brake light MAZDA 6 2002 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 602 of 909

TROUBLESHOOTING

K2–187

K2

End Of Sie

Vehicle dose not move in D range, or in R position

X

X

X

XXX X

XX X

XX X

XX X XX

X

X

X X XX

XX

X XXXXXXXXX

XXX

X

X

X X

XX XXX

X

X

XX X

X

X

X X

X

X

X X

XX

X XXX X XXX

XX X 1

Excessive creep 4

No creep at all 5

Low maximum speed and poor acceleration 6

No shifting 7

Does not shift to fifth gear (5GR) 8

Abnormal shifting 9

Frequent shifting 10

Shift point is high or low 11

Torque converter clutch (TCC) non-operation 12

No kickdown 13

Engine flares up or slips when upshifting or downshifting 14

Engine flares up or slip when accelerating vehicle 15

Judder upon torque converter clutch (TCC) operation 16

Excessive shift shock from N to D or N to R position/range 17

Excessive shift shock on torque converter clutch (TCC) 19

No engine braking in 1GR position of M range 22

Transaxle overheats 23

Engine stalls when shifted to D range, or in R position 24

Engine stalls when driving at slow speeds or stopping 25

Starter does not work 26Excessive shift shock is given when upshifting and

downshifting 18

Noise occurs at idle when vehicle is stopped in all

positions/ranges 20

Noise occurs at idle when vehicle is stopped in D

range, or in R position 21

Gear position indicator light illuminates in D range or P, N,

R positions 28Gear position indicator light does not illuminate in M range

Hydraulic system

components

Control valve bodyPowertrain 27

Does not shift up in M range

29

Does not shift down in M range

Symptom item

Cause of trouble

Reduction accumulator is not operating properly

Clogging

Clogging

Clogging

Clogging

Clogging

Clogging

Clogging Clogging

Clogging

Slipping (clutch, brake) Oil cooler is not operating properly

Torque converter is not operating properly Burned (clutch, brake)

TCC piston is not operating properly TCC piston is cracking or peeling2-4 brake solenoid valve hydraulic circuit Pressure control solenoid hydraulic circuit

TCC solenoid valve hydraulic circuit

High clutch solenoid valve hydraulic circuit

Shift solenoid A hydraulic circuit

Shift solenoid B hydraulic circuit

Shift solenoid C hydraulic circuit

Neutral shift solenoid valve

Reducation timing solenoid valve

30Vehicle moves in N position 2

Vehicle moves in P position, or parking gear does not

disengage when P is disengaged 3

A6E5780W003

Page 615 of 909

K2–200

TROUBLESHOOTING

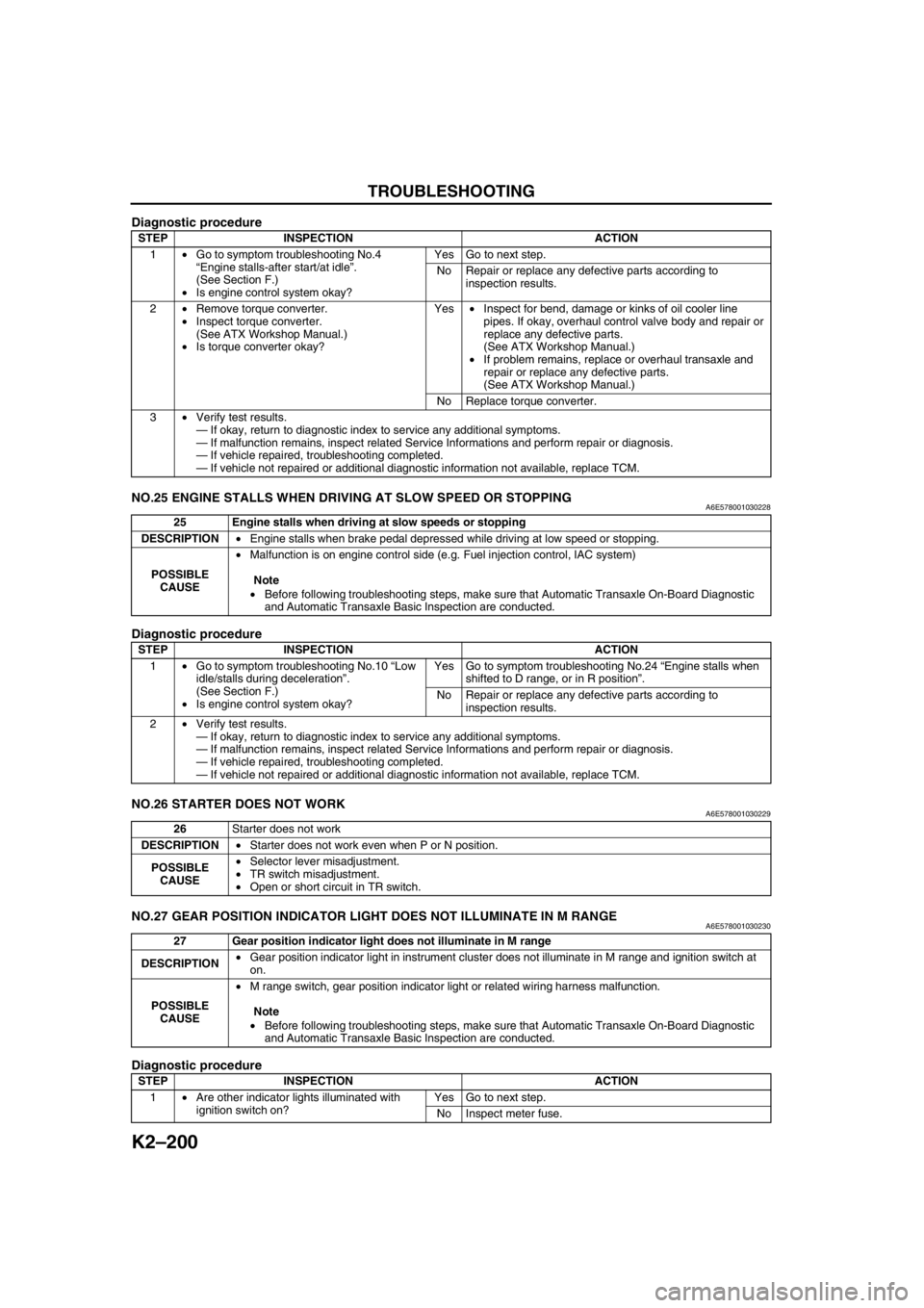

Diagnostic procedure

End Of SieNO.25 ENGINE STALLS WHEN DRIVING AT SLOW SPEED OR STOPPINGA6E578001030228

Diagnostic procedure

End Of SieNO.26 STARTER DOES NOT WORKA6E578001030229

End Of SieNO.27 GEAR POSITION INDICATOR LIGHT DOES NOT ILLUMINATE IN M RANGEA6E578001030230

Diagnostic procedure

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.4

“Engine stalls-after start/at idle”.

(See Section F.)

•Is engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Inspect for bend, damage or kinks of oil cooler line

pipes. If okay, overhaul control valve body and repair or

replace any defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace torque converter.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

25 Engine stalls when driving at slow speeds or stopping

DESCRIPTION•Engine stalls when brake pedal depressed while driving at low speed or stopping.

POSSIBLE

CAUSE•Malfunction is on engine control side (e.g. Fuel injection control, IAC system)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.10 “Low

idle/stalls during deceleration”.

(See Section F.)

•Is engine control system okay?Yes Go to symptom troubleshooting No.24 “Engine stalls when

shifted to D range, or in R position”.

No Repair or replace any defective parts according to

inspection results.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

26Starter does not work

DESCRIPTION•Starter does not work even when P or N position.

POSSIBLE

CAUSE•Selector lever misadjustment.

•TR switch misadjustment.

•Open or short circuit in TR switch.

27 Gear position indicator light does not illuminate in M range

DESCRIPTION•Gear position indicator light in instrument cluster does not illuminate in M range and ignition switch at

on.

POSSIBLE

CAUSE•M range switch, gear position indicator light or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Are other indicator lights illuminated with

ignition switch on? Yes Go to next step.

No Inspect meter fuse.

Page 643 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–13

M

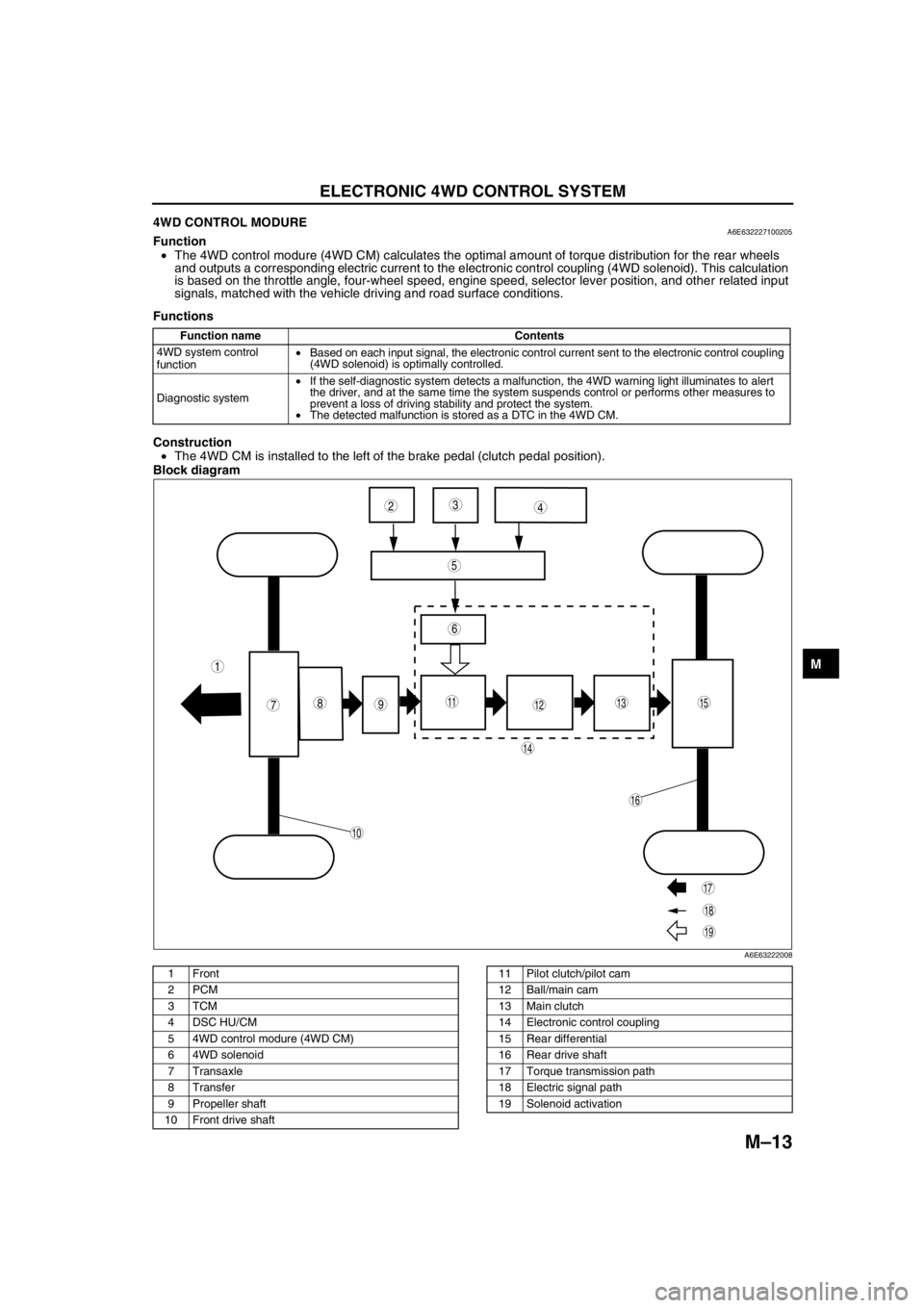

4WD CONTROL MODUREA6E632227100205Function

•The 4WD control modure (4WD CM) calculates the optimal amount of torque distribution for the rear wheels

and outputs a corresponding electric current to the electronic control coupling (4WD solenoid). This calculation

is based on the throttle angle, four-wheel speed, engine speed, selector lever position, and other related input

signals, matched with the vehicle driving and road surface conditions.

Functions

Construction

•The 4WD CM is installed to the left of the brake pedal (clutch pedal position).

Block diagram

.

Function name Contents

4WD system control

function•Based on each input signal, the electronic control current sent to the electronic control coupling

(4WD solenoid) is optimally controlled.

Diagnostic system•If the self-diagnostic system detects a malfunction, the 4WD warning light illuminates to alert

the driver, and at the same time the system suspends control or performs other measures to

prevent a loss of driving stability and protect the system.

•The detected malfunction is stored as a DTC in the 4WD CM.

987

5

43

10

19

18

17

15

16

14

131112

6

1

2

A6E63222008

1Front

2PCM

3TCM

4 DSC HU/CM

5 4WD control modure (4WD CM)

6 4WD solenoid

7Transaxle

8Transfer

9 Propeller shaft

10 Front drive shaft11 Pilot clutch/pilot cam

12 Ball/main cam

13 Main clutch

14 Electronic control coupling

15 Rear differential

16 Rear drive shaft

17 Torque transmission path

18 Electric signal path

19 Solenoid activation

Page 652 of 909

M–22

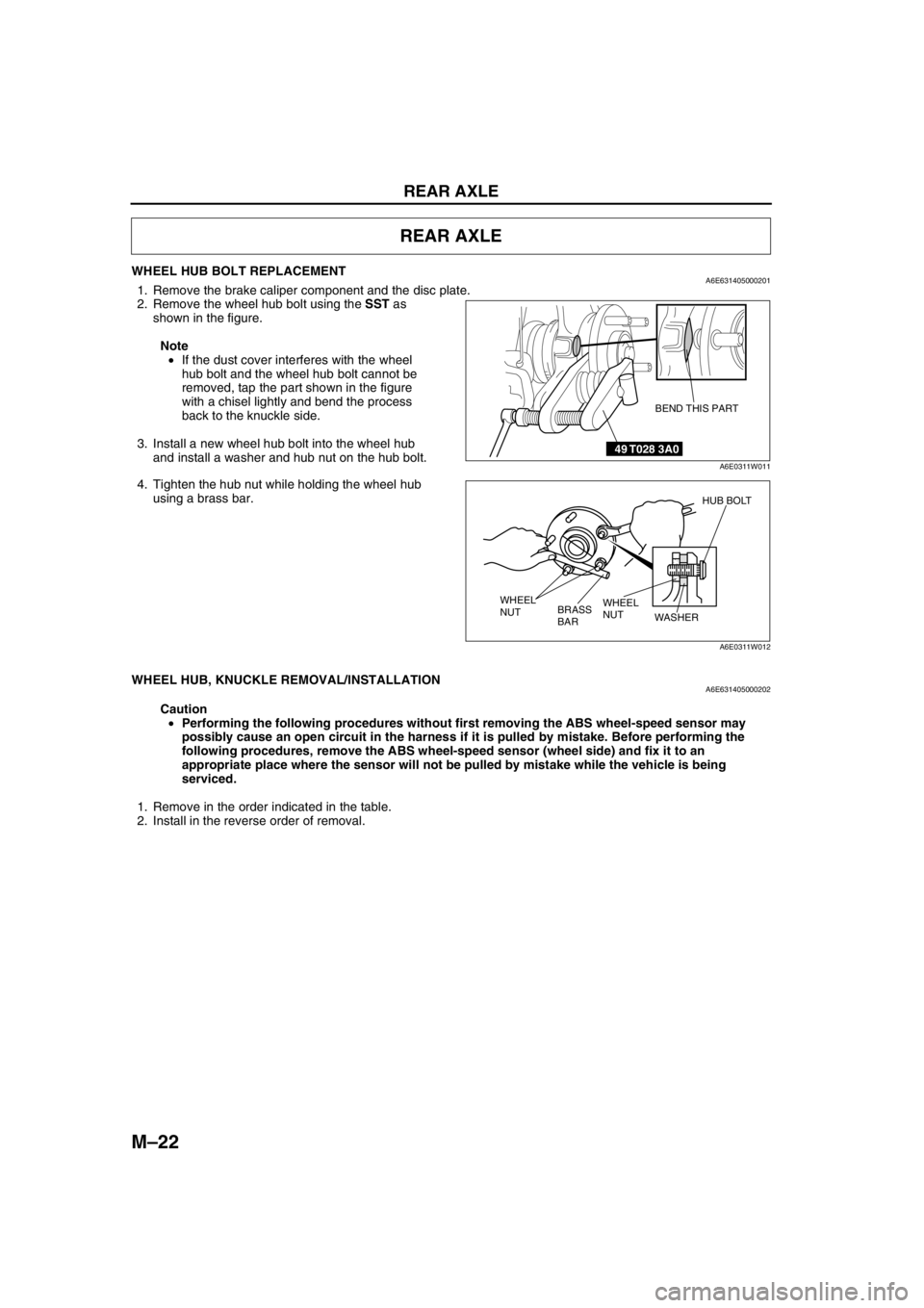

REAR AXLE

WHEEL HUB BOLT REPLACEMENTA6E6314050002011. Remove the brake caliper component and the disc plate.

2. Remove the wheel hub bolt using the SST as

shown in the figure.

Note

•If the dust cover interferes with the wheel

hub bolt and the wheel hub bolt cannot be

removed, tap the part shown in the figure

with a chisel lightly and bend the process

back to the knuckle side.

3. Install a new wheel hub bolt into the wheel hub

and install a washer and hub nut on the hub bolt.

4. Tighten the hub nut while holding the wheel hub

using a brass bar.

End Of Sie

WHEEL HUB, KNUCKLE REMOVAL/INSTALLATIONA6E631405000202

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (wheel side) and fix it to an

appropriate place where the sensor will not be pulled by mistake while the vehicle is being

serviced.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

REAR AXLE

49 T028 3A0

BEND THIS PART

A6E0311W011

HUB BOLT

WHEEL

NUT WHEEL

NUT

WASHER

BRASS

BAR

A6E0311W012

Page 713 of 909

TROUBLESHOOTING

M–83

M

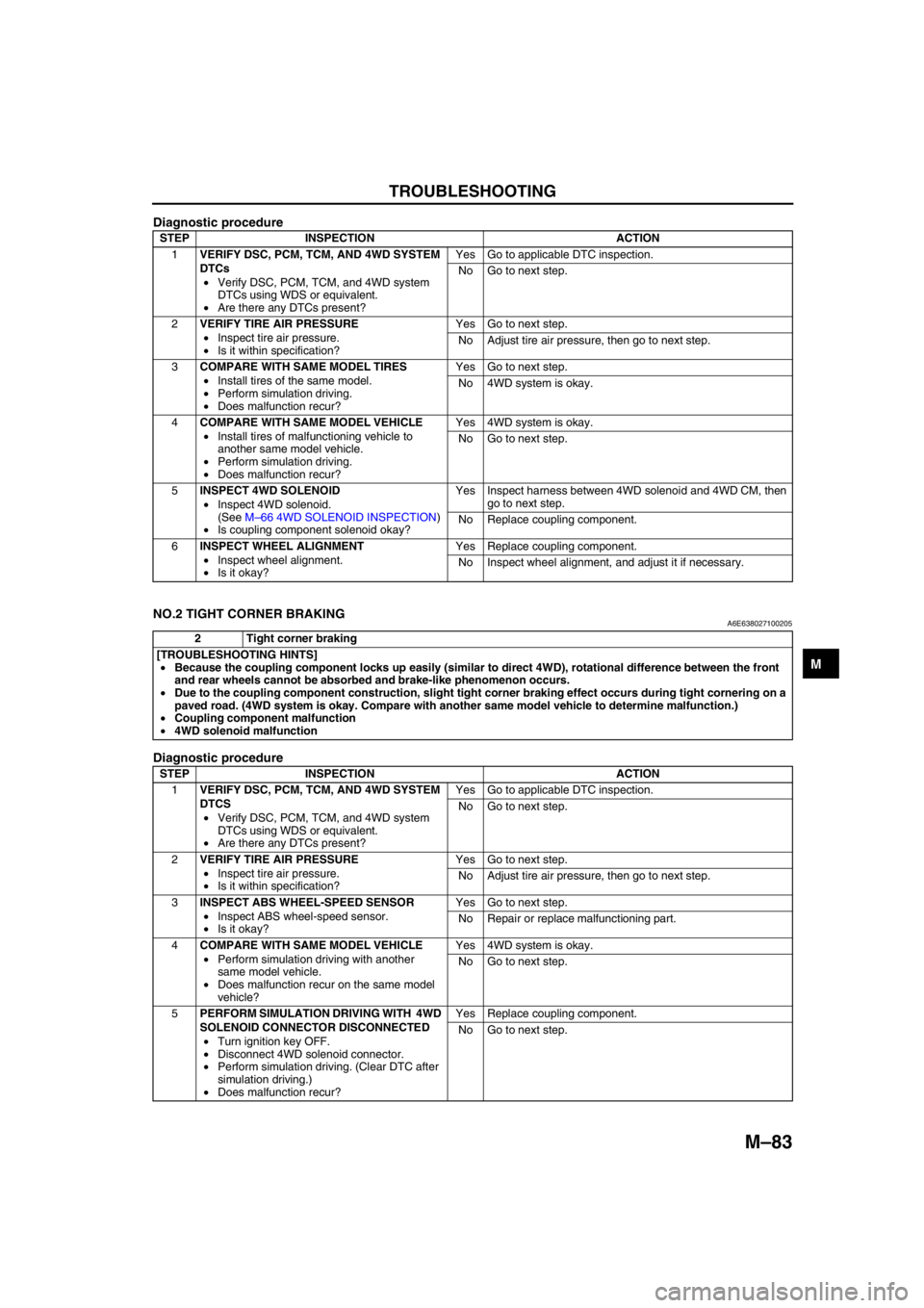

Diagnostic procedure

End Of Sie

NO.2 TIGHT CORNER BRAKINGA6E638027100205

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCs

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY TIRE AIR PRESSURE

•Inspect tire air pressure.

•Is it within specification?Yes Go to next step.

No Adjust tire air pressure, then go to next step.

3COMPARE WITH SAME MODEL TIRES

•Install tires of the same model.

•Perform simulation driving.

•Does malfunction recur?Yes Go to next step.

No 4WD system is okay.

4COMPARE WITH SAME MODEL VEHICLE

•Install tires of malfunctioning vehicle to

another same model vehicle.

•Perform simulation driving.

•Does malfunction recur?Yes 4WD system is okay.

No Go to next step.

5INSPECT 4WD SOLENOID

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is coupling component solenoid okay?Yes Inspect harness between 4WD solenoid and 4WD CM, then

go to next step.

No Replace coupling component.

6INSPECT WHEEL ALIGNMENT

•Inspect wheel alignment.

•Is it okay?Yes Replace coupling component.

No Inspect wheel alignment, and adjust it if necessary.

2 Tight corner braking

[TROUBLESHOOTING HINTS]

•Because the coupling component locks up easily (similar to direct 4WD), rotational difference between the front

and rear wheels cannot be absorbed and brake-like phenomenon occurs.

•Due to the coupling component construction, slight tight corner braking effect occurs during tight cornering on a

paved road. (4WD system is okay. Compare with another same model vehicle to determine malfunction.)

•Coupling component malfunction

•4WD solenoid malfunction

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCS

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY TIRE AIR PRESSURE

•Inspect tire air pressure.

•Is it within specification?Yes Go to next step.

No Adjust tire air pressure, then go to next step.

3INSPECT ABS WHEEL-SPEED SENSOR

•Inspect ABS wheel-speed sensor.

•Is it okay?Yes Go to next step.

No Repair or replace malfunctioning part.

4COMPARE WITH SAME MODEL VEHICLE

•Perform simulation driving with another

same model vehicle.

•Does malfunction recur on the same model

vehicle?Yes 4WD system is okay.

No Go to next step.

5PERFORM SIMULATION DRIVING WITH 4WD

SOLENOID CONNECTOR DISCONNECTED

•Turn ignition key OFF.

•Disconnect 4WD solenoid connector.

•Perform simulation driving. (Clear DTC after

simulation driving.)

•Does malfunction recur?Yes Replace coupling component.

No Go to next step.

Page 737 of 909

P–4

ABS/TCS

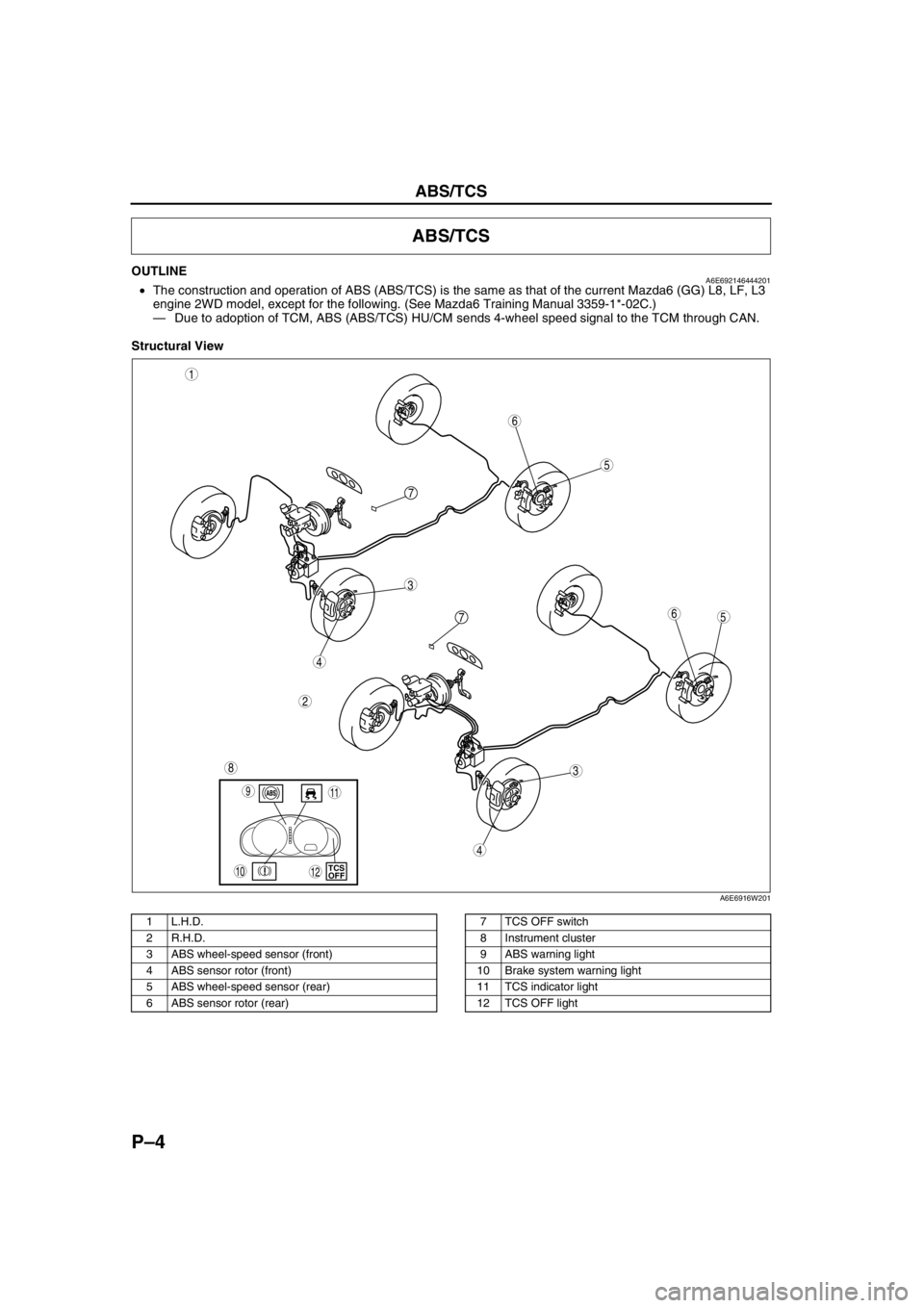

OUTLINEA6E692146444201•The construction and operation of ABS (ABS/TCS) is the same as that of the current Mazda6 (GG) L8, LF, L3

engine 2WD model, except for the following. (See Mazda6 Training Manual 3359-1*-02C.)

—Due to adoption of TCM, ABS (ABS/TCS) HU/CM sends 4-wheel speed signal to the TCM through CAN.

Structural View

.

ABS/TCS

5

3

1

2

6

7

5

3

6

8

4

4

7

9

10TCS

OFF

11

12

A6E6916W201

1 L.H.D.

2 R.H.D.

3 ABS wheel-speed sensor (front)

4 ABS sensor rotor (front)

5 ABS wheel-speed sensor (rear)

6 ABS sensor rotor (rear)7 TCS OFF switch

8 Instrument cluster

9 ABS warning light

10 Brake system warning light

11 TCS indicator light

12 TCS OFF light

Page 738 of 909

ABS/TCS

P–5

P

System Diagram

.

End Of Sie

9

9

8

7

5

43

12

6

18

17

15

16

14

13

11

12

RF

FL

RR

RL

PCMG

E

FI Z

U

D

A

B

C

Y

AC

X

V O

R ADAB AA

ABS/TCS HU/CM

pP

9

10

19

920

A6E6921W201

1 IG switch

2SUS 15 A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 TCS OFF light

8 TCS indicator light

9CAN driver

10 Brake light11 Cruise actuator

12 TCS OFF switch

13 DLC-2

14 CAN-H

15 CAN-L

16 ABS Wheel-speed sensor

17 Battery

18 Brake switch

19 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

20 TCM, 4WD CM

Page 739 of 909

P–6

DYNAMIC STABILITY CONTROL

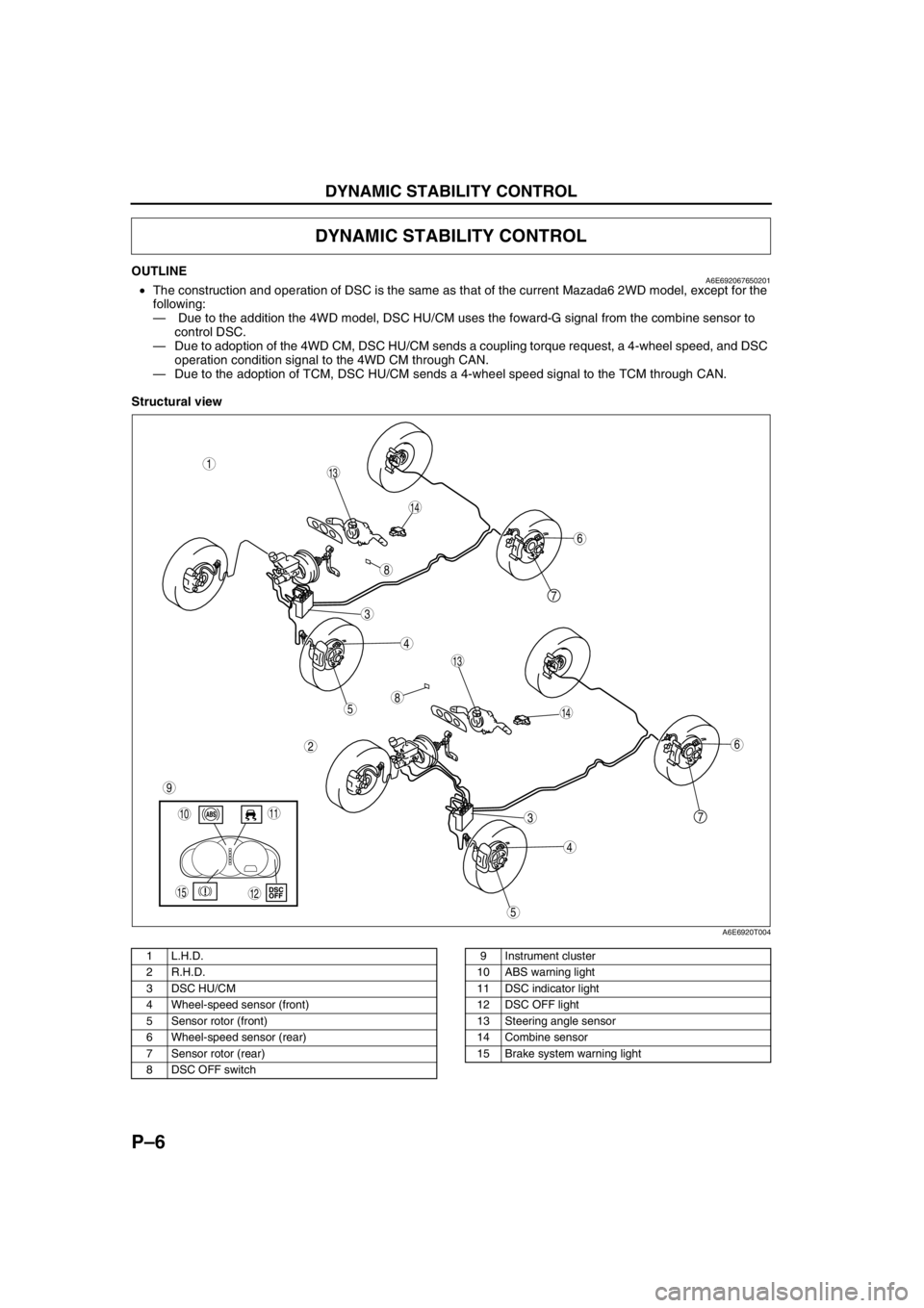

OUTLINEA6E692067650201•The construction and operation of DSC is the same as that of the current Mazada6 2WD model, except for the

following:

— Due to the addition the 4WD model, DSC HU/CM uses the foward-G signal from the combine sensor to

control DSC.

—Due to adoption of the 4WD CM, DSC HU/CM sends a coupling torque request, a 4-wheel speed, and DSC

operation condition signal to the 4WD CM through CAN.

—Due to the adoption of TCM, DSC HU/CM sends a 4-wheel speed signal to the TCM through CAN.

Structural view

.

DYNAMIC STABILITY CONTROL

7

5

4

3

1

2

14

13

6

13

12

5

4

3

7

6

1011

9

14

8

8

15

A6E6920T004

1 L.H.D.

2 R.H.D.

3 DSC HU/CM

4 Wheel-speed sensor (front)

5 Sensor rotor (front)

6 Wheel-speed sensor (rear)

7 Sensor rotor (rear)

8 DSC OFF switch9 Instrument cluster

10 ABS warning light

11 DSC indicator light

12 DSC OFF light

13 Steering angle sensor

14 Combine sensor

15 Brake system warning light

Page 740 of 909

DYNAMIC STABILITY CONTROL

P–7

P

Wiring Diagram

.

9

RF

FL

RR

RL

PCM

G

E

M

I

F

K

H

Q

NJ

P

S

T

V

O

Y

X

W

U

R

L

Z

AC

D

B

AG

AF

AE

AC

AA

AB

C

F

D

A

B

EDSC HU/CM

A

B

C

D

F

1

3

2

8

7

5

4

6

9

9

9

10

11

13

12

15

14

18

17

16

1920

2122

24

23

A6E6921W203

1 IG switch

2SUS 15A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 DSC OFF light

8 DSC indicator light

9CAN driver

10 Battery

11 Cruise actuator

12 DSC OFF switch13 DLC-2

14 CAN-H

15 CAN-L

16 Wheel-speed sensor

17 Combine sensor

18 Steering angle sensor

19 Brake switch

20 Brake light

21 Back-up light switch (MTX only)

22 Back-up light (MTX only)

23 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

24 TCM, 4WD CM

Page 742 of 909

ON-BOARD DIAGNOSTIC

P–9

P

OUTLINEA6E697043000201•The operation of the on-board diagnostic system for ABS (ABS/TCS) or DSC is the same as that of the current

Mazda6 (GG) L8, LF, L3 engine 2WD model, except for the following. (See Mazda6 Training Manual

3359-1*-02C.)

— Due to the addition of the 4WD model, DTCs and PID data monitor has been added.

—Due to the addition of the MZR-CD (RF Turbo) engine model, the DTC C1119 fail-safe function and the

detection condition have been changed.

Fail-safe Function

Fail-safe function table

*1: When engine speed signal through CAN is out of specification, the light illuminates.*2: When engine speed signal through CAN is out of specification, the system is suspended.*3: When engine speed signal value through CAN is invalid, only brake TCS is available.*4: When fuel injection information through CAN is out of specification or invalid, only brake TCS is available.*5: When engine speed signal value through CAN is invalid, only brake DSC is available.*6: When the engine control system has a malfunction, only brake DSC is available.

PID/DATA Monitor Table

End Of Sie

ON-BOARD DIAGNOSTIC

Malfunc-

tion

locationDTC Fail-safe function

WDS

or

equiva-

lentWarning light illumination condition Control condition

ABS

warning

lightBRAKE

system

warning

light

(when

parking

brake is

released)DSC

(TCS)

OFF lightDSC

(TCS)

indicator

light ABS

controlEBD

controlTCS

controlDSC

controlBrake

assist

control

PCM and/

or engine

speed

signal lineC1119Not

Illuminated Not

Illuminated Not

Illuminated

*1Illuminated Available AvailableAvailable*2, *3, *4Available*2, *5, *6Available

Combine

sensor

(forward-

G) lineC1949

Illuminated Not

Illuminated Illuminated IlluminatedNot

availableAvailable—Not

availableNot

available

C1950

CAN line U2511Not

Illuminated Not

Illuminated Not

Illuminated Illuminated Available Available—Available Available

PID name input/output part Operation/unit

ACCLMTR Accelerometer ACCELERATION