wiring MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 204 of 909

F2–52

FUEL SYSTEM

SEDIMENTOR WATER DRAININGA6E4012348022041. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Loosen the drain plug located at the bottom of the fuel filter.

4. Pump the priming pump and drain the water.

5. After all the water has been drained, tighten the drain plug.

6. Complete the “AFTER REPAIR PROCEDURE”. (See F2–45 AFTER REPAIR PROCEDURE.)

7. Reconnect the negative battery cable.

End Of Sie

SEDIMENTOR SWITCH INSPECTIONA6E401213840201

Note

•Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Drain fuel from the fuel filter. (See F2–52 SEDIMENTOR WATER DRAINING.)

4. Remove the sedimentor switch.

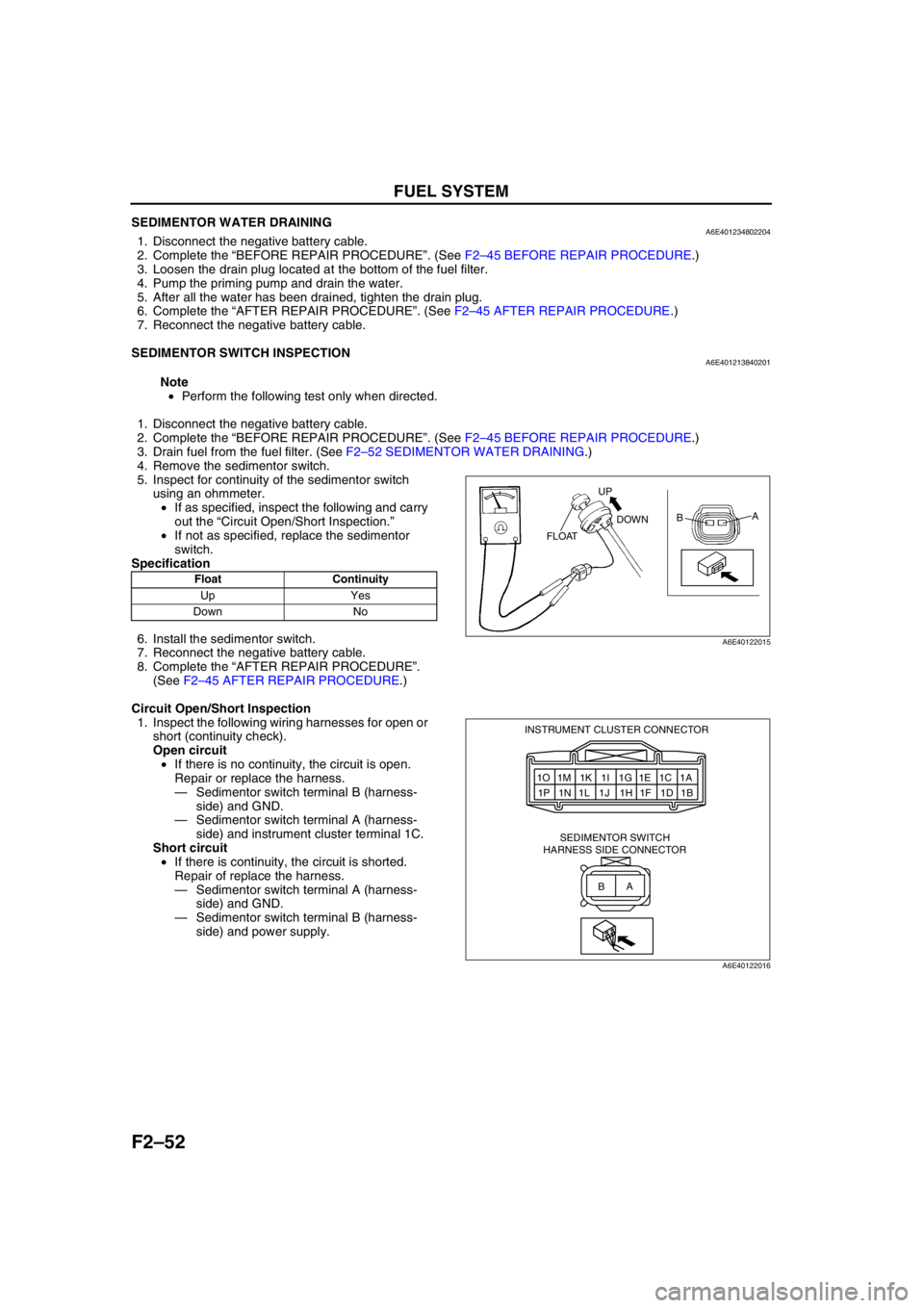

5. Inspect for continuity of the sedimentor switch

using an ohmmeter.

•If as specified, inspect the following and carry

out the “Circuit Open/Short Inspection.”

•If not as specified, replace the sedimentor

switch.

Specification

6. Install the sedimentor switch.

7. Reconnect the negative battery cable.

8. Complete the “AFTER REPAIR PROCEDURE”.

(See F2–45 AFTER REPAIR PROCEDURE.)

Circuit Open/Short Inspection

1. Inspect the following wiring harnesses for open or

short (continuity check).

Open circuit

•If there is no continuity, the circuit is open.

Repair or replace the harness.

—Sedimentor switch terminal B (harness-

side) and GND.

—Sedimentor switch terminal A (harness-

side) and instrument cluster terminal 1C.

Short circuit

•If there is continuity, the circuit is shorted.

Repair of replace the harness.

—Sedimentor switch terminal A (harness-

side) and GND.

—Sedimentor switch terminal B (harness-

side) and power supply.

End Of Sie

Float Continuity

Up Yes

Down No

UP

DOWN

FLOATA

B

A6E40122015

1O 1M 1K 1I 1G 1E 1C 1A

1P 1N 1L 1J 1H 1F 1D 1B INSTRUMENT CLUSTER CONNECTOR

SEDIMENTOR SWITCH

HARNESS SIDE CONNECTOR

A

B

A6E40122016

Page 206 of 909

F2–54

FUEL SYSTEM

SUPPLY PUMP INSPECTIONA6E401213350202

Caution

•The supply pump is sealed to maintain proper function. Special tools and testers are required

when disassembling the supply pump. Disassembling the supply pump without special tools and

testers will cause a malfunction.

•Consult an authorized DENSO parts distributor for repair if any of the following supply pump parts

are possibly malfunctioning.

1. Supply pump inner parts

2. Suction control valve

3. Fuel temperature sensor

End Of Sie

SUCTION CONTROL VALVE INSPECTIONA6E401213350203

Caution

•The supply pump is sealed to maintain proper function. Special tools and testers are required

when disassembling the supply pump. Disassembling the supply pump without special tools and

testers will cause a malfunction.

•Consult an authorized DENSO parts distributor for repair if suction control valve is possibly

malfunctioning.

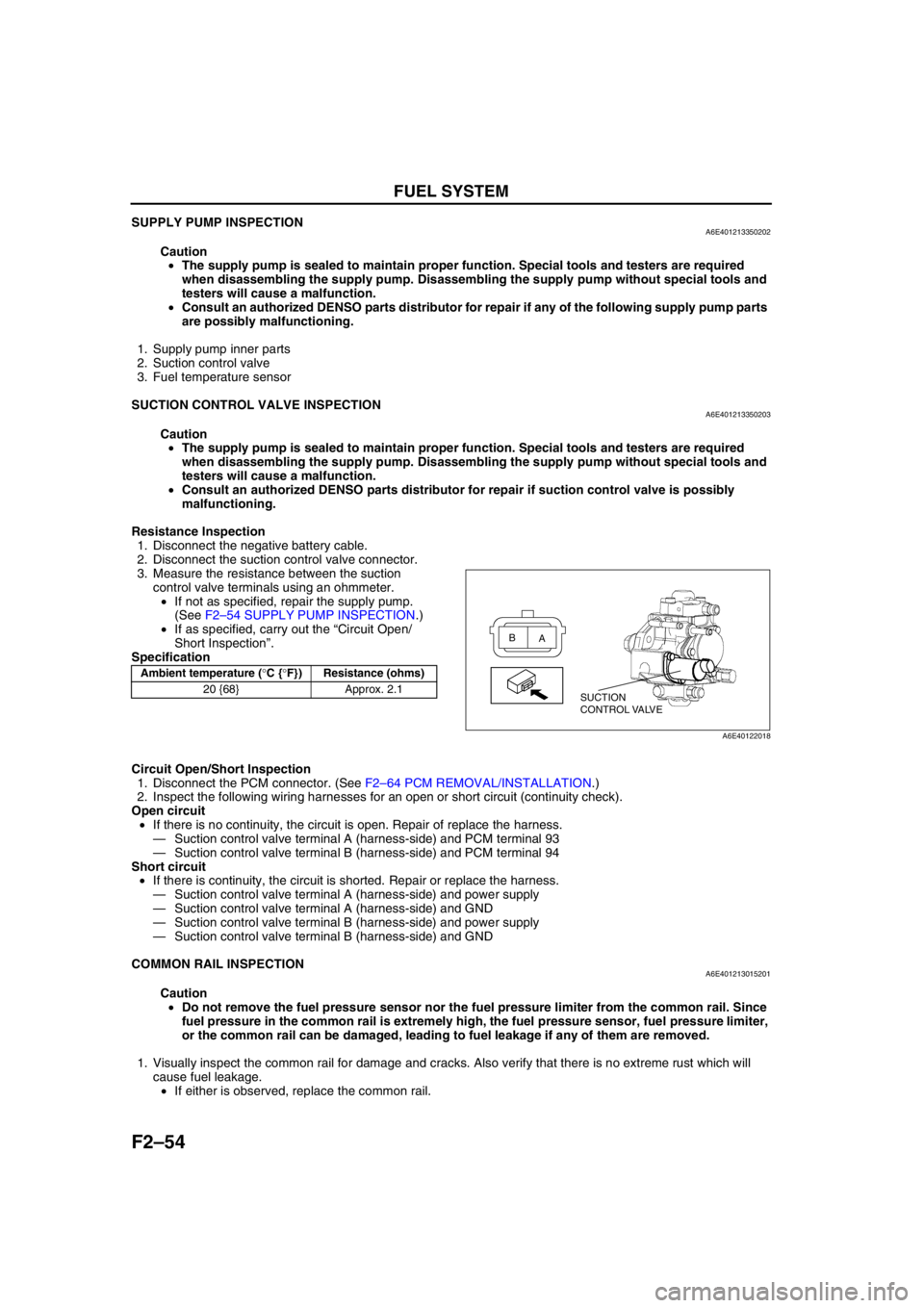

Resistance Inspection

1. Disconnect the negative battery cable.

2. Disconnect the suction control valve connector.

3. Measure the resistance between the suction

control valve terminals using an ohmmeter.

•If not as specified, repair the supply pump.

(See F2–54 SUPPLY PUMP INSPECTION.)

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Specification

Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM REMOVAL/INSTALLATION.)

2. Inspect the following wiring harnesses for an open or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair of replace the harness.

—Suction control valve terminal A (harness-side) and PCM terminal 93

—Suction control valve terminal B (harness-side) and PCM terminal 94

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Suction control valve terminal A (harness-side) and power supply

—Suction control valve terminal A (harness-side) and GND

—Suction control valve terminal B (harness-side) and power supply

—Suction control valve terminal B (harness-side) and GND

End Of Sie

COMMON RAIL INSPECTIONA6E401213015201

Caution

•Do not remove the fuel pressure sensor nor the fuel pressure limiter from the common rail. Since

fuel pressure in the common rail is extremely high, the fuel pressure sensor, fuel pressure limiter,

or the common rail can be damaged, leading to fuel leakage if any of them are removed.

1. Visually inspect the common rail for damage and cracks. Also verify that there is no extreme rust which will

cause fuel leakage.

•If either is observed, replace the common rail.

End Of Sie

Ambient temperature (°C {°F}) Resistance (ohms)

20 {68} Approx. 2.1

SUCTION

CONTROL VALVE A B

A6E40122018

Page 208 of 909

F2–56

FUEL SYSTEM

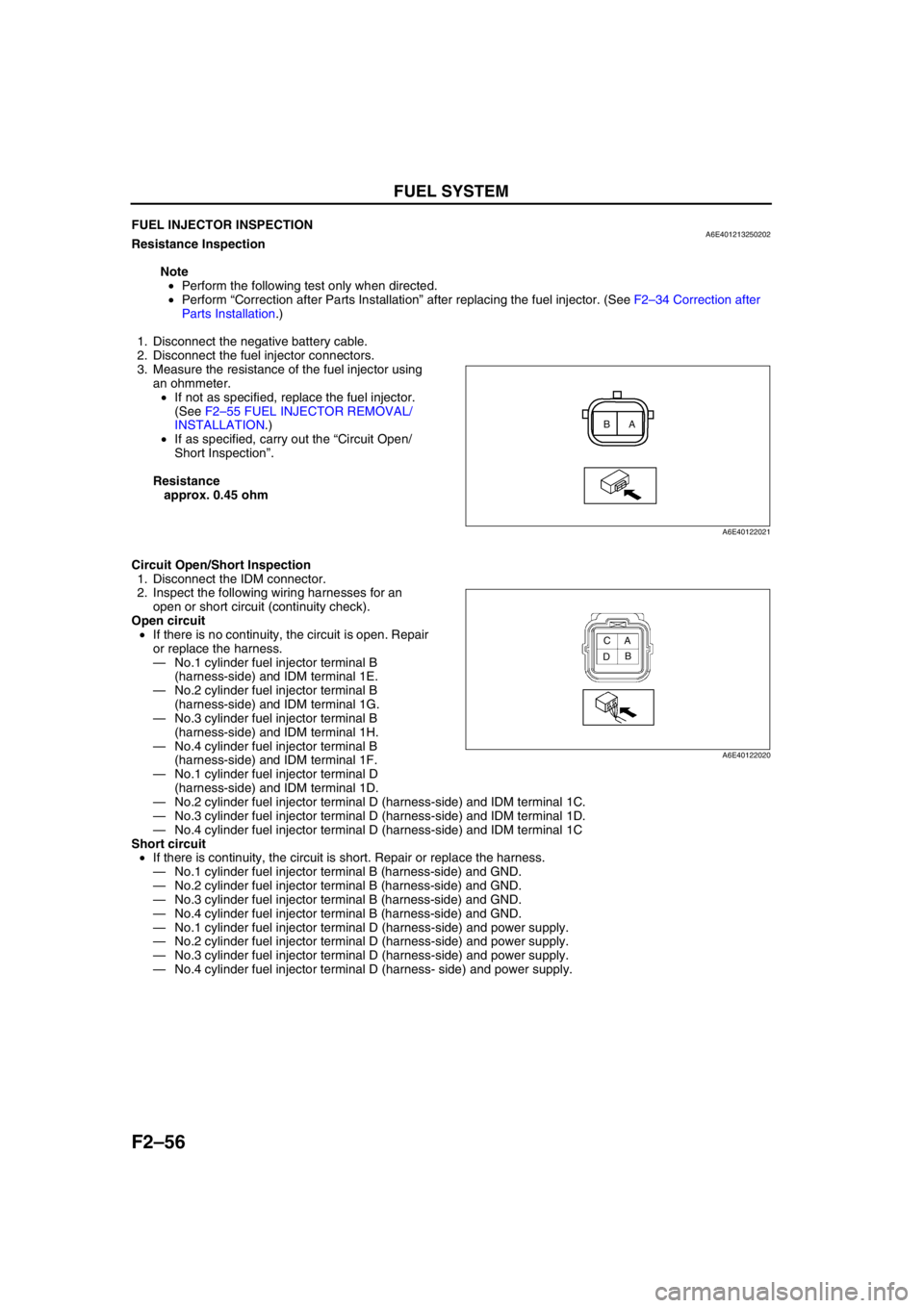

End Of SieFUEL INJECTOR INSPECTIONA6E401213250202Resistance Inspection

Note

•Perform the following test only when directed.

•Perform “Correction after Parts Installation” after replacing the fuel injector. (See F2–34 Correction after

Parts Installation.)

1. Disconnect the negative battery cable.

2. Disconnect the fuel injector connectors.

3. Measure the resistance of the fuel injector using

an ohmmeter.

•If not as specified, replace the fuel injector.

(See F2–55 FUEL INJECTOR REMOVAL/

INSTALLATION.)

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Resistance

approx. 0.45 ohm

Circuit Open/Short Inspection

1. Disconnect the IDM connector.

2. Inspect the following wiring harnesses for an

open or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—No.1 cylinder fuel injector terminal B

(harness-side) and IDM terminal 1E.

—No.2 cylinder fuel injector terminal B

(harness-side) and IDM terminal 1G.

—No.3 cylinder fuel injector terminal B

(harness-side) and IDM terminal 1H.

—No.4 cylinder fuel injector terminal B

(harness-side) and IDM terminal 1F.

—No.1 cylinder fuel injector terminal D

(harness-side) and IDM terminal 1D.

—No.2 cylinder fuel injector terminal D (harness-side) and IDM terminal 1C.

—No.3 cylinder fuel injector terminal D (harness-side) and IDM terminal 1D.

—No.4 cylinder fuel injector terminal D (harness-side) and IDM terminal 1C

Short circuit

•If there is continuity, the circuit is short. Repair or replace the harness.

—No.1 cylinder fuel injector terminal B (harness-side) and GND.

—No.2 cylinder fuel injector terminal B (harness-side) and GND.

—No.3 cylinder fuel injector terminal B (harness-side) and GND.

—No.4 cylinder fuel injector terminal B (harness-side) and GND.

—No.1 cylinder fuel injector terminal D (harness-side) and power supply.

—No.2 cylinder fuel injector terminal D (harness-side) and power supply.

—No.3 cylinder fuel injector terminal D (harness-side) and power supply.

—No.4 cylinder fuel injector terminal D (harness- side) and power supply.

End Of Sie

A B

A6E40122021

A

B C

D

A6E40122020

Page 212 of 909

F2–60

EMISSION SYSTEM

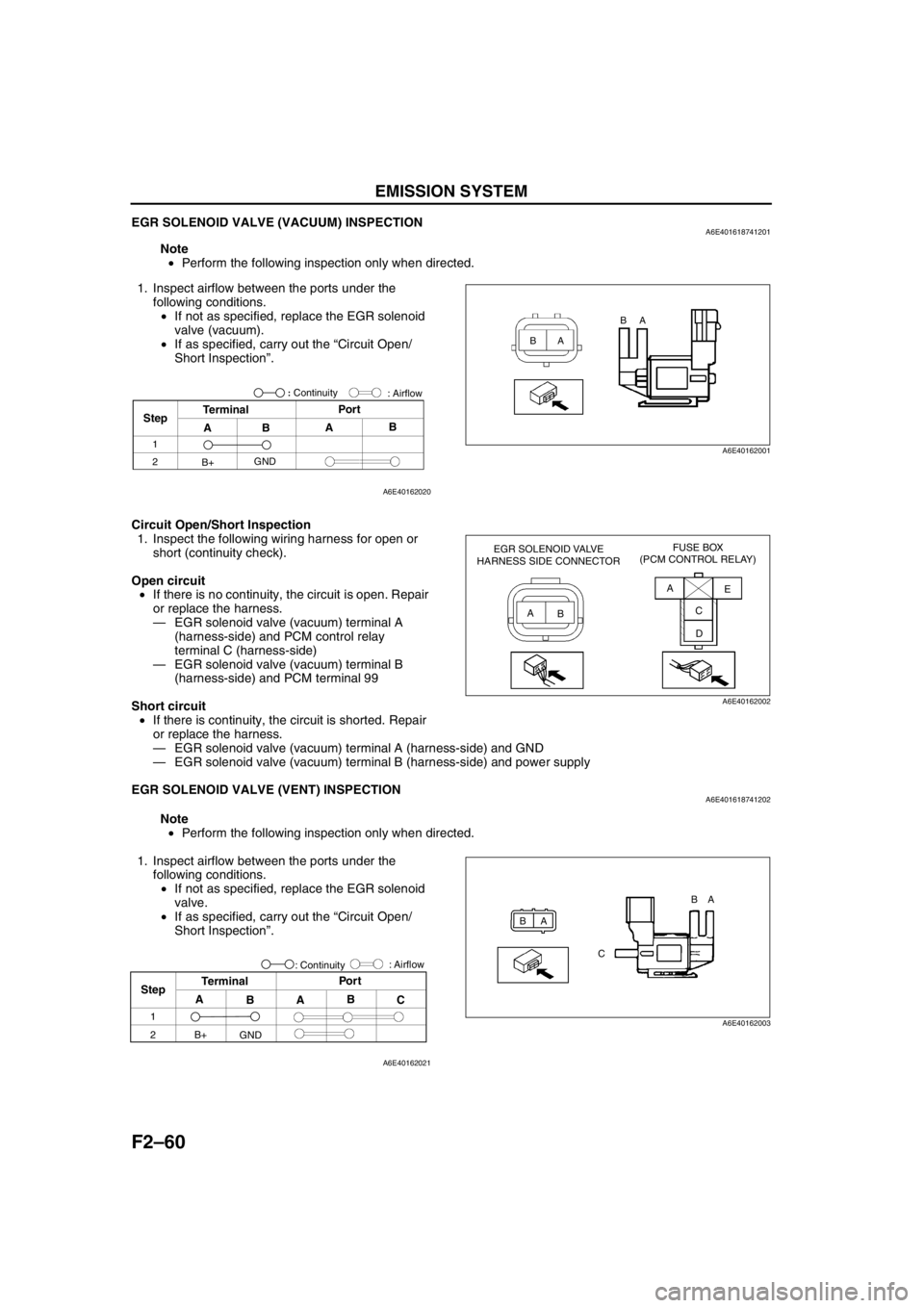

EGR SOLENOID VALVE (VACUUM) INSPECTIONA6E401618741201

Note

•Perform the following inspection only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the EGR solenoid

valve (vacuum).

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Circuit Open/Short Inspection

1. Inspect the following wiring harness for open or

short (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—EGR solenoid valve (vacuum) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—EGR solenoid valve (vacuum) terminal B

(harness-side) and PCM terminal 99

Short circuit

•If there is continuity, the circuit is shorted. Repair

or replace the harness.

—EGR solenoid valve (vacuum) terminal A (harness-side) and GND

—EGR solenoid valve (vacuum) terminal B (harness-side) and power supply

End Of Sie

EGR SOLENOID VALVE (VENT) INSPECTIONA6E401618741202

Note

•Perform the following inspection only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the EGR solenoid

valve.

•If as specified, carry out the “Circuit Open/

Short Inspection”.

BAA B

A6E40162001

StepTerminal

ABAB Por t

1

2

B+GND: Airflow

: Continuity

A6E40162020

EGR SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

A

BA

E

C

D

A6E40162002

BA

CBA

A6E40162003

Step

1

2

A

BAB

C Por t

Terminal

: Airflow

B+

GND: Continuity

A6E40162021

Page 213 of 909

EMISSION SYSTEM

F2–61

F2

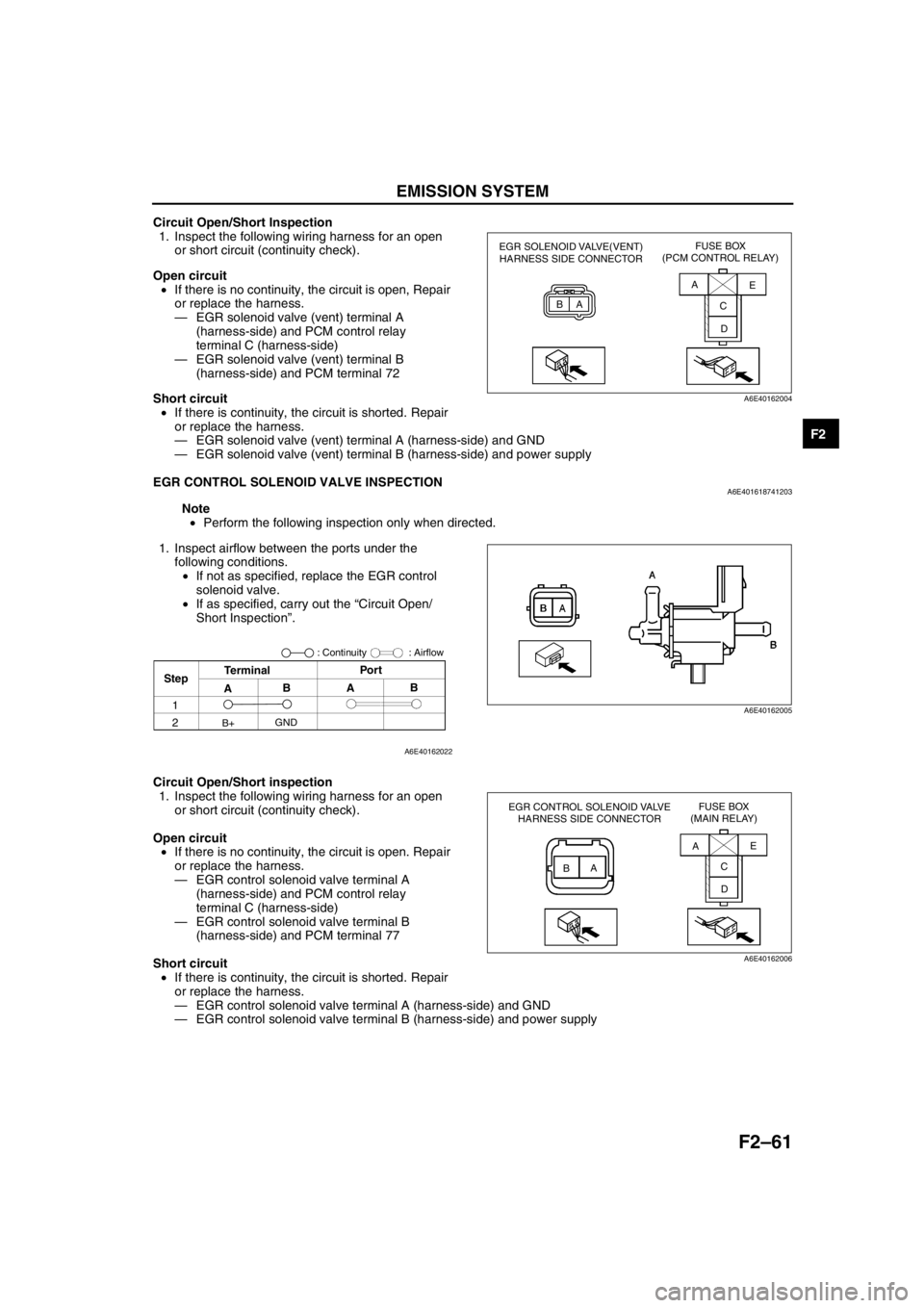

Circuit Open/Short Inspection

1. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open, Repair

or replace the harness.

—EGR solenoid valve (vent) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—EGR solenoid valve (vent) terminal B

(harness-side) and PCM terminal 72

Short circuit

•If there is continuity, the circuit is shorted. Repair

or replace the harness.

—EGR solenoid valve (vent) terminal A (harness-side) and GND

—EGR solenoid valve (vent) terminal B (harness-side) and power supply

End Of Sie

EGR CONTROL SOLENOID VALVE INSPECTIONA6E401618741203

Note

•Perform the following inspection only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the EGR control

solenoid valve.

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Circuit Open/Short inspection

1. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—EGR control solenoid valve terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—EGR control solenoid valve terminal B

(harness-side) and PCM terminal 77

Short circuit

•If there is continuity, the circuit is shorted. Repair

or replace the harness.

—EGR control solenoid valve terminal A (harness-side) and GND

—EGR control solenoid valve terminal B (harness-side) and power supply

End Of Sie

EGR SOLENOID VALVE(VENT)

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

BAA

C

DE

A6E40162004

B

AA

B

A6E40162005

StepTerminalPor t

: Airflow

ABAB

GND

B+

1

2

: Continuity

A6E40162022

EGR CONTROL SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(MAIN RELAY)

BAAE

C

D

A6E40162006

Page 215 of 909

EMISSION SYSTEM

F2–63

F2

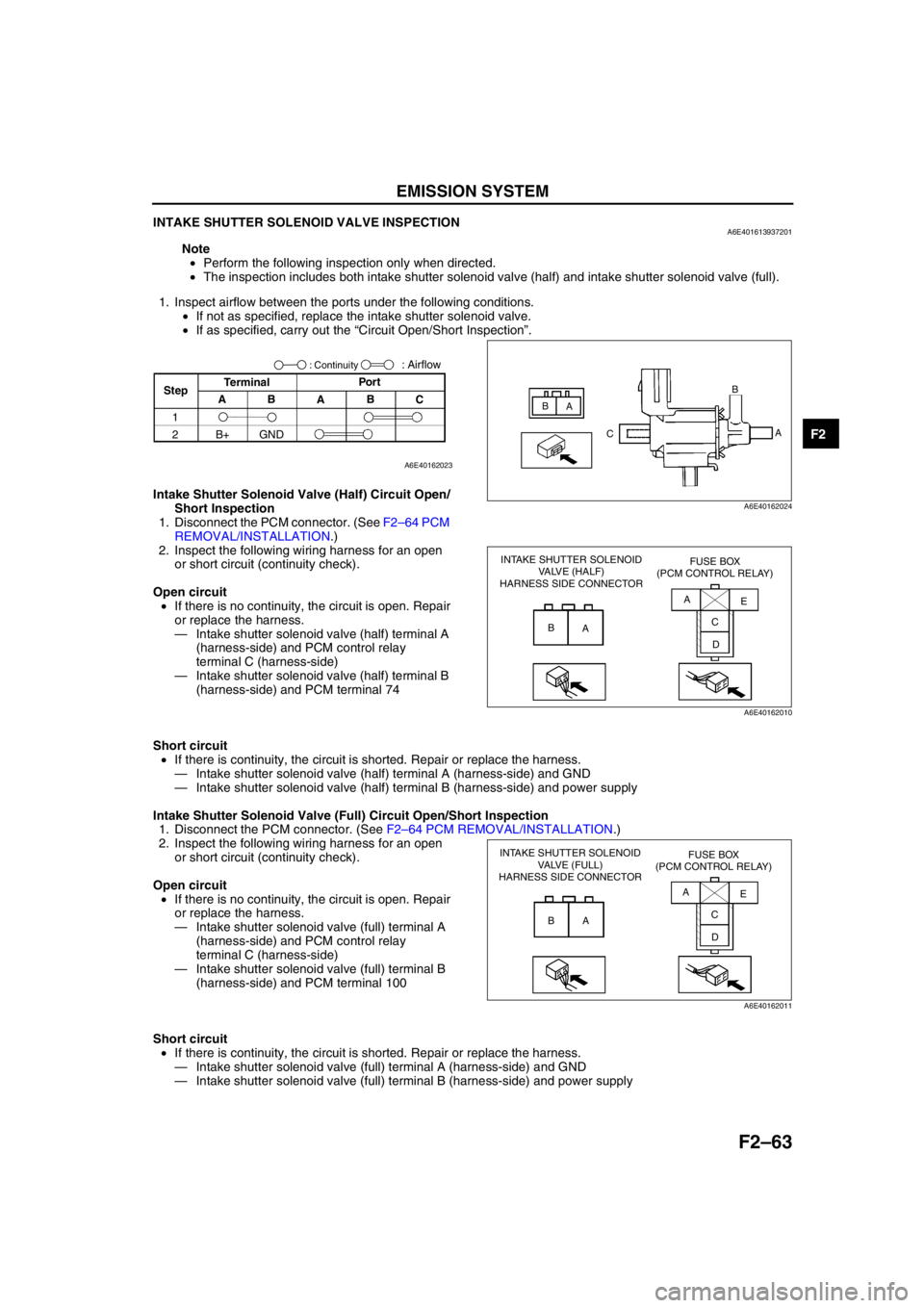

INTAKE SHUTTER SOLENOID VALVE INSPECTIONA6E401613937201

Note

•Perform the following inspection only when directed.

•The inspection includes both intake shutter solenoid valve (half) and intake shutter solenoid valve (full).

1. Inspect airflow between the ports under the following conditions.

•If not as specified, replace the intake shutter solenoid valve.

•If as specified, carry out the “Circuit Open/Short Inspection”.

Intake Shutter Solenoid Valve (Half) Circuit Open/

Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM

REMOVAL/INSTALLATION.)

2. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—Intake shutter solenoid valve (half) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—Intake shutter solenoid valve (half) terminal B

(harness-side) and PCM terminal 74

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Intake shutter solenoid valve (half) terminal A (harness-side) and GND

—Intake shutter solenoid valve (half) terminal B (harness-side) and power supply

Intake Shutter Solenoid Valve (Full) Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM REMOVAL/INSTALLATION.)

2. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—Intake shutter solenoid valve (full) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—Intake shutter solenoid valve (full) terminal B

(harness-side) and PCM terminal 100

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Intake shutter solenoid valve (full) terminal A (harness-side) and GND

—Intake shutter solenoid valve (full) terminal B (harness-side) and power supply

End Of Sie

B

A

CB

A

A6E40162024

StepTerminal

C B

A B APor t: Airflow

1

2B+ GND

: Continuity

A6E40162023

INTAKE SHUTTER SOLENOID

VALVE (HALF)

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

B

AA

E

C

D

A6E40162010

INTAKE SHUTTER SOLENOID

VALVE (FULL)

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

B

AA

C

DE

A6E40162011

Page 220 of 909

F2–68

CONTROL SYSTEM

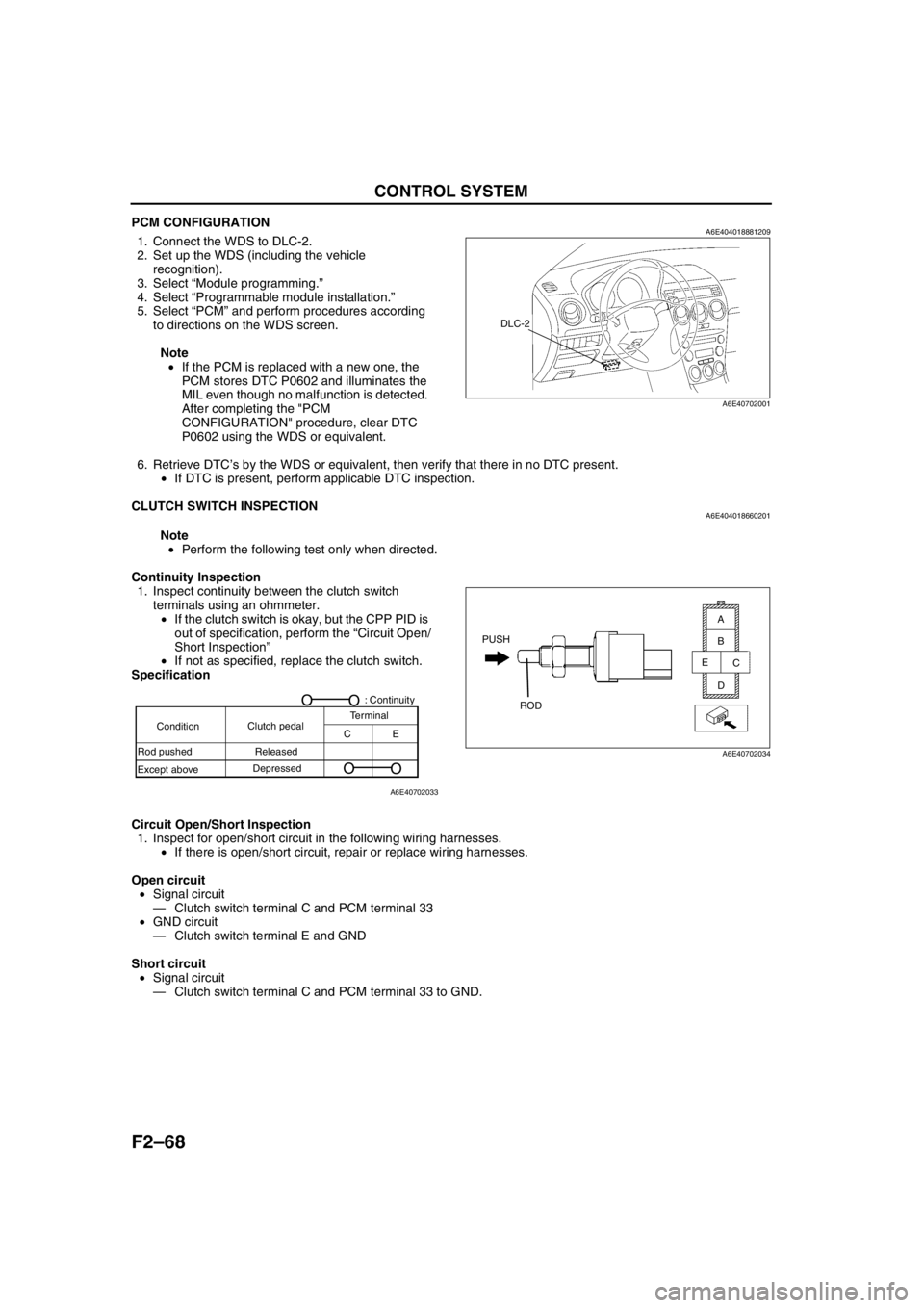

PCM CONFIGURATIONA6E4040188812091. Connect the WDS to DLC-2.

2. Set up the WDS (including the vehicle

recognition).

3. Select “Module programming.”

4. Select “Programmable module installation.”

5. Select “PCM” and perform procedures according

to directions on the WDS screen.

Note

•If the PCM is replaced with a new one, the

PCM stores DTC P0602 and illuminates the

MIL even though no malfunction is detected.

After completing the "PCM

CONFIGURATION" procedure, clear DTC

P0602 using the WDS or equivalent.

6. Retrieve DTC’s by the WDS or equivalent, then verify that there in no DTC present.

•If DTC is present, perform applicable DTC inspection.

End Of Sie

CLUTCH SWITCH INSPECTIONA6E404018660201

Note

•Perform the following test only when directed.

Continuity Inspection

1. Inspect continuity between the clutch switch

terminals using an ohmmeter.

•If the clutch switch is okay, but the CPP PID is

out of specification, perform the “Circuit Open/

Short Inspection”

•If not as specified, replace the clutch switch.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•Signal circuit

—Clutch switch terminal C and PCM terminal 33

•GND circuit

—Clutch switch terminal E and GND

Short circuit

•Signal circuit

—Clutch switch terminal C and PCM terminal 33 to GND.

End Of Sie

DLC-2

A6E40702001

PUSH

ROD

A

B

C

D E

A6E40702034

A6E40702033

ConditionClutch pedalTerminal

CE

Rod pushed

Except aboveReleased

Depressed

O

O

O

O: Continuity

Page 221 of 909

CONTROL SYSTEM

F2–69

F2

NEUTRAL SWITCH INSPECTIONA6E404017640201

Note

•Perform the following test only when directed.

Continuity Inspection

1. Inspect for continuity between the neutral switch

terminals using an ohmmeter.

•If the neutral switch is okay, but the CPP/PNP

PID is out of specification, perform the “Circuit

Open/Short Inspection”

•If not as specified, replace the neutral switch.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following wiring harnesses.

•If there is open/short circuit, repair or replace wiring harnesses.

Open circuit

•Signal circuit

—Neutral switch terminal A and PCM terminal 56

•GND circuit

—Neutral switch terminal B and GND

Short circuit

•Signal circuit

—Neutral switch terminal A and PCM terminal 56 to GND

End Of Sie

PUSH

RODB

A

A6E40702036

Condition

TransmissionTerminal

O

O: Continuity

A

B

Rod pushed

Except aboveIn neutral

Other

O

O

A6E40702035

Page 222 of 909

F2–70

CONTROL SYSTEM

IDLE SWITCH INSPECTIONA6E404041600201

Note

•Perform the following test only when directed.

1. Verify that the accelerator position sensor is normal.

2. Visually inspect all accelerator pedal components for looseness.

3. Verify that the idle switch is installed to the accelerator pedal properly.

4. Verify that the power circuit voltage.

(1) Verify that the voltage between the PCM terminals 90 (power circuit) and 91(GND circuit) is 4.75—5.25 V.

Note

•Voltage at the PCM terminal 10 may deviate when the power circuit voltage is abnormal.

5. Verify that the voltage at the PCM terminal 31

(idle signal) is 1 V or less with the accelerator

pedal fully released.

6. Depress the accelerator pedal gradually and hold

the pedal when the PCM terminal 31 voltage

changes to approximately 10 V.

7. Verify that the voltage between the PCM

terminals 10 (accelerator position detection

signal) and 91 is within the specification.

•If the circuit is okay, replace the idle switch.

Specification

0.85—1.15 V (Target value: 1.0 V)

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•Signal circuit

—Idle switch terminal A and PCM terminal 31

•GND circuit

—Idle switch terminal B and GND

Short circuit

•Signal circuit

—Idle switch terminal A and PCM terminal 31 to

GND

End Of Sie

ACCELERATOR POSITION SENSOR

IDLE SWITCHPCM B

A

C

D

A

B31 10

90

88

91

A6E40702037

IDLE SWITCH

HARNESS SIDE CONNECTOR

A

B

A6E40702038

Page 224 of 909

F2–72

CONTROL SYSTEM

ACCELERATOR POSITION SENSOR INSPECTIONA6E404041602201

Note

•Perform the following test only when directed.

1. Visually inspect all accelerator pedal components for looseness.

2. Verify that the accelerator position sensor is installed to the accelerator pedal properly.

3. Verify the power circuit voltage.

(1) Verify that the voltage between the PCM terminal 90 (power circuit) and 91 (GND circuit) is 4.75—5.25 V.

Note

•Voltage at the PCM terminal 10 may deviate when the power circuit voltage is abnormal.

4. Verify that the voltage between the PCM

terminals 10 (accelerator position detection

signal) and 91 is as shown below according to the

accelerator pedal conditions.

•If the circuit is okay, replace the accelerator

position sensor.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•Power circuit

—Accelerator position sensor terminal A and

PCM terminal 90

•Signal circuit

—Accelerator position sensor terminal B and

PCM terminal 10

—Accelerator position sensor terminal C and

PCM terminal 88

•GND circuit

—Accelerator position sensor terminal D and PCM terminal 91

Short circuit

•Power circuit

—Accelerator position sensor terminal A and PCM terminal 90 to GND

•Signal circuit

—Accelerator position sensor terminal B and PCM terminal 10 to power circuit

—Accelerator position sensor terminal B and PCM terminal 10 to GND

—Accelerator position sensor terminal C and PCM terminal 88 to power circuit

—Accelerator position sensor terminal C and PCM terminal 88 to GND

End Of Sie

Accelerator pedal

conditionOutput voltage (V)

Fully released 0.45—0.75 (Target value: 0.6)

Gradually depressed Increases linearly

Fully depressed 3.35—4.03 (Target value: 3.6)

ACCELERATOR POSITION SENSOR

PCM

B

A

C

D10

90

88

91

A6E40702041

ACCELERATOR POSITION SENSOR

HARNESS SIDE CONNECTOR

A B

C D

A6E40702042