MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 291 of 909

ON-BOARD DIAGNOSTIC

F2–139

F2

End Of Sie

2INSPECT POOR CONNECTION OF CKP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT CKP SENSOR CIRCUIT FOR SHORT

TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CKP sensor terminal A and body GND.

—CKP sensor terminal B and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

4INSPECT CKP SENSOR

•Inspect CKP sensor.

(See F2–82 CRANKSHAFT POSITION (CKP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CKP sensor, go to Step 7.

(See F2–81 CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT CKP SENSOR CIRCUIT FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CKP sensor terminal A and PCM terminal

29.

—CKP sensor terminal B and PCM terminal 3.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0337

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 292 of 909

F2–140

ON-BOARD DIAGNOSTIC

DTC P0341A6E407001082231

Diagnostic procedure

End Of Sie

DTC P0341 CMP sensor circuit performance problem

DETECTION

CONDITION•PCM monitors input signal from CMP sensor while engine is running. If input signal from CMP sensor is not

proper pulse number, PCM determines CMP sensor circuit performance problem.

POSSIBLE

CAUSE•CMP sensor malfunction

•Connector or terminal malfunction

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2VERIFY DTC P0341 DETECTED AGAIN

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

3INSPECT POOR CONNECTION OF CMP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

4INSPECT CMP SENSOR

•Inspect CMP sensor.

(See F2–80 CAMSHAFT POSITION (CMP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CMP sensor, go to Step 6.

(See F2–80 CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0341

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 293 of 909

ON-BOARD DIAGNOSTIC

F2–141

F2

DTC P0342A6E407001082232

Diagnostic procedure

DTC P0342 CMP sensor circuit low input

DETECTION

CONDITION•PCM monitors input signal from CMP sensor while engine is running. If input signal from CMP sensor is not

input at 12 crankshaft revolutions, PCM determines CMP sensor circuit low input.

POSSIBLE

CAUSE•CMP sensor malfunction

•Connector or terminal malfunction

•Short to GND in wiring between CMP sensor terminal A and PCM terminal 81

•Short to GND in wiring between CMP sensor terminal B and PCM terminal 55

•Open circuit in wiring between CMP sensor terminal A and PCM terminal 81

•Open circuit in wiring between CMP sensor terminal B and PCM terminal 55

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT POOR CONNECTION OF CMP

SENSOR CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT CMP SENSOR CIRCUIT FOR SHORT

TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CMP sensor terminal A and body GND.

—CMP sensor terminal B and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

A

B CMP SENSOR

A B

55

81 81

55PCM

3

2

2

4

4

6

6

5

5

CMP SENSOR

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 294 of 909

F2–142

ON-BOARD DIAGNOSTIC

End Of Sie

4INSPECT CMP SENSOR

•Inspect CMP sensor.

(See F2–80 CAMSHAFT POSITION (CMP)

SENSOR INSPECTION)

•Is there any malfunction?Yes Replace CMP sensor, go to Step 7.

(See F2–80 CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION)

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT CMP SENSOR CIRCUIT FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—CMP sensor terminal A and PCM terminal

81.

—CMP sensor terminal B and PCM terminal

55.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0342

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 295 of 909

ON-BOARD DIAGNOSTIC

F2–143

F2

DTC P0380A6E407001082233

Diagnostic procedure

DTC P0380 Glow plug relay circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from glow plug relay while engine is running. PCM determines glow plug relay

circuit malfunction if input voltage from glow plug relay is as following:

—1.0 V or below when glow plug relay is on.

—4.0 V or above when glow plug relay is off.

POSSIBLE

CAUSE•Glow plug relay malfunction

•Connector or terminal malfunction

•Short to GND in wiring between glow plug relay terminal D and PCM terminal 68

•Short to GND in wiring between glow plug fuse and glow plug relay terminal A

•Short to GND in wiring between glow plug relay terminal C and PCM terminal 86

•Short to power circuit in wiring between glow plug relay terminal D and PCM terminal 68

•Short to power circuit in wiring between glow plug relay terminal C and PCM terminal 86

•Glow plug relay power and signal circuits short each other

•Open circuit in wiring between glow plug fuse and glow plug relay terminal A

•Open circuit in wiring between glow plug relay terminal B and GND

•Open circuit in wiring between glow plug relay terminal D and PCM terminal 68

•Open circuit in wiring between glow plug relay terminal C and PCM terminal 86

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT POOR CONNECTION OF GLOW

PLUG RELAY CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 9.

No Go to next step.

A

B

C

D

GLOW FUSE

GLOW PLUG RELAY

AD

BC

6886

68 86PCM

54362

262

23598

4398

PCM

HARNESS SIDE CONNECTOR

7

GLOW PLUG RELAY

HARNESS SIDE CONNECTOR

Page 296 of 909

F2–144

ON-BOARD DIAGNOSTIC

End Of Sie

3INSPECT GLOW PLUG RELAY CIRCUIT FOR

SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Glow plug relay terminal A and body GND.

—Glow plug relay terminal C and body GND.

—Glow plug relay terminal D and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 9.

No Go to next step.

4INSPECT GLOW PLUG RELAY CIRCUIT FOR

SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspect voltage between following harnesses:

—Glow plug relay terminal C and body GND.

—Glow plug relay terminal D and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 9.

5INSPECT GLOW PLUG RELAY CIRCUIT FOR

SHORT WITH EACH OTHER

•Turn engine switch to OFF.

•Inspect continuity between glow plug relay

terminals A and C.

•Is there continuity?Yes Repair or replace harness for short with each other, go to

Step 7.

No Go to next step.

6INSPECT GLOW PLUG RELAY CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Glow plug fuse and glow plug relay terminal

A.

—Glow plug relay terminal B and body GND.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 9.

7INSPECT GLOW PLUG RELAY

•Inspect glow plug relay.

(See T–19 RELAY INSPECTION)

•Is there any malfunction?Yes Replace glow plug relay, go to Step 9.

No Go to next step.

8INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 9.

No Go to next step.

9INSPECT GLOW PLUG RELAY CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Glow plug relay terminal D and PCM

terminal 68.

—Glow plug relay terminal C and PCM

terminal 86.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

10VERIFY TROUBLESHOOTING OF DTC P0380

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

11VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 297 of 909

ON-BOARD DIAGNOSTIC

F2–145

F2

DTC P0504A6E407001082234

Diagnostic procedure

DTC P0504 Brake switch signal correlation malfunction

DETECTION

CONDITION•PCM monitors input signal from brake switch 1 and brake switch 2 while engine is running. PCM

determines brake switch signal correlation malfunction if input signal from brake switch 1 brake switch 2 is

as following:

—Brake switch 1 is ON and brake switch 2 is ON.

—Brake switch 1 is OFF and brake switch 2 is OFF.

POSSIBLE

CAUSE•Brake switch malfunction

•Connector or terminal malfunction

•Open circuit in wiring between main fuse and brake switch terminal B

•Open circuit in wiring between brake switch terminal D and PCM terminal 7

•Short to power circuit in wiring between brake switch terminal D and PCM terminal 7

•Open circuit in wiring between brake switch terminal C and GND

•Short to GND in wiring between brake switch terminal A and PCM terminal 34

•Open circuit in wiring between brake switch terminal A and PCM terminal 34

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2CLASSIFY MALFUNCTION OF BRAKE SWITCH

1 OR BRAKE SWITCH 2

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Verify that BOO PID is changed according to

brake pedal condition.

(See F2–65 PCM INSPECTION)

•Is BOO PID okay?Yes Go to Step 15.

No Go to next step.

3CLASSIFY HIGH INPUT OR LOW INPUT

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Verify BOO PID during brake pedal operation.

•Is BOO PID always OFF?Yes Go to next step.

No Go to Step 10.

MAIN FUSE

BRAKE SWITCH

A B

CD

BRAKE SWITCHPCM

7

34

PCM

HARNESS SIDE CONNECTOR

HARNESS SIDE CONNECTOR

A

B C

D

7 34

4

6

7

8

910

4

10

12

1918

17

1516

1413

2015

Page 298 of 909

F2–146

ON-BOARD DIAGNOSTIC

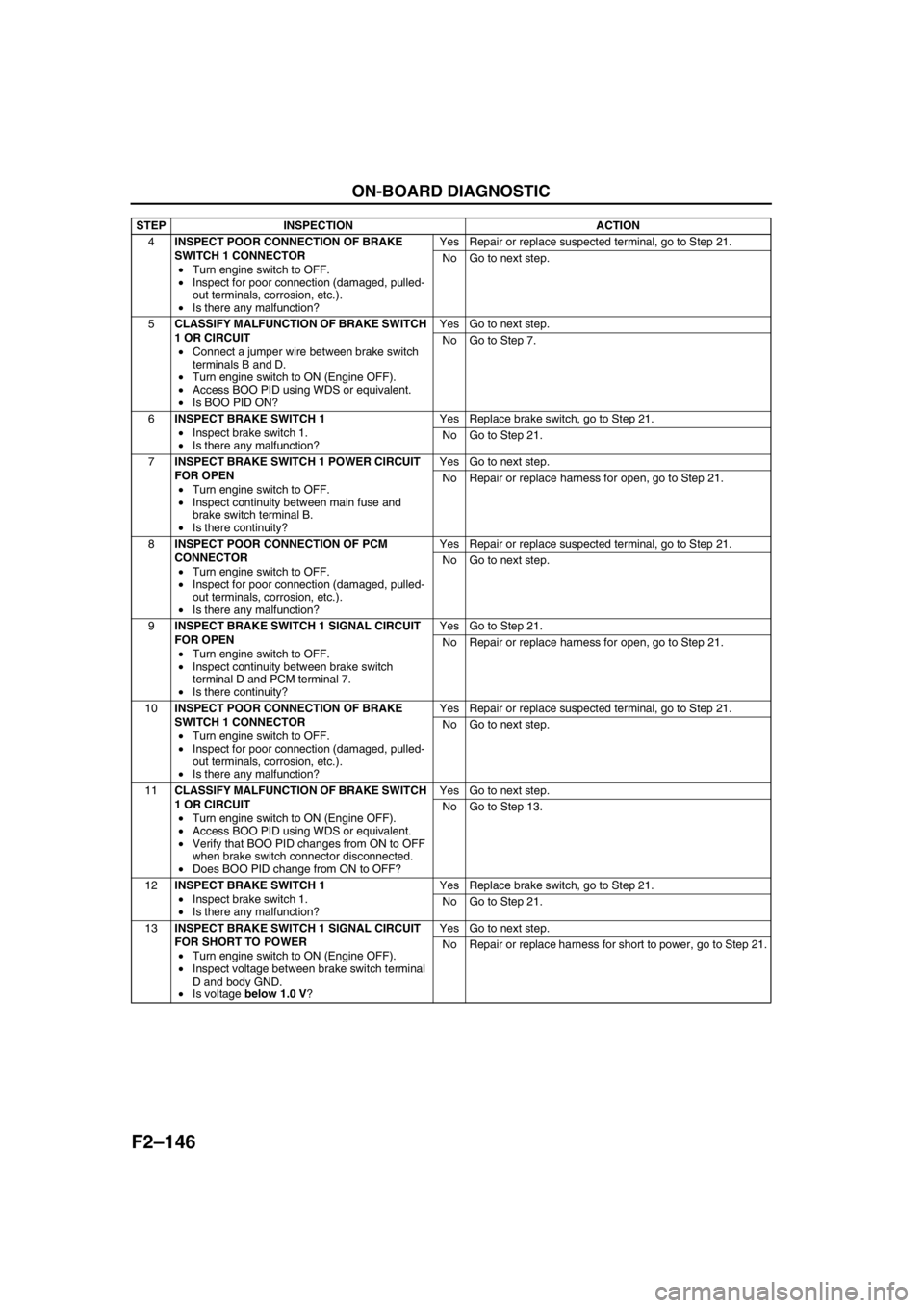

4INSPECT POOR CONNECTION OF BRAKE

SWITCH 1 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

5CLASSIFY MALFUNCTION OF BRAKE SWITCH

1 OR CIRCUIT

•Connect a jumper wire between brake switch

terminals B and D.

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Is BOO PID ON?Yes Go to next step.

No Go to Step 7.

6INSPECT BRAKE SWITCH 1

•Inspect brake switch 1.

•Is there any malfunction?Yes Replace brake switch, go to Step 21.

No Go to Step 21.

7INSPECT BRAKE SWITCH 1 POWER CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between main fuse and

brake switch terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 21.

8INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

9INSPECT BRAKE SWITCH 1 SIGNAL CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between brake switch

terminal D and PCM terminal 7.

•Is there continuity?Yes Go to Step 21.

No Repair or replace harness for open, go to Step 21.

10INSPECT POOR CONNECTION OF BRAKE

SWITCH 1 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

11CLASSIFY MALFUNCTION OF BRAKE SWITCH

1 OR CIRCUIT

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Verify that BOO PID changes from ON to OFF

when brake switch connector disconnected.

•Does BOO PID change from ON to OFF?Yes Go to next step.

No Go to Step 13.

12INSPECT BRAKE SWITCH 1

•Inspect brake switch 1.

•Is there any malfunction?Yes Replace brake switch, go to Step 21.

No Go to Step 21.

13INSPECT BRAKE SWITCH 1 SIGNAL CIRCUIT

FOR SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspect voltage between brake switch terminal

D and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 21. STEP INSPECTION ACTION

Page 299 of 909

ON-BOARD DIAGNOSTIC

F2–147

F2

End Of Sie

14INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to Step 21.

15INSPECT POOR CONNECTION OF BRAKE

SWITCH 2 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

16INSPECT BRAKE SWITCH 2 GND CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between brake switch

terminal C and body GND.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 21.

17INSPECT BRAKE SWITCH 2

•Inspect brake switch 2.

•Is there any malfunction?Yes Replace brake switch, go to Step 21.

No Go to next step.

18INSPECT BRAKE SWITCH 2 SIGNAL CIRCUIT

FOR SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between brake switch

terminal A and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 21.

No Go to next step.

19INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

20INSPECT BRAKE SWITCH 2 SIGNAL CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between brake switch

terminal A and PCM terminal 34.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

21VERIFY TROUBLESHOOTING OF DTC P0504

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

22VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 300 of 909

F2–148

ON-BOARD DIAGNOSTIC

DTC P0510A6E407001082235

Diagnostic procedure

DTC P0510 Idle switch circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from idle switch while engine is running. If input voltage from idle switch is B+

when accelerator position sensor No.1 voltage is below 0.7 V, PCM determines idle switch circuit

malfunction.

POSSIBLE

CAUSE•Idle switch malfunction

•Connector or terminal malfunction

•Open circuit in wiring between idle switch terminal B and GND

•Open circuit in wiring between idle switch terminal A and PCM terminal 31

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

BA IDLE SWITCH

A B

31 31PCM

4

2

23

65

IDLE SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR