brakes MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 21 of 909

SCHEDULED MAINTENANCE

GI–17

GI

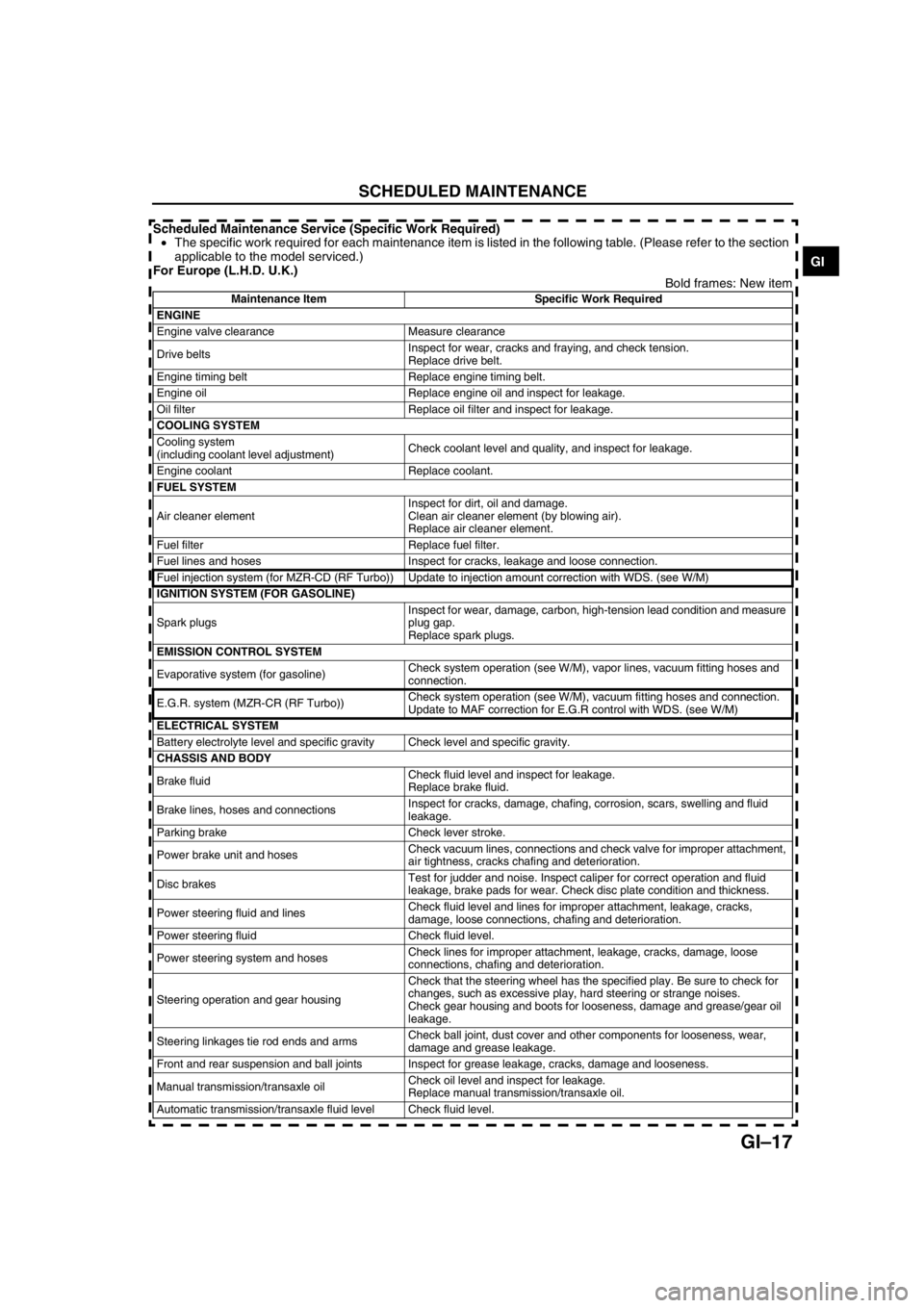

Scheduled Maintenance Service (Specific Work Required)

•The specific work required for each maintenance item is listed in the following table. (Please refer to the section

applicable to the model serviced.)

For Europe (L.H.D. U.K.)

Bold frames: New item

Maintenance Item Specific Work Required

ENGINE

Engine valve clearance Measure clearance

Drive beltsInspect for wear, cracks and fraying, and check tension.

Replace drive belt.

Engine timing belt Replace engine timing belt.

Engine oil Replace engine oil and inspect for leakage.

Oil filter Replace oil filter and inspect for leakage.

COOLING SYSTEM

Cooling system

(including coolant level adjustment)Check coolant level and quality, and inspect for leakage.

Engine coolant Replace coolant.

FUEL SYSTEM

Air cleaner elementInspect for dirt, oil and damage.

Clean air cleaner element (by blowing air).

Replace air cleaner element.

Fuel filter Replace fuel filter.

Fuel lines and hoses Inspect for cracks, leakage and loose connection.

Fuel injection system (for MZR-CD (RF Turbo)) Update to injection amount correction with WDS. (see W/M)

IGNITION SYSTEM (FOR GASOLINE)

Spark plugsInspect for wear, damage, carbon, high-tension lead condition and measure

plug gap.

Replace spark plugs.

EMISSION CONTROL SYSTEM

Evaporative system (for gasoline)Check system operation (see W/M), vapor lines, vacuum fitting hoses and

connection.

E.G.R. system (MZR-CR (RF Turbo))Check system operation (see W/M), vacuum fitting hoses and connection.

Update to MAF correction for E.G.R control with WDS. (see W/M)

ELECTRICAL SYSTEM

Battery electrolyte level and specific gravity Check level and specific gravity.

CHASSIS AND BODY

Brake fluidCheck fluid level and inspect for leakage.

Replace brake fluid.

Brake lines, hoses and connectionsInspect for cracks, damage, chafing, corrosion, scars, swelling and fluid

leakage.

Parking brake Check lever stroke.

Power brake unit and hosesCheck vacuum lines, connections and check valve for improper attachment,

air tightness, cracks chafing and deterioration.

Disc brakesTest for judder and noise. Inspect caliper for correct operation and fluid

leakage, brake pads for wear. Check disc plate condition and thickness.

Power steering fluid and linesCheck fluid level and lines for improper attachment, leakage, cracks,

damage, loose connections, chafing and deterioration.

Power steering fluid Check fluid level.

Power steering system and hosesCheck lines for improper attachment, leakage, cracks, damage, loose

connections, chafing and deterioration.

Steering operation and gear housingCheck that the steering wheel has the specified play. Be sure to check for

changes, such as excessive play, hard steering or strange noises.

Check gear housing and boots for looseness, damage and grease/gear oil

leakage.

Steering linkages tie rod ends and armsCheck ball joint, dust cover and other components for looseness, wear,

damage and grease leakage.

Front and rear suspension and ball joints Inspect for grease leakage, cracks, damage and looseness.

Manual transmission/transaxle oilCheck oil level and inspect for leakage.

Replace manual transmission/transaxle oil.

Automatic transmission/transaxle fluid level Check fluid level.

Page 469 of 909

K2–54

AUTOMATIC TRANSAXLE

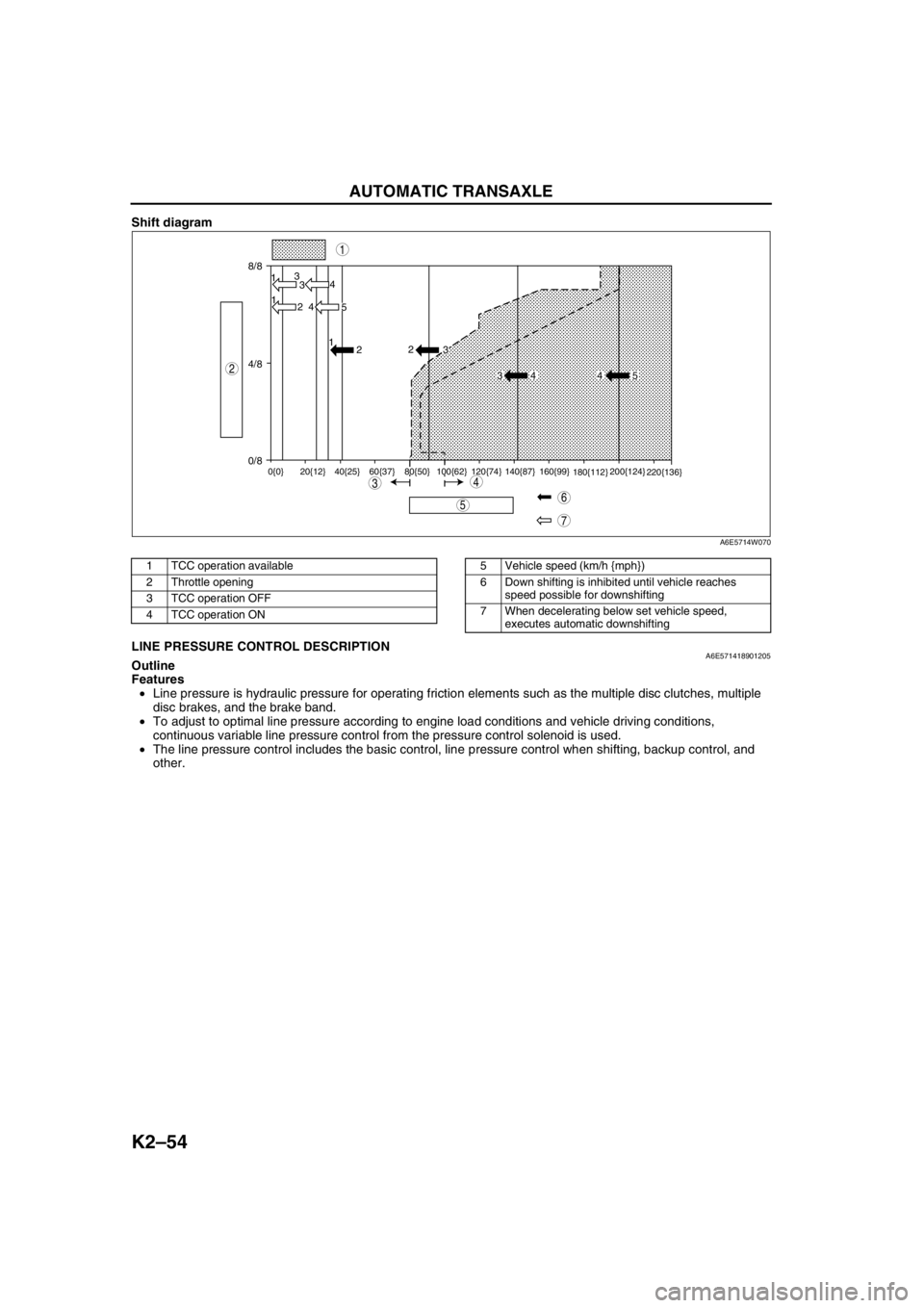

Shift diagram

.

End Of SieLINE PRESSURE CONTROL DESCRIPTIONA6E571418901205Outline

Features

•Line pressure is hydraulic pressure for operating friction elements such as the multiple disc clutches, multiple

disc brakes, and the brake band.

•To adjust to optimal line pressure according to engine load conditions and vehicle driving conditions,

continuous variable line pressure control from the pressure control solenoid is used.

•The line pressure control includes the basic control, line pressure control when shifting, backup control, and

other.

8/8

4/8

0/813

3

1

2 4

4

5 1

2

0{0} 20{12} 40{25} 60{37} 80{50} 100{62} 120{74} 140{87} 160{99}

180{112}200{124}

220{136}

2

3

34 4 5

7

5

43

1

2

6

A6E5714W070

1 TCC operation available

2 Throttle opening

3 TCC operation OFF

4 TCC operation ON5 Vehicle speed (km/h {mph})

6 Down shifting is inhibited until vehicle reaches

speed possible for downshifting

7 When decelerating below set vehicle speed,

executes automatic downshifting

Page 651 of 909

GENERAL PROCEDURES

M–21

M

PRECAUTION (FRONT AND REAR AXLE)A6E631001018201Wheel and Tire Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}

Brake Line Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid gets on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

2. If any brake line has been disconnected any time during the procedure, add brake fluid, bleed the brakes, and

inspect for leakage after the procedure has been completed.

Suspension Arm Removal/Installation

1. Tighten any part of the suspension that uses rubber bushings only after vehicle has been lowered and

unloaded.

Note

•Unloaded: Fuel tank is full. Engine coolant and engine oil are at specified level. Spare tire, jack, and tools

are in designated position.

Connector Disconnection

1. Disconnect the negative (-) battery cable before disconnecting connectors.

Electronic Control 4WD System Parts

1. After servicing the electronic control 4WD system parts, verify that no DTC has been stored. Clear any DTCs

remaining in the memory.

End Of Sie

GENERAL PROCEDURES

Page 654 of 909

M–24

REAR AXLE

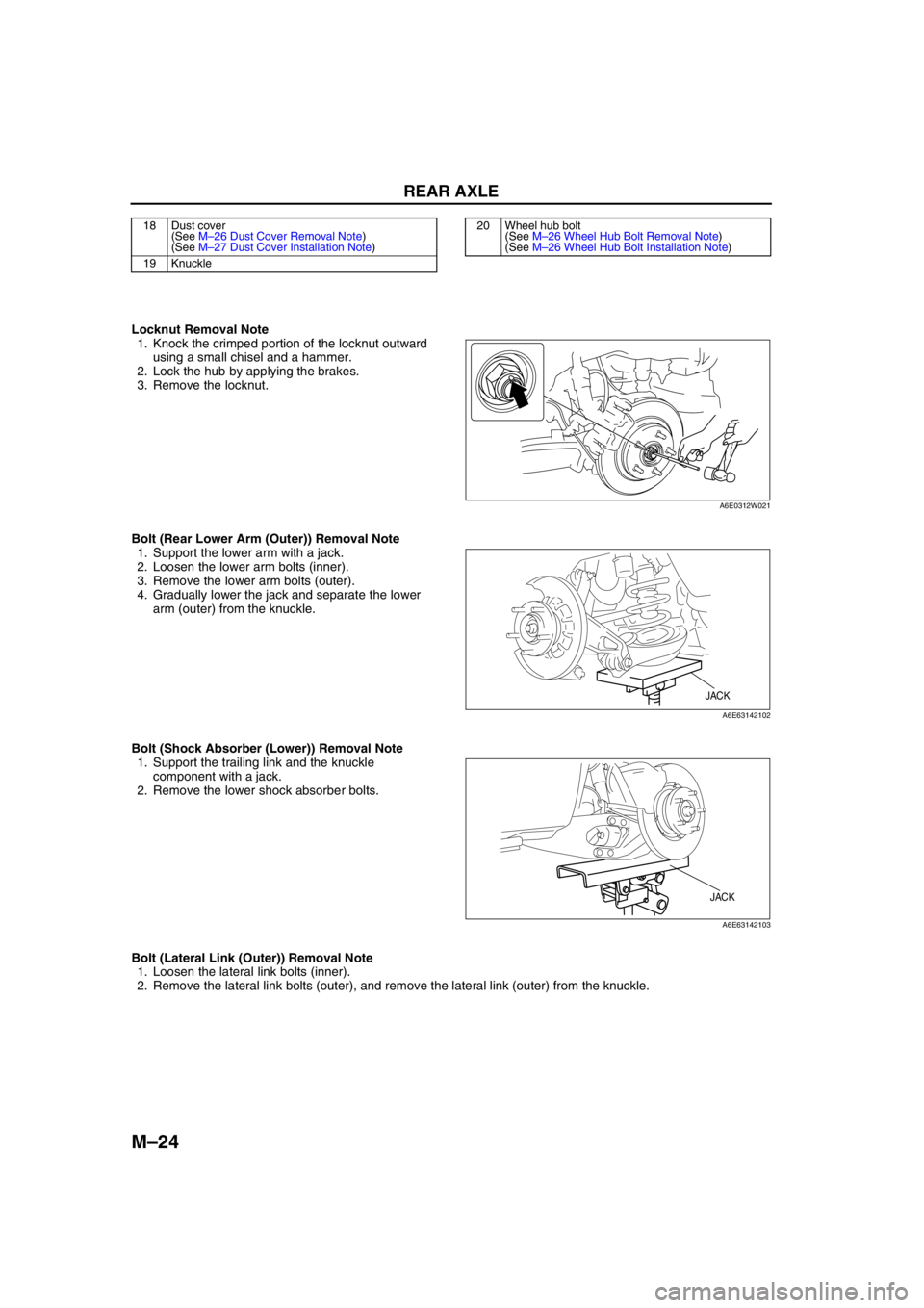

Locknut Removal Note

1. Knock the crimped portion of the locknut outward

using a small chisel and a hammer.

2. Lock the hub by applying the brakes.

3. Remove the locknut.

Bolt (Rear Lower Arm (Outer)) Removal Note

1. Support the lower arm with a jack.

2. Loosen the lower arm bolts (inner).

3. Remove the lower arm bolts (outer).

4. Gradually lower the jack and separate the lower

arm (outer) from the knuckle.

Bolt (Shock Absorber (Lower)) Removal Note

1. Support the trailing link and the knuckle

component with a jack.

2. Remove the lower shock absorber bolts.

Bolt (Lateral Link (Outer)) Removal Note

1. Loosen the lateral link bolts (inner).

2. Remove the lateral link bolts (outer), and remove the lateral link (outer) from the knuckle.

18 Dust cover

(See M–26 Dust Cover Removal Note)

(See M–27 Dust Cover Installation Note)

19 Knuckle20 Wheel hub bolt

(See M–26 Wheel Hub Bolt Removal Note)

(See M–26 Wheel Hub Bolt Installation Note)

A6E0312W021

JACK

A6E63142102

JACK

A6E63142103

Page 712 of 909

M–82

TROUBLESHOOTING

FOREWORDA6E638027100202

End Of Sie

SYMPTOM TROUBLESHOOTINGA6E638027100203•Verify the symptoms, and perform troubleshooting according to the appropriate number.

End Of Sie

NO.1 FREQUENT FRONT WHEEL SLIPA6E638027100204

Warning

•During simulation driving, vehicle stability may decrease extremely and cause an accident. Be

sure to perform the simulation test driving in a safe area.

Malfunction vehicle delivered

Questionnaire

Verify malfunction symptoms

Symptom troubleshooting

Verify that malfunctions have been repaired

Troubleshooting completedConfirm all customer problems using a questionnaire.

Confirm malfunction on actual vehicle.

DTC inspection

Inspect for DTCs using WDS or equivalent.

Perform applicable troubleshooting inspection according to

diagnostic index.

A6E63802001

No. Symptom Description

1 Frequent front wheel slip Front wheels slip frequently during acceleration on low-friction road.

2

Tight corner braking effectBrakes seem to be applied during tight cornering while driving very

slowly on paved road.

3 Abnormal noise and/or vibration from

coupling unitThere is abnormal noise and/or vibration from coupling unit during

driving.

1 Frequent front wheel slip

[TROUBLESHOOTING HINTS]

•Tire traction performance is extremely poor for given road friction. (4WD system is normal.)

•Improper wheel alignment (4WD system is normal.)

•Rear differential oil temperature is extremely high (Fail-safe condition)

•Differential oil temperature sensor malfunction (Fail-safe condition)

•Compare slip frequency with another vehicle of the same model (under the same road conditions and tire traction

performance).

•Replace tires with others of the same model and perform test under the same road conditions to determine if the

malfunction was caused by tire traction performance.

•Coupling component malfunction

•4WD solenoid malfunction

Page 734 of 909

P–1

P

PBRAKING SYSTEM

OUTLINE................................................................ P-2

OUTLINE OF CONSTRUCTION.......................... P-2

FEATURES .......................................................... P-2

SPECIFICATIONS ............................................... P-2

STRUCTURAL VIEW ........................................... P-3

ABS/TCS................................................................ P-4

OUTLINE.............................................................. P-4

DYNAMIC STABILITY CONTROL......................... P-6

OUTLINE.............................................................. P-6

COMBINE SENSOR

(FORWARD-G SENSOR) ................................. P-8

CONTROLLER AREA NETWORK (CAN) ........... P-8

ON-BOARD DIAGNOSTIC..................................... P-9

OUTLINE.............................................................. P-9

OUTLINE.............................................................. P-10

SUPPLEMENTAL SERVICE INFORMATION ... P-10

GENERAL PROCEDURES.................................. P-10

PRECAUTION (BRAKES).................................. P-10

CONVENTIONAL BRAKE SYSTEM.................... P-11

POWER BRAKE UNIT

REMOVAL/INSTALLATION ............................ P-11

VACUUM SWITCH INSPECTION

(MZR-CD (RF TURBO)) .................................. P-11

VACUUM SWITCH

REMOVAL/INSTALLATION

(MZR-CD (RF TURBO)) .................................. P-12

VACUUM PUMP INSPECTION

(MZR-CD (RF TURBO)) .................................. P-12

VACUUM PUMP REMOVAL/INSTALLATION

(MZR-CD (RF TURBO)) .................................. P-13

FRONT BRAKE (DISC) INSPECTION............... P-13

FRONT BRAKE (DISC)

REMOVAL/INSTALLATION ............................ P-14

DISC PAD (FRONT) REPLACEMENT .............. P-16

PARKING BRAKE SYSTEM................................ P-17

PARKING BRAKE (LEVER TYPE)

ADJUSTMENT ................................................ P-17

DYNAMIC STABILITY CONTROL....................... P-17

DSC HU/CM INSPECTION ................................ P-17

COMBINE SENSOR

(FORWARD-G SENSOR) INSPECTION ........ P-20

ON-BOARD DIAGNOSTIC................................... P-21

DSC ON-BOARD DIAGNOSIS .......................... P-21

DTC C1119 ........................................................ P-26

DTC C1949, C1950............................................ P-27

DTC U2511 ........................................................ P-29 FEATURES

SERVICE

Page 743 of 909

P–10

OUTLINE , GENERAL PROCEDURES

SUPPLEMENTAL SERVICE INFORMATIONA6E690201020205•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

Power brake unit

•Removal/installation procedure has been modified.

Vacuum switch (MZR-CD (RF Turbo))

•Inspection procedure has been added.

•Removal/installation procedure has been added.

Vacuum pump (MZR-CD (RF Turbo))

•Inspection procedure has been added.

•Removal/installation procedure has been added.

Front brake (disc)

•Inspection procedure has been modified.

•Removal/installation procedure has been modified.

Disc pad (front)

•Replacement procedure has been modified.

Parking brake (lever type)

•Adjustment procedure has been modified.

DSC HU/CM

•Inspection procedure has been modified.

Combine sensor (Forward-G sensor)

•Inspection procedure has been modified.

On-board diagnostic (ABS/TCS)

•4WD and MZR-CD (RF Turbo) have been added.

End Of Sie

PRECAUTION (BRAKES)A6E691001020201Wheels and Tires Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}.

Brake Lines Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

•If any brake line has been disconnected anytime during the procedure, add brake fluid, bleed the brakes,

and inspect for leakage after the procedure has been completed.

Connectors Disconnection

1. Disconnect the negative battery cable before doing any work that requires handling of connectors. Reconnect

the negative battery cable only after the work is completed.

ABS, ABS/TCS, or DSC Components Operations

1. Make sure that there are no DTCs in the ABS, ABS/TCS, or DSC memory after working on ABS, ABS/TCS or

DSC components.

•If there are any DTCs in the memory, clear them.

End Of Sie

OUTLINE

GENERAL PROCEDURES

Page 750 of 909

PARKING BRAKE SYSTEM, DYNAMIC STABILITY CONTROL

P–17

P

PARKING BRAKE (LEVER TYPE) ADJUSTMENTA6E6914440002011. Start the engine and depress the brake pedal several times.

2. Stop the engine.

3. For the 2WD model, remove the rear ashtray case behind the center console

4. For the 4WD model, remove the 4 screws (back side) and pull up the rear of the center console, then remove

the rear ashtray case.

5. Turn the adjusting nut as shown in the figure.

6. After adjustment, inspect the following points:

(1) Turn the ignition switch to ON, pull the parking

brake lever one notch, and verify that the

parking brake warning light illuminates.

(2) Verify that the rear brakes do not drag.

End Of Sie

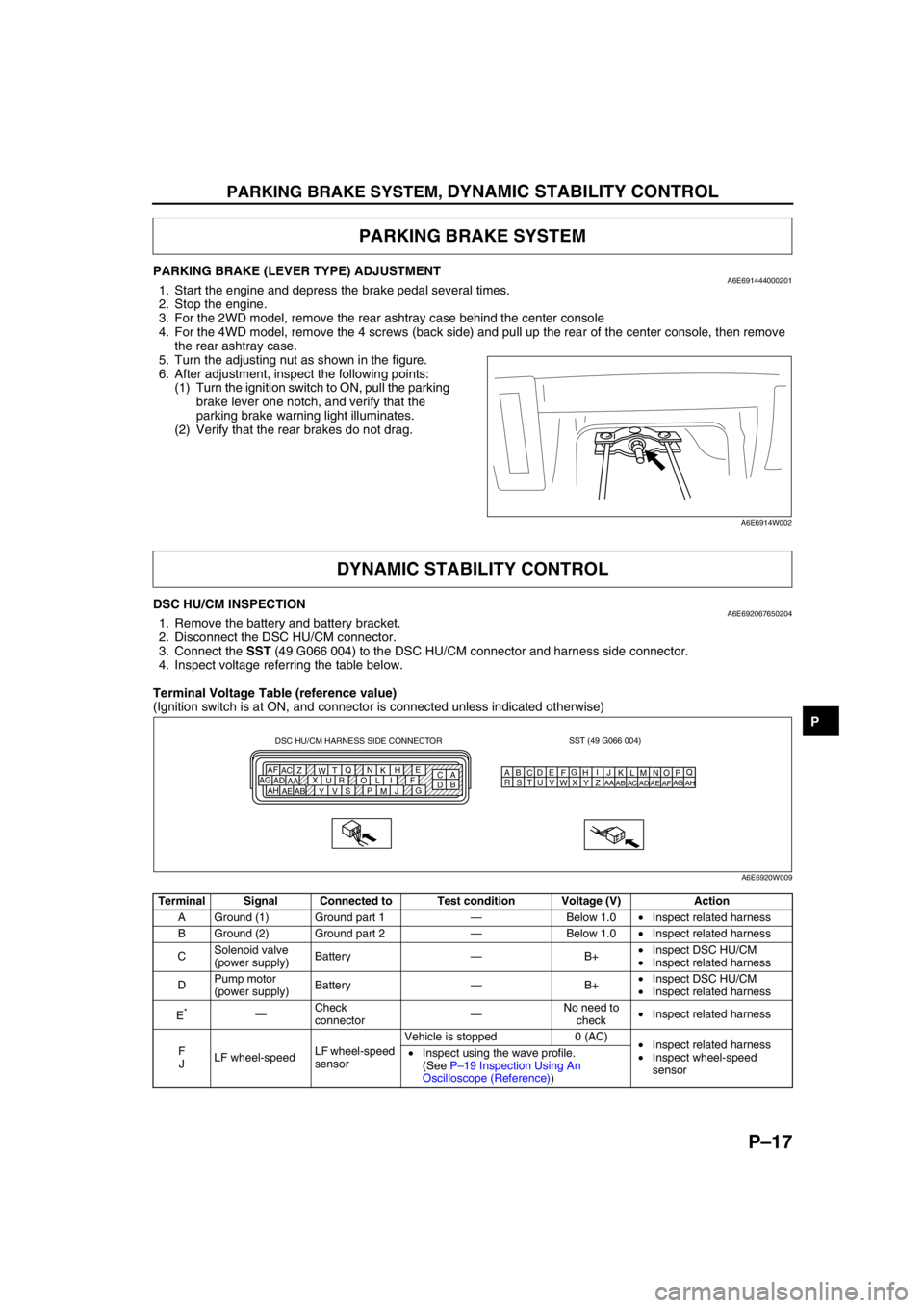

DSC HU/CM INSPECTIONA6E6920676502041. Remove the battery and battery bracket.

2. Disconnect the DSC HU/CM connector.

3. Connect the SST (49 G066 004) to the DSC HU/CM connector and harness side connector.

4. Inspect voltage referring the table below.

Terminal Voltage Table (reference value)

(Ignition switch is at ON, and connector is connected unless indicated otherwise)

PARKING BRAKE SYSTEM

A6E6914W002

DYNAMIC STABILITY CONTROL

Terminal Signal Connected to Test condition Voltage (V) Action

A Ground (1) Ground part 1—Below 1.0•Inspect related harness

B Ground (2) Ground part 2—Below 1.0•Inspect related harness

CSolenoid valve

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

DPump motor

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

E

*—Check

connector—No need to

check•Inspect related harness

F

JLF wheel-speedLF wheel-speed

sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH

A6E6920W009