brake light MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 430 of 909

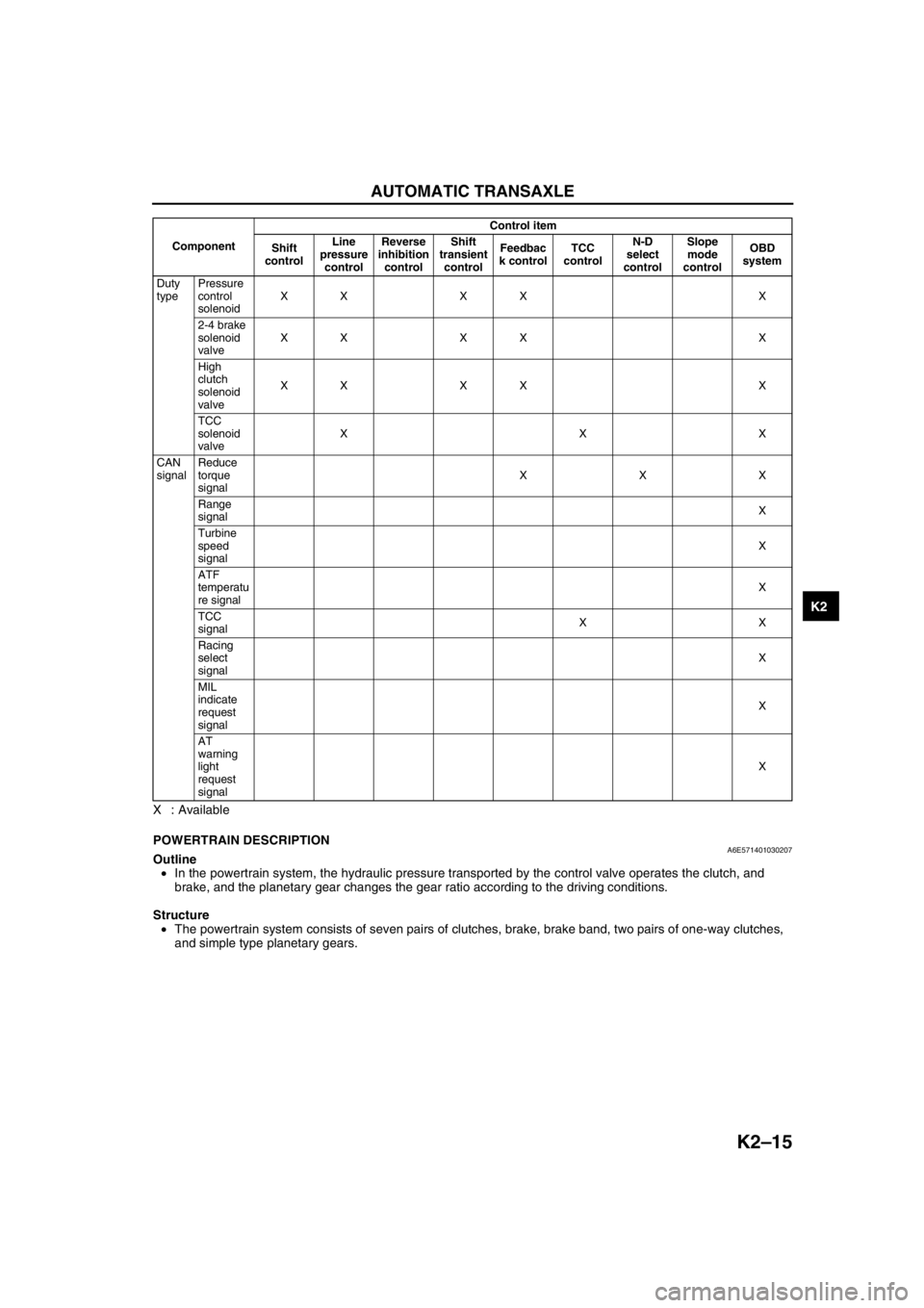

AUTOMATIC TRANSAXLE

K2–15

K2

X : Available

End Of SiePOWERTRAIN DESCRIPTIONA6E571401030207Outline

•In the powertrain system, the hydraulic pressure transported by the control valve operates the clutch, and

brake, and the planetary gear changes the gear ratio according to the driving conditions.

Structure

•The powertrain system consists of seven pairs of clutches, brake, brake band, two pairs of one-way clutches,

and simple type planetary gears.

Duty

typePressure

control

solenoidXX XX X

2-4 brake

solenoid

valveXX XX X

High

clutch

solenoid

valveXX XX X

TCC

solenoid

valveXXX

CAN

signalReduce

torque

signalXXX

Range

signalX

Turbine

speed

signalX

ATF

temperatu

re signalX

TCC

signalXX

Racing

select

signalX

MIL

indicate

request

signalX

AT

warning

light

request

signalX ComponentControl item

Shift

controlLine

pressure

controlReverse

inhibition

controlShift

transient

controlFeedbac

k controlTCC

controlN-D

select

controlSlope

mode

controlOBD

system

Page 480 of 909

AUTOMATIC TRANSAXLE

K2–65

K2

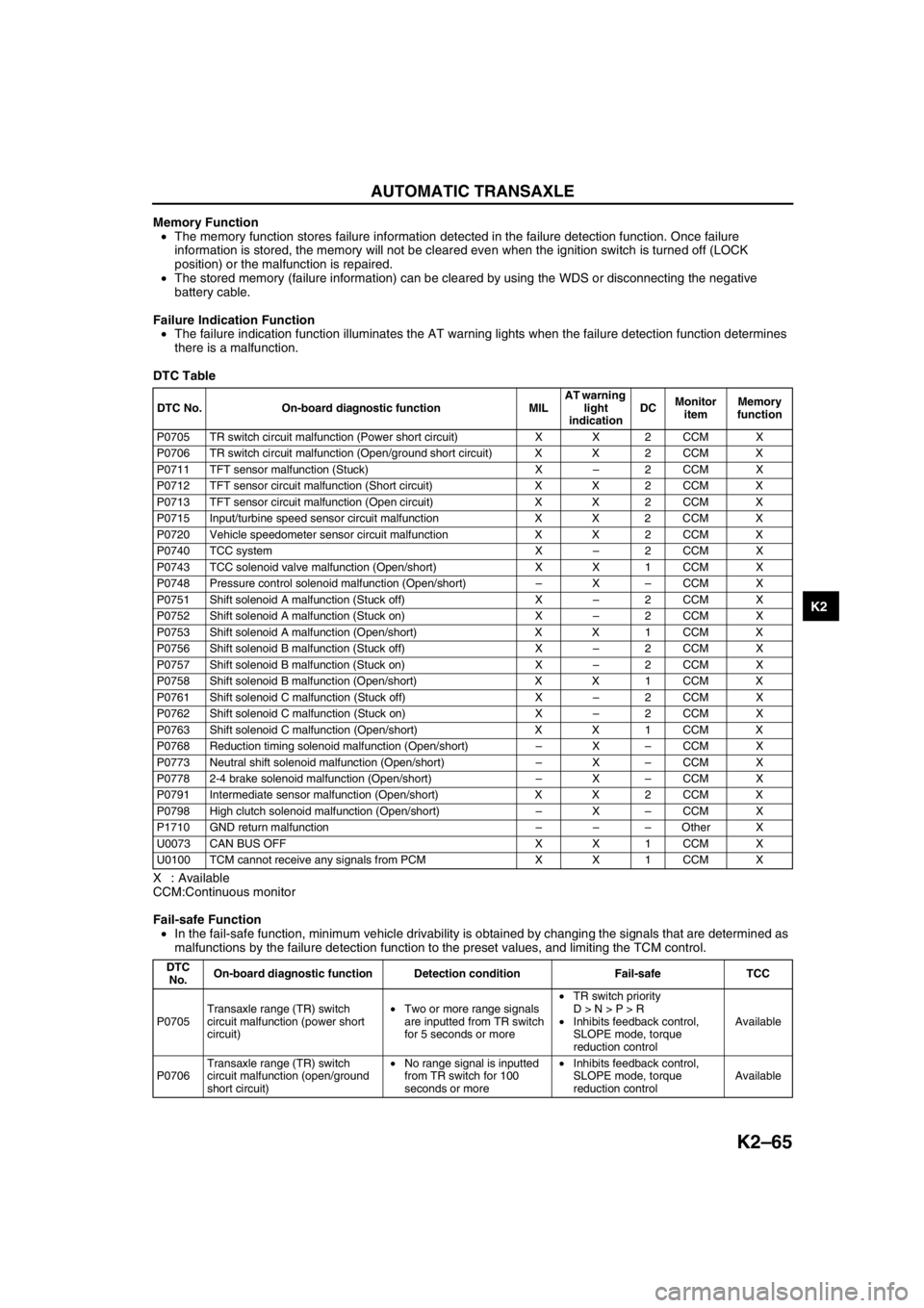

Memory Function

•The memory function stores failure information detected in the failure detection function. Once failure

information is stored, the memory will not be cleared even when the ignition switch is turned off (LOCK

position) or the malfunction is repaired.

•The stored memory (failure information) can be cleared by using the WDS or disconnecting the negative

battery cable.

Failure Indication Function

•The failure indication function illuminates the AT warning lights when the failure detection function determines

there is a malfunction.

DTC Table

X : Available

CCM:Continuous monitor

Fail-safe Function

•In the fail-safe function, minimum vehicle drivability is obtained by changing the signals that are determined as

malfunctions by the failure detection function to the preset values, and limiting the TCM control.

DTC No. On-board diagnostic function MILAT warning

light

indicationDCMonitor

itemMemory

function

P0705 TR switch circuit malfunction (Power short circuit) X X 2 CCM X

P0706 TR switch circuit malfunction (Open/ground short circuit) X X 2 CCM X

P0711 TFT sensor malfunction (Stuck) X–2 CCM X

P0712 TFT sensor circuit malfunction (Short circuit) X X 2 CCM X

P0713 TFT sensor circuit malfunction (Open circuit) X X 2 CCM X

P0715 Input/turbine speed sensor circuit malfunction X X 2 CCM X

P0720 Vehicle speedometer sensor circuit malfunction X X 2 CCM X

P0740 TCC system X–2 CCM X

P0743 TCC solenoid valve malfunction (Open/short) X X 1 CCM X

P0748 Pressure control solenoid malfunction (Open/short)–X–CCM X

P0751 Shift solenoid A malfunction (Stuck off) X–2 CCM X

P0752 Shift solenoid A malfunction (Stuck on) X–2 CCM X

P0753 Shift solenoid A malfunction (Open/short) X X 1 CCM X

P0756 Shift solenoid B malfunction (Stuck off) X–2 CCM X

P0757 Shift solenoid B malfunction (Stuck on) X–2 CCM X

P0758 Shift solenoid B malfunction (Open/short) X X 1 CCM X

P0761 Shift solenoid C malfunction (Stuck off) X–2 CCM X

P0762 Shift solenoid C malfunction (Stuck on) X–2 CCM X

P0763 Shift solenoid C malfunction (Open/short) X X 1 CCM X

P0768 Reduction timing solenoid malfunction (Open/short)–X–CCM X

P0773 Neutral shift solenoid malfunction (Open/short)–X–CCM X

P0778 2-4 brake solenoid malfunction (Open/short)–X–CCM X

P0791 Intermediate sensor malfunction (Open/short) X X 2 CCM X

P0798 High clutch solenoid malfunction (Open/short)–X–CCM X

P1710 GND return malfunction–––Other X

U0073 CAN BUS OFF X X 1 CCM X

U0100 TCM cannot receive any signals from PCM X X 1 CCM X

DTC

No.On-board diagnostic function Detection condition Fail-safe TCC

P0705Transaxle range (TR) switch

circuit malfunction (power short

circuit)•Two or more range signals

are inputted from TR switch

for 5 seconds or more•TR switch priority

D > N > P > R

•Inhibits feedback control,

SLOPE mode, torque

reduction controlAvailable

P0706Transaxle range (TR) switch

circuit malfunction (open/ground

short circuit)•No range signal is inputted

from TR switch for 100

seconds or more•Inhibits feedback control,

SLOPE mode, torque

reduction controlAvailable

Page 483 of 909

K2–68

AUTOMATIC TRANSAXLE

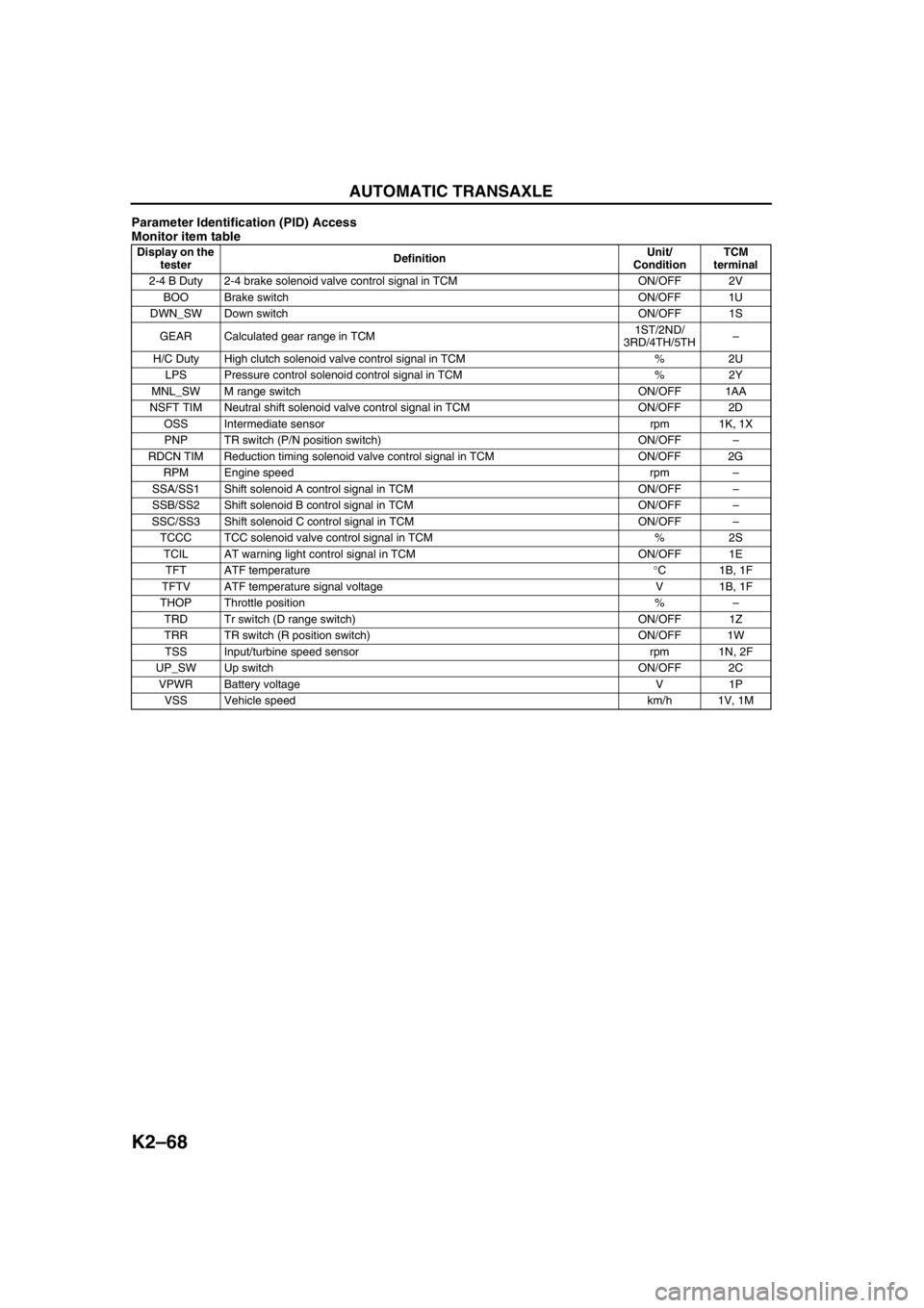

Parameter Identification (PID) Access

Monitor item table

End Of Sie

Display on the

testerDefinitionUnit/

ConditionTCM

terminal

2-4 B Duty 2-4 brake solenoid valve control signal in TCM ON/OFF 2V

BOO Brake switch ON/OFF 1U

DWN_SW Down switch ON/OFF 1S

GEAR Calculated gear range in TCM1ST/2ND/

3RD/4TH/5TH–

H/C Duty High clutch solenoid valve control signal in TCM % 2U

LPS Pressure control solenoid control signal in TCM % 2Y

MNL_SW M range switch ON/OFF 1AA

NSFT TIM Neutral shift solenoid valve control signal in TCM ON/OFF 2D

OSS Intermediate sensor rpm 1K, 1X

PNP TR switch (P/N position switch) ON/OFF–

RDCN TIM Reduction timing solenoid valve control signal in TCM ON/OFF 2G

RPM Engine speed rpm–

SSA/SS1 Shift solenoid A control signal in TCM ON/OFF–

SSB/SS2 Shift solenoid B control signal in TCM ON/OFF–

SSC/SS3 Shift solenoid C control signal in TCM ON/OFF–

TCCC TCC solenoid valve control signal in TCM % 2S

TCIL AT warning light control signal in TCM ON/OFF 1E

TFT ATF temperature°C1B, 1F

TFTV ATF temperature signal voltage V 1B, 1F

THOP Throttle position %–

TRD Tr switch (D range switch) ON/OFF 1Z

TRR TR switch (R position switch) ON/OFF 1W

TSS Input/turbine speed sensor rpm 1N, 2F

UP_SW Up switch ON/OFF 2C

VPWR Battery voltage V 1P

VSS Vehicle speed km/h 1V, 1M

Page 493 of 909

K2–78

AUTOMATIC TRANSAXLE

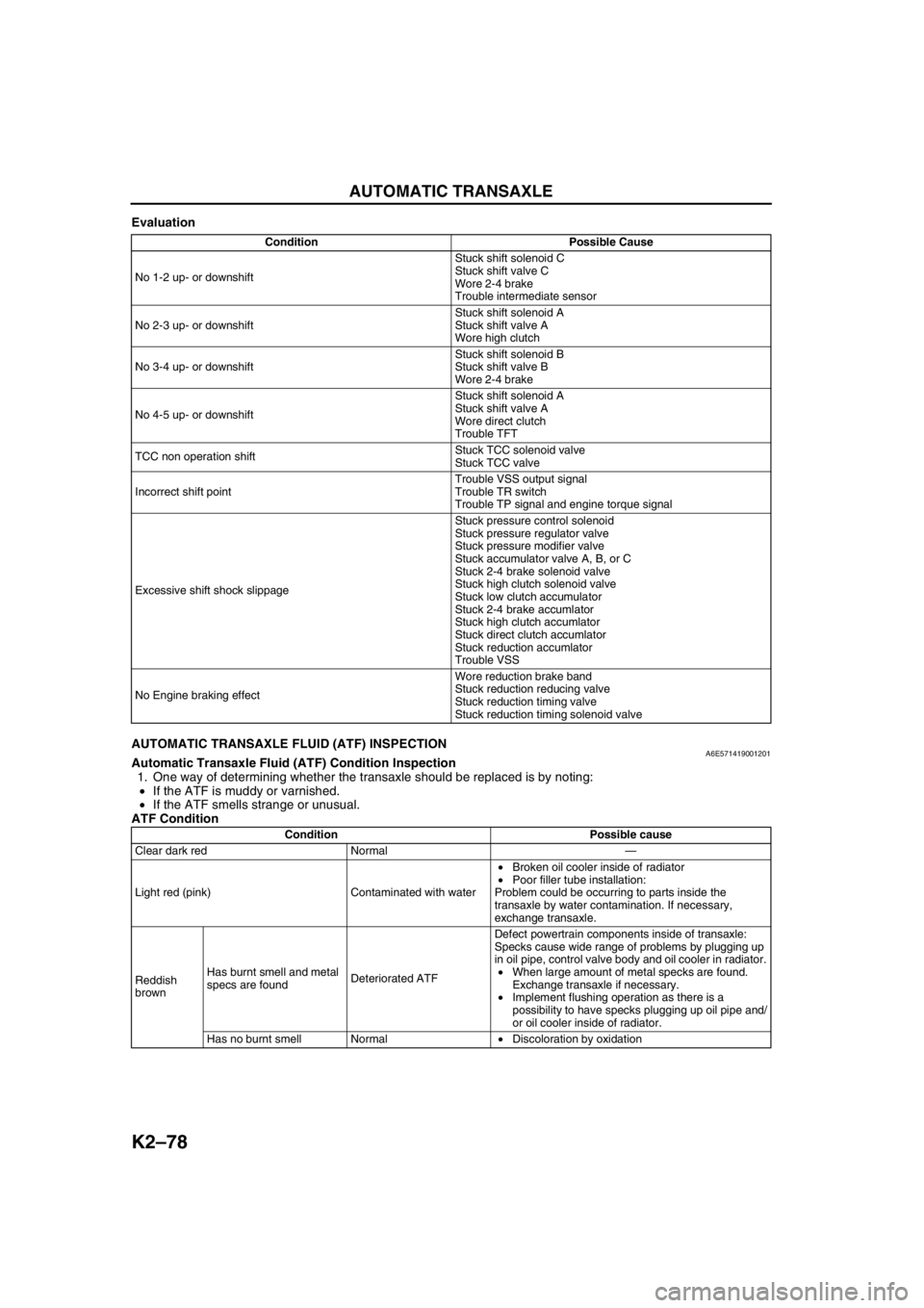

Evaluation

End Of SieAUTOMATIC TRANSAXLE FLUID (ATF) INSPECTIONA6E571419001201Automatic Transaxle Fluid (ATF) Condition Inspection

1. One way of determining whether the transaxle should be replaced is by noting:

•If the ATF is muddy or varnished.

•If the ATF smells strange or unusual.

ATF Condition

Condition Possible Cause

No 1-2 up- or downshiftStuck shift solenoid C

Stuck shift valve C

Wore 2-4 brake

Trouble intermediate sensor

No 2-3 up- or downshiftStuck shift solenoid A

Stuck shift valve A

Wore high clutch

No 3-4 up- or downshiftStuck shift solenoid B

Stuck shift valve B

Wore 2-4 brake

No 4-5 up- or downshiftStuck shift solenoid A

Stuck shift valve A

Wore direct clutch

Trouble TFT

TCC non operation shiftStuck TCC solenoid valve

Stuck TCC valve

Incorrect shift pointTrouble VSS output signal

Trouble TR switch

Trouble TP signal and engine torque signal

Excessive shift shock slippageStuck pressure control solenoid

Stuck pressure regulator valve

Stuck pressure modifier valve

Stuck accumulator valve A, B, or C

Stuck 2-4 brake solenoid valve

Stuck high clutch solenoid valve

Stuck low clutch accumulator

Stuck 2-4 brake accumlator

Stuck high clutch accumlator

Stuck direct clutch accumlator

Stuck reduction accumlator

Trouble VSS

No Engine braking effect Wore reduction brake band

Stuck reduction reducing valve

Stuck reduction timing valve

Stuck reduction timing solenoid valve

Condition Possible cause

Clear dark red Normal—

Light red (pink) Contaminated with water•Broken oil cooler inside of radiator

•Poor filler tube installation:

Problem could be occurring to parts inside the

transaxle by water contamination. If necessary,

exchange transaxle.

Reddish

brownHas burnt smell and metal

specs are foundDeteriorated ATFDefect powertrain components inside of transaxle:

Specks cause wide range of problems by plugging up

in oil pipe, control valve body and oil cooler in radiator.

•When large amount of metal specks are found.

Exchange transaxle if necessary.

•Implement flushing operation as there is a

possibility to have specks plugging up oil pipe and/

or oil cooler inside of radiator.

Has no burnt smell Normal•Discoloration by oxidation

Page 532 of 909

AUTOMATIC TRANSAXLE SHIFT MECHANISM

K2–117

K2

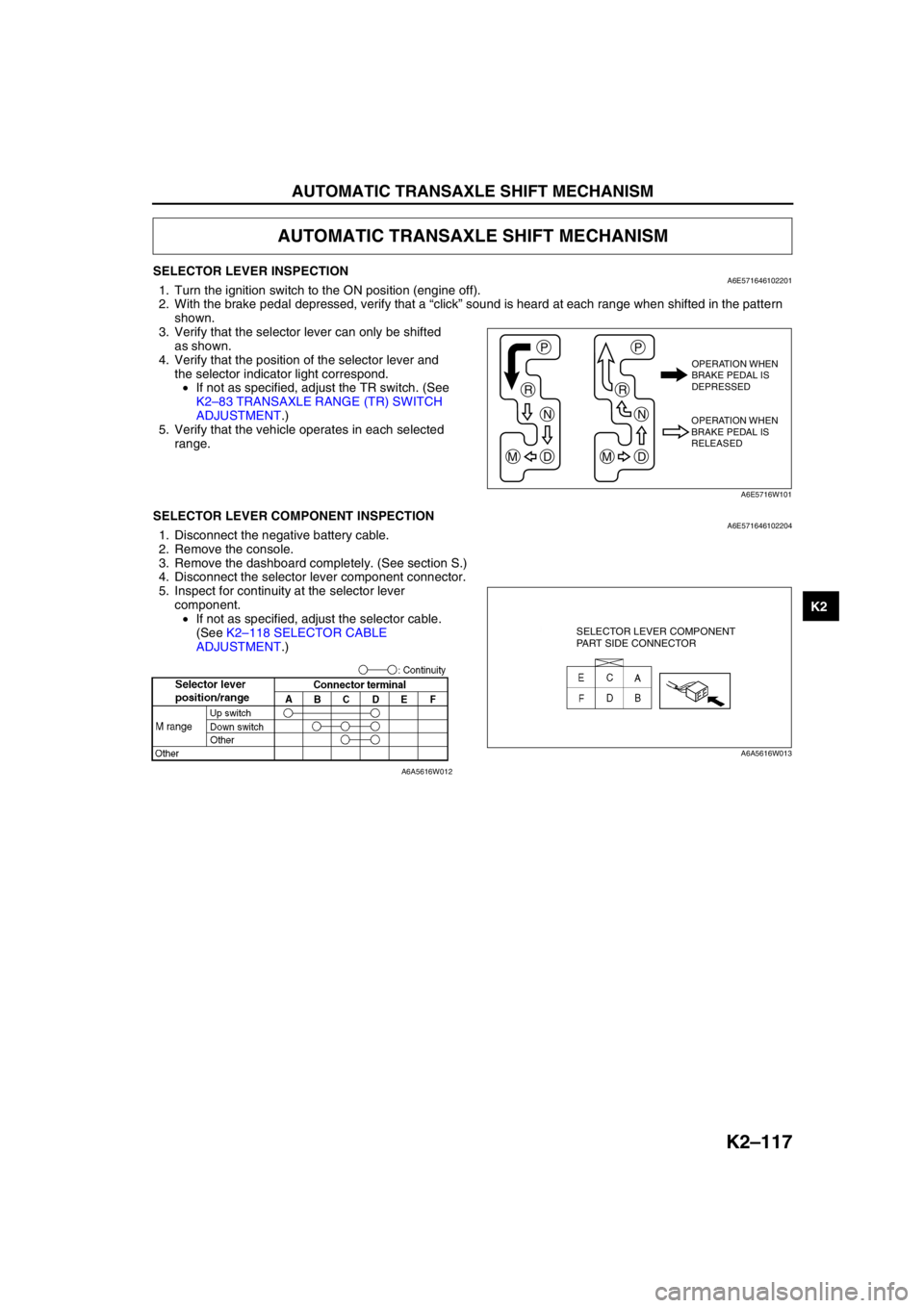

SELECTOR LEVER INSPECTIONA6E5716461022011. Turn the ignition switch to the ON position (engine off).

2. With the brake pedal depressed, verify that a “click” sound is heard at each range when shifted in the pattern

shown.

3. Verify that the selector lever can only be shifted

as shown.

4. Verify that the position of the selector lever and

the selector indicator light correspond.

•If not as specified, adjust the TR switch. (See

K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT.)

5. Verify that the vehicle operates in each selected

range.

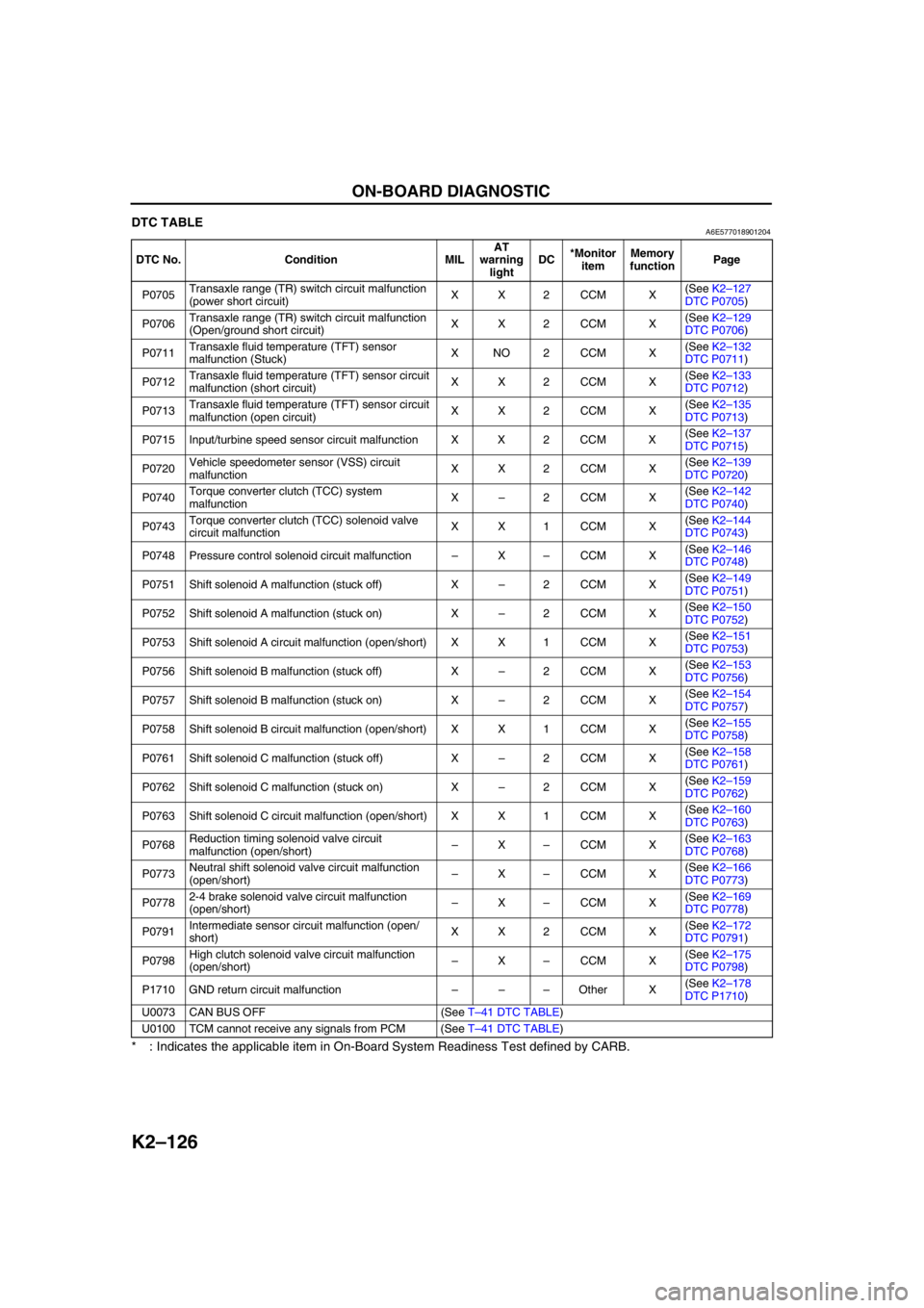

End Of SieSELECTOR LEVER COMPONENT INSPECTIONA6E5716461022041. Disconnect the negative battery cable.

2. Remove the console.

3. Remove the dashboard completely. (See section S.)

4. Disconnect the selector lever component connector.

5. Inspect for continuity at the selector lever

component.

•If not as specified, adjust the selector cable.

(See K2–118 SELECTOR CABLE

ADJUSTMENT.)

End Of Sie

AUTOMATIC TRANSAXLE SHIFT MECHANISM

P

R

N

DM

P

R

N

DM

OPERATION WHEN

BRAKE PEDAL IS

DEPRESSED

OPERATION WHEN

BRAKE PEDAL IS

RELEASED

A6E5716W101

SELECTOR LEVER COMPONENT

PART SIDE CONNECTOR

A6A5616W013

A6A5616W012

Page 541 of 909

K2–126

ON-BOARD DIAGNOSTIC

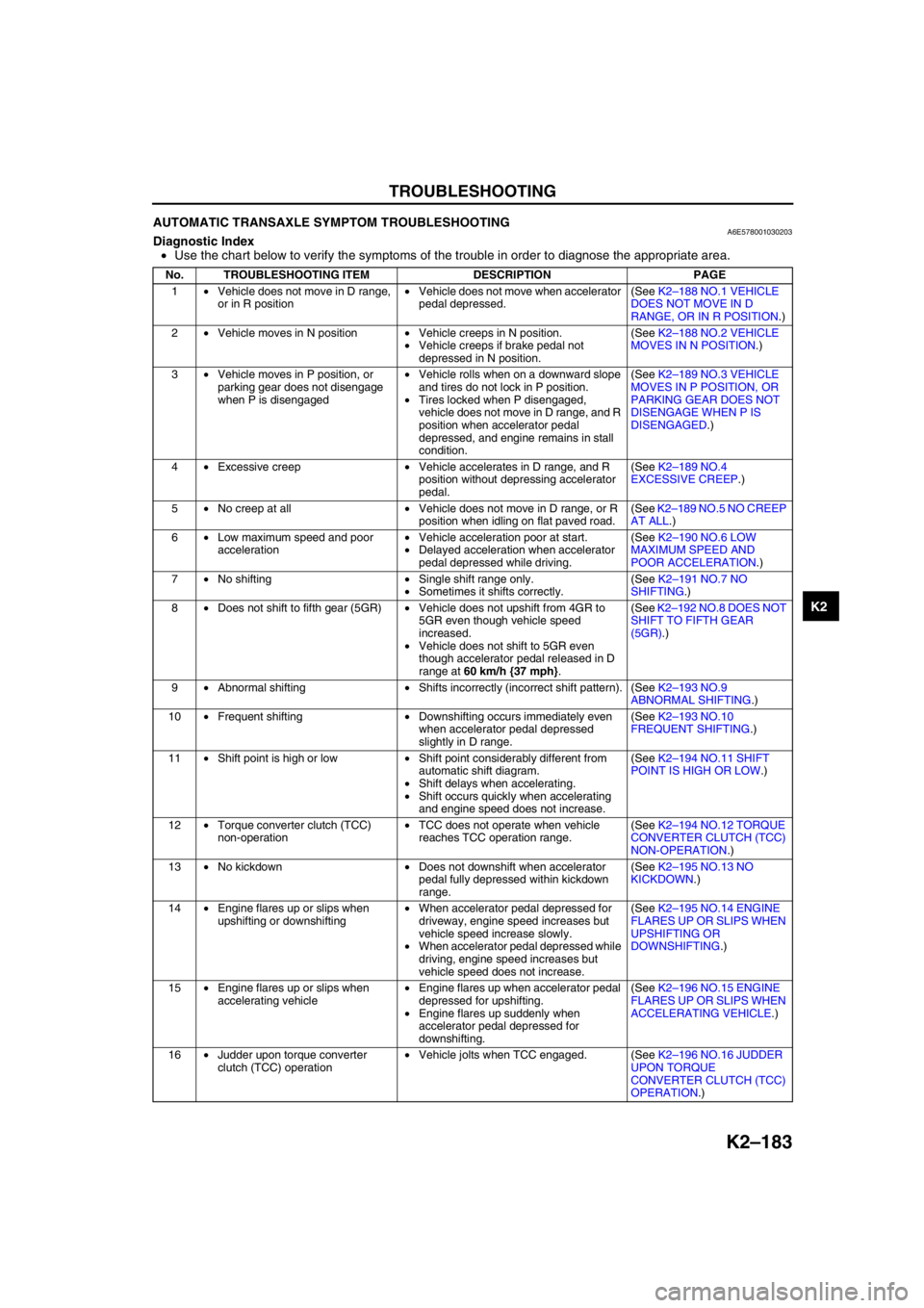

DTC TABLEA6E577018901204

* : Indicates the applicable item in On-Board System Readiness Test defined by CARB.

End Of Sie

DTC No. Condition MILAT

warning

lightDC*Monitor

itemMemory

functionPage

P0705Transaxle range (TR) switch circuit malfunction

(power short circuit)XX2CCM X(See K2–127

DTC P0705)

P0706Transaxle range (TR) switch circuit malfunction

(Open/ground short circuit)XX2CCM X(See K2–129

DTC P0706)

P0711Transaxle fluid temperature (TFT) sensor

malfunction (Stuck)XNO2CCM X(See K2–132

DTC P0711)

P0712Transaxle fluid temperature (TFT) sensor circuit

malfunction (short circuit)XX2CCM X(See K2–133

DTC P0712)

P0713Transaxle fluid temperature (TFT) sensor circuit

malfunction (open circuit)XX2CCM X(See K2–135

DTC P0713)

P0715 Input/turbine speed sensor circuit malfunction X X 2 CCM X(See K2–137

DTC P0715)

P0720Vehicle speedometer sensor (VSS) circuit

malfunctionXX2CCM X(See K2–139

DTC P0720)

P0740Torque converter clutch (TCC) system

malfunctionX–2CCM X(See K2–142

DTC P0740)

P0743Torque converter clutch (TCC) solenoid valve

circuit malfunctionXX1CCM X(See K2–144

DTC P0743)

P0748 Pressure control solenoid circuit malfunction–X–CCM X(See K2–146

DTC P0748)

P0751 Shift solenoid A malfunction (stuck off) X–2CCM X(See K2–149

DTC P0751)

P0752 Shift solenoid A malfunction (stuck on) X–2CCM X(See K2–150

DTC P0752)

P0753 Shift solenoid A circuit malfunction (open/short) X X 1 CCM X(See K2–151

DTC P0753)

P0756 Shift solenoid B malfunction (stuck off) X–2CCM X(See K2–153

DTC P0756)

P0757 Shift solenoid B malfunction (stuck on) X–2CCM X(See K2–154

DTC P0757)

P0758 Shift solenoid B circuit malfunction (open/short) X X 1 CCM X(See K2–155

DTC P0758)

P0761 Shift solenoid C malfunction (stuck off) X–2CCM X(See K2–158

DTC P0761)

P0762 Shift solenoid C malfunction (stuck on) X–2CCM X(See K2–159

DTC P0762)

P0763 Shift solenoid C circuit malfunction (open/short) X X 1 CCM X(See K2–160

DTC P0763)

P0768Reduction timing solenoid valve circuit

malfunction (open/short)–X–CCM X(See K2–163

DTC P0768)

P0773Neutral shift solenoid valve circuit malfunction

(open/short)–X–CCM X(See K2–166

DTC P0773)

P07782-4 brake solenoid valve circuit malfunction

(open/short)–X–CCM X(See K2–169

DTC P0778)

P0791Intermediate sensor circuit malfunction (open/

short)XX2CCM X(See K2–172

DTC P0791)

P0798High clutch solenoid valve circuit malfunction

(open/short)–X–CCM X(See K2–175

DTC P0798)

P1710 GND return circuit malfunction–––Other X(See K2–178

DTC P1710)

U0073 CAN BUS OFF (See T–41 DTC TABLE)

U0100 TCM cannot receive any signals from PCM (See T–41 DTC TABLE)

Page 584 of 909

ON-BOARD DIAGNOSTIC

K2–169

K2

DTC P0778A6E577018901226

DTC P0778 2-4 brake solenoid valve circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in 2-4 brake solenoid signal system (while TCM monitors solenoid output voltage, the

voltage that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL does not illuminates.

•PENDING CODE is not available.

•FREEZE FRAME DATA is not available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between 2-4 brake solenoid valve terminal A and TCM terminal 2V

•Short to ground between 2-4 brake solenoid valve terminal A and TCM terminal 2V

•Short to power between 2-4 brake solenoid valve terminal A and TCM terminal 2V

•2-4 brake solenoid valve malfunction

•Damaged connector between 2-4 brake solenoid valve and TCM

•TCM malfunction

CPU

CPU2V

A

D

A

A J 2PB TCM

AT X

TCM

HARNESS SIDE CONNECTORTERMINAL COMPONENT

NO.1(12-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(10-PIN)

PART SIDE CONNECTOR2-4 BRAKE

SOLENOID VALVE

2-4 BRAKE

SOLENOID VALVE

HARNESS SIDE CONNECTOR

Page 598 of 909

TROUBLESHOOTING

K2–183

K2

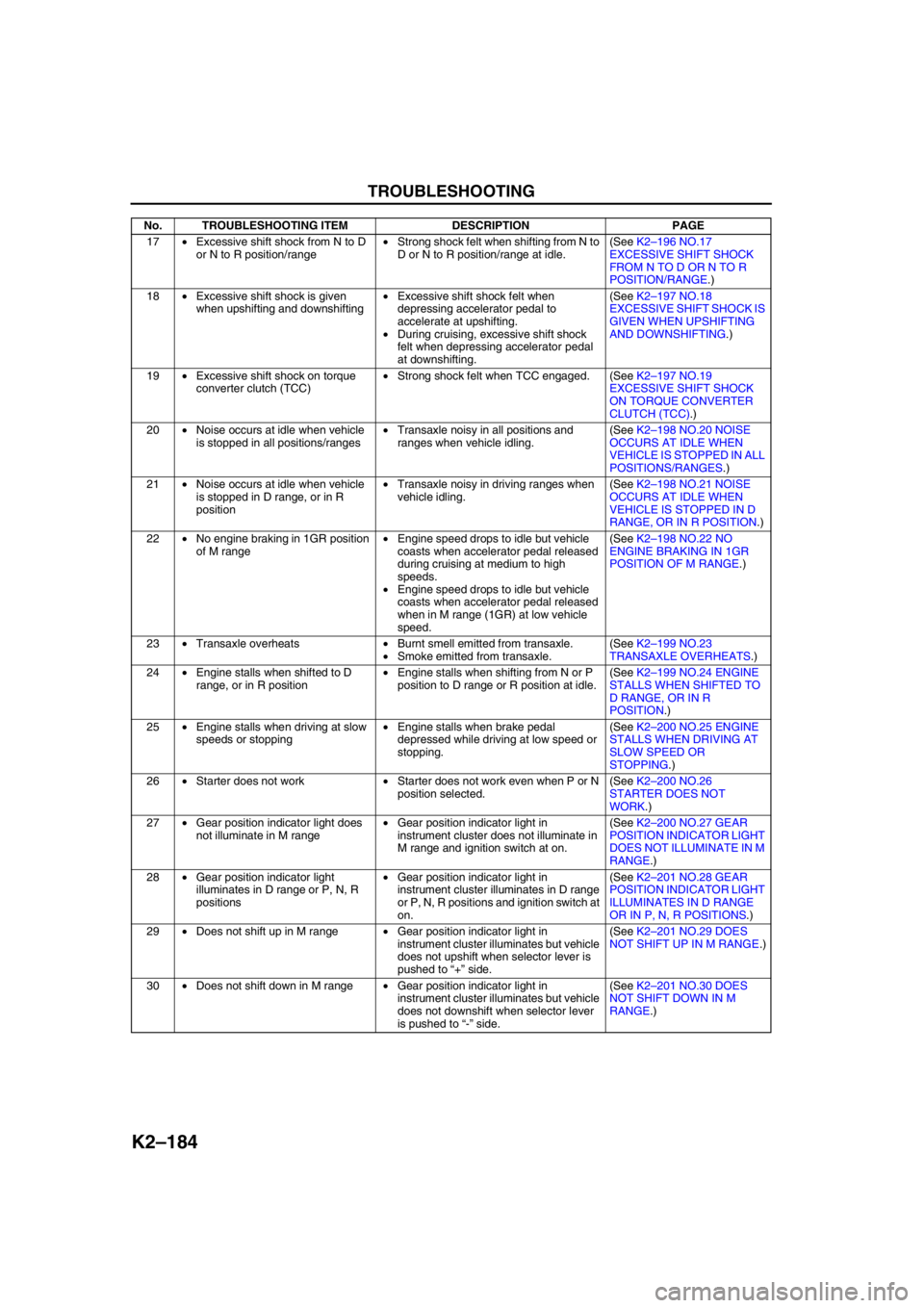

AUTOMATIC TRANSAXLE SYMPTOM TROUBLESHOOTINGA6E578001030203Diagnostic Index

•Use the chart below to verify the symptoms of the trouble in order to diagnose the appropriate area.

No. TROUBLESHOOTING ITEM DESCRIPTION PAGE

1•Vehicle does not move in D range,

or in R position•Vehicle does not move when accelerator

pedal depressed.(See K2–188 NO.1 VEHICLE

DOES NOT MOVE IN D

RANGE, OR IN R POSITION.)

2•Vehicle moves in N position•Vehicle creeps in N position.

•Vehicle creeps if brake pedal not

depressed in N position.(See K2–188 NO.2 VEHICLE

MOVES IN N POSITION.)

3•Vehicle moves in P position, or

parking gear does not disengage

when P is disengaged•Vehicle rolls when on a downward slope

and tires do not lock in P position.

•Tires locked when P disengaged,

vehicle does not move in D range, and R

position when accelerator pedal

depressed, and engine remains in stall

condition.(See K2–189 NO.3 VEHICLE

MOVES IN P POSITION, OR

PARKING GEAR DOES NOT

DISENGAGE WHEN P IS

DISENGAGED.)

4•Excessive creep•Vehicle accelerates in D range, and R

position without depressing accelerator

pedal.(See K2–189 NO.4

EXCESSIVE CREEP.)

5•No creep at all•Vehicle does not move in D range, or R

position when idling on flat paved road.(See K2–189 NO.5 NO CREEP

AT ALL.)

6•Low maximum speed and poor

acceleration•Vehicle acceleration poor at start.

•Delayed acceleration when accelerator

pedal depressed while driving.(See K2–190 NO.6 LOW

MAXIMUM SPEED AND

POOR ACCELERATION.)

7•No shifting•Single shift range only.

•Sometimes it shifts correctly.(See K2–191 NO.7 NO

SHIFTING.)

8•Does not shift to fifth gear (5GR)•Vehicle does not upshift from 4GR to

5GR even though vehicle speed

increased.

•Vehicle does not shift to 5GR even

though accelerator pedal released in D

range at 60 km/h {37 mph}.(See K2–192 NO.8 DOES NOT

SHIFT TO FIFTH GEAR

(5GR).)

9•Abnormal shifting•Shifts incorrectly (incorrect shift pattern). (See K2–193 NO.9

ABNORMAL SHIFTING.)

10•Frequent shifting•Downshifting occurs immediately even

when accelerator pedal depressed

slightly in D range.(See K2–193 NO.10

FREQUENT SHIFTING.)

11•Shift point is high or low•Shift point considerably different from

automatic shift diagram.

•Shift delays when accelerating.

•Shift occurs quickly when accelerating

and engine speed does not increase.(See K2–194 NO.11 SHIFT

POINT IS HIGH OR LOW.)

12•Torque converter clutch (TCC)

non-operation•TCC does not operate when vehicle

reaches TCC operation range.(See K2–194 NO.12 TORQUE

CONVERTER CLUTCH (TCC)

NON-OPERATION.)

13•No kickdown•Does not downshift when accelerator

pedal fully depressed within kickdown

range.(See K2–195 NO.13 NO

KICKDOWN.)

14•Engine flares up or slips when

upshifting or downshifting•When accelerator pedal depressed for

driveway, engine speed increases but

vehicle speed increase slowly.

•When accelerator pedal depressed while

driving, engine speed increases but

vehicle speed does not increase.(See K2–195 NO.14 ENGINE

FLARES UP OR SLIPS WHEN

UPSHIFTING OR

DOWNSHIFTING.)

15•Engine flares up or slips when

accelerating vehicle•Engine flares up when accelerator pedal

depressed for upshifting.

•Engine flares up suddenly when

accelerator pedal depressed for

downshifting.(See K2–196 NO.15 ENGINE

FLARES UP OR SLIPS WHEN

ACCELERATING VEHICLE.)

16•Judder upon torque converter

clutch (TCC) operation•Vehicle jolts when TCC engaged. (See K2–196 NO.16 JUDDER

UPON TORQUE

CONVERTER CLUTCH (TCC)

OPERATION.)

Page 599 of 909

K2–184

TROUBLESHOOTING

17•Excessive shift shock from N to D

or N to R position/range•Strong shock felt when shifting from N to

D or N to R position/range at idle.(See K2–196 NO.17

EXCESSIVE SHIFT SHOCK

FROM N TO D OR N TO R

POSITION/RANGE.)

18•Excessive shift shock is given

when upshifting and downshifting•Excessive shift shock felt when

depressing accelerator pedal to

accelerate at upshifting.

•During cruising, excessive shift shock

felt when depressing accelerator pedal

at downshifting.(See K2–197 NO.18

EXCESSIVE SHIFT SHOCK IS

GIVEN WHEN UPSHIFTING

AND DOWNSHIFTING.)

19•Excessive shift shock on torque

converter clutch (TCC)•Strong shock felt when TCC engaged. (See K2–197 NO.19

EXCESSIVE SHIFT SHOCK

ON TORQUE CONVERTER

CLUTCH (TCC).)

20•Noise occurs at idle when vehicle

is stopped in all positions/ranges•Transaxle noisy in all positions and

ranges when vehicle idling.(See K2–198 NO.20 NOISE

OCCURS AT IDLE WHEN

VEHICLE IS STOPPED IN ALL

POSITIONS/RANGES.)

21•Noise occurs at idle when vehicle

is stopped in D range, or in R

position•Transaxle noisy in driving ranges when

vehicle idling.(See K2–198 NO.21 NOISE

OCCURS AT IDLE WHEN

VEHICLE IS STOPPED IN D

RANGE, OR IN R POSITION.)

22•No engine braking in 1GR position

of M range•Engine speed drops to idle but vehicle

coasts when accelerator pedal released

during cruising at medium to high

speeds.

•Engine speed drops to idle but vehicle

coasts when accelerator pedal released

when in M range (1GR) at low vehicle

speed.(See K2–198 NO.22 NO

ENGINE BRAKING IN 1GR

POSITION OF M RANGE.)

23•Transaxle overheats•Burnt smell emitted from transaxle.

•Smoke emitted from transaxle.(See K2–199 NO.23

TRANSAXLE OVERHEATS.)

24•Engine stalls when shifted to D

range, or in R position•Engine stalls when shifting from N or P

position to D range or R position at idle.(See K2–199 NO.24 ENGINE

STALLS WHEN SHIFTED TO

D RANGE, OR IN R

POSITION.)

25•Engine stalls when driving at slow

speeds or stopping•Engine stalls when brake pedal

depressed while driving at low speed or

stopping.(See K2–200 NO.25 ENGINE

STALLS WHEN DRIVING AT

SLOW SPEED OR

STOPPING.)

26•Starter does not work•Starter does not work even when P or N

position selected.(See K2–200 NO.26

STARTER DOES NOT

WORK.)

27•Gear position indicator light does

not illuminate in M range•Gear position indicator light in

instrument cluster does not illuminate in

M range and ignition switch at on.(See K2–200 NO.27 GEAR

POSITION INDICATOR LIGHT

DOES NOT ILLUMINATE IN M

RANGE.)

28•Gear position indicator light

illuminates in D range or P, N, R

positions•Gear position indicator light in

instrument cluster illuminates in D range

or P, N, R positions and ignition switch at

on.(See K2–201 NO.28 GEAR

POSITION INDICATOR LIGHT

ILLUMINATES IN D RANGE

OR IN P, N, R POSITIONS.)

29•Does not shift up in M range•Gear position indicator light in

instrument cluster illuminates but vehicle

does not upshift when selector lever is

pushed to “+” side.(See K2–201 NO.29 DOES

NOT SHIFT UP IN M RANGE.)

30•Does not shift down in M range•Gear position indicator light in

instrument cluster illuminates but vehicle

does not downshift when selector lever

is pushed to “-” side.(See K2–201 NO.30 DOES

NOT SHIFT DOWN IN M

RANGE.) No. TROUBLESHOOTING ITEM DESCRIPTION PAGE

Page 601 of 909

K2–186

TROUBLESHOOTING

CAN signal

Vehicle dose not move in D range, or in R position

X

XXX X

X

X X

X

XX

X

X

X

X

X

XX

XX

XX

XXX

XX

XX

X

XXX X

XX X

XX X

XX X

XXX

XX

X

XX

X XX XX

X

XX

XX

X XX

X XXXX

XXXX

XXXXX XX XXX

X

X

XX

X

X

X

X

X

X

X

X

X

X X

X

X

X X

XXX

XX

XX X X

X 1

Excessive creep 4

No creep at all 5

Low maximum speed and poor acceleration 6

No shifting 7

Does not shift to fifth gear (5GR) 8

Abnormal shifting 9

Frequent shifting 10

Shift point is high or low 11

Torque converter clutch (TCC) non-operation 12

No kickdown 13

Engine flares up or slips when upshifting or downshifting 14

Engine flares up or slip when accelerating vehicle 15

Judder upon torque converter clutch (TCC) operation 16

Excessive shift shock from N to D or N to R position/range 17

Excessive shift shock on torque converter clutch (TCC) 19

No engine braking in 1GR position of M range 22

Transaxle overheats 23

Engine stalls when shifted to D range, or in R position 24

Engine stalls when driving at slow speeds or stopping 25

Starter does not work 26Excessive shift shock is given when upshifting and

downshifting 18

Noise occurs at idle when vehicle is stopped in all

positions/ranges 20

Noise occurs at idle when vehicle is stopped in D

range, or in R position 21

Gear position indicator light illuminates in D range or P, N,

R positions 28Gear position indicator light does not illuminate in M range

Electrical system components

ATX inner parts

ATX outer parts

Hydraulic system

components

Control valve body 27

Does not shift up in M range

29

Does not shift down in M rangeSymptom item

Cause of trouble

Open/short

Malfunction signal is inputed Signal is inputed

Open/short

Open/short Open/short

Open/short

Open/short

Open/short

Open/short

Open/short Open/short

Open/short

Open/short Open/short

Control valve spool is not operating properly ATF amount

2-4 brake accumulator is not operating properly Low clutch solenoid accumulator is not operating properly

Direct clutch accumulator is not operating properly High clutch accumulator is not operating properly2-4 brake solenoid valve Pressure control solenoid

TCC solenoid valve

High clutch solenoid valve TFT sensor N-D select

Transaxle range switch

Power supply, GND

Shift solenoid A

Shift solenoid B

Shift solenoid C

Neutral shift solenoid valve

Reducation timing solenoid

GND return line

30Vehicle moves in N position 2

Vehicle moves in P position, or parking gear does not

disengage when P is disengaged 3

A6E5780W002