instrument cluster MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 334 of 909

F2–182

TROUBLESHOOTING

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11Note

•Ignore DTC P0122, P0123, P0222 or

P0223 while performing this test.

Disconnect accelerator position sensor

connector.

Measure voltage at accelerator position sensor

connector VREF terminal (terminal D) with

engine switch ON.

Specification

4.5—5.5 V

Is voltage okay?Yes Go to next step.

No Go to symptom troubleshooting “NO.26 CONSTANT

VOLTAGE”.

12 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step. STEP INSPECTION RESULTS ACTION

Page 364 of 909

F2–212

TROUBLESHOOTING

NO.18 COOLING SYSTEM CONCERNS-RUNS COLDA6E408018881220

Diagnostic Procedure

End Of Sie

18 COOLING SYSTEM CONCERNS-RUNS COLD

DESCRIPTION•Engine takes excessive period for reaching normal operating temperature.

POSSIBLE

CAUSE•Thermostat malfunction

•Cooling fan No.2 system malfunction

•Cooling fan No.1 system malfunction

•Coolant heater system malfunction

STEP INSPECTION RESULTS ACTION

1 Is customer complaint “Lack of passenger

compartment heat”?Yes Inspect A/C heater system.

No Go to next step.

2 Does engine speed continue at fast idle? Yes Go to symptom troubleshooting “NO.7 SLOW

RETURN TO IDLE”.

No Go to next step.

3 Connect WDS or equivalent to DLC-2.

Access ECT PID.

Inspect for both ECT PID and temperature

gauge on instrument cluster readings.

Is ECT PID same as temperature gauge

reading?Yes Go to next step.

No If temperature gauge on instrument cluster indicates

normal range but ECT PID is not same as temperature

gauge reading, inspect ECT sensor.

If temperature gauge on instrument cluster indicates

cold range but ECT PID is normal, inspect

temperature gauge and heat gauge unit.

4 Remove thermostat and inspect operation.

(See E–9 THERMOSTAT REMOVAL/

INSTALLATION)

(See E–10 THERMOSTAT INSPECTION)

Is thermostat okay?Yes Go to next step.

No Replace thermostat.

5 Inspect cooling fan No.1 and cooling fan No.2

operations.

If both or either fan operate normally, inspect for

following:

•Cooling fan relay No.2 is stuck closed

•Short to GND between cooling fan relay No.2

and PCM terminal 76

•Circuit between cooling fan relay No.2 and

fan motor short to battery supply line

•Cooling fan relay No.1 is stuck closed

•Short to GND between cooling fan relay No.1

and PCM terminal 102

•Circuit between cooling fan relay No.1 and

fan motor short to battery supply line

•Short to GND between A/C switch and PCM

terminal 84

Are all circuits okay?Yes Perform coolant heater system inspection.

Repair or replace malfunctioning part according to

coolant heater system operation results.

No Repair or replace as necessary.

6 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 426 of 909

AUTOMATIC TRANSAXLE

K2–11

K2

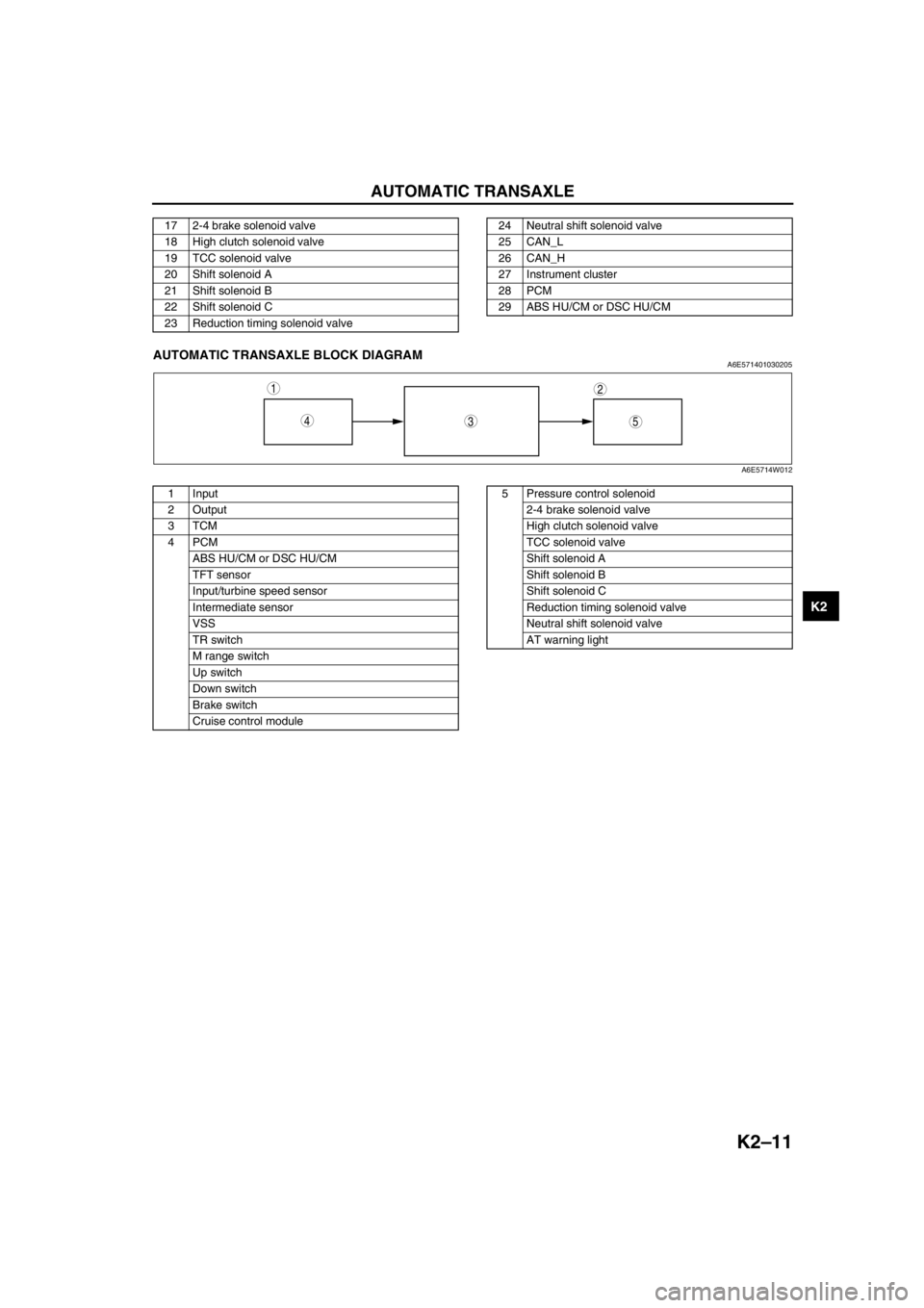

End Of SieAUTOMATIC TRANSAXLE BLOCK DIAGRAMA6E571401030205

.

17 2-4 brake solenoid valve

18 High clutch solenoid valve

19 TCC solenoid valve

20 Shift solenoid A

21 Shift solenoid B

22 Shift solenoid C

23 Reduction timing solenoid valve24 Neutral shift solenoid valve

25 CAN_L

26 CAN_H

27 Instrument cluster

28 PCM

29 ABS HU/CM or DSC HU/CM

543

12

A6E5714W012

1 Input

2Output

3TCM

4PCM

ABS HU/CM or DSC HU/CM

TFT sensor

Input/turbine speed sensor

Intermediate sensor

VSS

TR switch

M range switch

Up switch

Down switch

Brake switch

Cruise control module5 Pressure control solenoid

2-4 brake solenoid valve

High clutch solenoid valve

TCC solenoid valve

Shift solenoid A

Shift solenoid B

Shift solenoid C

Reduction timing solenoid valve

Neutral shift solenoid valve

AT warning light

Page 467 of 909

K2–52

AUTOMATIC TRANSAXLE

Operation

Range determination

•Each range is determined by operating the selector lever, and switching ON/OFF the switch in the TR switch

internal circuit. The present range is detected according to the ON/OFF signal of the switch.

•The following switches are built into the TR switch, and determine each range when the switch is on.

P position switch

R position switch

N position switch

D range switch

End Of Sie

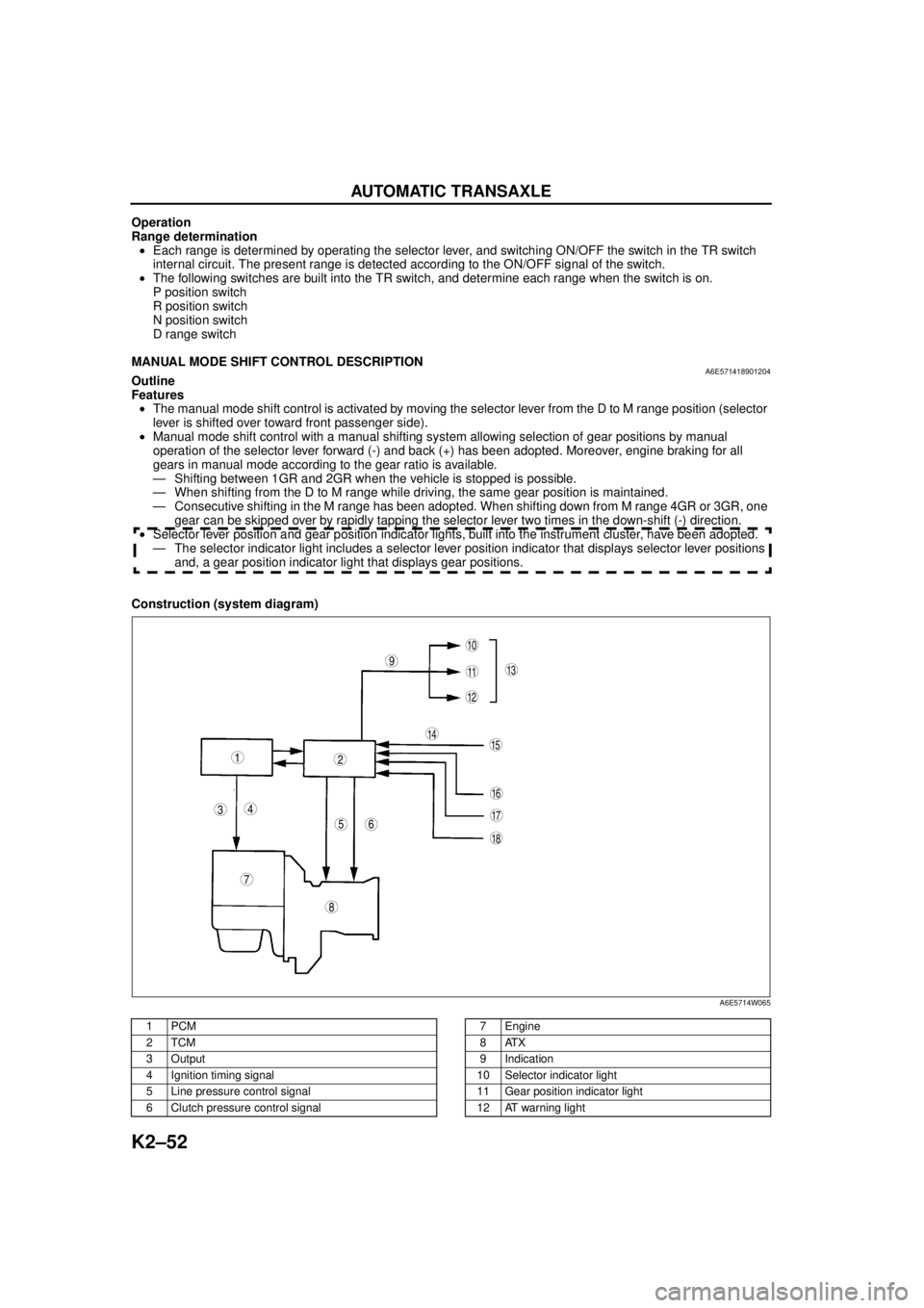

MANUAL MODE SHIFT CONTROL DESCRIPTIONA6E571418901204Outline

Features

•The manual mode shift control is activated by moving the selector lever from the D to M range position (selector

lever is shifted over toward front passenger side).

•Manual mode shift control with a manual shifting system allowing selection of gear positions by manual

operation of the selector lever forward (-) and back (+) has been adopted. Moreover, engine braking for all

gears in manual mode according to the gear ratio is available.

— Shifting between 1GR and 2GR when the vehicle is stopped is possible.

— When shifting from the D to M range while driving, the same gear position is maintained.

— Consecutive shifting in the M range has been adopted. When shifting down from M range 4GR or 3GR, one

gear can be skipped over by rapidly tapping the selector lever two times in the down-shift (-) direction.

•Selector lever position and gear position indicator lights, built into the instrument cluster, have been adopted.

— The selector indicator light includes a selector lever position indicator that displays selector lever positions

and, a gear position indicator light that displays gear positions.

Construction (system diagram)

.

9

8

7

5

43

12

10

18

17

15

16

14

1311

12

6

A6E5714W065

1PCM

2TCM

3Output

4 Ignition timing signal

5 Line pressure control signal

6 Clutch pressure control signal7Engine

8ATX

9 Indication

10 Selector indicator light

11 Gear position indicator light

12 AT warning light

Page 468 of 909

AUTOMATIC TRANSAXLE

K2–53

K2

Operation

Manual mode shift

•When the selector lever is shifted over from the D to M range position, the M range switch in the selector lever

component turns on, sending a manual mode command signal to the PCM which activates the manual mode

shift control.

•When in manual mode and the selector lever is operated in the back (+) direction, the up switch in the selector

lever component is turned on and an up-shift command signal is inputted to the PCM.

—The PCM, triggered by the up-shift command signal, carries out shifting by outputting an operation signal to

the shift solenoid if the ATF temperature is not low (for 3GR only), vehicle speed is higher than the set

speed and the gear position is 3GR or lower.

•Conversely, when the selector lever is operated in the forward (-) direction, the down switch in the selector lever

component turns on, and a down-shift command signal is inputted to the PCM.

—The PCM, triggered by the down-shift command signal, carries out shifting by outputting an operation

signal to the shift solenoid if the vehicle speed is less than the set speed and the gear position is 2GR or

above.

•The PCM utilizes a specialized M range automatic shift diagram when down shifting. This restriction of manual

downshifting is carried out to reduce load on the ATX and prevent engine over-revving.

13 Instrument cluster

14 Input15 Selector lever component

-M range switch

-Up switch

-Down switch

16 TR switch

17 ABS HU/CM or DSC HU/CM

18 TFT sensor

Condition Shift control Note

2GR→3GR up-shift command

at low speed•To reduce load on the ATX, upshifting is

inhibited until vehicle reaches speed

possible for upshifting

— 3GR→4GR up-shift command

at low speed

3GR→4GR up-shift command,

low ATF temperature•To reduce load on the ATX, upshifting to

4GR is inhibited

4GR→3GR down-shift

command, above set speed•To prevent engine over-rev, downshifting is

inhibited until vehicle reaches speed

possible for downshifting•Selector indicator “M” light and gear

position indicator light flash to alert

driver

3GR→2GR down-shift

command, above set speed

2GR→1GR down-shift

command, above set speed

In 4GR deceleration, speed

goes below coast-down set

speed (deceleration down-

shift)•To assure drive stability, automatically

downshifts from 4GR to 3GR

— In 3GR deceleration, speed

goes below coast-down set

speed (deceleration down-

shift)•To assure drive stability, automatically

downshifts from 3GR to 1GR

In 2GR deceleration, speed

goes below coast-down set

speed (deceleration down-

shift)•To assure driving stability, automatically

downshifts from 2GR to 1GR

Page 479 of 909

K2–64

AUTOMATIC TRANSAXLE

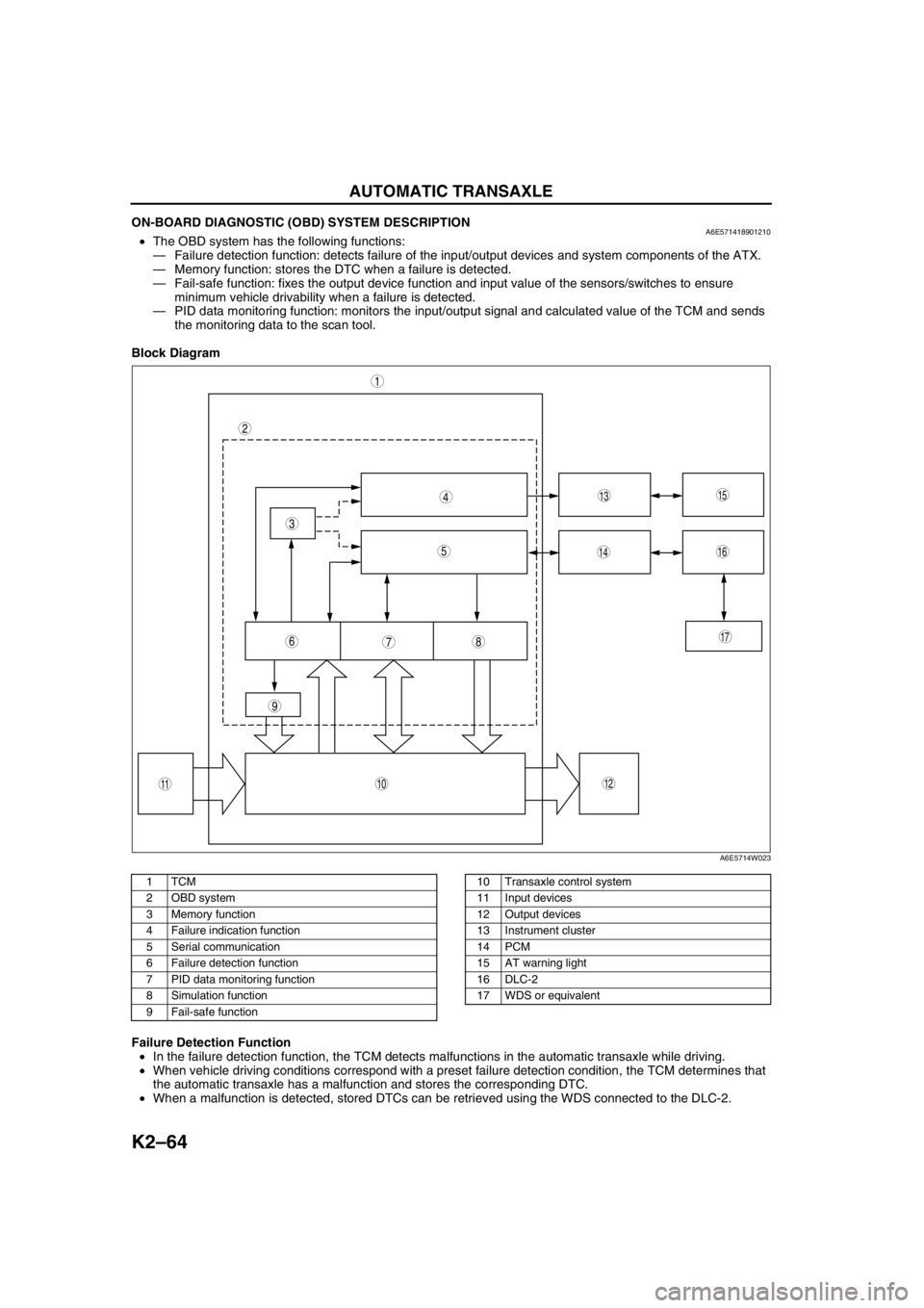

ON-BOARD DIAGNOSTIC (OBD) SYSTEM DESCRIPTIONA6E571418901210•The OBD system has the following functions:

—Failure detection function: detects failure of the input/output devices and system components of the ATX.

—Memory function: stores the DTC when a failure is detected.

—Fail-safe function: fixes the output device function and input value of the sensors/switches to ensure

minimum vehicle drivability when a failure is detected.

—PID data monitoring function: monitors the input/output signal and calculated value of the TCM and sends

the monitoring data to the scan tool.

Block Diagram

.

Failure Detection Function

•In the failure detection function, the TCM detects malfunctions in the automatic transaxle while driving.

•When vehicle driving conditions correspond with a preset failure detection condition, the TCM determines that

the automatic transaxle has a malfunction and stores the corresponding DTC.

•When a malfunction is detected, stored DTCs can be retrieved using the WDS connected to the DLC-2.

9

87

5

4

3

1

2

10

17

15

1614

13

1112

6

A6E5714W023

1TCM

2 OBD system

3 Memory function

4 Failure indication function

5 Serial communication

6 Failure detection function

7 PID data monitoring function

8 Simulation function

9 Fail-safe function10 Transaxle control system

11 Input devices

12 Output devices

13 Instrument cluster

14 PCM

15 AT warning light

16 DLC-2

17 WDS or equivalent

Page 599 of 909

K2–184

TROUBLESHOOTING

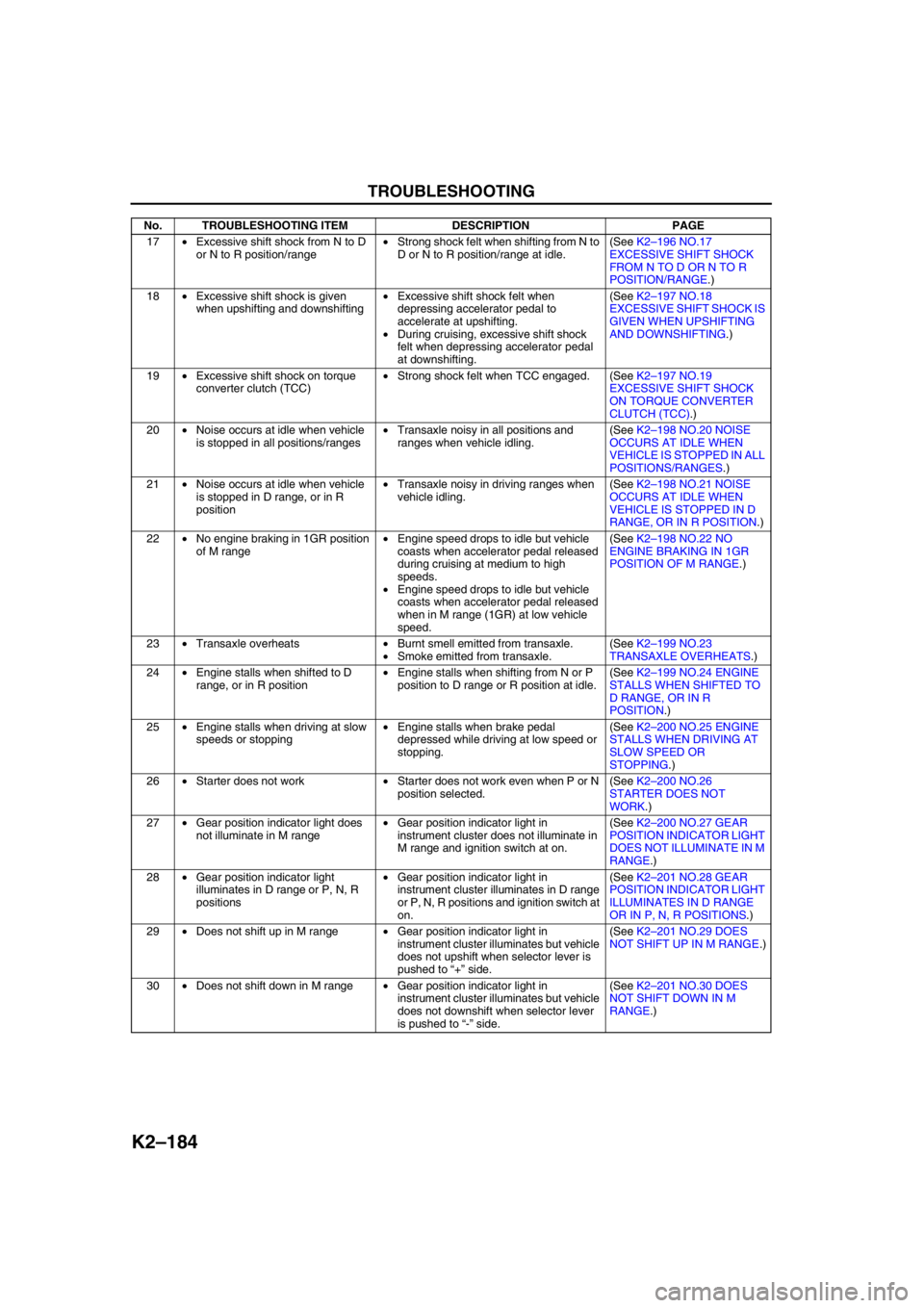

17•Excessive shift shock from N to D

or N to R position/range•Strong shock felt when shifting from N to

D or N to R position/range at idle.(See K2–196 NO.17

EXCESSIVE SHIFT SHOCK

FROM N TO D OR N TO R

POSITION/RANGE.)

18•Excessive shift shock is given

when upshifting and downshifting•Excessive shift shock felt when

depressing accelerator pedal to

accelerate at upshifting.

•During cruising, excessive shift shock

felt when depressing accelerator pedal

at downshifting.(See K2–197 NO.18

EXCESSIVE SHIFT SHOCK IS

GIVEN WHEN UPSHIFTING

AND DOWNSHIFTING.)

19•Excessive shift shock on torque

converter clutch (TCC)•Strong shock felt when TCC engaged. (See K2–197 NO.19

EXCESSIVE SHIFT SHOCK

ON TORQUE CONVERTER

CLUTCH (TCC).)

20•Noise occurs at idle when vehicle

is stopped in all positions/ranges•Transaxle noisy in all positions and

ranges when vehicle idling.(See K2–198 NO.20 NOISE

OCCURS AT IDLE WHEN

VEHICLE IS STOPPED IN ALL

POSITIONS/RANGES.)

21•Noise occurs at idle when vehicle

is stopped in D range, or in R

position•Transaxle noisy in driving ranges when

vehicle idling.(See K2–198 NO.21 NOISE

OCCURS AT IDLE WHEN

VEHICLE IS STOPPED IN D

RANGE, OR IN R POSITION.)

22•No engine braking in 1GR position

of M range•Engine speed drops to idle but vehicle

coasts when accelerator pedal released

during cruising at medium to high

speeds.

•Engine speed drops to idle but vehicle

coasts when accelerator pedal released

when in M range (1GR) at low vehicle

speed.(See K2–198 NO.22 NO

ENGINE BRAKING IN 1GR

POSITION OF M RANGE.)

23•Transaxle overheats•Burnt smell emitted from transaxle.

•Smoke emitted from transaxle.(See K2–199 NO.23

TRANSAXLE OVERHEATS.)

24•Engine stalls when shifted to D

range, or in R position•Engine stalls when shifting from N or P

position to D range or R position at idle.(See K2–199 NO.24 ENGINE

STALLS WHEN SHIFTED TO

D RANGE, OR IN R

POSITION.)

25•Engine stalls when driving at slow

speeds or stopping•Engine stalls when brake pedal

depressed while driving at low speed or

stopping.(See K2–200 NO.25 ENGINE

STALLS WHEN DRIVING AT

SLOW SPEED OR

STOPPING.)

26•Starter does not work•Starter does not work even when P or N

position selected.(See K2–200 NO.26

STARTER DOES NOT

WORK.)

27•Gear position indicator light does

not illuminate in M range•Gear position indicator light in

instrument cluster does not illuminate in

M range and ignition switch at on.(See K2–200 NO.27 GEAR

POSITION INDICATOR LIGHT

DOES NOT ILLUMINATE IN M

RANGE.)

28•Gear position indicator light

illuminates in D range or P, N, R

positions•Gear position indicator light in

instrument cluster illuminates in D range

or P, N, R positions and ignition switch at

on.(See K2–201 NO.28 GEAR

POSITION INDICATOR LIGHT

ILLUMINATES IN D RANGE

OR IN P, N, R POSITIONS.)

29•Does not shift up in M range•Gear position indicator light in

instrument cluster illuminates but vehicle

does not upshift when selector lever is

pushed to “+” side.(See K2–201 NO.29 DOES

NOT SHIFT UP IN M RANGE.)

30•Does not shift down in M range•Gear position indicator light in

instrument cluster illuminates but vehicle

does not downshift when selector lever

is pushed to “-” side.(See K2–201 NO.30 DOES

NOT SHIFT DOWN IN M

RANGE.) No. TROUBLESHOOTING ITEM DESCRIPTION PAGE

Page 615 of 909

K2–200

TROUBLESHOOTING

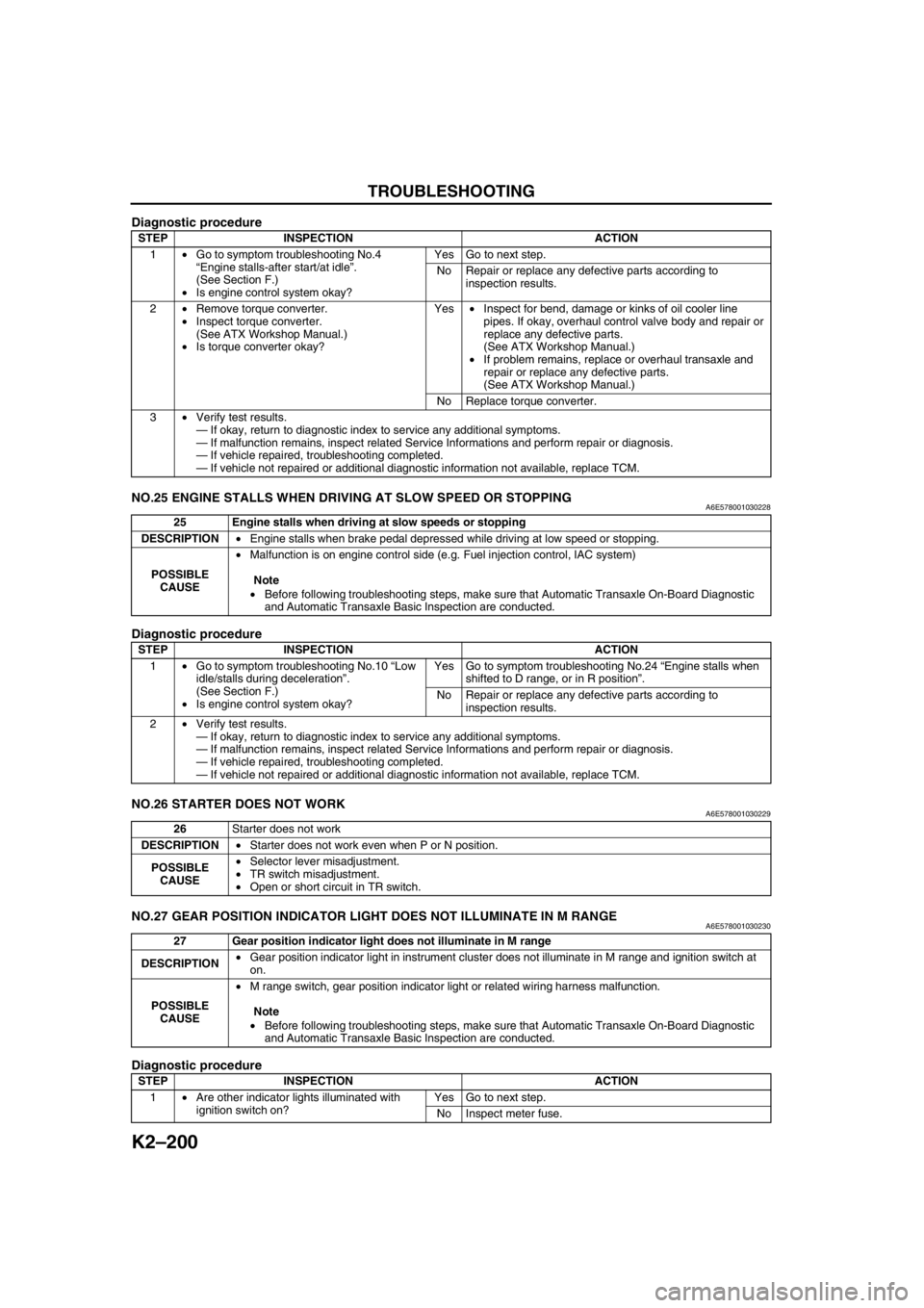

Diagnostic procedure

End Of SieNO.25 ENGINE STALLS WHEN DRIVING AT SLOW SPEED OR STOPPINGA6E578001030228

Diagnostic procedure

End Of SieNO.26 STARTER DOES NOT WORKA6E578001030229

End Of SieNO.27 GEAR POSITION INDICATOR LIGHT DOES NOT ILLUMINATE IN M RANGEA6E578001030230

Diagnostic procedure

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.4

“Engine stalls-after start/at idle”.

(See Section F.)

•Is engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Inspect for bend, damage or kinks of oil cooler line

pipes. If okay, overhaul control valve body and repair or

replace any defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace torque converter.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

25 Engine stalls when driving at slow speeds or stopping

DESCRIPTION•Engine stalls when brake pedal depressed while driving at low speed or stopping.

POSSIBLE

CAUSE•Malfunction is on engine control side (e.g. Fuel injection control, IAC system)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.10 “Low

idle/stalls during deceleration”.

(See Section F.)

•Is engine control system okay?Yes Go to symptom troubleshooting No.24 “Engine stalls when

shifted to D range, or in R position”.

No Repair or replace any defective parts according to

inspection results.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

26Starter does not work

DESCRIPTION•Starter does not work even when P or N position.

POSSIBLE

CAUSE•Selector lever misadjustment.

•TR switch misadjustment.

•Open or short circuit in TR switch.

27 Gear position indicator light does not illuminate in M range

DESCRIPTION•Gear position indicator light in instrument cluster does not illuminate in M range and ignition switch at

on.

POSSIBLE

CAUSE•M range switch, gear position indicator light or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Are other indicator lights illuminated with

ignition switch on? Yes Go to next step.

No Inspect meter fuse.

Page 616 of 909

TROUBLESHOOTING

K2–201

K2

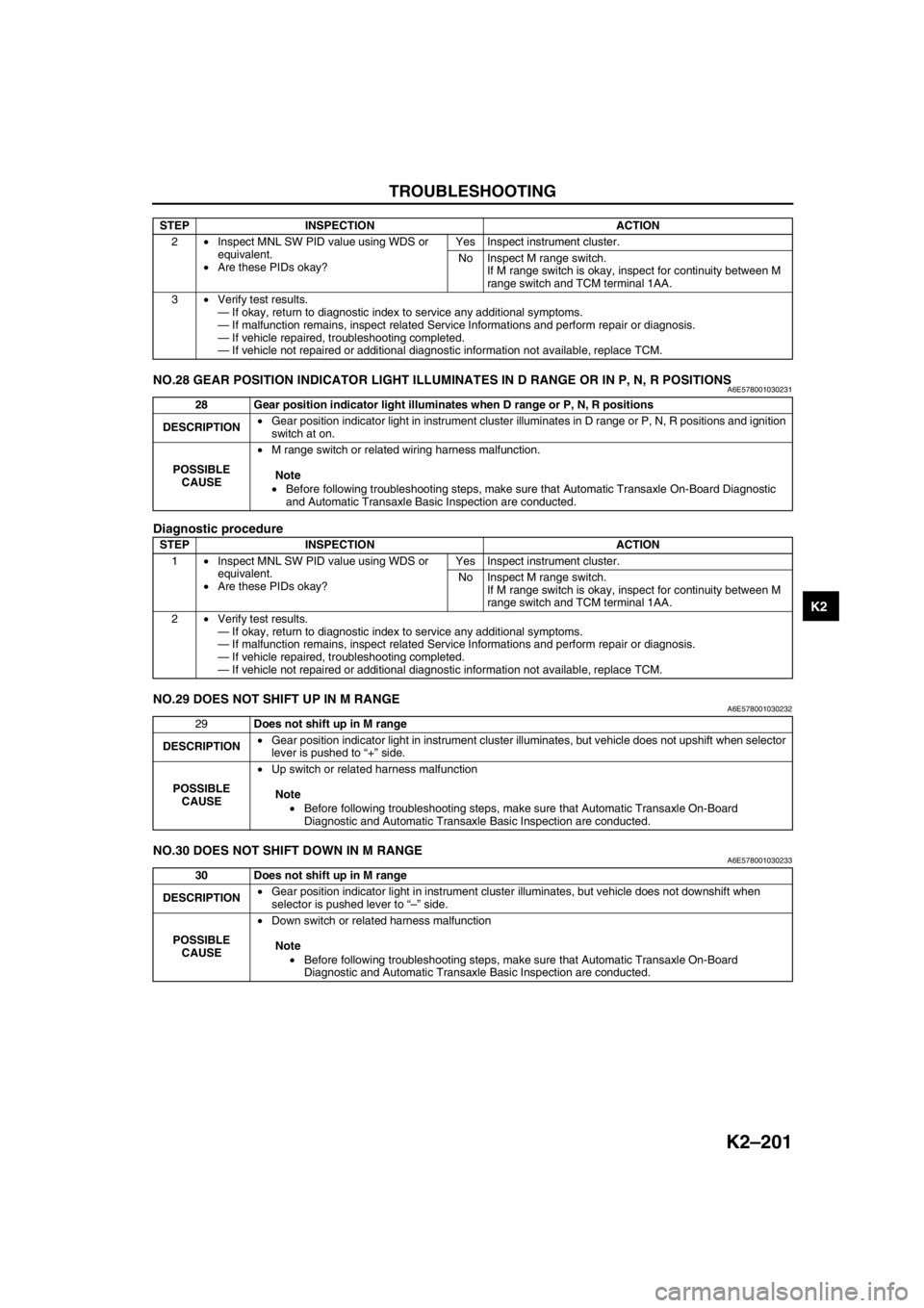

End Of SieNO.28 GEAR POSITION INDICATOR LIGHT ILLUMINATES IN D RANGE OR IN P, N, R POSITIONSA6E578001030231

Diagnostic procedure

End Of SieNO.29 DOES NOT SHIFT UP IN M RANGEA6E578001030232

End Of SieNO.30 DOES NOT SHIFT DOWN IN M RANGEA6E578001030233

End Of Sie

2•Inspect MNL SW PID value using WDS or

equivalent.

•Are these PIDs okay?Yes Inspect instrument cluster.

No Inspect M range switch.

If M range switch is okay, inspect for continuity between M

range switch and TCM terminal 1AA.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM. STEP INSPECTION ACTION

28 Gear position indicator light illuminates when D range or P, N, R positions

DESCRIPTION•Gear position indicator light in instrument cluster illuminates in D range or P, N, R positions and ignition

switch at on.

POSSIBLE

CAUSE•M range switch or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Inspect MNL SW PID value using WDS or

equivalent.

•Are these PIDs okay?Yes Inspect instrument cluster.

No Inspect M range switch.

If M range switch is okay, inspect for continuity between M

range switch and TCM terminal 1AA.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

29Does not shift up in M range

DESCRIPTION•Gear position indicator light in instrument cluster illuminates, but vehicle does not upshift when selector

lever is pushed to “+” side.

POSSIBLE

CAUSE•Up switch or related harness malfunction

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board

Diagnostic and Automatic Transaxle Basic Inspection are conducted.

30 Does not shift up in M range

DESCRIPTION•Gear position indicator light in instrument cluster illuminates, but vehicle does not downshift when

selector is pushed lever to “–” side.

POSSIBLE

CAUSE•Down switch or related harness malfunction

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board

Diagnostic and Automatic Transaxle Basic Inspection are conducted.

Page 638 of 909

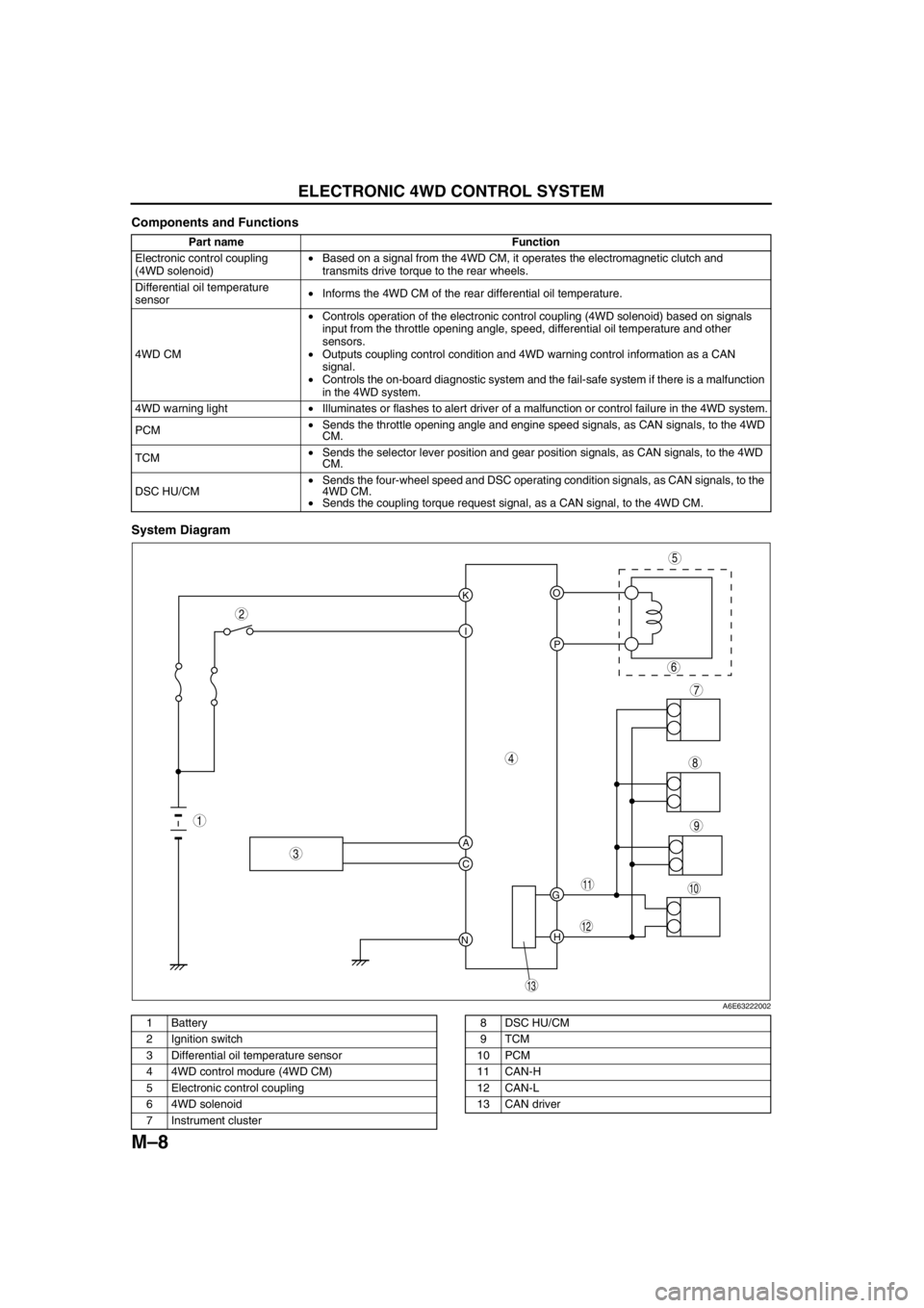

M–8

ELECTRONIC 4WD CONTROL SYSTEM

Components and Functions

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver