brake light MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 122 of 909

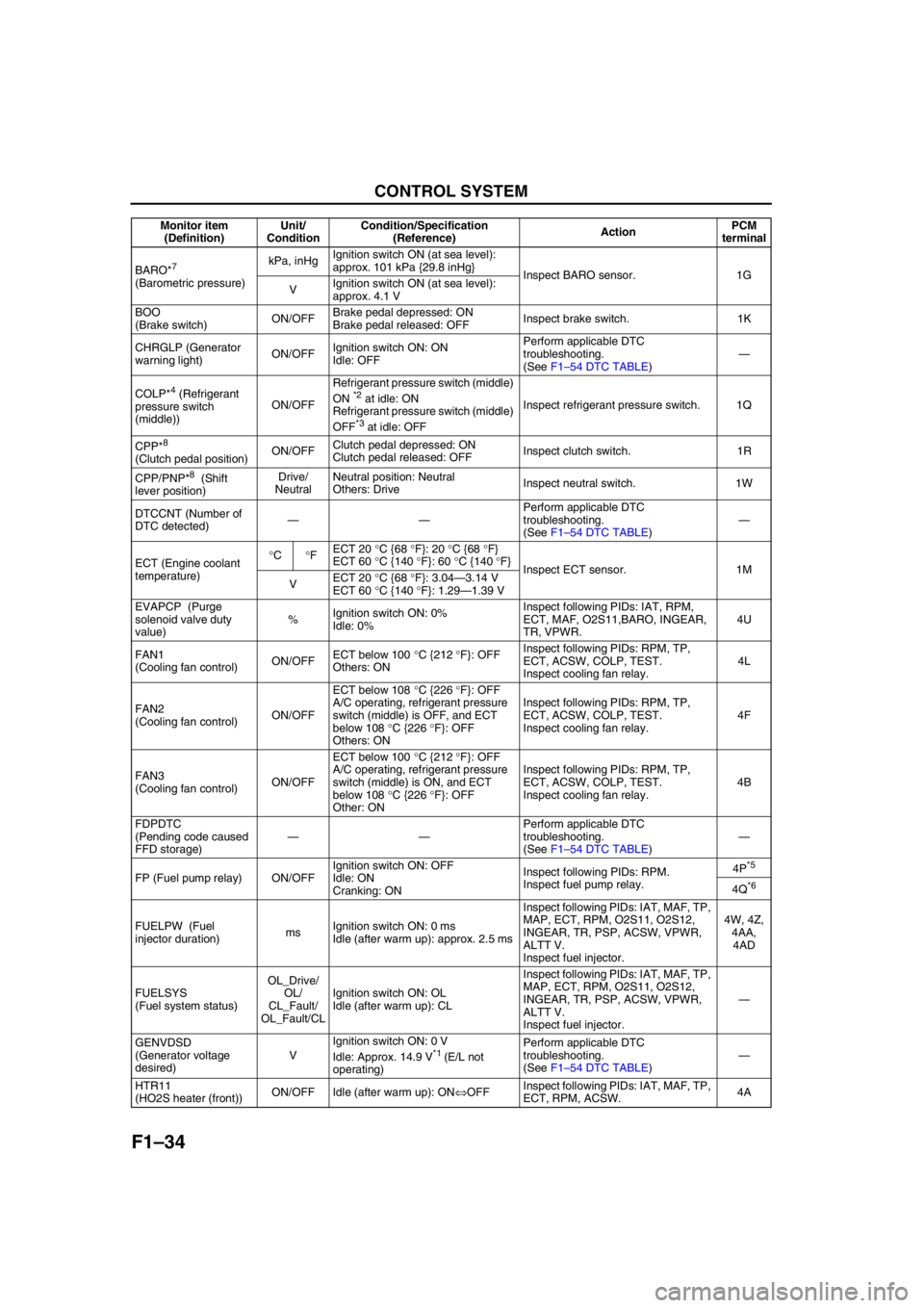

F1–34

CONTROL SYSTEM

BARO*7

(Barometric pressure)kPa, inHgIgnition switch ON (at sea level):

approx. 101 kPa {29.8 inHg}

Inspect BARO sensor. 1G

VIgnition switch ON (at sea level):

approx. 4.1 V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Brake pedal released: OFFInspect brake switch. 1K

CHRGLP (Generator

warning light)ON/OFFIgnition switch ON: ON

Idle: OFFPerform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

COLP*

4 (Refrigerant

pressure switch

(middle))ON/OFFRefrigerant pressure switch (middle)

ON *2 at idle: ON

Refrigerant pressure switch (middle)

OFF

*3 at idle: OFFInspect refrigerant pressure switch. 1Q

CPP*

8

(Clutch pedal position)ON/OFFClutch pedal depressed: ON

Clutch pedal released: OFFInspect clutch switch. 1R

CPP/PNP*

8 (Shift

lever position)Drive/

NeutralNeutral position: Neutral

Others: DriveInspect neutral switch. 1W

DTCCNT (Number of

DTC detected)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

ECT (Engine coolant

temperature)°C°FECT 20 °C {68 °F}: 20 °C {68 °F}

ECT 60 °C {140 °F}: 60 °C {140 °F}

Inspect ECT sensor. 1M

VECT 20 °C {68 °F}: 3.04—3.14 V

ECT 60 °C {140 °F}: 1.29—1.39 V

EVAPCP (Purge

solenoid valve duty

value)%Ignition switch ON: 0%

Idle: 0%Inspect following PIDs: IAT, RPM,

ECT, MAF, O2S11,BARO, INGEAR,

TR, VPWR.4U

FAN1

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4L

FAN2

(Cooling fan control)ON/OFFECT below 108 °C {226 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is OFF, and ECT

below 108 °C {226 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4F

FAN3

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is ON, and ECT

below 108 °C {226 °F}: OFF

Other: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4B

FDPDTC

(Pending code caused

FFD storage)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

FP (Fuel pump relay) ON/OFFIgnition switch ON: OFF

Idle: ON

Cranking: ONInspect following PIDs: RPM.

Inspect fuel pump relay.4P

*5

4Q*6

FUELPW (Fuel

injector duration)msIgnition switch ON: 0 ms

Idle (after warm up): approx. 2.5 msInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.4W, 4Z,

4AA,

4AD

FUELSYS

(Fuel system status)OL_Drive/

OL/

CL_Fault/

OL_Fault/CLIgnition switch ON: OL

Idle (after warm up): CLInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.—

GENVDSD

(Generator voltage

desired)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

HTR11

(HO2S heater (front))ON/OFF Idle (after warm up): ON⇔OFFInspect following PIDs: IAT, MAF, TP,

ECT, RPM, ACSW.4A Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 171 of 909

CONTROL SYSTEM

F2–19

F2

End Of Sie

1PCM (with built-in BARO sensor and immobilizer

unit)

2Battery

3Starter

4 Starter relay

5 Clutch switch

6 Neutral switch

7 Brake switch

8 Idle switch

9 Cruise control switch

10 Accelerator position sensor

11 MAF/IAT sensor

12 IAT sensor No.2

13 ECT sensor

14 Fuel temperature sensor

15 Boost sensor

16 Fuel pressure sensor

17 CMP sensor

18 CKP sensor

19 VSS

20 Calibration resistor

21 Suction control valve

22 IDM

23 VSC solenoid valve

24 VBC solenoid valve

25 EGR control solenoid valve

26 EGR solenoid valve (vacuum)

27 EGR solenoid valve (vent)

28 Intake shutter solenoid valve (half)

29 Intake shutter solenoid valve (full)

30 Glow indicator light

31 Cruise main indicator light

32 Cruise set indicator light

33 Glow plug relay

34 Cooling fan relay No.1

35 Cooling fan relay No.2

36 A/C relay

37 PCM control relay

38 L.H.D.

39 R.H.D.

Page 173 of 909

CONTROL SYSTEM

F2–21

F2

End Of Sie

1PCM

2 Idle speed control

3Glow control

4 VSC

5 Boost pressure control

6 Fuel injection amount control

7 Fuel injection timing control

8 Multiple fuel injection control

9 Fuel pressure control

10 EGR control

11 Cruise control system

12 Electrical fan control

13 A/C cut-off control

14 Immobilizer system

15 Battery

16 Starter (starter signal)

17 Starter relay

18 Clutch switch

19 Neutral switch

20 Brake switch

21 Idle switch

22 A/C switch

23 Refrigerant pressure switch

24 Cruise control switch

25 Accelerator position sensor

26 MAF/IAT sensor

27 IAT sensor No.2

28 ECT sensor

29 Fuel temperature sensor

30 BARO sensor (integrated in PCM)

31 Boost sensor

32 Fuel pressure sensor

33 CMP sensor

34 CKP sensor

35 VSS

36 Calibration resistor

37 Immobilizer unit (integrated in PCM)

38 Suction control valve

39 IDM

40 VSC solenoid valve

41 VBC solenoid valve

42 EGR control solenoid valve

43 EGR solenoid valve (vacuum)

44 EGR solenoid valve (vent)

45 Intake shutter solenoid valve (half)

46 Intake shutter solenoid valve (full)

47 Glow indicator light

48 Cruise main indicator light

49 Cruise set indicator light

50 Glow plug relay

51 Cooling fan relay No.1

52 Cooling fan relay No.2

53 A/C relay

Page 174 of 909

F2–22

CONTROL SYSTEM

CONTROL DEVICE AND CONTROL RELATIONSHIP CHARTA6E404018881204

×: Applicable

End Of Sie

Item

Input device

Battery××

Starter (starter signal)××××××××× ×

Starter relay××××××××× ×

Clutch switch× × ××× ×× ×

Neutral switch× × ××× ×× ×

Brake switch×

Idle switch× × ××× × ×

A/C switch×××××

Refrigerant pressure switch×××××

Cruise control switch×

Accelerator position sensor××××××××

MAF/IAT sensor× ××××

IAT sensor No.2××

ECT sensor××× ××××× ××

Fuel temperature sensor×

BARO sensor (integrated in PCM)×××

Boost sensor××× ×

Fuel pressure sensor×× ××

CMP sensor×××××

CKP sensor× ××××××× ×

VSS××× ××× ××

Calibration resistor××

Immobilizer unit (integrated in PCM)×

Output device

Suction control valve××

IDM× ××× × ×

VSC solenoid valve×

VBC solenoid valve×

EGR control solenoid valve×

EGR solenoid valve (vacuum)×

EGR solenoid valve (vent)×

Intake shutter solenoid valve (half)×

Intake shutter solenoid valve (full)×

Glow indicator light×

Cruise main indicator light×

Cruise set indicator light×

Glow plug relay×

Cooling fan relay No.1×

Cooling fan relay No.2×

A/C relay×

Idle speed controlGlow controlVSCBoost pressure controlFuel injection amount controlFuel injection timing controlMultiple fuel injection controlFuel pressure controlEGR controlCruise control systemElectrical fan controlA/C cut-off controlImmobilizer system

Page 175 of 909

CONTROL SYSTEM

F2–23

F2

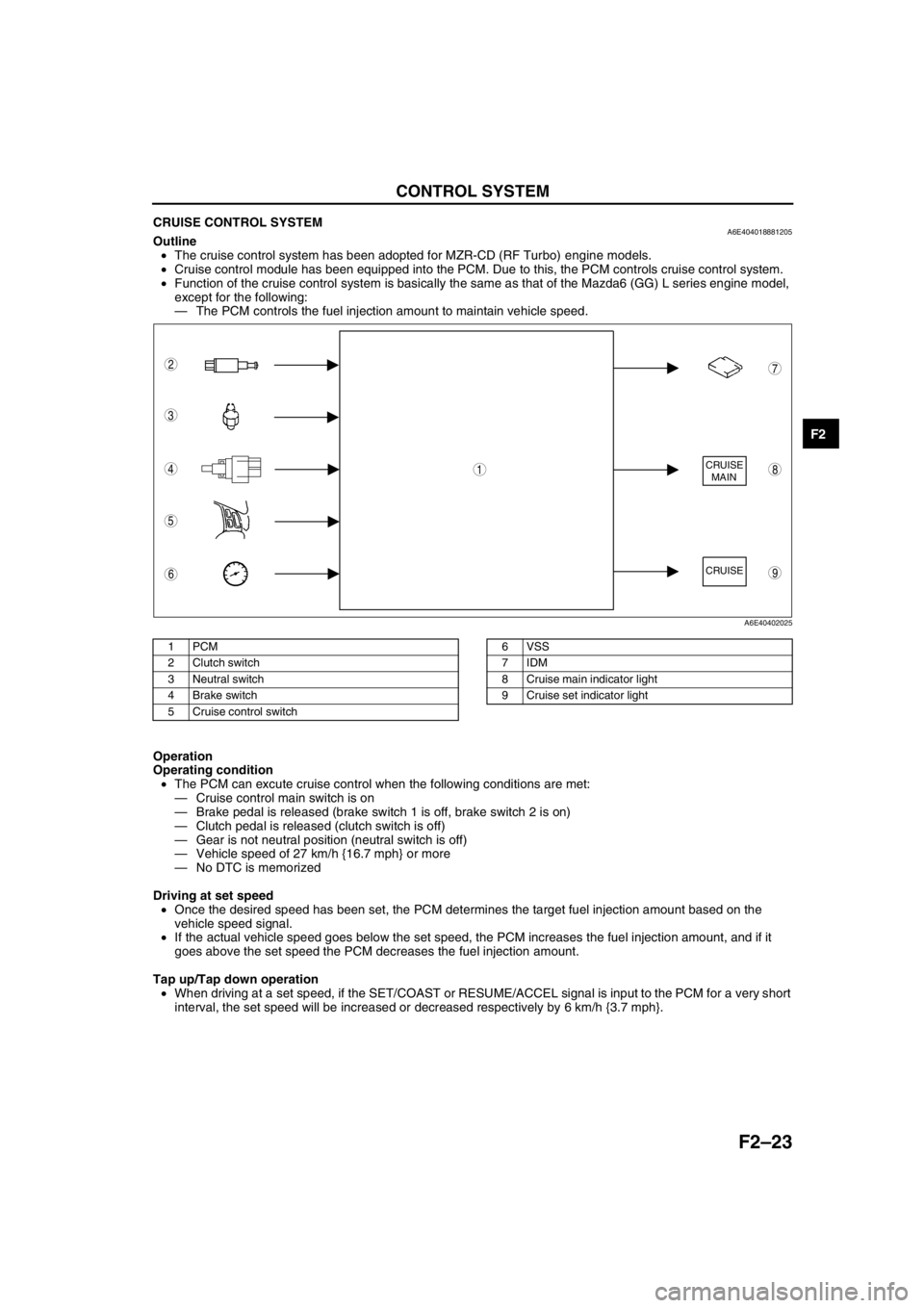

CRUISE CONTROL SYSTEMA6E404018881205Outline

•The cruise control system has been adopted for MZR-CD (RF Turbo) engine models.

•Cruise control module has been equipped into the PCM. Due to this, the PCM controls cruise control system.

•Function of the cruise control system is basically the same as that of the Mazda6 (GG) L series engine model,

except for the following:

—The PCM controls the fuel injection amount to maintain vehicle speed.

.

Operation

Operating condition

•The PCM can excute cruise control when the following conditions are met:

—Cruise control main switch is on

—Brake pedal is released (brake switch 1 is off, brake switch 2 is on)

—Clutch pedal is released (clutch switch is off)

—Gear is not neutral position (neutral switch is off)

—Vehicle speed of 27 km/h {16.7 mph} or more

—No DTC is memorized

Driving at set speed

•Once the desired speed has been set, the PCM determines the target fuel injection amount based on the

vehicle speed signal.

•If the actual vehicle speed goes below the set speed, the PCM increases the fuel injection amount, and if it

goes above the set speed the PCM decreases the fuel injection amount.

Tap up/Tap down operation

•When driving at a set speed, if the SET/COAST or RESUME/ACCEL signal is input to the PCM for a very short

interval, the set speed will be increased or decreased respectively by 6 km/h {3.7 mph}.

End Of Sie

CRUISE

MAIN

CRUISE

8

7

5

4

3

6

1

2

9

A6E40402025

1PCM

2 Clutch switch

3 Neutral switch

4 Brake switch

5 Cruise control switch6 VSS

7IDM

8 Cruise main indicator light

9 Cruise set indicator light

Page 179 of 909

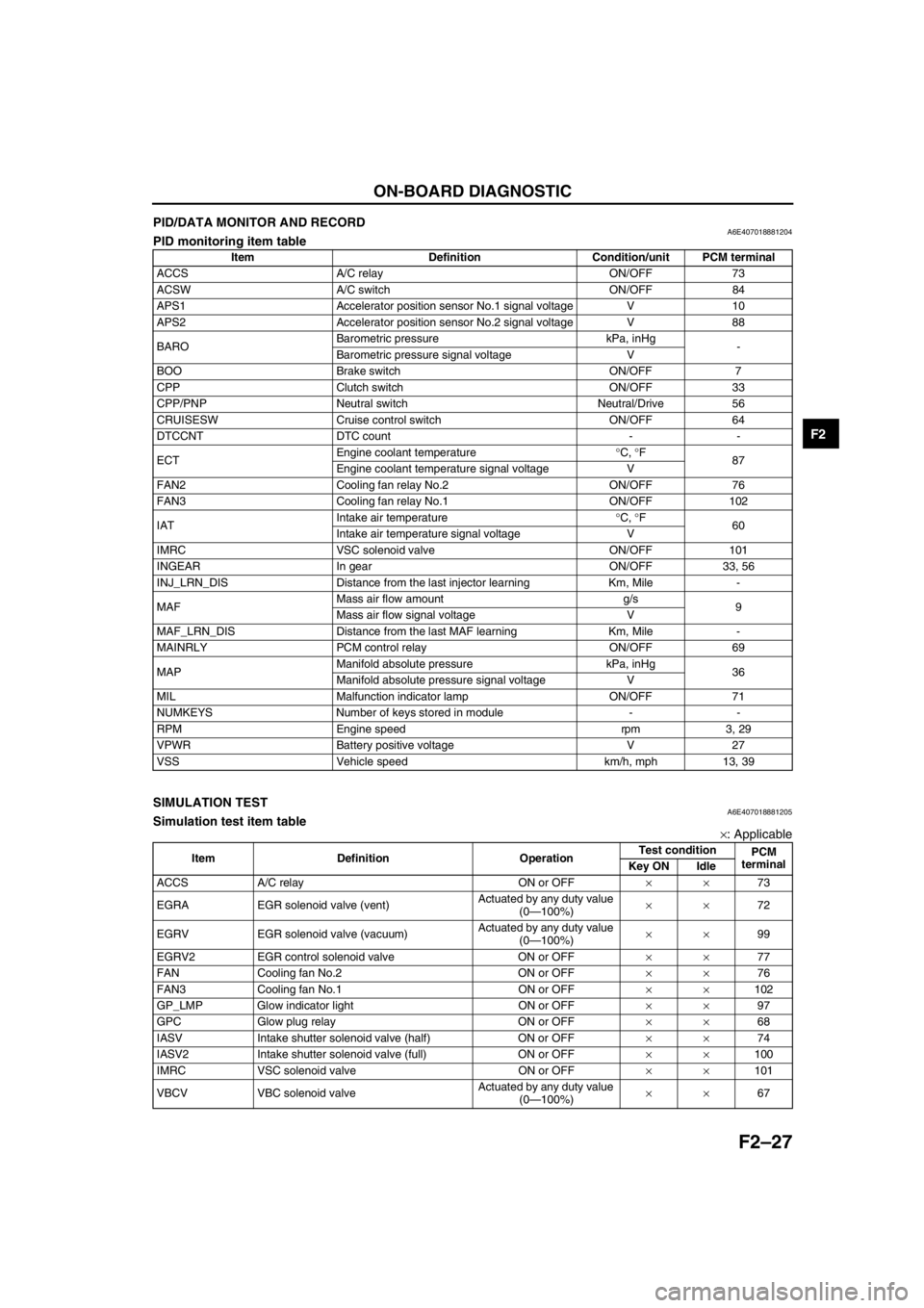

ON-BOARD DIAGNOSTIC

F2–27

F2

PID/DATA MONITOR AND RECORDA6E407018881204PID monitoring item table

End Of Sie

SIMULATION TESTA6E407018881205Simulation test item table

×: Applicable

Item Definition Condition/unit PCM terminal

ACCS A/C relay ON/OFF 73

ACSW A/C switch ON/OFF 84

APS1 Accelerator position sensor No.1 signal voltage V 10

APS2 Accelerator position sensor No.2 signal voltage V 88

BAROBarometric pressure kPa, inHg

-

Barometric pressure signal voltage V

BOO Brake switch ON/OFF 7

CPP Clutch switch ON/OFF 33

CPP/PNP Neutral switch Neutral/Drive 56

CRUISESW Cruise control switch ON/OFF 64

DTCCNT DTC count - -

ECTEngine coolant temperature°C, °F

87

Engine coolant temperature signal voltage V

FAN2 Cooling fan relay No.2 ON/OFF 76

FAN3 Cooling fan relay No.1 ON/OFF 102

IATIntake air temperature°C, °F

60

Intake air temperature signal voltage V

IMRC VSC solenoid valve ON/OFF 101

INGEAR In gear ON/OFF 33, 56

INJ_LRN_DIS Distance from the last injector learning Km, Mile -

MAFMass air flow amount g/s

9

Mass air flow signal voltage V

MAF_LRN_DIS Distance from the last MAF learning Km, Mile -

MAINRLY PCM control relay ON/OFF 69

MAPManifold absolute pressure kPa, inHg

36

Manifold absolute pressure signal voltage V

MIL Malfunction indicator lamp ON/OFF 71

NUMKEYS Number of keys stored in module - -

RPM Engine speed rpm 3, 29

VPWR Battery positive voltage V 27

VSS Vehicle speed km/h, mph 13, 39

Item Definition OperationTest condition

PCM

terminal

Key ON Idle

ACCS A/C relay ON or OFF××73

EGRA EGR solenoid valve (vent)Actuated by any duty value

(0—100%)××72

EGRV EGR solenoid valve (vacuum)Actuated by any duty value

(0—100%)××99

EGRV2 EGR control solenoid valve ON or OFF××77

FAN Cooling fan No.2 ON or OFF××76

FAN3 Cooling fan No.1 ON or OFF××102

GP_LMP Glow indicator light ON or OFF××97

GPC Glow plug relay ON or OFF××68

IASV Intake shutter solenoid valve (half) ON or OFF××74

IASV2 Intake shutter solenoid valve (full) ON or OFF××100

IMRC VSC solenoid valve ON or OFF××101

VBCV VBC solenoid valveActuated by any duty value

(0—100%)××67

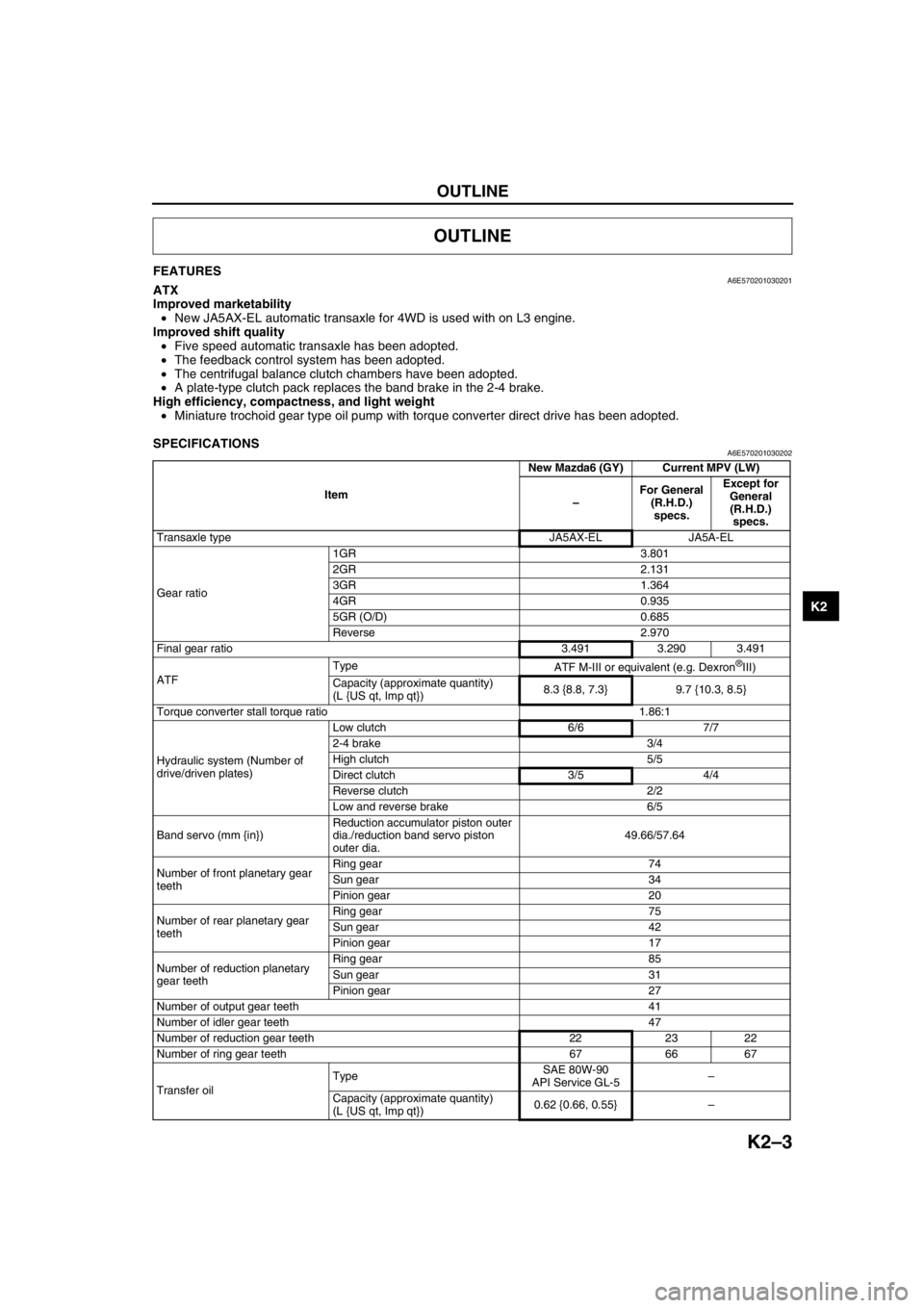

Page 418 of 909

OUTLINE

K2–3

K2

FEATURESA6E570201030201ATX

Improved marketability

•New JA5AX-EL automatic transaxle for 4WD is used with on L3 engine.

Improved shift quality

•Five speed automatic transaxle has been adopted.

•The feedback control system has been adopted.

•The centrifugal balance clutch chambers have been adopted.

•A plate-type clutch pack replaces the band brake in the 2-4 brake.

High efficiency, compactness, and light weight

•Miniature trochoid gear type oil pump with torque converter direct drive has been adopted.

End Of Sie

SPECIFICATIONSA6E570201030202

OUTLINE

ItemNew Mazda6 (GY) Current MPV (LW)

–For General

(R.H.D.)

specs.Except for

General

(R.H.D.)

specs.

Transaxle type JA5AX-EL JA5A-EL

Gear ratio1GR 3.801

2GR 2.131

3GR 1.364

4GR 0.935

5GR (O/D) 0.685

Reverse 2.970

Final gear ratio 3.491 3.290 3.491

ATFType

ATF M-III or equivalent (e.g. Dexron

®III)

Capacity (approximate quantity)

(L {US qt, Imp qt})8.3 {8.8, 7.3} 9.7 {10.3, 8.5}

Torque converter stall torque ratio 1.86:1

Hydraulic system (Number of

drive/driven plates)Low clutch 6/6 7/7

2-4 brake 3/4

High clutch 5/5

Direct clutch 3/5 4/4

Reverse clutch 2/2

Low and reverse brake 6/5

Band servo (mm {in})Reduction accumulator piston outer

dia./reduction band servo piston

outer dia.49.66/57.64

Number of front planetary gear

teethRing gear 74

Sun gear 34

Pinion gear 20

Number of rear planetary gear

teethRing gear 75

Sun gear 42

Pinion gear 17

Number of reduction planetary

gear teethRing gear 85

Sun gear 31

Pinion gear 27

Number of output gear teeth 41

Number of idler gear teeth 47

Number of reduction gear teeth 22 23 22

Number of ring gear teeth 67 66 67

Transfer oilTypeSAE 80W-90

API Service GL-5–

Capacity (approximate quantity)

(L {US qt, Imp qt})0.62 {0.66, 0.55}–

Page 423 of 909

K2–8

AUTOMATIC TRANSAXLE

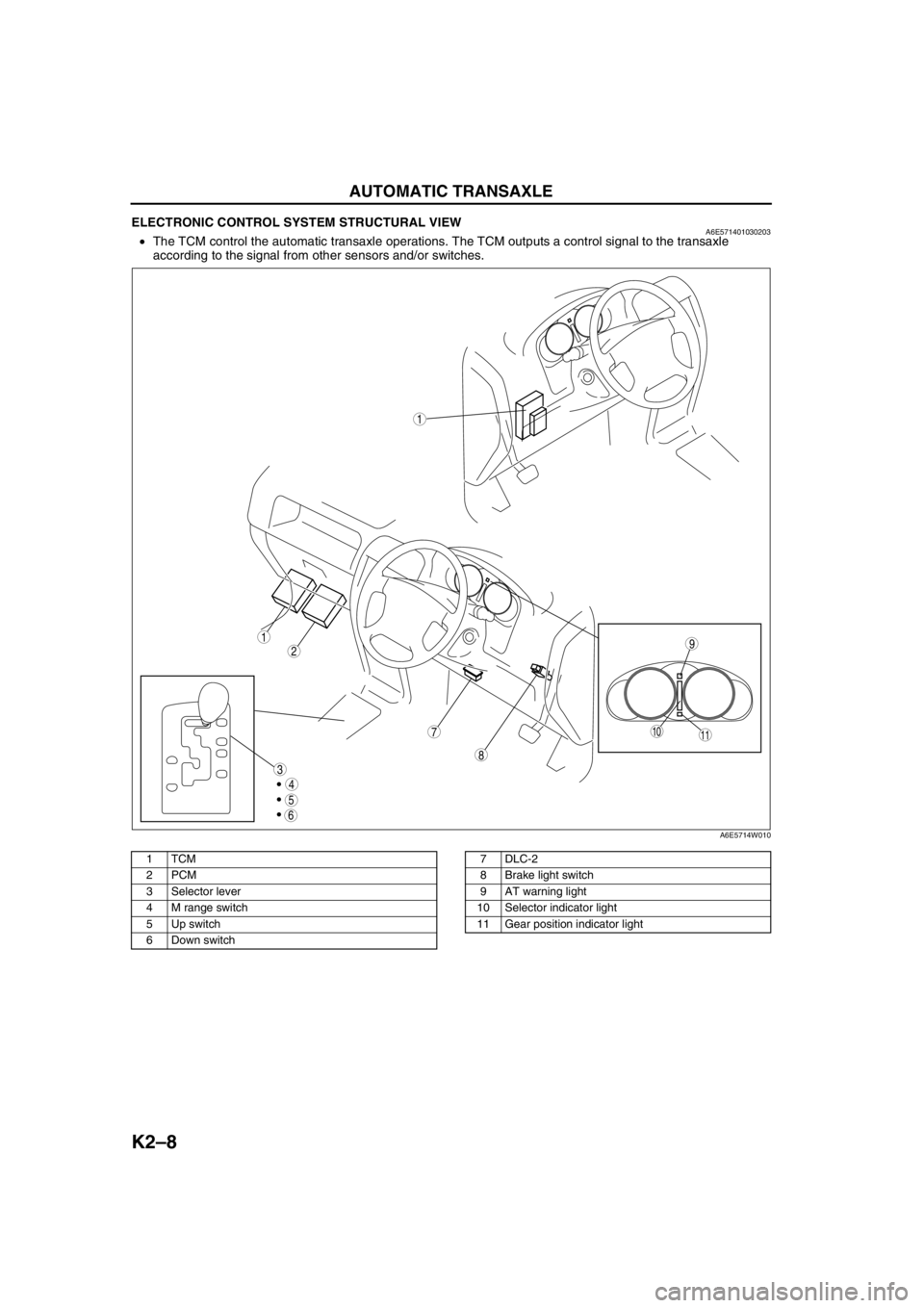

ELECTRONIC CONTROL SYSTEM STRUCTURAL VIEWA6E571401030203•The TCM control the automatic transaxle operations. The TCM outputs a control signal to the transaxle

according to the signal from other sensors and/or switches.

.

9

8

7

5

4

3

1

2

1011

6

1

A6E5714W010

1TCM

2PCM

3Selector lever

4 M range switch

5 Up switch

6 Down switch7DLC-2

8 Brake light switch

9 AT warning light

10 Selector indicator light

11 Gear position indicator light

Page 426 of 909

AUTOMATIC TRANSAXLE

K2–11

K2

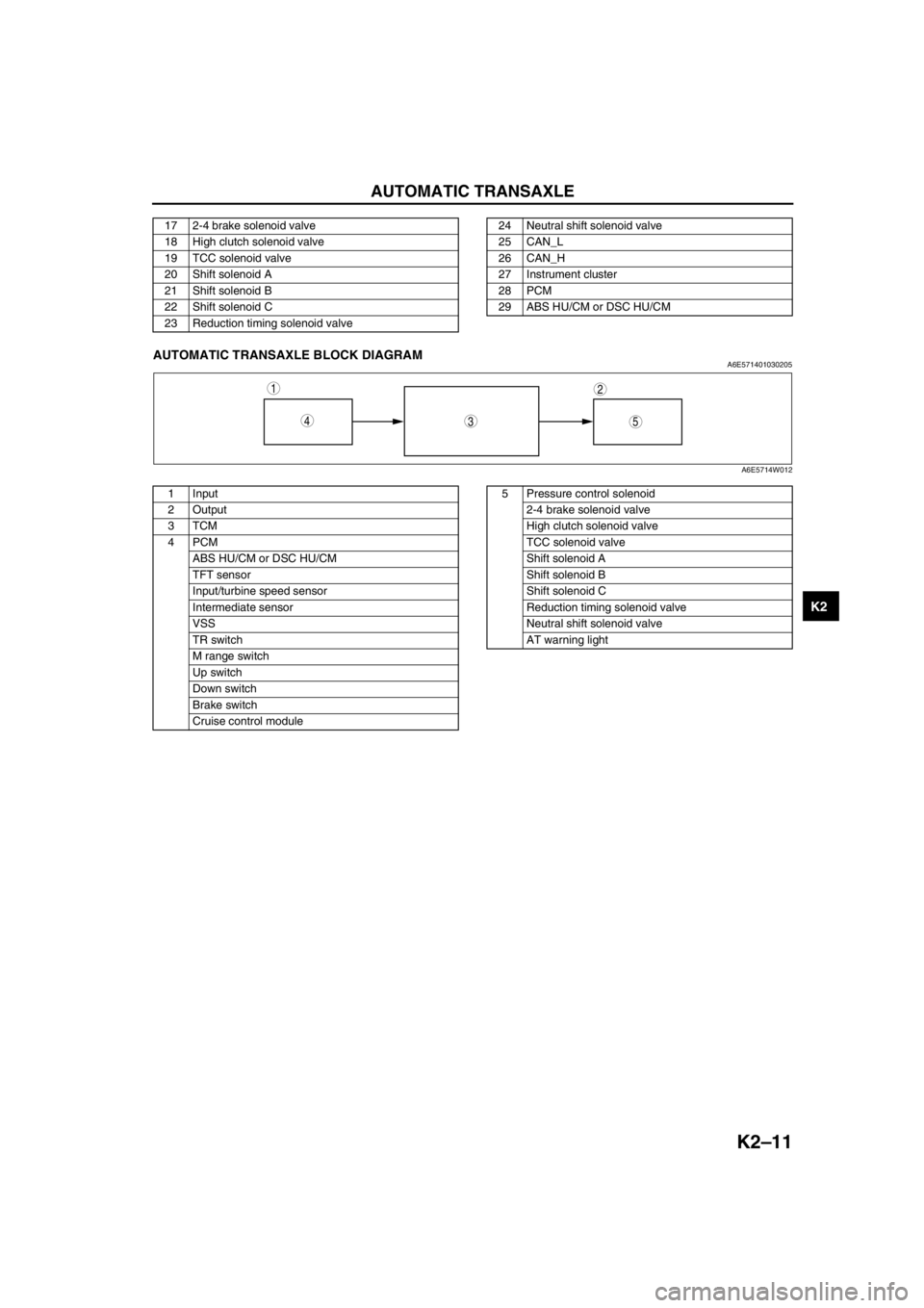

End Of SieAUTOMATIC TRANSAXLE BLOCK DIAGRAMA6E571401030205

.

17 2-4 brake solenoid valve

18 High clutch solenoid valve

19 TCC solenoid valve

20 Shift solenoid A

21 Shift solenoid B

22 Shift solenoid C

23 Reduction timing solenoid valve24 Neutral shift solenoid valve

25 CAN_L

26 CAN_H

27 Instrument cluster

28 PCM

29 ABS HU/CM or DSC HU/CM

543

12

A6E5714W012

1 Input

2Output

3TCM

4PCM

ABS HU/CM or DSC HU/CM

TFT sensor

Input/turbine speed sensor

Intermediate sensor

VSS

TR switch

M range switch

Up switch

Down switch

Brake switch

Cruise control module5 Pressure control solenoid

2-4 brake solenoid valve

High clutch solenoid valve

TCC solenoid valve

Shift solenoid A

Shift solenoid B

Shift solenoid C

Reduction timing solenoid valve

Neutral shift solenoid valve

AT warning light

Page 428 of 909

AUTOMATIC TRANSAXLE

K2–13

K2

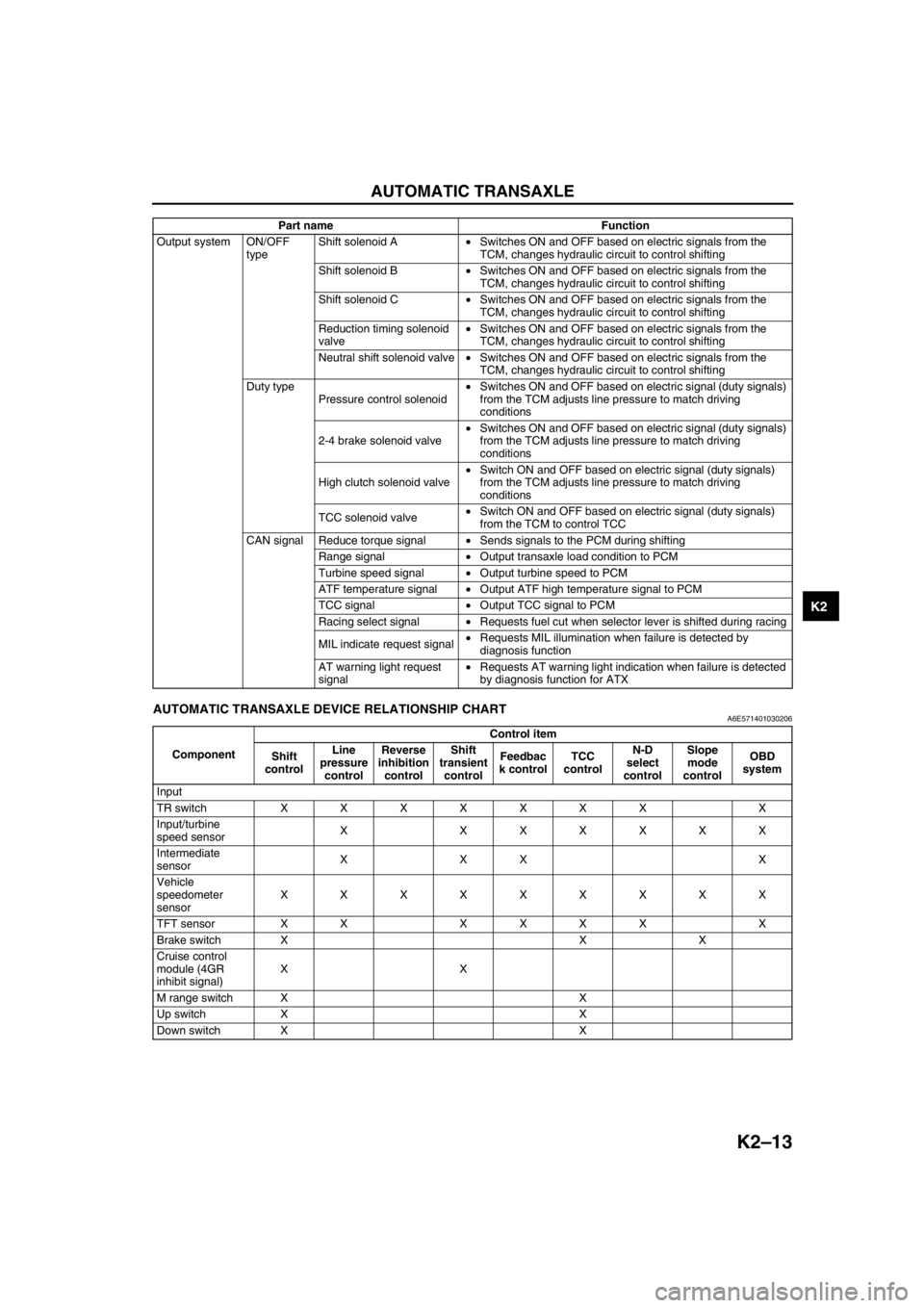

End Of SieAUTOMATIC TRANSAXLE DEVICE RELATIONSHIP CHARTA6E571401030206

Output system ON/OFF

typeShift solenoid A•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Shift solenoid B•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Shift solenoid C•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Reduction timing solenoid

valve•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Neutral shift solenoid valve•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Duty type

Pressure control solenoid•Switches ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

2-4 brake solenoid valve•Switches ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

High clutch solenoid valve•Switch ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

TCC solenoid valve•Switch ON and OFF based on electric signal (duty signals)

from the TCM to control TCC

CAN signal Reduce torque signal•Sends signals to the PCM during shifting

Range signal•Output transaxle load condition to PCM

Turbine speed signal•Output turbine speed to PCM

ATF temperature signal•Output ATF high temperature signal to PCM

TCC signal•Output TCC signal to PCM

Racing select signal•Requests fuel cut when selector lever is shifted during racing

MIL indicate request signal•Requests MIL illumination when failure is detected by

diagnosis function

AT warning light request

signal•Requests AT warning light indication when failure is detected

by diagnosis function for ATX Part name Function

ComponentControl item

Shift

controlLine

pressure

controlReverse

inhibition

controlShift

transient

controlFeedbac

k controlTCC

controlN-D

select

controlSlope

mode

controlOBD

system

Input

TR switch XXXXXXX X

Input/turbine

speed sensorX XXXXXX

Intermediate

sensorXXX X

Vehicle

speedometer

sensorXXXXXXXXX

TFT sensor XX XXXX X

Brake switch X X X

Cruise control

module (4GR

inhibit signal)XX

M range switch X X

Up switch X X

Down switch X X