sensor MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 294 of 909

F2–142

ON-BOARD DIAGNOSTIC

End Of Sie

4INSPECT CMP SENSOR

•Inspect CMP sensor.

(See F2–80 CAMSHAFT POSITION (CMP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CMP sensor, go to Step 7.

(See F2–80 CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT CMP SENSOR CIRCUIT FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CMP sensor terminal A and PCM terminal

81.

—CMP sensor terminal B and PCM terminal

55.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0342

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 300 of 909

F2–148

ON-BOARD DIAGNOSTIC

DTC P0510A6E407001082235

Diagnostic procedure

DTC P0510 Idle switch circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from idle switch while engine is running. If input voltage from idle switch is B+

when accelerator position sensor No.1 voltage is below 0.7 V, PCM determines idle switch circuit

malfunction.

POSSIBLE

CAUSE•Idle switch malfunction

•Connector or terminal malfunction

•Open circuit in wiring between idle switch terminal B and GND

•Open circuit in wiring between idle switch terminal A and PCM terminal 31

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

BA IDLE SWITCH

A B

31 31PCM

4

2

23

65

IDLE SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 316 of 909

F2–164

ON-BOARD DIAGNOSTIC

DTC P2228A6W407001082244

Diagnostic procedure

End Of Sie

DTC P2229A6E407001082245

Diagnostic procedure

End Of Sie

DTC P2228 BARO sensor circuit low input

DETECTION

CONDITION•PCM monitors input voltage from BARO sensor while engine is running. If input voltage from BARO sensor

is below 0.7 V, PCM determines BARO sensor circuit low input.

POSSIBLE

CAUSE•BARO sensor malfunction

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2VERIFY TROUBLESHOOTING OF DTC P2228

COMPLETED

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–26 KOEO/KOER SELF-TEST)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

3VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

DTC P2229 BARO sensor circuit high input

DETECTION

CONDITION•PCM monitors input voltage from BARO sensor while engine is running. If input voltage from BARO sensor

is above 4.5 V, PCM determines BARO sensor circuit high input.

POSSIBLE

CAUSE•BARO sensor malfunction

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2VERIFY TROUBLESHOOTING OF DTC P2229

COMPLETED

•Clear DTC from PCM memory using WDS or

equivalent.

•Perform KOEO/KOER self-test.

(See F2–26 KOEO/KOER SELF-TEST)

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

3VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 321 of 909

TROUBLESHOOTING

F2–169

F2

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates×× × ×

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×× ×××××××

5 Engine stalls After start/at idle×× ×××××××

6 Cranks normally but will not start×× ×××××××

7 Slow return to idle××××××××

8 Engine runs rough/rolling idle×××××××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××××××××××

11Engine stalls/quits Acceleration/cruise× × ×××××××

Engine runs rough Acceleration/cruise× ××××××××××

Misses Acceleration/cruise× ××××××××××

Buck/jerk Acceleration/cruise/ deceleration× ××××××××××

Hesitation/stumble Acceleration× ××××××××××

Surges Acceleration/cruise× ×× ×××××××

12 Lack/loss of power Acceleration/cruise××× ×××××××××

13 Knocking/pinging××××× ××× × ×

14 Poor fuel economy××× ×××××× ×

15 Emissions compliance×××××××××××××

16 High oil consumption/leakage×

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××× × ××× ×××

20 Fuel odor (in engine compartment)××

21 Engine noise× ××× ×

22 Vibration concerns (engine)

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Turbocharger malfunctionCarge air cooler malfunctionVBC system malfunctionGlow system malfunctionIncorrect fuel injection timingIncorrect idle speedCKP sensor is damaged (e.g.: open or short circuits)CKP sensor pulse wheel is damagedImproper gap between CKP sensor and pulse wheelSupply pump malfunctionSuction control valve malfunctionFuel pressure limiter malfunctionFuel line restriction or clogging

Page 322 of 909

F2–170

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates××

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank× × ××××× ×

5 Engine stalls After start/at idle×××××××××

6 Cranks normally but will not start× × ×××× × ×

7 Slow return to idle××××

8 Engine runs rough/rolling idle× × ×××× ××

9 Fast idle/runs on××

10 Low idle/stalls during deceleration× × ×××× ×

11Engine stalls/quits Acceleration/cruise× ××××× ×

Engine runs rough Acceleration/cruise× ××××× ×

Misses Acceleration/cruise× ××××× ×

Buck/jerk Acceleration/cruise/ deceleration× ××××× ×

Hesitation/stumble Acceleration× ××××× ×

Surges Acceleration/cruise× ××××× ×

12 Lack/loss of power Acceleration/cruise× ××××× ×

13 Knocking/pinging××××

14 Poor fuel economy×××××××

15 Emissions compliance× ×××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)×

21 Engine noise××××

22 Vibration concerns (engine)×××

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage×

Fuel injectors malfunction (Leakage or clogging,

inoperative)Fuel leakage from fuel system (including insulator,

fuel injector)Fuel filter restriction or cloggingCMP sensor is damaged (e.g: open or short circuit)CMP sensor pulse wheel is damagedIDM or related circuit malfunctionExhaust system restriction or cloggingCatalyst converter malfunctionEGR system malfunctionEGR water cooler malfunctionV-reference voltage supply circuit malfunction

Page 323 of 909

TROUBLESHOOTING

F2–171

F2

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates×××××× × ×××

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×× ×× ×

5 Engine stalls After start/at idle×× × × × ××

6 Cranks normally but will not start×× ×

7 Slow return to idle××× × × ×××

8 Engine runs rough/rolling idle××× × × ××××

9 Fast idle/runs on×××

10 Low idle/stalls during deceleration××× × × ××××

11Engine stalls/quits Acceleration/cruise× × × × ××××

Engine runs rough Acceleration/cruise××× × × ××××

Misses Acceleration/cruise× × × × ××××

Buck/jerk Acceleration/cruise/ deceleration× ×××× × ××××

Hesitation/stumble Acceleration× ×××× × ××××

Surges Acceleration/cruise× ×××× × ××××

12 Lack/loss of power Acceleration/cruise× ×××× × ××××

13 Knocking/pinging××××× ×

14 Poor fuel economy× ×××× ×××

15 Emissions compliance×××××× × ×××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke×× ×

20 Fuel odor (in engine compartment)×

21 Engine noise××××× ×

22 Vibration concerns (engine)×× ××××

23 A/C does not work sufficiently×

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions××

26 Constant voltage××××× ×

PCM control relay malfunctionECT sensor or related circuit malfunctionNeutral switch or related circuit malfunctionMAF/IAT sensor or related circuit malfunctionIAT sensor No.2 or related circuit malfunctionBoost sensor or related circuit malfunctionAccelerator position sensor or related circuit malfunctionAccelerator position sensor misadjustment

(including looseness)Idle switch or related circuit malfunctionIdle switch misadjustment (including looseness)Fuel pressure sensor or related circuit malfunctionImproper refrigerant charging amount

Page 325 of 909

![MAZDA 6 2002 Workshop Manual Suplement TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiri MAZDA 6 2002 Workshop Manual Suplement TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiri](/img/28/57057/w960_57057-324.png)

TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiring harness

MAINMAIN fuse

•BTN fuse

•FAN fuse

•AD FAN fuse

•IG KEY 2 fuse

IG KEY 1IG KEY 1 fuse

•Engine switch

—ENGINE fuse

FUEL PUMPFUEL PUMP fuse

•Fuel warmer

•PCM control relay

BTNBTN fuse

•ROOM fuse

IG KEY 2IG KEY 2 fuse

•Engine switch

ROOMROOM fuse

•DLC-2

ENGINEENGINE fuse

•PCM

INJINJ fuse

•PCM

•IDM

•MAF/IAT sensor

•VSC solenoid valve

•VBC solenoid valve

•EGR control solenoid valve

•EGR solenoid valve (vacuum)

•EGR solenoid valve (vent)

•Intake shutter solenoid valve (half)

•Intake shutter solenoid valve (full)

GLOWGLOW fuse

•Glow plug relay

—Glow plug

—GLOW SIG

ENG+BENG+B fuse

•PCM

FANFAN fuse

•Cooling fan relay No.2

AD FANAD FAN fuse

•Cooling fan relay No.1

Shorted harness

Repair shorted harness and replace fuseFuseDeterioration

Replace fuse

Page 328 of 909

F2–176

TROUBLESHOOTING

NO.4 HARD START/LONG CRANK/ERRATIC START/ERRATIC CRANKA6E408018881206

Diagnostic Procedure

4 HARD START/LONG CRANK/ERRATIC START/ERRATIC CRANK

DESCRIPTION•Starter cranks engine at normal speed but engine requires excessive cranking time before starting.

•Battery is in normal condition.

POSSIBLE

CAUSE•Poor fuel quality

•Intake-air system restriction or clogging

•Starting system malfunction

•Inadequate fuel pressure

•Fuel pressure limiter malfunction (built-in common rail)

•Suction control valve malfunction (built-in supply pump)

•Engine overheating

•Glow system malfunction

•Fuel filter clogging or restriction

•Fuel line clogging or restriction

•Fuel leakage

•Exhaust system and/or catalyst converter restriction or clogging

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•ECT sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•Accelerator position sensor misadjustment

•MAF/IAT sensor or related circuit malfunction

•Fuel pressure sensor or related circuit malfunction

•Supply pump malfunction

•Fuel injector malfunction

•Low engine compression

•IDM or related circuit malfunction

•EGR system malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Is engine overheating? Yes Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS-OVERHEATING”.

No Go to next step.

3 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

Page 329 of 909

TROUBLESHOOTING

F2–177

F2

4 Does engine start normally after warm-up? Yes Inspect glow system operation.

(See T–19 RELAY INSPECTION)

Replace any malfunctioning part as necessary.

If glow system is okay, go to next step.

No Go to next step.

5 Is there any restriction in exhaust system or

catalyst converter?Yes Repair or replace as necessary.

No Go to next step.

6 Inspect for fuel leakage from fuel pipe.

Is any fuel leakage found on fuel pipe?Yes Repair or replace as necessary.

No Go to next step.

7 Inspect adjustment of accelerator position

sensor and idle switch.

(See F2–72 ACCELERATOR POSITION

SENSOR INSPECTION)

(See F2–70 IDLE SWITCH INSPECTION)

Are accelerator position sensor and idle switch

adjusted correctly?Yes Go to next step.

No Adjust accelerator position sensor and idle switch

correctly.

(See F2–73 ACCELERATOR POSITION SENSOR

ADJUSTMENT)

(See F2–71 IDLE SWITCH ADJUSTMENT)

8 Visually inspect CKP sensor and teeth of pulse

wheel.

Are CKP sensor and teeth of pulse wheel okay?Yes Go to next step.

No Replace malfunctioning parts.

9 Measure gap between CKP sensor and teeth of

pulse wheel.

Specification

1.5—2.5 mm {0.059—0.098 in}

Is gap within specification?Yes Go to next step.

No Adjust CKP sensor position.

10 Visually inspect CMP sensor and teeth of pulse

wheel.

Are CMP sensor and teeth of pulse wheel okay?Yes Inspect following PIDs:

(See F2–65 PCM INSPECTION)

•ECT

•IAT

•MAF

•RPM

If PID value is not as specified, repair or replace

malfunctioning parts.

If PID value is okay, go to next step.

No Replace malfunctioning parts.

11 Inspect fuel pressure sensor.

(See F2–79 FUEL PRESSURE SENSOR

INSPECTION)

Is fuel pressure okay?Yes Go to next step.

No Replace common rail.

12 Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

Is suction control valve okay?Yes Go to next step.

No Repair supply pump.

(See F2–54 SUPPLY PUMP INSPECTION)

13 Is engine compression correct?

(See B2–8 COMPRESSION INSPECTION)Yes Go to next step.

No Inspect for following:

•Damaged valve seat

•Worn valve stem and valve guide

•Worn or stuck piston ring

•Worn piston, piston ring or cylinder

Service as necessary.

14 Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Go to next step.

No Repair or replace as necessary.

15 Inspect EGR system operation.

Is EGR system operation normal?Yes Go to next step.

No Repair or replace malfunctioning part according to

EGR system operation results.

16 Inspect IDM.

(See F2–84 INJECTOR DRIVER MODULE

(IDM) INSPECTION)

Is IDM okay?Yes Go to next step.

No Repair or replace as necessary.

17 Inspect starting system.

Is starting system normal?Yes Inspect for loose connectors or poor terminal contact.

If okay, remove and inspect supply pump and common

rail.

No Repair or replace components as required. STEP INSPECTION RESULTS ACTION

Page 330 of 909

F2–178

TROUBLESHOOTING

End Of Sie

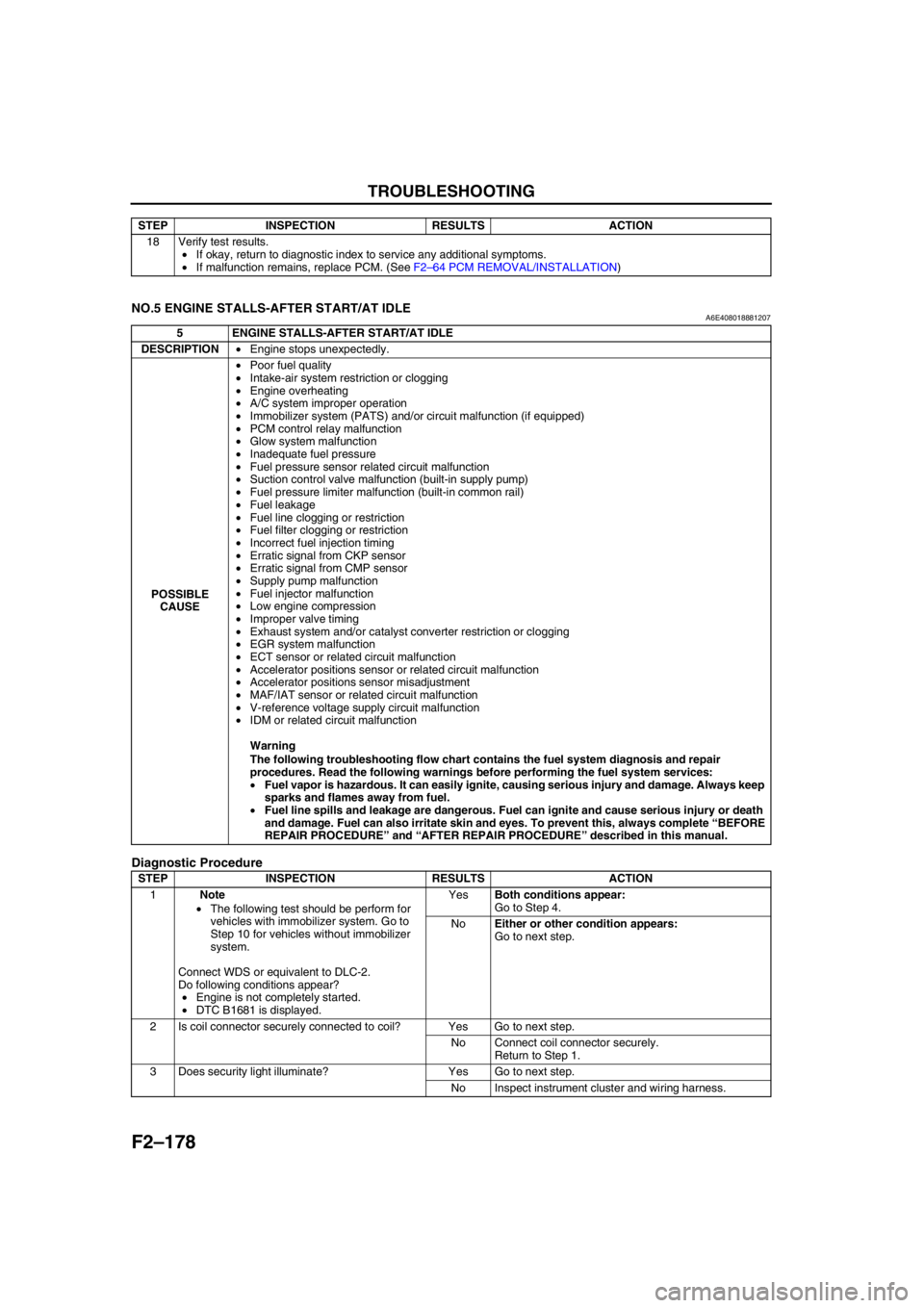

NO.5 ENGINE STALLS-AFTER START/AT IDLEA6E408018881207

Diagnostic Procedure

18 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

5 ENGINE STALLS-AFTER START/AT IDLE

DESCRIPTION•Engine stops unexpectedly.

POSSIBLE

CAUSE•Poor fuel quality

•Intake-air system restriction or clogging

•Engine overheating

•A/C system improper operation

•Immobilizer system (PATS) and/or circuit malfunction (if equipped)

•PCM control relay malfunction

•Glow system malfunction

•Inadequate fuel pressure

•Fuel pressure sensor related circuit malfunction

•Suction control valve malfunction (built-in supply pump)

•Fuel pressure limiter malfunction (built-in common rail)

•Fuel leakage

•Fuel line clogging or restriction

•Fuel filter clogging or restriction

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Supply pump malfunction

•Fuel injector malfunction

•Low engine compression

•Improper valve timing

•Exhaust system and/or catalyst converter restriction or clogging

•EGR system malfunction

•ECT sensor or related circuit malfunction

•Accelerator positions sensor or related circuit malfunction

•Accelerator positions sensor misadjustment

•MAF/IAT sensor or related circuit malfunction

•V-reference voltage supply circuit malfunction

•IDM or related circuit malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1Note

•The following test should be perform for

vehicles with immobilizer system. Go to

Step 10 for vehicles without immobilizer

system.

Connect WDS or equivalent to DLC-2.

Do following conditions appear?

•Engine is not completely started.

•DTC B1681 is displayed.YesBoth conditions appear:

Go to Step 4.

NoEither or other condition appears:

Go to next step.

2 Is coil connector securely connected to coil? Yes Go to next step.

No Connect coil connector securely.

Return to Step 1.

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.