sensor MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 284 of 909

F2–132

ON-BOARD DIAGNOSTIC

DTC P0222A6E407001082226

Diagnostic procedure

DTC P0222 Accelerator position sensor No.2 circuit low input

DETECTION

CONDITION•PCM monitors input voltage from accelerator position sensor No.2 while engine is running. If input voltage

from accelerator position sensor No.2 is below 0.3 V, PCM determines accelerator position sensor No.2

circuit low input.

POSSIBLE

CAUSE•Accelerator position sensor No.2 malfunction

•Connector or terminal malfunction

•Open circuit in wiring between accelerator position sensor terminal A and PCM terminal 90

•Short to GND in wiring between accelerator position sensor terminal C and PCM terminal 88

•Accelerator position sensor No.2 signal and GND circuits short each other

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

ACCELERATOR POSITION SENSOR NO.2

72

7

5

6

27

54

3

2

A

C

D90

88

91PCM

DC B

A

91

9010 PCM

HARNESS SIDE CONNECTOR ACCELERATOR POSITION SENSOR

HARNESS SIDE CONNECTOR

Page 285 of 909

ON-BOARD DIAGNOSTIC

F2–133

F2

End Of Sie

2INSPECT POOR CONNECTION OF

ACCELERATOR POSITION SENSOR NO.2

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 8.

No Go to next step.

3INSPECT ACCELERATOR POSITION SENSOR

NO.2 POWER CIRCUIT FOR OPEN

•Turn engine switch to ON. (Engine OFF).

•Inspect voltage at accelerator position sensor

terminal A (harness side).

•Is voltage below 1.0 V?Yes Repair or replace harness for open, go to Step 8.

No Go to next step.

4INSPECT ACCELERATOR POSITION SENSOR

NO.2 SIGNAL CIRCUIT FOR SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between accelerator position

sensor terminal C and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 8.

No Go to next step.

5INSPECT ACCELERATOR POSITION SENSOR

NO.2 CIRCUIT FOR SHORT WITH EACH OTHER

•Turn engine switch to OFF.

•Inspect continuity between accelerator position

sensor terminals C and D.

•Is there continuity?Yes Repair or replace harness for short with each other, go to

Step 8.

No Go to next step.

6INSPECT ACCELERATOR POSITION SENSOR

NO.2

•Inspect accelerator position sensor No.2.

(See F2–72 ACCELERATOR POSITION

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace accelerator position sensor, go to Step 8.

(See F2–44 ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY)

No Go to next step.

7INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

8VERIFY TROUBLESHOOTING OF DTC P0222

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

9VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 286 of 909

F2–134

ON-BOARD DIAGNOSTIC

DTC P0223A6E407001082227

Diagnostic procedure

DTC P0223 Accelerator position sensor No.2 circuit high input

DETECTION

CONDITION•PCM monitors input voltage from accelerator position sensor No.2 while engine is running. If input voltage

from accelerator position sensor No.2 is above 4.7 V, PCM determines accelerator position sensor No.2

circuit high input.

POSSIBLE

CAUSE•Accelerator position sensor No.2 malfunction

•Connector or terminal malfunction

•Accelerator position sensor No.2 power and signal circuits short each other

•Open circuit in wiring between accelerator position sensor terminal C and PCM terminal 88

•Open circuit in wiring between accelerator position sensor terminal D and PCM terminal 91

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

A

C

D90

88

91 ACCELERATOR POSITION SENSOR NO.2

91

9010 PCM

A

B C D

6

25

4

3

2

2

5

53

6

ACCELERATOR POSITION SENSOR

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 287 of 909

ON-BOARD DIAGNOSTIC

F2–135

F2

End Of Sie

2INSPECT POOR CONNECTION OF

ACCELERATOR POSITION SENSOR NO.2

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT ACCELERATOR POSITION SENSOR

NO.2 CIRCUIT FOR SHORT WITH EACH OTHER

•Turn engine switch to OFF.

•Inspect continuity between accelerator position

sensor terminals A and C

•Is there continuity?Yes Repair or replace harness for short with each other, go to

Step 7.

No Go to next step.

4INSPECT ACCELERATOR POSITION SENSOR

NO.2

•Inspect accelerator position sensor No.2.

(See F2–72 ACCELERATOR POSITION

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace accelerator position sensor, go to Step 7.

(See F2–44 ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT ACCELERATOR POSITION SENSOR

NO.2 CIRCUIT FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Accelerator position sensor terminal C and

PCM terminal 88.

—Accelerator position sensor terminal D and

PCM terminal 91.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 7.

7VERIFY TROUBLESHOOTING OF DTC P0223

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 288 of 909

F2–136

ON-BOARD DIAGNOSTIC

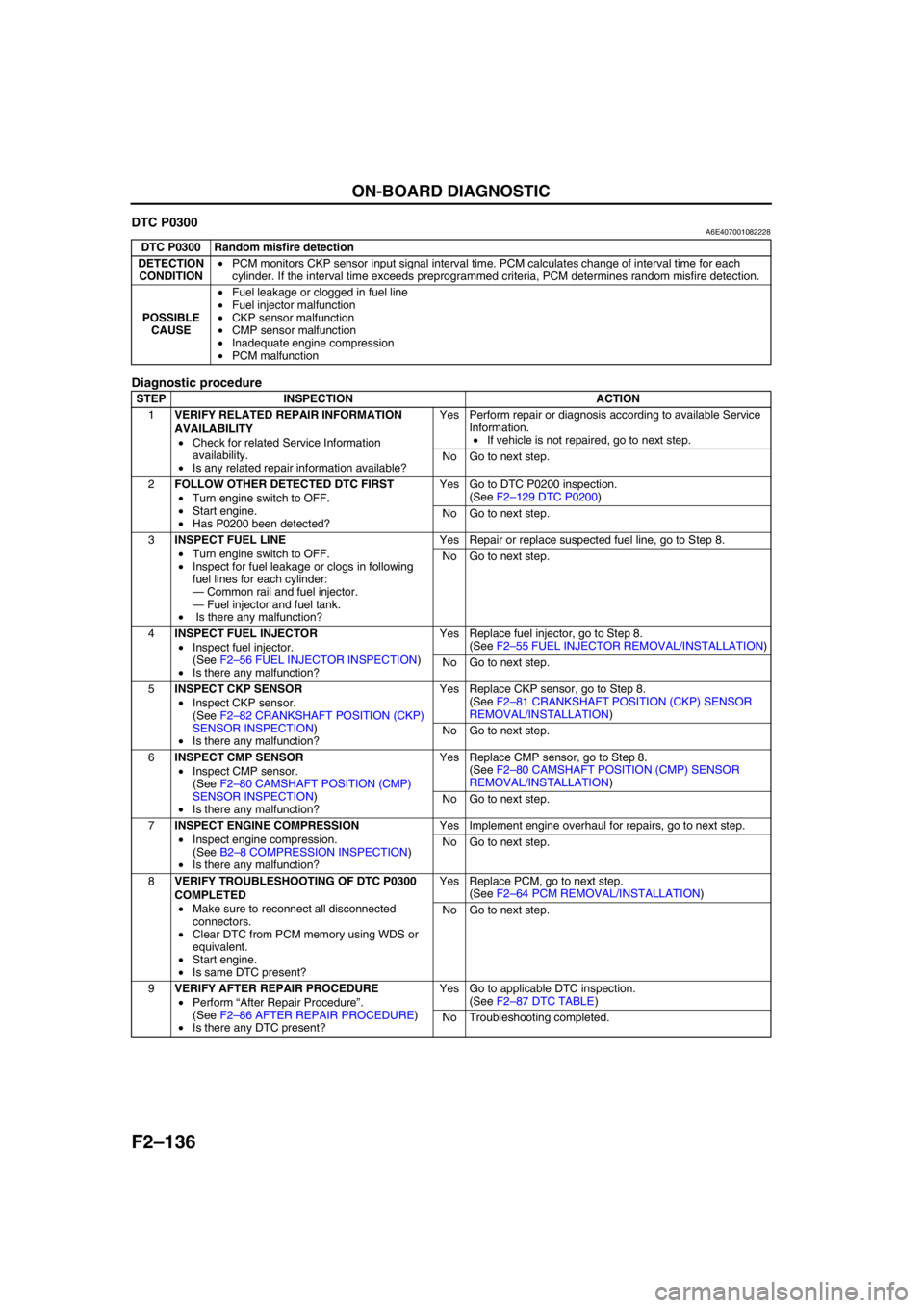

DTC P0300A6E407001082228

Diagnostic procedure

End Of Sie

DTC P0300 Random misfire detection

DETECTION

CONDITION•PCM monitors CKP sensor input signal interval time. PCM calculates change of interval time for each

cylinder. If the interval time exceeds preprogrammed criteria, PCM determines random misfire detection.

POSSIBLE

CAUSE•Fuel leakage or clogged in fuel line

•Fuel injector malfunction

•CKP sensor malfunction

•CMP sensor malfunction

•Inadequate engine compression

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2FOLLOW OTHER DETECTED DTC FIRST

•Turn engine switch to OFF.

•Start engine.

•Has P0200 been detected?Yes Go to DTC P0200 inspection.

(See F2–129 DTC P0200)

No Go to next step.

3INSPECT FUEL LINE

•Turn engine switch to OFF.

•Inspect for fuel leakage or clogs in following

fuel lines for each cylinder:

—Common rail and fuel injector.

—Fuel injector and fuel tank.

• Is there any malfunction?Yes Repair or replace suspected fuel line, go to Step 8.

No Go to next step.

4INSPECT FUEL INJECTOR

•Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

•Is there any malfunction?Yes Replace fuel injector, go to Step 8.

(See F2–55 FUEL INJECTOR REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT CKP SENSOR

•Inspect CKP sensor.

(See F2–82 CRANKSHAFT POSITION (CKP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CKP sensor, go to Step 8.

(See F2–81 CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

6INSPECT CMP SENSOR

•Inspect CMP sensor.

(See F2–80 CAMSHAFT POSITION (CMP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CMP sensor, go to Step 8.

(See F2–80 CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

7INSPECT ENGINE COMPRESSION

•Inspect engine compression.

(See B2–8 COMPRESSION INSPECTION)

•Is there any malfunction?Yes Implement engine overhaul for repairs, go to next step.

No Go to next step.

8VERIFY TROUBLESHOOTING OF DTC P0300

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

9VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 289 of 909

ON-BOARD DIAGNOSTIC

F2–137

F2

DTC P0336A6E407001082229

Diagnostic procedure

End Of Sie

DTC P0336 CKP sensor circuit performance problem

DETECTION

CONDITION•PCM monitors input signal from CKP sensor while engine is running. If input signal from CKP sensor is not

proper pulse number, PCM determines CKP sensor circuit performance problem.

POSSIBLE

CAUSE•CKP sensor malfunction

•Connector or terminal malfunction

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2VERIFY DTC P0336 DETECTED AGAIN

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

3INSPECT POOR CONNECTION OF CKP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

4INSPECT CKP SENSOR

•Inspect CKP sensor.

(See F2–82 CRANKSHAFT POSITION (CKP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CKP sensor, go to Step 6.

(See F2–81 CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0336

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 290 of 909

F2–138

ON-BOARD DIAGNOSTIC

DTC P0337A6E407001082230

Diagnostic procedure

DTC P0337 CKP sensor circuit low input

DETECTION

CONDITION•PCM monitors input signal from CKP sensor while engine is running. If input signal from CKP sensor is not

input at 12 crankshaft revolutions, PCM determines CKP sensor circuit low input.

POSSIBLE

CAUSE•CKP sensor malfunction

•Connector or terminal malfunction

•Short to GND in wiring between CKP sensor terminal A and PCM terminal 29

•Short to GND in wiring between CKP sensor terminal B and PCM terminal 3

•Open circuit in wiring between CKP sensor terminal A and PCM terminal 29

•Open circuit in wiring between CKP sensor terminal B and PCM terminal 3

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

CKP SENSOR

A

B

5

4

3

62

25

3

6

29

3PCM

CKP SENSOR

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

A

BC

29 3

Page 291 of 909

ON-BOARD DIAGNOSTIC

F2–139

F2

End Of Sie

2INSPECT POOR CONNECTION OF CKP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT CKP SENSOR CIRCUIT FOR SHORT

TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CKP sensor terminal A and body GND.

—CKP sensor terminal B and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

4INSPECT CKP SENSOR

•Inspect CKP sensor.

(See F2–82 CRANKSHAFT POSITION (CKP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CKP sensor, go to Step 7.

(See F2–81 CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT CKP SENSOR CIRCUIT FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CKP sensor terminal A and PCM terminal

29.

—CKP sensor terminal B and PCM terminal 3.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0337

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 292 of 909

F2–140

ON-BOARD DIAGNOSTIC

DTC P0341A6E407001082231

Diagnostic procedure

End Of Sie

DTC P0341 CMP sensor circuit performance problem

DETECTION

CONDITION•PCM monitors input signal from CMP sensor while engine is running. If input signal from CMP sensor is not

proper pulse number, PCM determines CMP sensor circuit performance problem.

POSSIBLE

CAUSE•CMP sensor malfunction

•Connector or terminal malfunction

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2VERIFY DTC P0341 DETECTED AGAIN

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

3INSPECT POOR CONNECTION OF CMP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

4INSPECT CMP SENSOR

•Inspect CMP sensor.

(See F2–80 CAMSHAFT POSITION (CMP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CMP sensor, go to Step 6.

(See F2–80 CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0341

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 293 of 909

ON-BOARD DIAGNOSTIC

F2–141

F2

DTC P0342A6E407001082232

Diagnostic procedure

DTC P0342 CMP sensor circuit low input

DETECTION

CONDITION•PCM monitors input signal from CMP sensor while engine is running. If input signal from CMP sensor is not

input at 12 crankshaft revolutions, PCM determines CMP sensor circuit low input.

POSSIBLE

CAUSE•CMP sensor malfunction

•Connector or terminal malfunction

•Short to GND in wiring between CMP sensor terminal A and PCM terminal 81

•Short to GND in wiring between CMP sensor terminal B and PCM terminal 55

•Open circuit in wiring between CMP sensor terminal A and PCM terminal 81

•Open circuit in wiring between CMP sensor terminal B and PCM terminal 55

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT POOR CONNECTION OF CMP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT CMP SENSOR CIRCUIT FOR SHORT

TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CMP sensor terminal A and body GND.

—CMP sensor terminal B and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

A

B CMP SENSOR

A B

55

81 81

55PCM

3

2

2

4

4

6

6

5

5

CMP SENSOR

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR