wiring MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 226 of 909

F2–74

CONTROL SYSTEM

MASS AIR FLOW (MAF)/INTAKE AIR TEMPERATURE (IAT) SENSOR INSPECTIONA6E404013210201

Note

•Perform the following test only when directed.

•Perform “MAF Correction” after replacing the MAF/IAT sensor. (See F2–35 MAF Correction.)

MAF Sensor Voltage Inspection

1. Turn the engine switch to ON.

2. Monitor the MAF PID using the WDS or equivalent.

•If not as specified, perform the “Circuit Open/Short Inspection”.

MAF PID

0.0—1.0 V

3. Start the engine and warm up the engine completely.

4. Monitor the MAF PID using the WDS or equivalent at idle.

•If not as specified, perform the “Circuit Open/Short Inspection”.

MAF PID

1.5—2.1 V

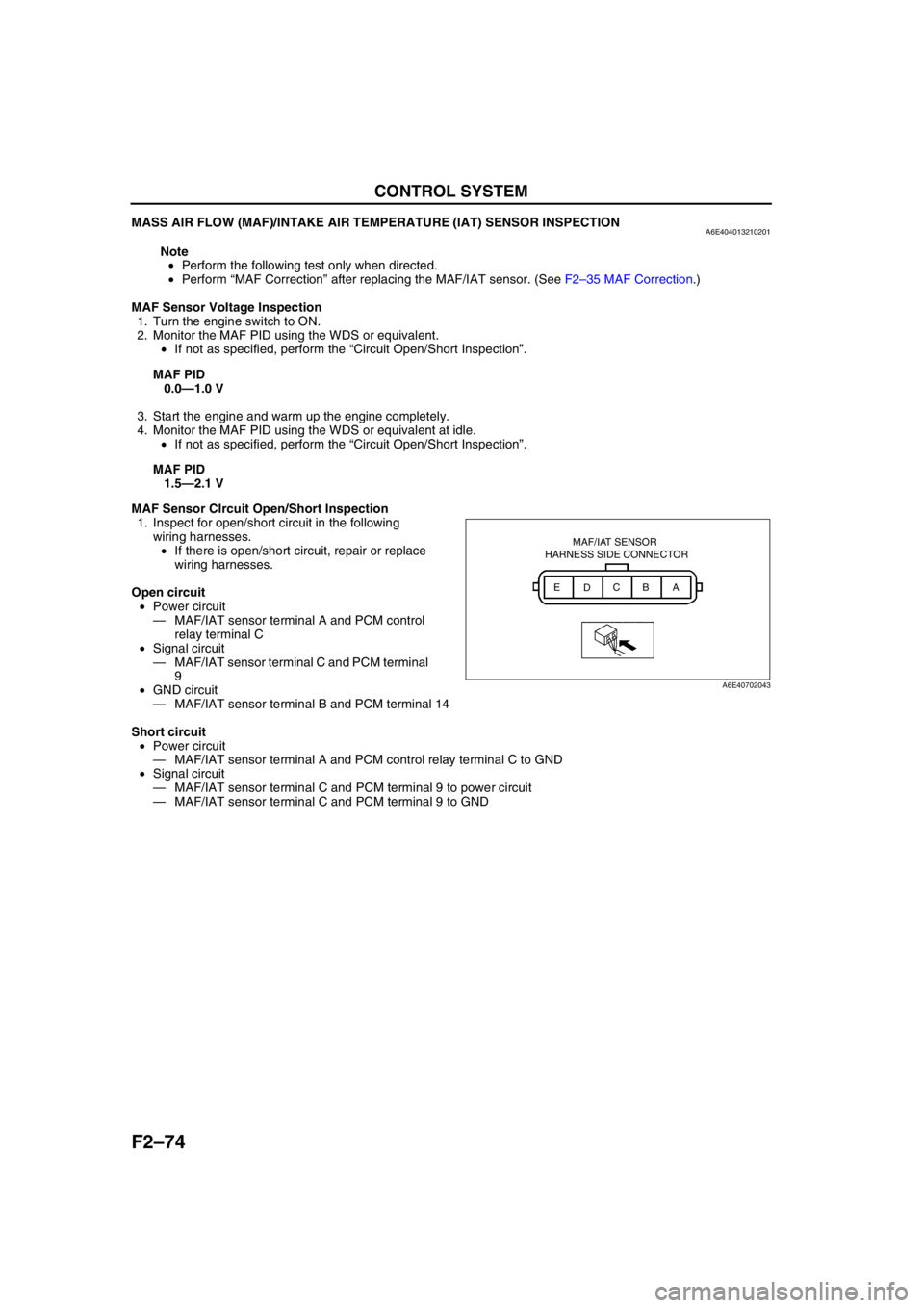

MAF Sensor CIrcuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•Power circuit

—MAF/IAT sensor terminal A and PCM control

relay terminal C

•Signal circuit

—MAF/IAT sensor terminal C and PCM terminal

9

•GND circuit

—MAF/IAT sensor terminal B and PCM terminal 14

Short circuit

•Power circuit

—MAF/IAT sensor terminal A and PCM control relay terminal C to GND

•Signal circuit

—MAF/IAT sensor terminal C and PCM terminal 9 to power circuit

—MAF/IAT sensor terminal C and PCM terminal 9 to GND

MAF/IAT SENSOR

HARNESS SIDE CONNECTOR

A

B

C

D E

A6E40702043

Page 227 of 909

CONTROL SYSTEM

F2–75

F2

IAT Sensor No.1 Resistance Inspection

1. Disconnect the MAF/IAT sensor connector.

2. Measure the resistance between MAF/IAT sensor terminals D and E using an ohmmeter.

•If not as specified, replace the MAF/IAT sensor.

Specification

IAT Sensor No.1 CIrcuit Open/Short Inspection

1. Inspect for open/short circuit in the following wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•Signal circuit

—MAF/IAT sensor terminal D and PCM terminal 60

•GND circuit

—MAF/IAT sensor terminal E and PCM terminal 91

Short circuit

•Signal circuit

—MAF/IAT sensor terminal D and PCM terminal 60 to power circuit

—MAF/IAT sensor terminal D and PCM terminal 60 to GND

End Of Sie

INTAKE AIR TEMPERATURE (IAT) SENSOR NO.2 INSPECTIONA6E404018845201

Note

•Perform the following test only when directed.

Resistance Inspection

1. Place the IAT sensor No.2 in water with a thermometer, and heat the water gradually.

2. Measure the resistance between the IAT sensor

No.2 terminals using an ohmmeter.

•If not as specified, replace the IAT sensor

No.2.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•Signal circuit

—IAT sensor No.2 terminal A and PCM terminal 8

•GND circuit

—IAT sensor No.2 terminal B and PCM terminal 91

Short circuit

•Signal circuit

—IAT sensor No.2 terminal A and PCM terminal 8 to power circuit

—IAT sensor No.2 terminal A and PCM terminal 8 to GND

End Of Sie

Ambient temperature (°C

{°F})Resistance (kilohm)

20 {68} 2.21—2.69

Water temperature (°C {°F}) Resistance (kilohm)

20 {68} 2.21—2.69

80 {176} 0.29—0.35

A B

A6E40702044

Page 228 of 909

F2–76

CONTROL SYSTEM

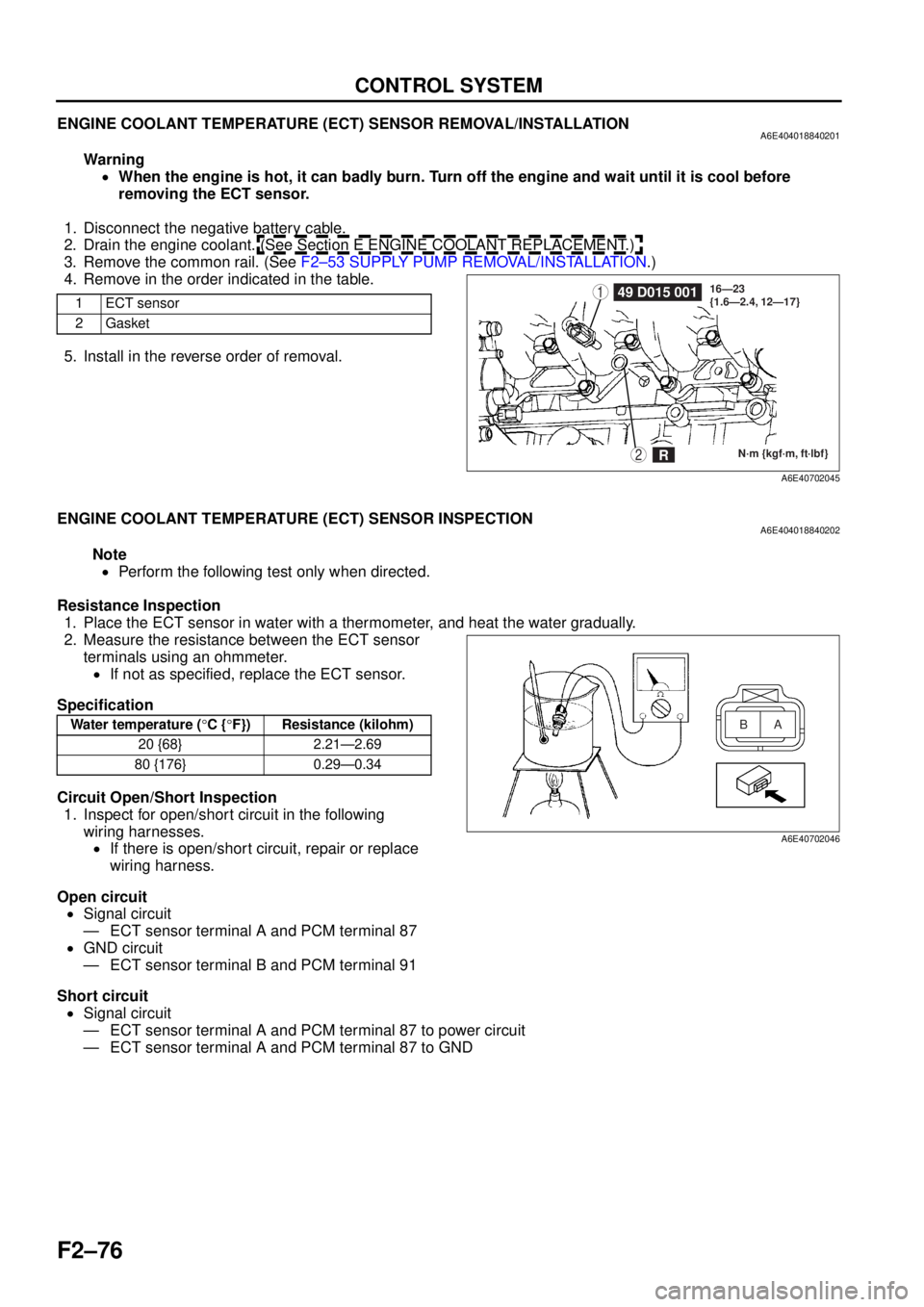

ENGINE COOLANT TEMPERATURE (ECT) SENSOR REMOVAL/INSTALLATIONA6E404018840201

Warning•When the engine is hot, it can badly burn. Turn off the engine and wait until it is cool before

removing the ECT sensor.

1. Disconnect the negative battery cable.

2. Drain the engine coolant. (See Section E ENGINE COOLANT REPLACEMENT.)

3. Remove the common rail. (See F2–53 SUPPLY PUMP REMOVAL/INSTALLATION .)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of Sie

ENGINE COOLANT TEMPERATURE (ECT) SENSOR INSPECTIONA6E404018840202

Note

• Perform the following test only when directed.

Resistance Inspection 1. Place the ECT sensor in water with a thermometer, and heat the water gradually.

2. Measure the resistance between the ECT sensor terminals using an ohmmeter.

• If not as specified, replace the ECT sensor.

Specification

Circuit Open/Short Inspection 1. Inspect for open/short circuit in the following

wiring harnesses.• If there is open/short circuit, repair or replace

wiring harness.

Open circuit • Signal circuit

— ECT sensor terminal A and PCM terminal 87

• GND circuit

— ECT sensor terminal B and PCM terminal 91

Short circuit • Signal circuit

— ECT sensor terminal A and PCM terminal 87 to power circuit

— ECT sensor terminal A and PCM terminal 87 to GND

End Of Sie

1ECT sensor

2Gasket149 D015 001

N·m {kgf·m, ft·lbf}

16—23

{1.6—2.4, 12—17}2R

A6E40702045

Water temperature (

°C { °F}) Resistance (kilohm)

20 {68} 2.21—2.69

80 {176} 0.29—0.34A

B

A6E40702046

Page 229 of 909

CONTROL SYSTEM

F2–77

F2

FUEL TEMPERATURE SENSOR INSPECTIONA6E404013350201

Note

•Perform the following test only when directed.

Resistance Inspection

1. Disconnect the negative battery cable.

2. Remove the supply pump. (See F2–53 SUPPLY PUMP REMOVAL/INSTALLATION.)

3. Measure the resistance between the fuel

temperature sensor terminals using an

ohmmeter.

•If not as specified, repair the supply pump.

(See F2–54 SUPPLY PUMP INSPECTION.)

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace wiring harness.

Open circuit

•Signal circuit

—Fuel temperature sensor terminal A and PCM terminal 35

•GND circuit

—Fuel temperature sensor terminal B and PCM terminal 91

Short circuit

•Signal circuit

—Fuel temperature sensor terminal A and PCM terminal 35 to power circuit

—Fuel temperature sensor terminal A and PCM terminal 35 to GND

End Of Sie

Ambient temperature (°C

{°F})Resistance (kilohm)

20 {68} 2.0—3.0

A

B

A6E40702047

Page 230 of 909

F2–78

CONTROL SYSTEM

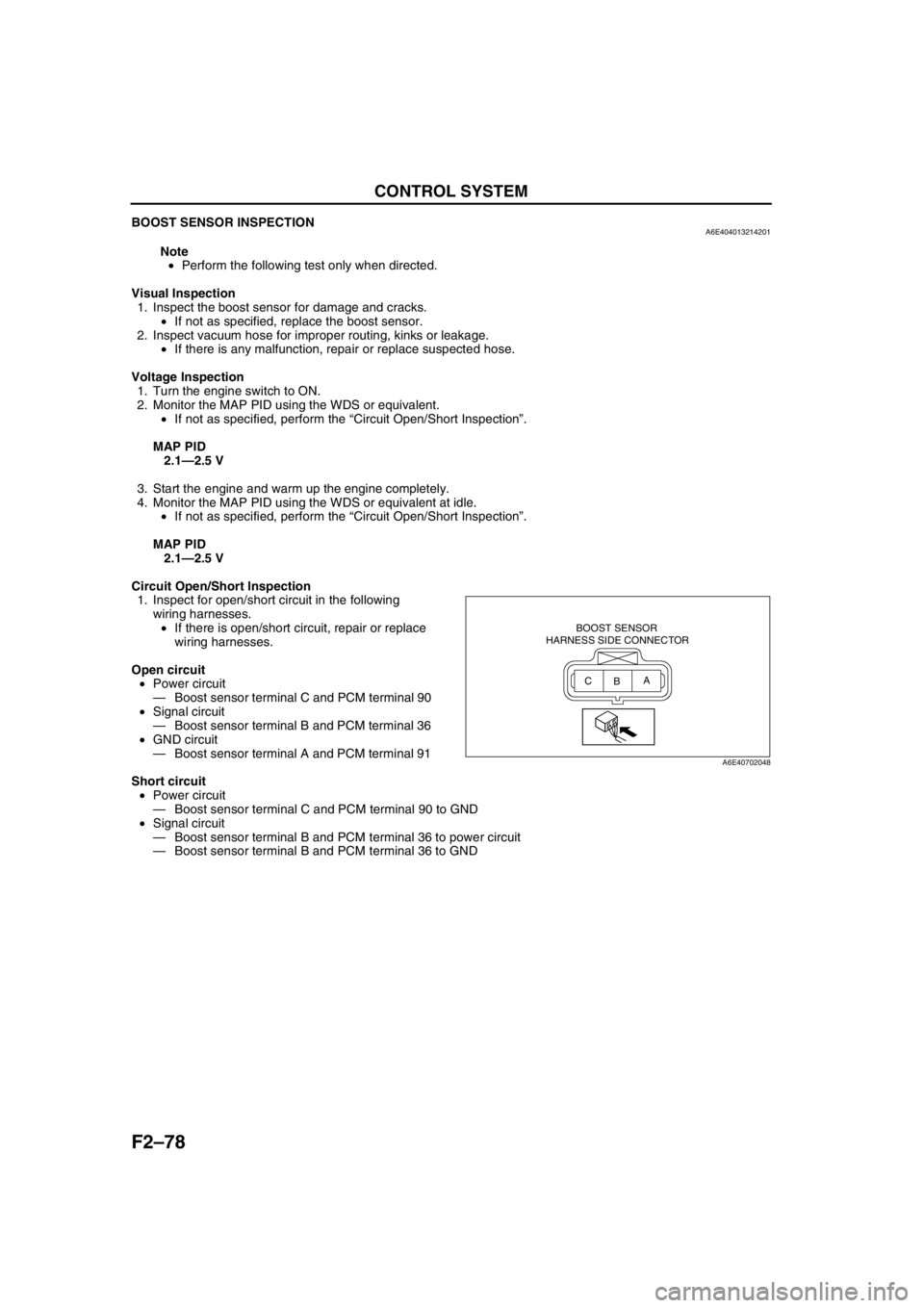

BOOST SENSOR INSPECTIONA6E404013214201

Note

•Perform the following test only when directed.

Visual Inspection

1. Inspect the boost sensor for damage and cracks.

•If not as specified, replace the boost sensor.

2. Inspect vacuum hose for improper routing, kinks or leakage.

•If there is any malfunction, repair or replace suspected hose.

Voltage Inspection

1. Turn the engine switch to ON.

2. Monitor the MAP PID using the WDS or equivalent.

•If not as specified, perform the “Circuit Open/Short Inspection”.

MAP PID

2.1—2.5 V

3. Start the engine and warm up the engine completely.

4. Monitor the MAP PID using the WDS or equivalent at idle.

•If not as specified, perform the “Circuit Open/Short Inspection”.

MAP PID

2.1—2.5 V

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•Power circuit

—Boost sensor terminal C and PCM terminal 90

•Signal circuit

—Boost sensor terminal B and PCM terminal 36

•GND circuit

—Boost sensor terminal A and PCM terminal 91

Short circuit

•Power circuit

—Boost sensor terminal C and PCM terminal 90 to GND

•Signal circuit

—Boost sensor terminal B and PCM terminal 36 to power circuit

—Boost sensor terminal B and PCM terminal 36 to GND

End Of Sie

BOOST SENSOR

HARNESS SIDE CONNECTOR

A

B C

A6E40702048

Page 231 of 909

CONTROL SYSTEM

F2–79

F2

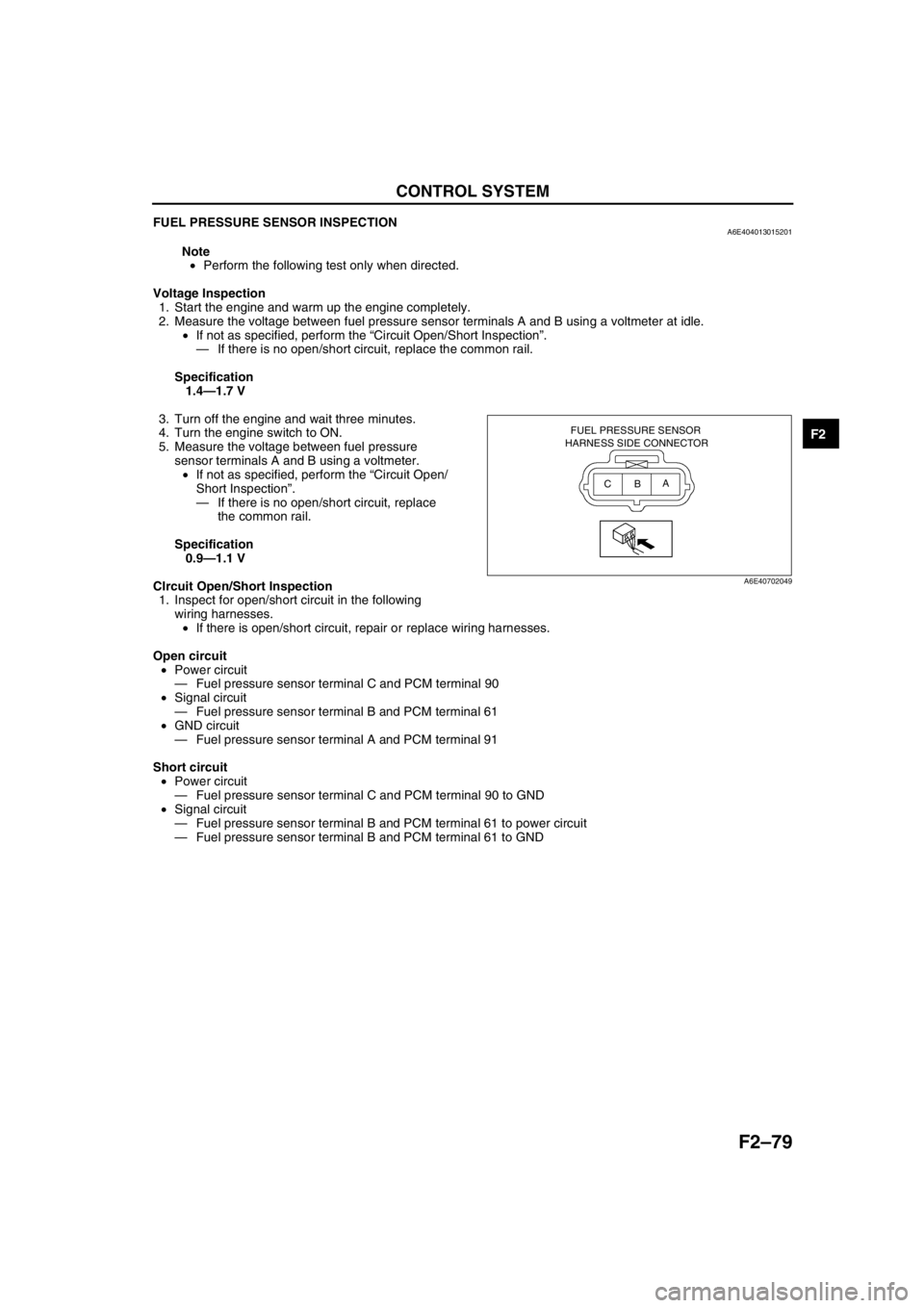

FUEL PRESSURE SENSOR INSPECTIONA6E404013015201

Note

•Perform the following test only when directed.

Voltage Inspection

1. Start the engine and warm up the engine completely.

2. Measure the voltage between fuel pressure sensor terminals A and B using a voltmeter at idle.

•If not as specified, perform the “Circuit Open/Short Inspection”.

—If there is no open/short circuit, replace the common rail.

Specification

1.4—1.7 V

3. Turn off the engine and wait three minutes.

4. Turn the engine switch to ON.

5. Measure the voltage between fuel pressure

sensor terminals A and B using a voltmeter.

•If not as specified, perform the “Circuit Open/

Short Inspection”.

—If there is no open/short circuit, replace

the common rail.

Specification

0.9—1.1 V

CIrcuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•Power circuit

—Fuel pressure sensor terminal C and PCM terminal 90

•Signal circuit

—Fuel pressure sensor terminal B and PCM terminal 61

•GND circuit

—Fuel pressure sensor terminal A and PCM terminal 91

Short circuit

•Power circuit

—Fuel pressure sensor terminal C and PCM terminal 90 to GND

•Signal circuit

—Fuel pressure sensor terminal B and PCM terminal 61 to power circuit

—Fuel pressure sensor terminal B and PCM terminal 61 to GND

End Of Sie

FUEL PRESSURE SENSOR

HARNESS SIDE CONNECTOR

A

B C

A6E40702049

Page 232 of 909

F2–80

CONTROL SYSTEM

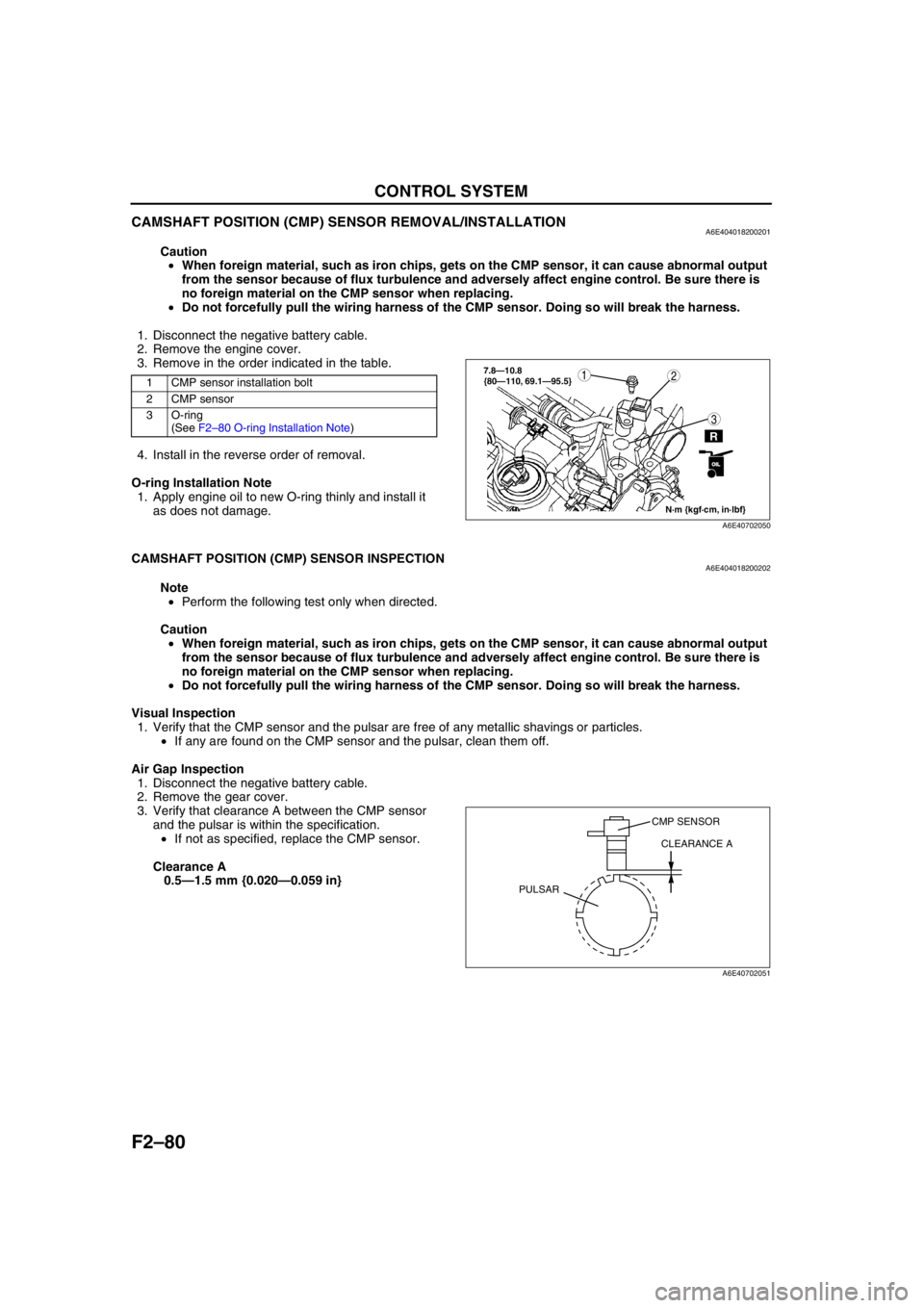

CAMSHAFT POSITION (CMP) SENSOR REMOVAL/INSTALLATIONA6E404018200201

Caution

•When foreign material, such as iron chips, gets on the CMP sensor, it can cause abnormal output

from the sensor because of flux turbulence and adversely affect engine control. Be sure there is

no foreign material on the CMP sensor when replacing.

•Do not forcefully pull the wiring harness of the CMP sensor. Doing so will break the harness.

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

O-ring Installation Note

1. Apply engine oil to new O-ring thinly and install it

as does not damage.

End Of Sie

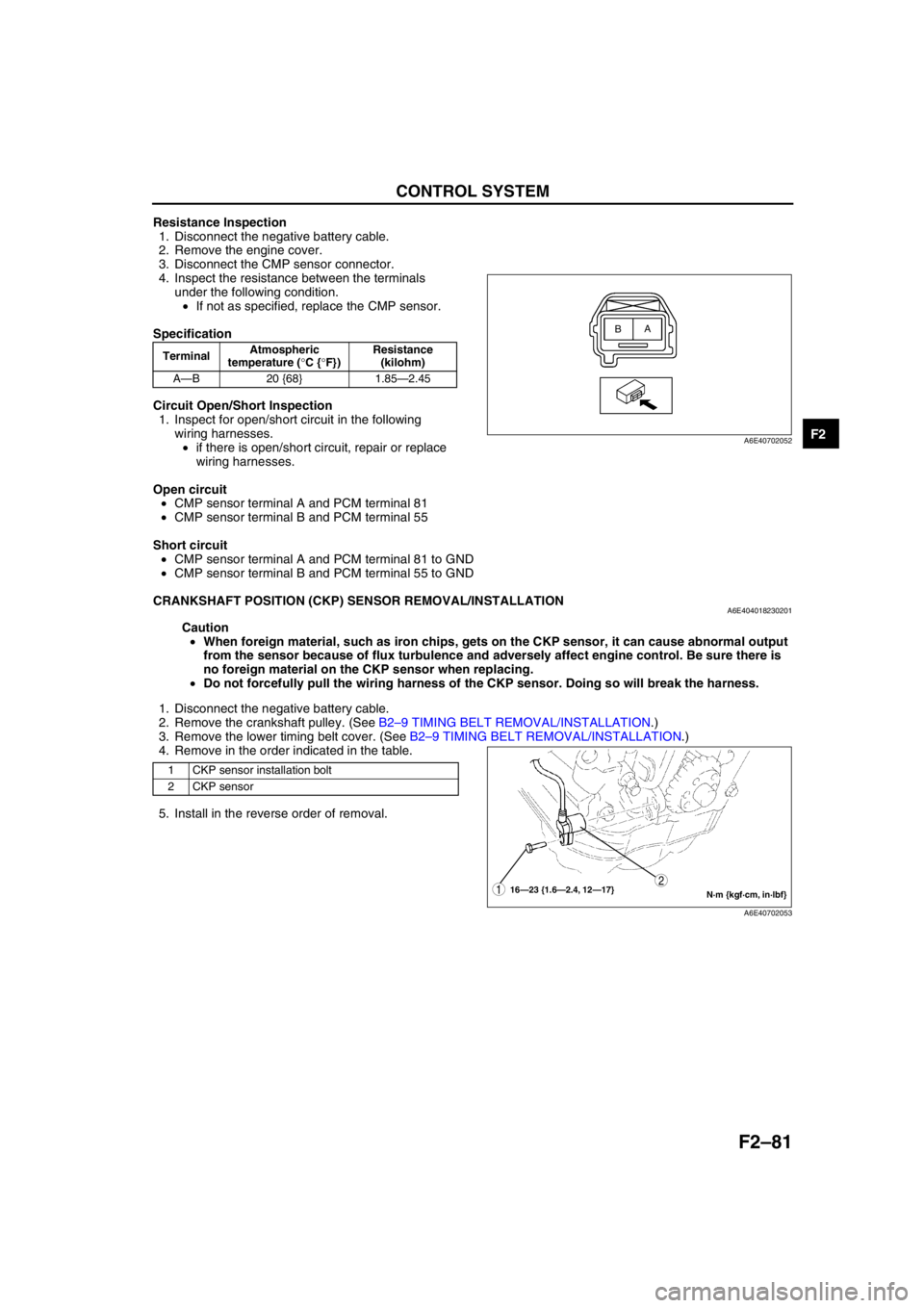

CAMSHAFT POSITION (CMP) SENSOR INSPECTIONA6E404018200202

Note

•Perform the following test only when directed.

Caution

•When foreign material, such as iron chips, gets on the CMP sensor, it can cause abnormal output

from the sensor because of flux turbulence and adversely affect engine control. Be sure there is

no foreign material on the CMP sensor when replacing.

•Do not forcefully pull the wiring harness of the CMP sensor. Doing so will break the harness.

Visual Inspection

1. Verify that the CMP sensor and the pulsar are free of any metallic shavings or particles.

•If any are found on the CMP sensor and the pulsar, clean them off.

Air Gap Inspection

1. Disconnect the negative battery cable.

2. Remove the gear cover.

3. Verify that clearance A between the CMP sensor

and the pulsar is within the specification.

•If not as specified, replace the CMP sensor.

Clearance A

0.5—1.5 mm {0.020—0.059 in}

1 CMP sensor installation bolt

2 CMP sensor

3 O-ring

(See F2–80 O-ring Installation Note)

N·m {kgf·cm, in·lbf}

3

127.8—10.8

{80—110, 69.1—95.5}

R

OILOIL

A6E40702050

CMP SENSOR

CLEARANCE A

PULSAR

A6E40702051

Page 233 of 909

CONTROL SYSTEM

F2–81

F2

Resistance Inspection

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Disconnect the CMP sensor connector.

4. Inspect the resistance between the terminals

under the following condition.

•If not as specified, replace the CMP sensor.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•if there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•CMP sensor terminal A and PCM terminal 81

•CMP sensor terminal B and PCM terminal 55

Short circuit

•CMP sensor terminal A and PCM terminal 81 to GND

•CMP sensor terminal B and PCM terminal 55 to GND

End Of Sie

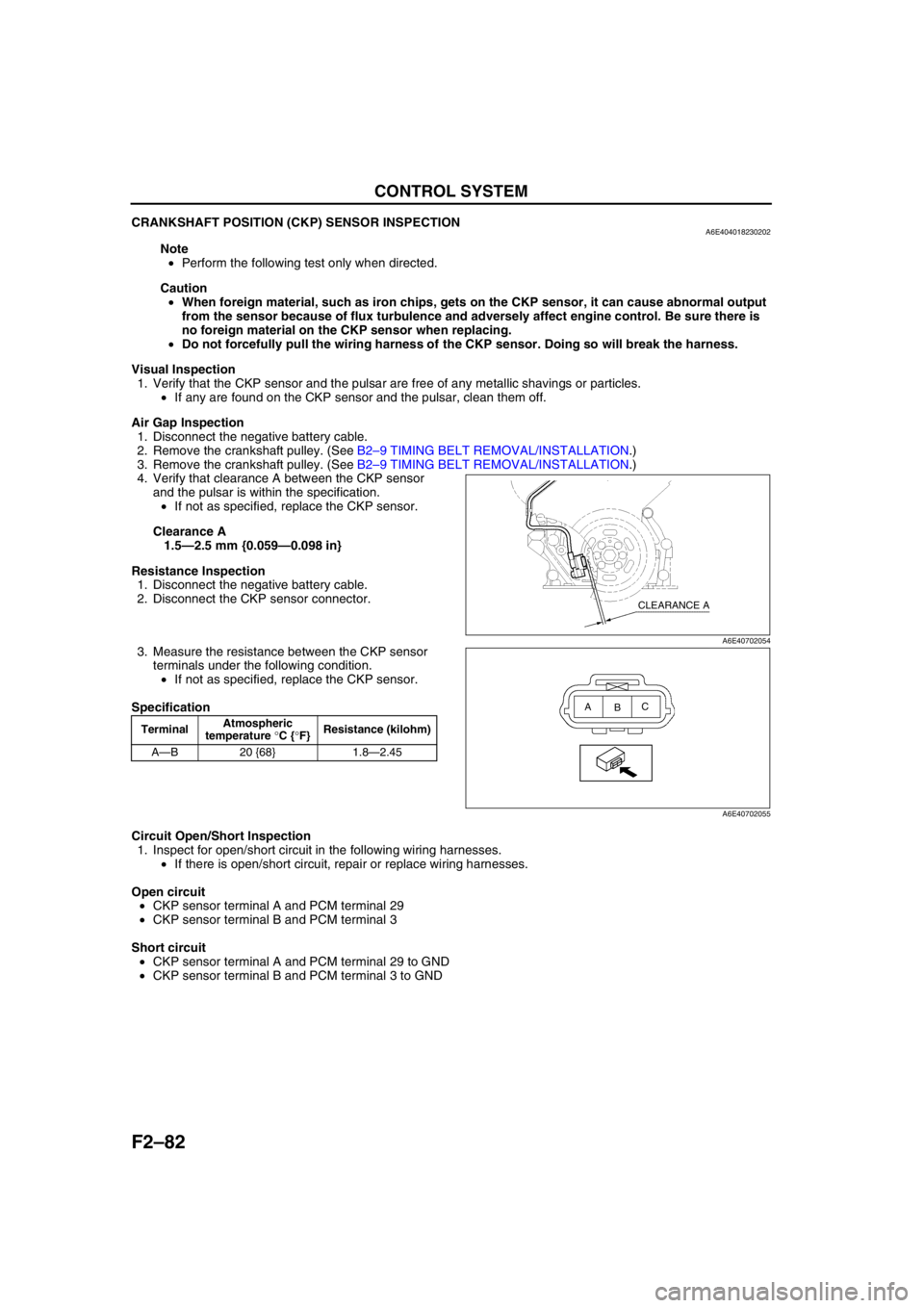

CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATIONA6E404018230201

Caution

•When foreign material, such as iron chips, gets on the CKP sensor, it can cause abnormal output

from the sensor because of flux turbulence and adversely affect engine control. Be sure there is

no foreign material on the CKP sensor when replacing.

•Do not forcefully pull the wiring harness of the CKP sensor. Doing so will break the harness.

1. Disconnect the negative battery cable.

2. Remove the crankshaft pulley. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

3. Remove the lower timing belt cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of Sie

TerminalAtmospheric

temperature (°C {°F})Resistance

(kilohm)

A—B 20 {68} 1.85—2.45

A

B

A6E40702052

1 CKP sensor installation bolt

2 CKP sensor

N·m {kgf·cm, in·lbf} 16—23 {1.6—2.4, 12—17}12

A6E40702053

Page 234 of 909

F2–82

CONTROL SYSTEM

CRANKSHAFT POSITION (CKP) SENSOR INSPECTIONA6E404018230202

Note

•Perform the following test only when directed.

Caution

•When foreign material, such as iron chips, gets on the CKP sensor, it can cause abnormal output

from the sensor because of flux turbulence and adversely affect engine control. Be sure there is

no foreign material on the CKP sensor when replacing.

•Do not forcefully pull the wiring harness of the CKP sensor. Doing so will break the harness.

Visual Inspection

1. Verify that the CKP sensor and the pulsar are free of any metallic shavings or particles.

•If any are found on the CKP sensor and the pulsar, clean them off.

Air Gap Inspection

1. Disconnect the negative battery cable.

2. Remove the crankshaft pulley. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

3. Remove the crankshaft pulley. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

4. Verify that clearance A between the CKP sensor

and the pulsar is within the specification.

•If not as specified, replace the CKP sensor.

Clearance A

1.5—2.5 mm {0.059—0.098 in}

Resistance Inspection

1. Disconnect the negative battery cable.

2. Disconnect the CKP sensor connector.

3. Measure the resistance between the CKP sensor

terminals under the following condition.

•If not as specified, replace the CKP sensor.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•CKP sensor terminal A and PCM terminal 29

•CKP sensor terminal B and PCM terminal 3

Short circuit

•CKP sensor terminal A and PCM terminal 29 to GND

•CKP sensor terminal B and PCM terminal 3 to GND

End Of Sie

TerminalAtmospheric

temperature °C {°F}Resistance (kilohm)

A—B 20 {68} 1.8—2.45

CLEARANCE A

A6E40702054

A

BC

A6E40702055

Page 236 of 909

F2–84

CONTROL SYSTEM

CIrcuit Open/Short Inspection

1. Inspect for open/short circuit in the following wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•Signal circuit

—Calibration resistor No.1 terminal A and PCM terminal 37

—Calibration resistor No.2 terminal A and PCM terminal 62

—Calibration resistor No.3 terminal A and PCM terminal 89

—Calibration resistor No.4 terminal A and PCM terminal 11

•GND circuit

—Each calibration resistor terminal C and PCM terminal 91

Short circuit

•Signal circuit

—Calibration resistor No.1 terminal A and PCM terminal 37 to power circuit

—Calibration resistor No.1 terminal A and PCM terminal 37 to GND

—Calibration resistor No.2 terminal A and PCM terminal 62 to power circuit

—Calibration resistor No.2 terminal A and PCM terminal 62 to GND

—Calibration resistor No.3 terminal A and PCM terminal 89 to power circuit

—Calibration resistor No.3 terminal A and PCM terminal 89 to GND

—Calibration resistor No.4 terminal A and PCM terminal 11 to power circuit

—Calibration resistor No.4 terminal A and PCM terminal 11 to GND

End Of Sie

INJECTOR DRIVER MODULE (IDM) INSPECTIONA6E404018701201

Warning

•The IDM outputs high voltage and current for fuel injector driving. Do not inspect the IDM terminal

voltage, as it may cause an electric shock.

Note

•Perform the following test only when directed.

1. If any IDM-related failures are suspected, inspect the following:

•DTCs

•IDM-related harnesses

•Fuel injectors

End Of Sie