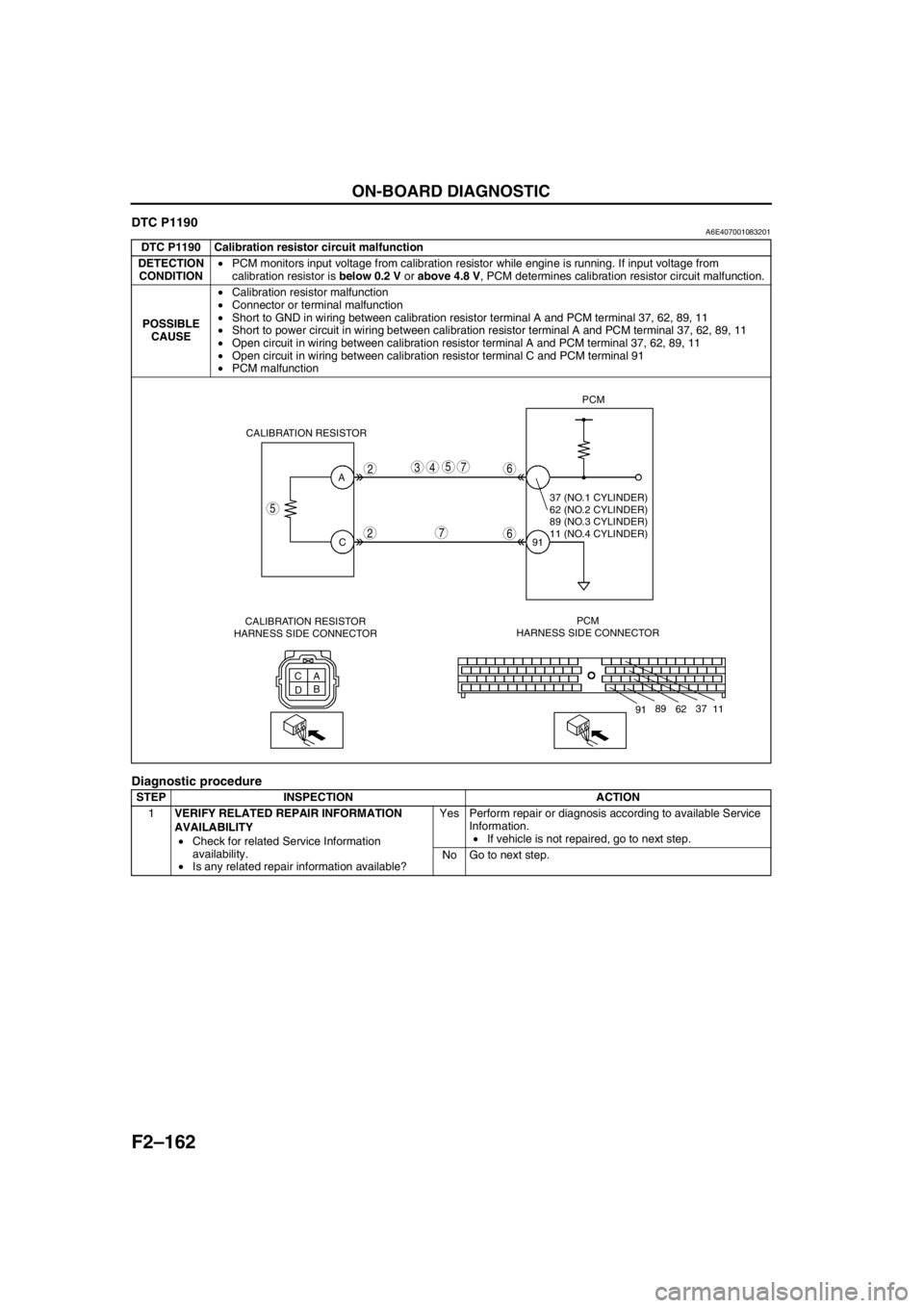

DTC P1190A6E407001083201

Diagnostic procedure

DTC P1190 Calibration resistor circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from calibration resistor while engine is running. If input voltage from

calibration resistor is below 0.2 V or above 4.8 V, PCM determines calibration resistor circuit malfunction.

POSSIBLE

CAUSE•Calibration resistor malfunction

•Connector or terminal malfunction

•Short to GND in wiring between calibration resistor terminal A and PCM terminal 37, 62, 89, 11

•Short to power circuit in wiring between calibration resistor terminal A and PCM terminal 37, 62, 89, 11

•Open circuit in wiring between calibration resistor terminal A and PCM terminal 37, 62, 89, 11

•Open circuit in wiring between calibration resistor terminal C and PCM terminal 91

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

A

C

C

A

DBPCM

HARNESS SIDE CONNECTOR91PCM

CALIBRATION RESISTOR

5

2

2

5437

7

6

6

11 37

62 89

91

37 (NO.1 CYLINDER)

62 (NO.2 CYLINDER)

89 (NO.3 CYLINDER)

11 (NO.4 CYLINDER)

CALIBRATION RESISTOR

HARNESS SIDE CONNECTOR

Page 316 of 909

F2–164

ON-BOARD DIAGNOSTIC

DTC P2228A6W407001082244

Diagnostic procedure

End Of Sie

DTC P2229A6E407001082245

Diagnostic procedure

End Of Sie

DTC P2228 BARO sensor circuit low input

DETECTION

CONDITION•PCM monitors input voltage from BARO sensor while engine is running. If input voltage from BARO sensor

is below 0.7 V, PCM determines BARO sensor circuit low input.

POSSIBLE

CAUSE•BARO sensor malfunction

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2VERIFY TROUBLESHOOTING OF DTC P2228

COMPLETED

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–26 KOEO/KOER SELF-TEST)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

3VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

DTC P2229 BARO sensor circuit high input

DETECTION

CONDITION•PCM monitors input voltage from BARO sensor while engine is running. If input voltage from BARO sensor

is above 4.5 V, PCM determines BARO sensor circuit high input.

POSSIBLE

CAUSE•BARO sensor malfunction

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2VERIFY TROUBLESHOOTING OF DTC P2229

COMPLETED

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–26 KOEO/KOER SELF-TEST)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

3VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 320 of 909

F2–168

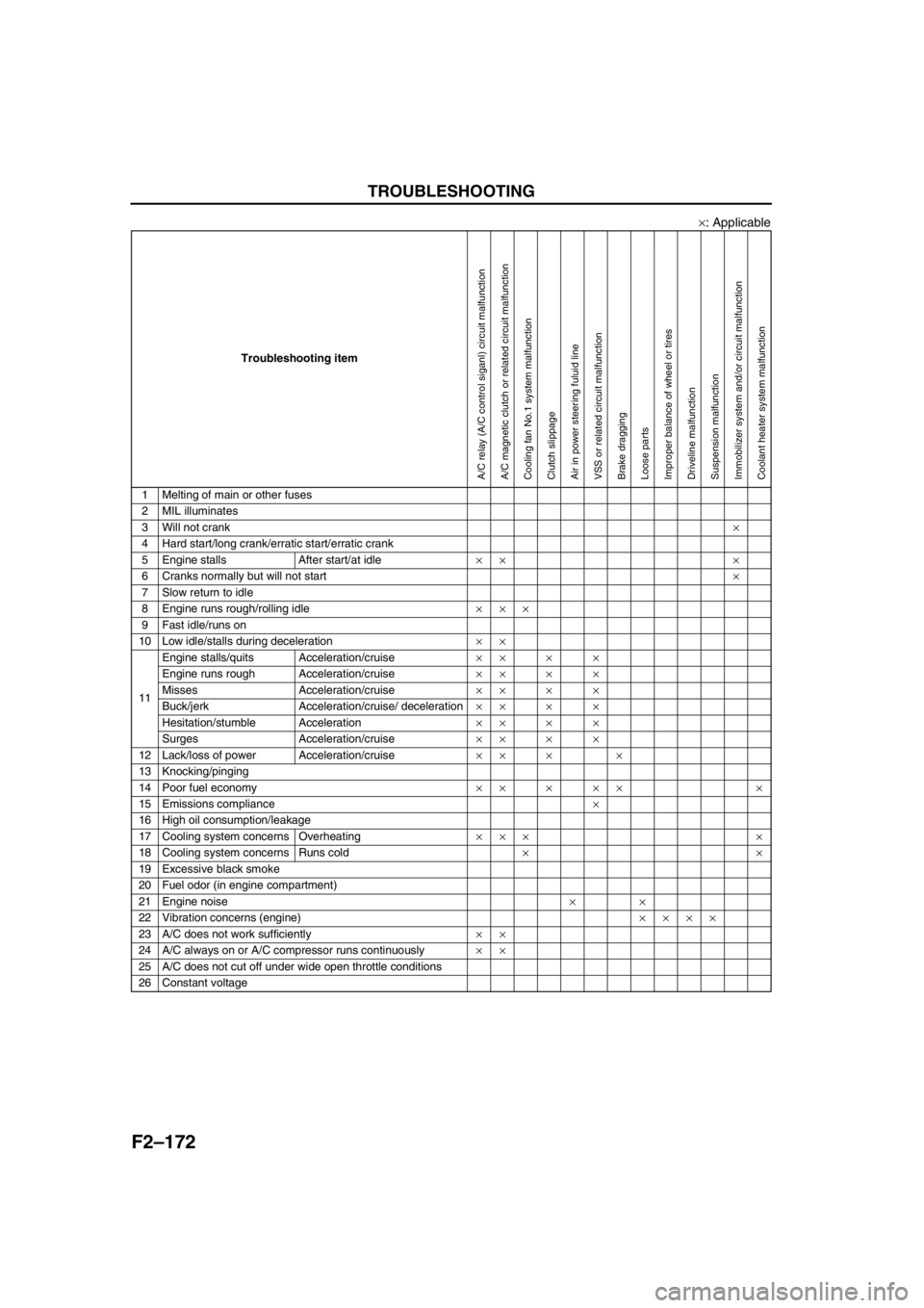

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×××

5 Engine stalls After start/at idle×××

6 Cranks normally but will not start××

7 Slow return to idle×

8 Engine runs rough/rolling idle××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××××

Engine runs rough Acceleration/cruise×××× ×

Misses Acceleration/cruise××××××

Buck/jerk Acceleration/cruise/ deceleration××××××

Hesitation/stumble Acceleration××××××

Surges Acceleration/cruise××××××

12 Lack/loss of power Acceleration/cruise×××××××

13 Knocking/pinging×××××

14 Poor fuel economy××××

15 Emissions compliance× ××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×× × ×

18 Cooling system concerns Runs cold××

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)

21 Engine noise××

22 Vibration concerns (engine)×× ×

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Improper engine coolant levelWater and anti-freeze mixture is improperCooling system malfunction (Radiator, hose,

over-flow system, thermostat, etc.)Cooling fan system malfunctionEngine or transaxle mounts are improperly installedCooling fan No.1 or No.2 seat are improperFuel qualityEngine overheatingIntake-air system clogging or restrictionAir leakage from intake-air systemVSC system malfunctionVacuum leakage

Page 321 of 909

TROUBLESHOOTING

F2–169

F2

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates×× × ×

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×× ×××××××

5 Engine stalls After start/at idle×× ×××××××

6 Cranks normally but will not start×× ×××××××

7 Slow return to idle××××××××

8 Engine runs rough/rolling idle×××××××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××××××××××

11Engine stalls/quits Acceleration/cruise× × ×××××××

Engine runs rough Acceleration/cruise× ××××××××××

Misses Acceleration/cruise× ××××××××××

Buck/jerk Acceleration/cruise/ deceleration× ××××××××××

Hesitation/stumble Acceleration× ××××××××××

Surges Acceleration/cruise× ×× ×××××××

12 Lack/loss of power Acceleration/cruise××× ×××××××××

13 Knocking/pinging××××× ××× × ×

14 Poor fuel economy××× ×××××× ×

15 Emissions compliance×××××××××××××

16 High oil consumption/leakage×

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××× × ××× ×××

20 Fuel odor (in engine compartment)××

21 Engine noise× ××× ×

22 Vibration concerns (engine)

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Turbocharger malfunctionCarge air cooler malfunctionVBC system malfunctionGlow system malfunctionIncorrect fuel injection timingIncorrect idle speedCKP sensor is damaged (e.g.: open or short circuits)CKP sensor pulse wheel is damagedImproper gap between CKP sensor and pulse wheelSupply pump malfunctionSuction control valve malfunctionFuel pressure limiter malfunctionFuel line restriction or clogging

Page 324 of 909

F2–172

TROUBLESHOOTING

×: Applicable

End Of Sie

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank×

4 Hard start/long crank/erratic start/erratic crank

5 Engine stalls After start/at idle×× ×

6 Cranks normally but will not start×

7 Slow return to idle

8 Engine runs rough/rolling idle×××

9 Fast idle/runs on

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××××

Engine runs rough Acceleration/cruise××××

Misses Acceleration/cruise××××

Buck/jerk Acceleration/cruise/ deceleration××××

Hesitation/stumble Acceleration××××

Surges Acceleration/cruise××××

12 Lack/loss of power Acceleration/cruise×× × ×

13 Knocking/pinging

14 Poor fuel economy××××× ×

15 Emissions compliance×

16 High oil consumption/leakage

17 Cooling system concerns Overheating××× ×

18 Cooling system concerns Runs cold××

19 Excessive black smoke

20 Fuel odor (in engine compartment)

21 Engine noise××

22 Vibration concerns (engine)××××

23 A/C does not work sufficiently××

24 A/C always on or A/C compressor runs continuously××

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

A/C relay (A/C control siganl) circuit malfunctionA/C magnetic clutch or related circuit malfunctionCooling fan No.1 system malfunctionClutch slippageAir in power steering fuluid lineVSS or related circuit malfunctionBrake draggingLoose partsImproper balance of wheel or tiresDriveline malfunctionSuspension malfunctionImmobilizer system and/or circuit malfunctionCoolant heater system malfunction

Page 325 of 909

![MAZDA 6 2002 Suplement Manual PDF TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiri MAZDA 6 2002 Suplement Manual PDF TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiri](/img/28/57057/w960_57057-324.png)

TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiring harness

MAINMAIN fuse

•BTN fuse

•FAN fuse

•AD FAN fuse

•IG KEY 2 fuse

IG KEY 1IG KEY 1 fuse

•Engine switch

—ENGINE fuse

FUEL PUMPFUEL PUMP fuse

•Fuel warmer

•PCM control relay

BTNBTN fuse

•ROOM fuse

IG KEY 2IG KEY 2 fuse

•Engine switch

ROOMROOM fuse

•DLC-2

ENGINEENGINE fuse

•PCM

INJINJ fuse

•PCM

•IDM

•MAF/IAT sensor

•VSC solenoid valve

•VBC solenoid valve

•EGR control solenoid valve

•EGR solenoid valve (vacuum)

•EGR solenoid valve (vent)

•Intake shutter solenoid valve (half)

•Intake shutter solenoid valve (full)

GLOWGLOW fuse

•Glow plug relay

—Glow plug

—GLOW SIG

ENG+BENG+B fuse

•PCM

FANFAN fuse

•Cooling fan relay No.2

AD FANAD FAN fuse

•Cooling fan relay No.1

Shorted harness

Repair shorted harness and replace fuseFuseDeterioration

Replace fuse