sensor MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 187 of 909

ENGINE TUNE-UP, INTAKE-AIR SYSTEM

F2–35

F2

Injection Amount Correction

Note

•Perform this procedure at the recommended interval as described under “Fuel injection system” in

“SCHEDULED MAINTENANCE.”

1. Perform “Engine Tune-up Preparation”. (See F2–34 ENGINE TUNE-UP PREPARATION.)

2. Perform “Injection Amount Correction” using the WDS or equivalent.

MAF Correction

Note

•Perform this procedure after replacing the MAF/IAT sensor or at the recommended interval as described

under “E.G.R. system” in “SCHEDULED MAINTENANCE.”

1. Perform “Engine Tune-up Preparation”. (See F2–34 ENGINE TUNE-UP PREPARATION.)

2. Perform “MAF Correction” using the WDS or equivalent.

End Of Sie

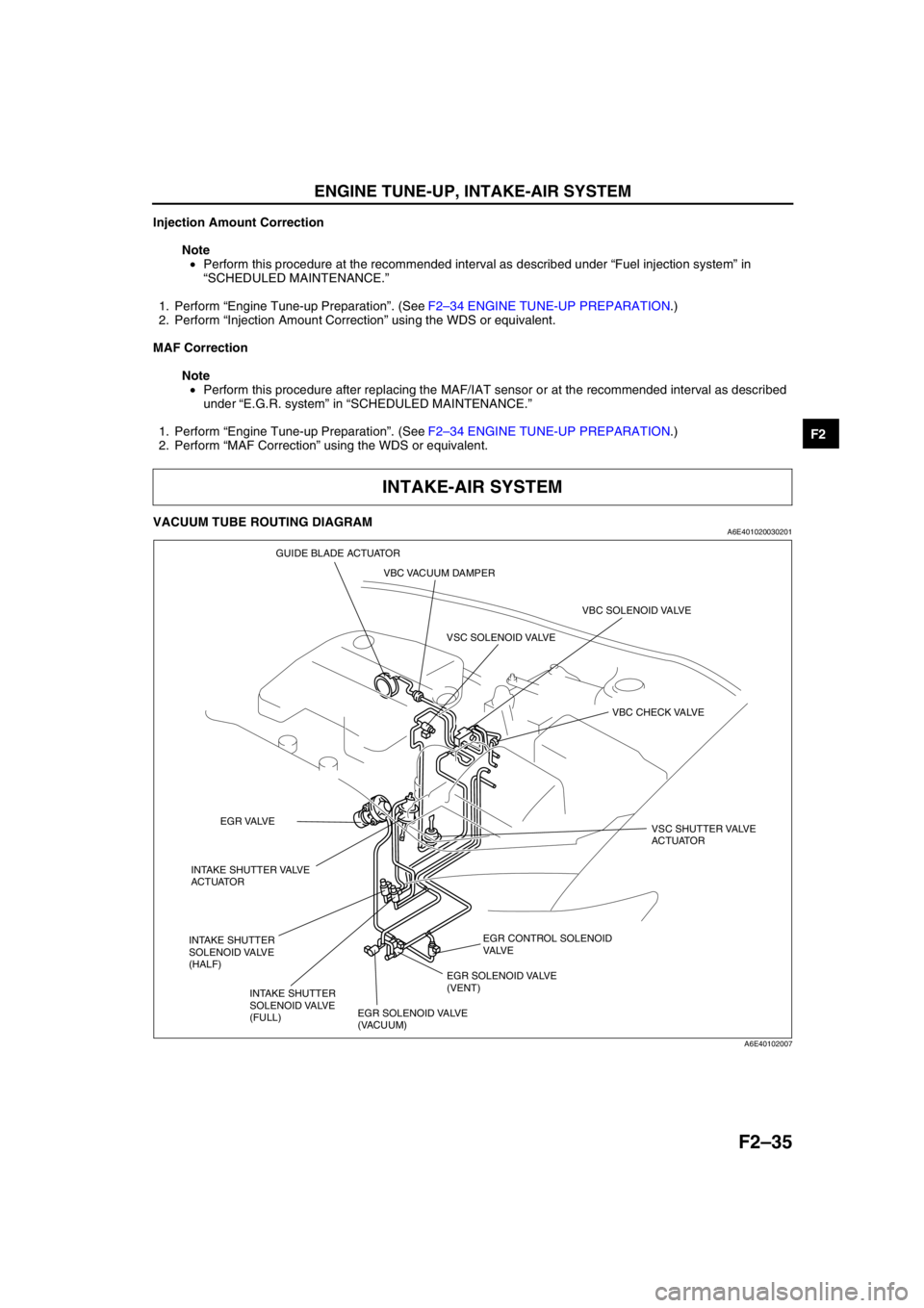

VACUUM TUBE ROUTING DIAGRAMA6E401020030201

End Of Sie

INTAKE-AIR SYSTEM

EGR CONTROL SOLENOID

VA LV E

VBC SOLENOID VALVE

VBC CHECK VALVE

EGR SOLENOID VALVE

(VACUUM)EGR SOLENOID VALVE

(VENT) VSC SOLENOID VALVE

VSC SHUTTER VALVE

ACTUATOR

INTAKE SHUTTER VALVE

ACTUATOREGR VALVE

INTAKE SHUTTER

SOLENOID VALVE

(HALF)

INTAKE SHUTTER

SOLENOID VALVE

(FULL)VBC VACUUM DAMPER GUIDE BLADE ACTUATOR

A6E40102007

Page 188 of 909

F2–36

INTAKE-AIR SYSTEM

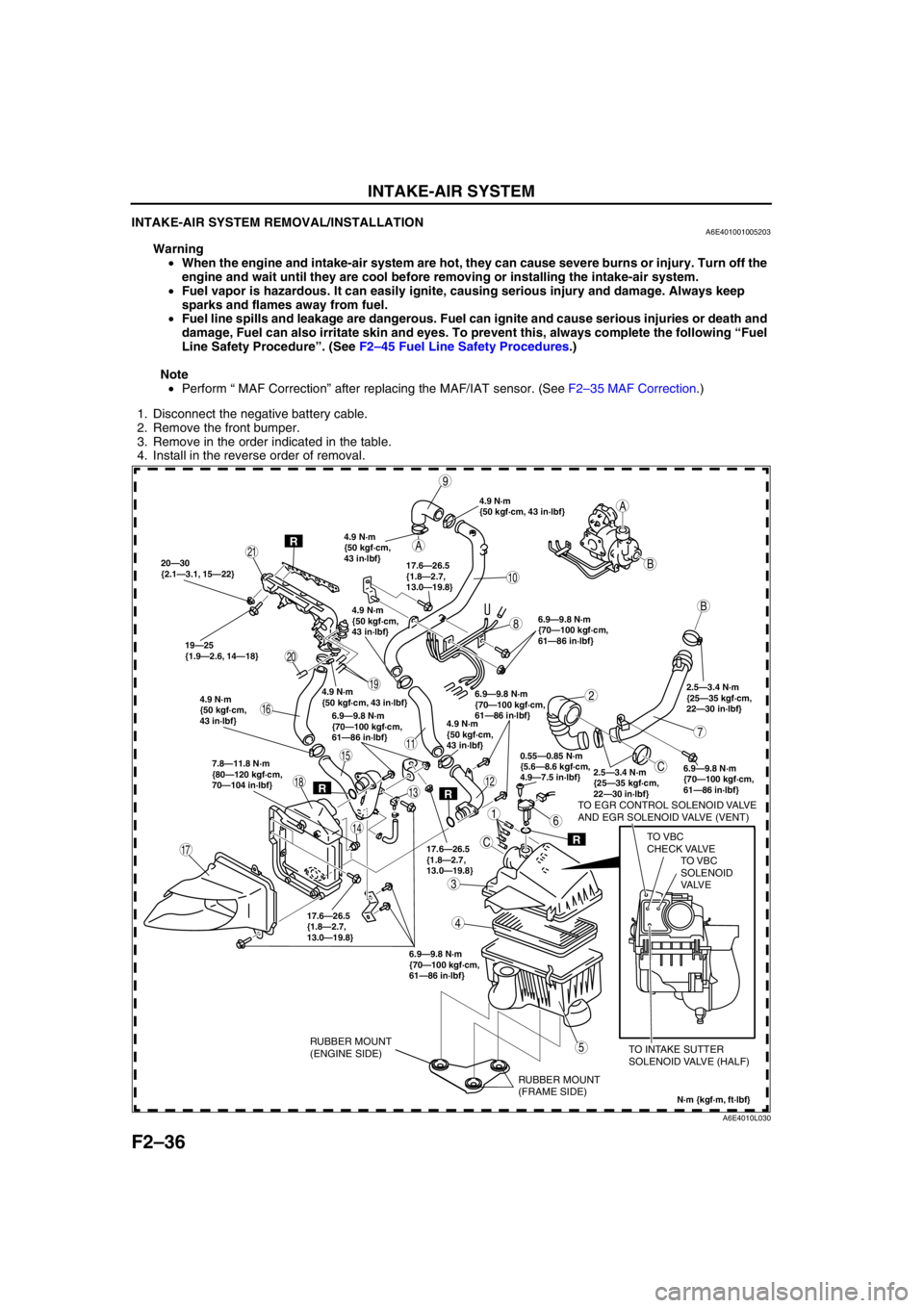

INTAKE-AIR SYSTEM REMOVAL/INSTALLATIONA6E401001005203

Warning

•When the engine and intake-air system are hot, they can cause severe burns or injury. Turn off the

engine and wait until they are cool before removing or installing the intake-air system.

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage, Fuel can also irritate skin and eyes. To prevent this, always complete the following “Fuel

Line Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

Note

•Perform “ MAF Correction” after replacing the MAF/IAT sensor. (See F2–35 MAF Correction.)

1. Disconnect the negative battery cable.

2. Remove the front bumper.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

A

A

C

C

B

B

20—30

{2.1—3.1, 15—22}

19—25

{1.9—2.6, 14—18}6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf}

2.5—3.4 N·m

{25—35 kgf·cm,

22—30 in·lbf}

6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf} 7.8—11.8 N·m

{80—120 kgf·cm,

70—104 in·lbf}

6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf} 17.6—26.5

{1.8—2.7,

13.0—19.8}6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf}

6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf}

2.5—3.4 N·m

{25—35 kgf·cm,

22—30 in·lbf}

TO EGR CONTROL SOLENOID VALVE

AND EGR SOLENOID VALVE (VENT)

TO VBC

CHECK VALVE

TO INTAKE SUTTER

SOLENOID VALVE (HALF)

9

10

19

17

11

20

21

1

2

3

5

4

7

6

8

12

14

13

15

16

18

0.55—0.85 N·m

{5.6—8.6 kgf·cm,

4.9—7.5 in·lbf}

N·m {kgf·m, ft·lbf}

R

RR

R

17.6—26.5

{1.8—2.7,

13.0—19.8}17.6—26.5

{1.8—2.7,

13.0—19.8}

4.9 N·m

{50 kgf·cm, 43 in·lbf}

4.9 N·m

{50 kgf·cm,

43 in·lbf}

4.9 N·m

{50 kgf·cm, 43 in·lbf}4.9 N·m

{50 kgf·cm,

43 in·lbf}

4.9 N·m

{50 kgf·cm,

43 in·lbf}

4.9 N·m

{50 kgf·cm,

43 in·lbf}

RUBBER MOUNT

(FRAME SIDE) RUBBER MOUNT

(ENGINE SIDE)

TO VBC

SOLENOID

VA LV E

A6E4010L030

Page 189 of 909

INTAKE-AIR SYSTEM

F2–37

F2Air Pipe Removal Note

1. Remove the battery and the battery tray before removing the air pipe. (See G–5 BATTERY REMOVAL/

INSTALLATION.)

Intake Manifold Removal Note

1. Remove the supply pump before removing the intake manifold. (See F2–53 SUPPLY PUMP REMOVAL/

INSTALLATION.)

2. Remove the EGR valve before removing the intake manifold. (See F2–59 EGR VALVE REMOVAL/

INSTALLATION.)

Air Cleaner Case Installation Note

Note

•Before assembling the air cleaner, verify that the rubber mounts have not fallen off from the air cleaner

bracket (3 locations).

•Always install the air cleaner case using the following procedure.

•When inserting the rubber mounts into the air cleaner case, soapy water can be applied.

1. Verify that the rubber mounts are set in the air cleaner bracket (3 locations).

2. Install the projections on the frame side (2 locations).

3. Verify that the projections on the frame side are installed securely.

4. Install the projection on the engine side (remaining location).

5. Verify that the projection on the engine side installed securely.

End Of Sie

AIR CLEANER ELEMENT INSPECTIONA6E4010010052041. Remove the air cleaner element. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

2. Verify that the air cleaner element surface is free of dirt.

•If there is dirt present, use an air gun or similar tool to clean the element.

•If the replacement time limit has passed, replace the element.

End Of Sie

1 Vacuum hose

2 Air hose

3 Air cleaner cover

4 Air cleaner element

5Air cleaner case

(See F2–37 Air Cleaner Case Installation Note)

6 MAF/IAT sensor

7Air pipe

(See F2–37 Air Pipe Removal Note)

8 Vacuum pipe

9 Air hose

10 Air pipe11 Air hose

12 Air pipe

13 Boost sensor

14 IAT sensor No. 2

15 Air pipe

16 Air hose

17 Air duct

18 Charge air cooler

19 Vacuum hose (Intake shutter valve actuator)

20 Vacuum hose (VSC shutter valve actuator)

21Intake manifold

(See F2–37 Intake Manifold Removal Note)

Page 196 of 909

F2–44

INTAKE-AIR SYSTEM

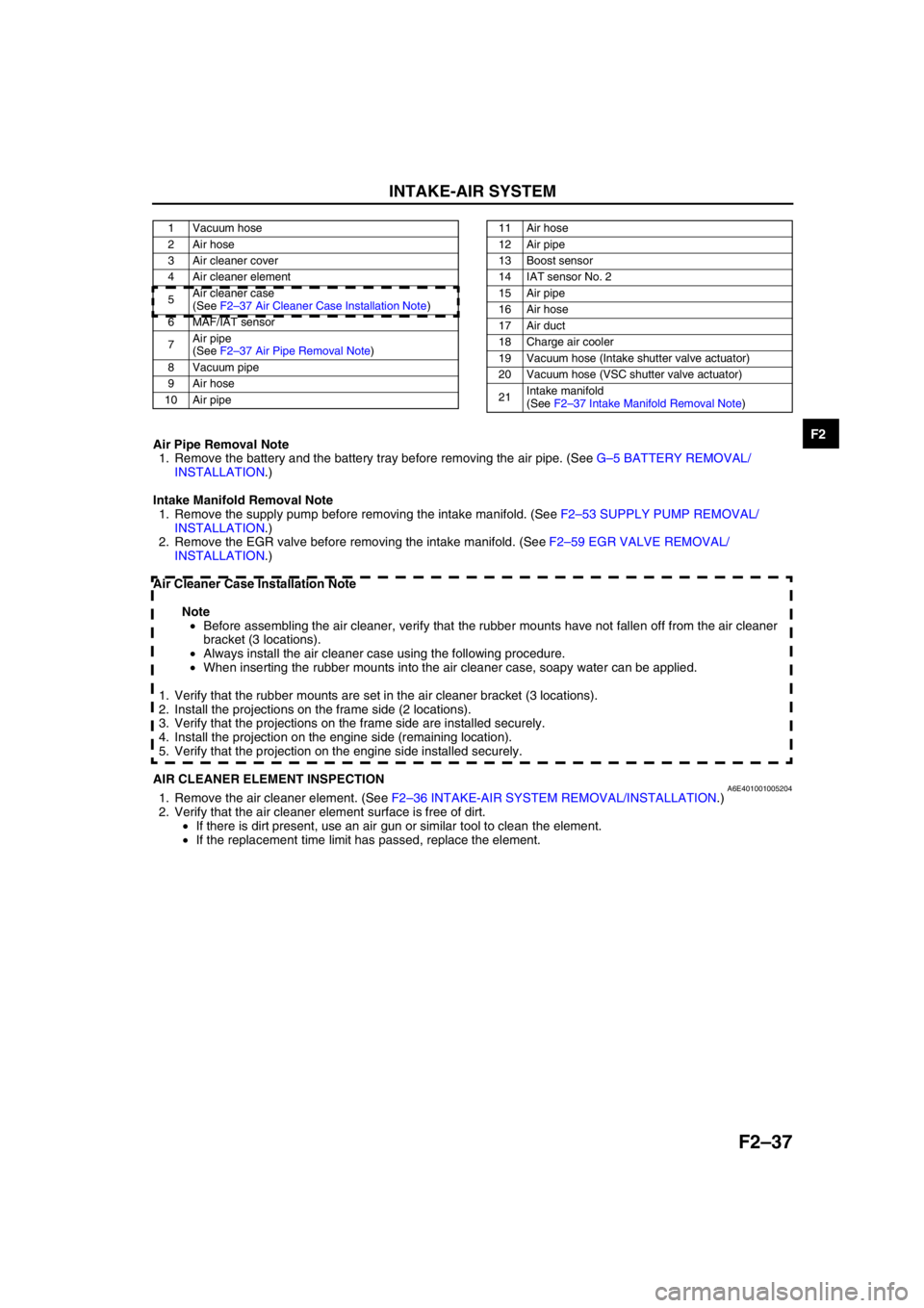

End Of SieACCELERATOR PEDAL COMPONENT REMOVAL/INSTALLATIONA6E4010416002011. Disconnect the negative battery cable.

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

End Of Sie

ACCELERATOR PEDAL COMPONENT DISASSEMBLY/ASSEMBLYA6E4010416002021. Remove the accelerator pedal component. (See F2–44 ACCELERATOR PEDAL COMPONENT REMOVAL/

INSTALLATION.)

2. Disassemble in the order indicated in the table.

3. Assemble in the reverse order of removal.

4. Install the accelerator pedal component. (See

F2–44 ACCELERATOR PEDAL COMPONENT

REMOVAL/INSTALLATION.)

5. Adjust the accelerator position sensor. (See F2–

73 ACCELERATOR POSITION SENSOR

ADJUSTMENT.)

6. Adjust the idle switch. (See F2–71 IDLE SWITCH

ADJUSTMENT.)

End Of Sie

1 Accelerator position sensor connector

2 Idle switch connector

3 Pedal component

7.8—10.8 N·m

{80—110 kgf·m,

69—95 in·lbf}

3

1

2

A6E40102026

1 Idle switch

2 Accelerator position sensor

3 Accelerator pedal

3

12

1.57—2.35 N·m

{16.0—23.9 kgf·cm,

13.9—20.7 in·lbf}13.7—17.6 N·m

{1.4—1.7 kgf·m,

11—12 ft·lbf}

A6E40102027

Page 206 of 909

F2–54

FUEL SYSTEM

SUPPLY PUMP INSPECTIONA6E401213350202

Caution

•The supply pump is sealed to maintain proper function. Special tools and testers are required

when disassembling the supply pump. Disassembling the supply pump without special tools and

testers will cause a malfunction.

•Consult an authorized DENSO parts distributor for repair if any of the following supply pump parts

are possibly malfunctioning.

1. Supply pump inner parts

2. Suction control valve

3. Fuel temperature sensor

End Of Sie

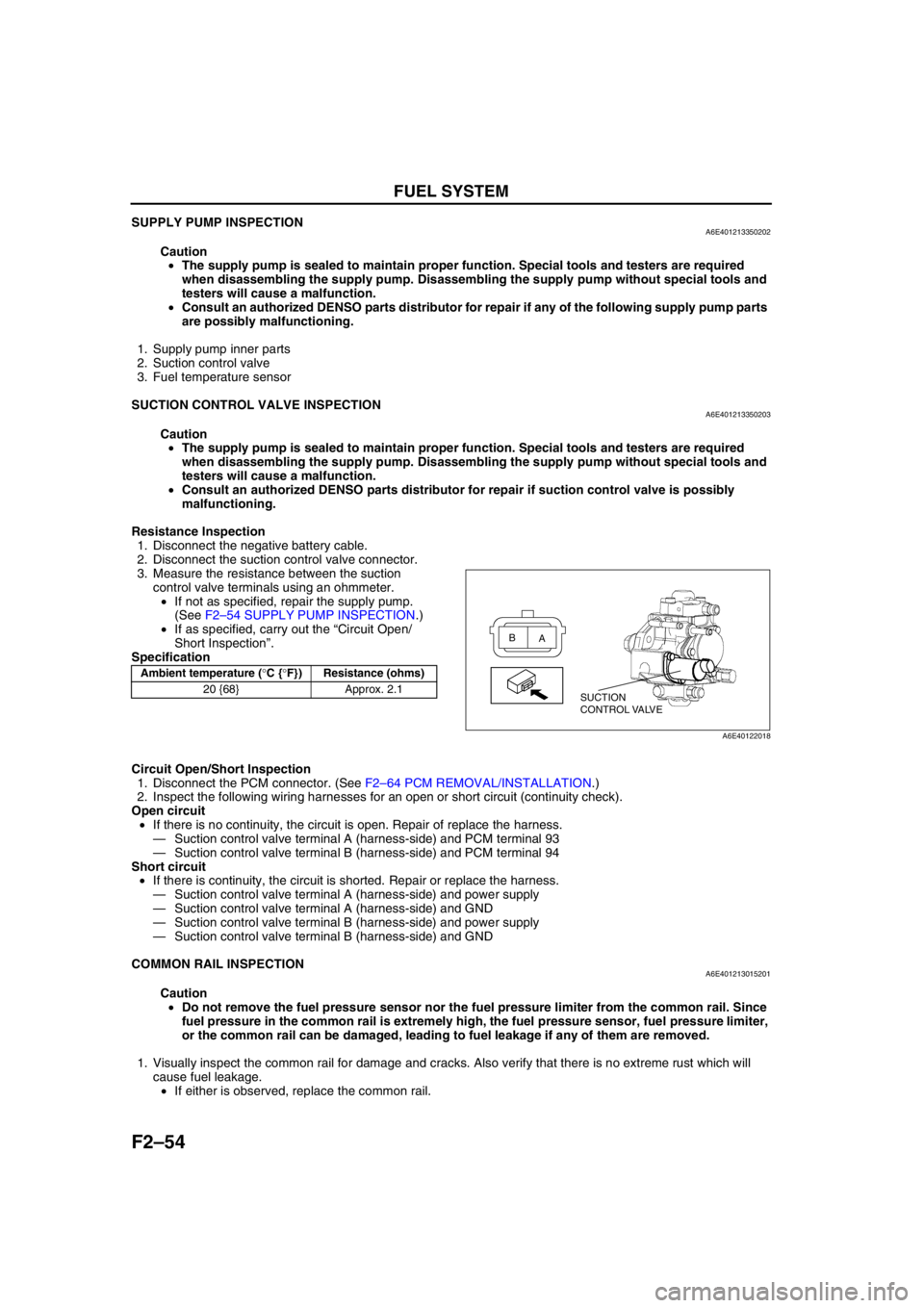

SUCTION CONTROL VALVE INSPECTIONA6E401213350203

Caution

•The supply pump is sealed to maintain proper function. Special tools and testers are required

when disassembling the supply pump. Disassembling the supply pump without special tools and

testers will cause a malfunction.

•Consult an authorized DENSO parts distributor for repair if suction control valve is possibly

malfunctioning.

Resistance Inspection

1. Disconnect the negative battery cable.

2. Disconnect the suction control valve connector.

3. Measure the resistance between the suction

control valve terminals using an ohmmeter.

•If not as specified, repair the supply pump.

(See F2–54 SUPPLY PUMP INSPECTION.)

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Specification

Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM REMOVAL/INSTALLATION.)

2. Inspect the following wiring harnesses for an open or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair of replace the harness.

—Suction control valve terminal A (harness-side) and PCM terminal 93

—Suction control valve terminal B (harness-side) and PCM terminal 94

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Suction control valve terminal A (harness-side) and power supply

—Suction control valve terminal A (harness-side) and GND

—Suction control valve terminal B (harness-side) and power supply

—Suction control valve terminal B (harness-side) and GND

End Of Sie

COMMON RAIL INSPECTIONA6E401213015201

Caution

•Do not remove the fuel pressure sensor nor the fuel pressure limiter from the common rail. Since

fuel pressure in the common rail is extremely high, the fuel pressure sensor, fuel pressure limiter,

or the common rail can be damaged, leading to fuel leakage if any of them are removed.

1. Visually inspect the common rail for damage and cracks. Also verify that there is no extreme rust which will

cause fuel leakage.

•If either is observed, replace the common rail.

End Of Sie

Ambient temperature (°C {°F}) Resistance (ohms)

20 {68} Approx. 2.1

SUCTION

CONTROL VALVE A B

A6E40122018

Page 217 of 909

CONTROL SYSTEM

F2–65

F2

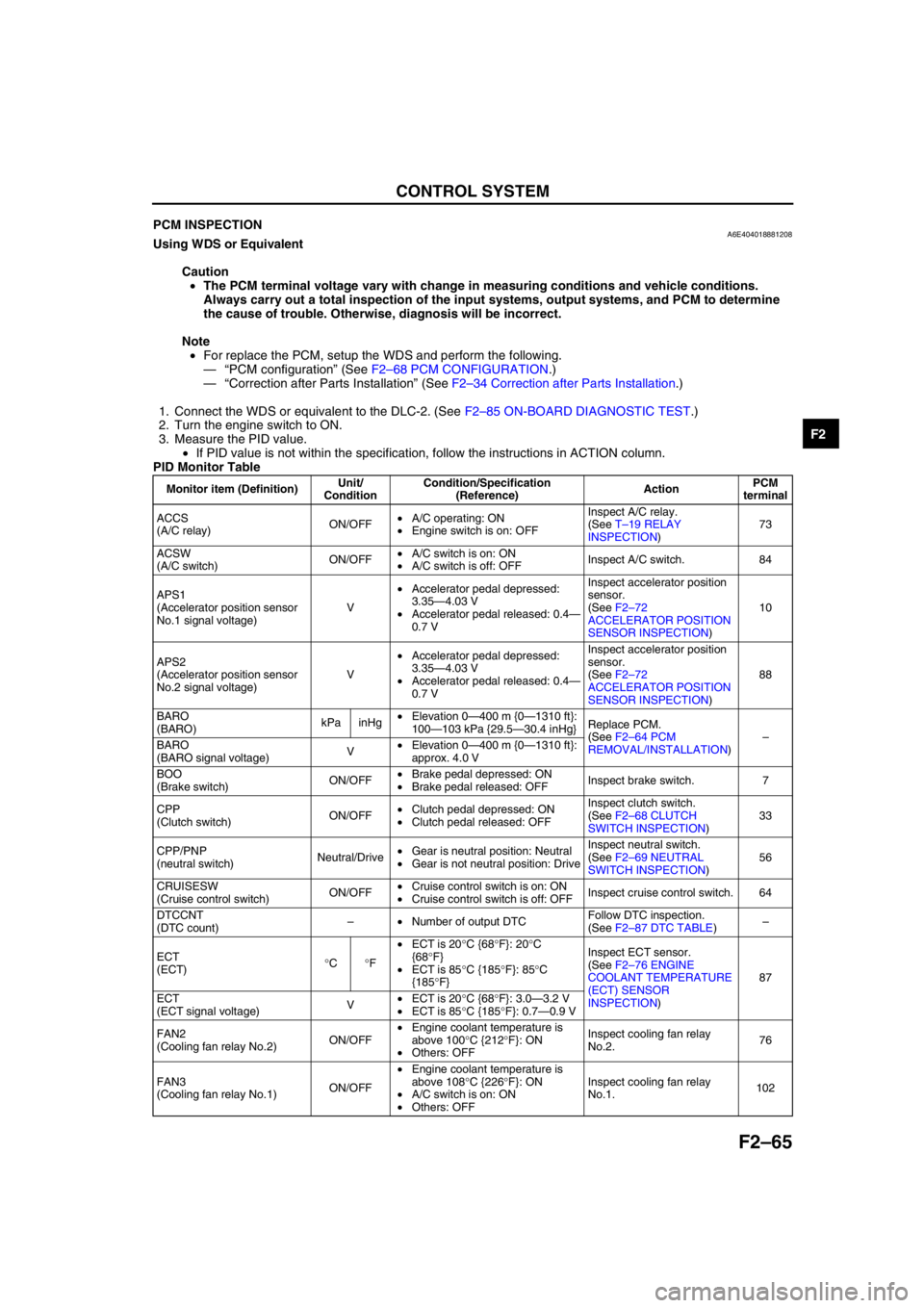

End Of SiePCM INSPECTIONA6E404018881208Using WDS or Equivalent

Caution

•The PCM terminal voltage vary with change in measuring conditions and vehicle conditions.

Always carry out a total inspection of the input systems, output systems, and PCM to determine

the cause of trouble. Otherwise, diagnosis will be incorrect.

Note

•For replace the PCM, setup the WDS and perform the following.

—“PCM configuration” (See F2–68 PCM CONFIGURATION.)

—“Correction after Parts Installation” (See F2–34 Correction after Parts Installation.)

1. Connect the WDS or equivalent to the DLC-2. (See F2–85 ON-BOARD DIAGNOSTIC TEST.)

2. Turn the engine switch to ON.

3. Measure the PID value.

•If PID value is not within the specification, follow the instructions in ACTION column.

PID Monitor Table

Monitor item (Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

ACCS

(A/C relay)ON/OFF•A/C operating: ON

•Engine switch is on: OFFInspect A/C relay.

(See T–19 RELAY

INSPECTION)73

ACSW

(A/C switch)ON/OFF•A/C switch is on: ON

•A/C switch is off: OFFInspect A/C switch. 84

APS1

(Accelerator position sensor

No.1 signal voltage)V•Accelerator pedal depressed:

3.35—4.03 V

•Accelerator pedal released: 0.4—

0.7 VInspect accelerator position

sensor.

(See F2–72

ACCELERATOR POSITION

SENSOR INSPECTION)10

APS2

(Accelerator position sensor

No.2 signal voltage)V•Accelerator pedal depressed:

3.35—4.03 V

•Accelerator pedal released: 0.4—

0.7 VInspect accelerator position

sensor.

(See F2–72

ACCELERATOR POSITION

SENSOR INSPECTION)88

BARO

(BARO)kPa inHg•Elevation 0—400 m {0—1310 ft}:

100—103 kPa {29.5—30.4 inHg}Replace PCM.

(See F2–64 PCM

REMOVAL/INSTALLATION)–

BARO

(BARO signal voltage)V•Elevation 0—400 m {0—1310 ft}:

approx. 4.0 V

BOO

(Brake switch)ON/OFF•Brake pedal depressed: ON

•Brake pedal released: OFFInspect brake switch. 7

CPP

(Clutch switch)ON/OFF•Clutch pedal depressed: ON

•Clutch pedal released: OFFInspect clutch switch.

(See F2–68 CLUTCH

SWITCH INSPECTION)33

CPP/PNP

(neutral switch)Neutral/Drive•Gear is neutral position: Neutral

•Gear is not neutral position: DriveInspect neutral switch.

(See F2–69 NEUTRAL

SWITCH INSPECTION)56

CRUISESW

(Cruise control switch)ON/OFF•Cruise control switch is on: ON

•Cruise control switch is off: OFFInspect cruise control switch. 64

DTCCNT

(DTC count)–•Number of output DTCFollow DTC inspection.

(See F2–87 DTC TABLE)–

ECT

(ECT)°C°F•ECT is 20°C {68°F}: 20°C

{68°F}

•ECT is 85°C {185°F}: 85°C

{185°F}Inspect ECT sensor.

(See F2–76 ENGINE

COOLANT TEMPERATURE

(ECT) SENSOR

INSPECTION)87

ECT

(ECT signal voltage)V•ECT is 20°C {68°F}: 3.0—3.2 V

•ECT is 85°C {185°F}: 0.7—0.9 V

FAN2

(Cooling fan relay No.2)ON/OFF•Engine coolant temperature is

above 100°C {212°F}: ON

•Others: OFFInspect cooling fan relay

No.2.76

FAN3

(Cooling fan relay No.1)ON/OFF•Engine coolant temperature is

above 108°C {226°F}: ON

•A/C switch is on: ON

•Others: OFFInspect cooling fan relay

No.1.102

Page 218 of 909

F2–66

CONTROL SYSTEM

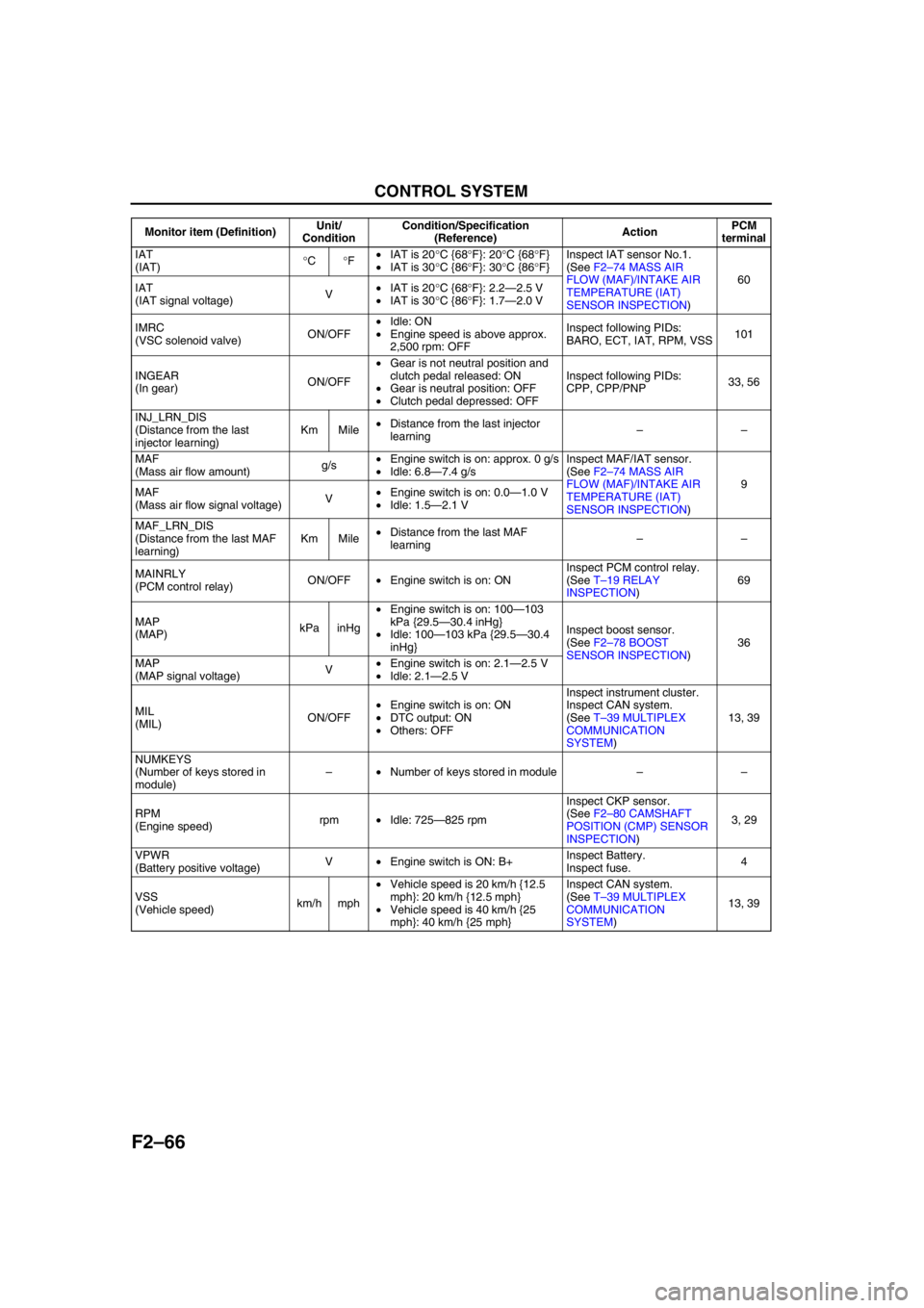

IAT

(IAT)°C°F•IAT is 20°C {68°F}: 20°C {68°F}

•IAT is 30°C {86°F}: 30°C {86°F}Inspect IAT sensor No.1.

(See F2–74 MASS AIR

FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT)

SENSOR INSPECTION)60

IAT

(IAT signal voltage)V•IAT is 20°C {68°F}: 2.2—2.5 V

•IAT is 30°C {86°F}: 1.7—2.0 V

IMRC

(VSC solenoid valve)ON/OFF•Idle: ON

•Engine speed is above approx.

2,500 rpm: OFFInspect following PIDs:

BARO, ECT, IAT, RPM, VSS101

INGEAR

(In gear)ON/OFF•Gear is not neutral position and

clutch pedal released: ON

•Gear is neutral position: OFF

•Clutch pedal depressed: OFFInspect following PIDs:

CPP, CPP/PNP33, 56

INJ_LRN_DIS

(Distance from the last

injector learning)Km Mile•Distance from the last injector

learning––

MAF

(Mass air flow amount)g/s•Engine switch is on: approx. 0 g/s

•Idle: 6.8—7.4 g/sInspect MAF/IAT sensor.

(See F2–74 MASS AIR

FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT)

SENSOR INSPECTION)9

MAF

(Mass air flow signal voltage)V•Engine switch is on: 0.0—1.0 V

•Idle: 1.5—2.1 V

MAF_LRN_DIS

(Distance from the last MAF

learning)Km Mile•Distance from the last MAF

learning––

MAINRLY

(PCM control relay)ON/OFF•Engine switch is on: ONInspect PCM control relay.

(See T–19 RELAY

INSPECTION)69

MAP

(MAP)kPa inHg•Engine switch is on: 100—103

kPa {29.5—30.4 inHg}

•Idle: 100—103 kPa {29.5—30.4

inHg}Inspect boost sensor.

(See F2–78 BOOST

SENSOR INSPECTION)36

MAP

(MAP signal voltage)V•Engine switch is on: 2.1—2.5 V

•Idle: 2.1—2.5 V

MIL

(MIL)ON/OFF•Engine switch is on: ON

•DTC output: ON

•Others: OFFInspect instrument cluster.

Inspect CAN system.

(See T–39 MULTIPLEX

COMMUNICATION

SYSTEM)13, 39

NUMKEYS

(Number of keys stored in

module)–•Number of keys stored in module––

RPM

(Engine speed)rpm•Idle: 725—825 rpmInspect CKP sensor.

(See F2–80 CAMSHAFT

POSITION (CMP) SENSOR

INSPECTION)3, 29

VPWR

(Battery positive voltage)V•Engine switch is ON: B+Inspect Battery.

Inspect fuse.4

VSS

(Vehicle speed)km/h mph•Vehicle speed is 20 km/h {12.5

mph}: 20 km/h {12.5 mph}

•Vehicle speed is 40 km/h {25

mph}: 40 km/h {25 mph}Inspect CAN system.

(See T–39 MULTIPLEX

COMMUNICATION

SYSTEM)13, 39 Monitor item (Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 219 of 909

CONTROL SYSTEM

F2–67

F2

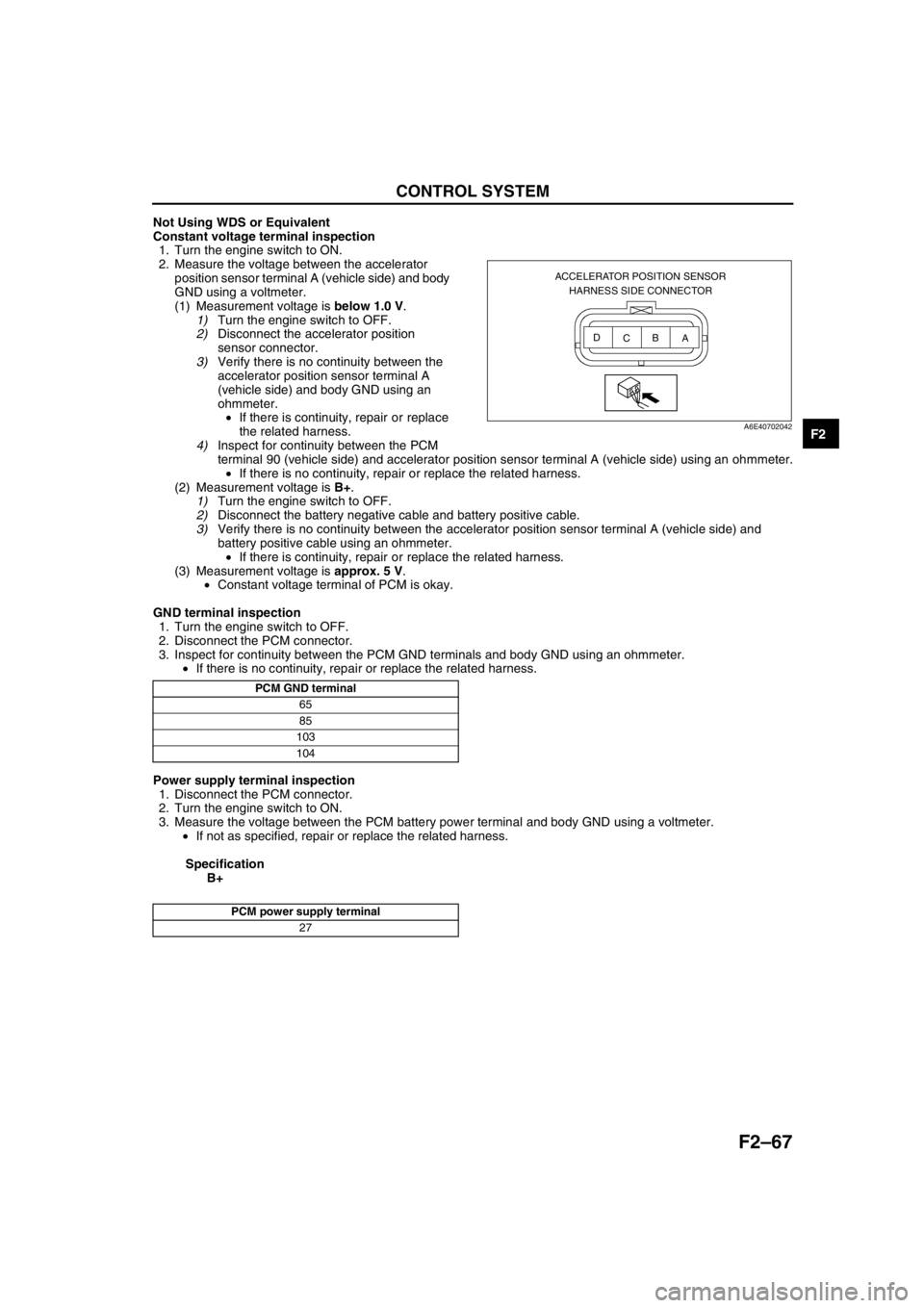

Not Using WDS or Equivalent

Constant voltage terminal inspection

1. Turn the engine switch to ON.

2. Measure the voltage between the accelerator

position sensor terminal A (vehicle side) and body

GND using a voltmeter.

(1) Measurement voltage is below 1.0 V.

1)Turn the engine switch to OFF.

2)Disconnect the accelerator position

sensor connector.

3)Verify there is no continuity between the

accelerator position sensor terminal A

(vehicle side) and body GND using an

ohmmeter.

•If there is continuity, repair or replace

the related harness.

4)Inspect for continuity between the PCM

terminal 90 (vehicle side) and accelerator position sensor terminal A (vehicle side) using an ohmmeter.

•If there is no continuity, repair or replace the related harness.

(2) Measurement voltage is B+.

1)Turn the engine switch to OFF.

2)Disconnect the battery negative cable and battery positive cable.

3)Verify there is no continuity between the accelerator position sensor terminal A (vehicle side) and

battery positive cable using an ohmmeter.

•If there is continuity, repair or replace the related harness.

(3) Measurement voltage is approx. 5 V.

•Constant voltage terminal of PCM is okay.

GND terminal inspection

1. Turn the engine switch to OFF.

2. Disconnect the PCM connector.

3. Inspect for continuity between the PCM GND terminals and body GND using an ohmmeter.

•If there is no continuity, repair or replace the related harness.

Power supply terminal inspection

1. Disconnect the PCM connector.

2. Turn the engine switch to ON.

3. Measure the voltage between the PCM battery power terminal and body GND using a voltmeter.

•If not as specified, repair or replace the related harness.

Specification

B+

End Of Sie

ACCELERATOR POSITION SENSOR

HARNESS SIDE CONNECTOR

A B

C D

A6E40702042

PCM GND terminal

65

85

103

104

PCM power supply terminal

27

Page 222 of 909

F2–70

CONTROL SYSTEM

IDLE SWITCH INSPECTIONA6E404041600201

Note

•Perform the following test only when directed.

1. Verify that the accelerator position sensor is normal.

2. Visually inspect all accelerator pedal components for looseness.

3. Verify that the idle switch is installed to the accelerator pedal properly.

4. Verify that the power circuit voltage.

(1) Verify that the voltage between the PCM terminals 90 (power circuit) and 91(GND circuit) is 4.75—5.25 V.

Note

•Voltage at the PCM terminal 10 may deviate when the power circuit voltage is abnormal.

5. Verify that the voltage at the PCM terminal 31

(idle signal) is 1 V or less with the accelerator

pedal fully released.

6. Depress the accelerator pedal gradually and hold

the pedal when the PCM terminal 31 voltage

changes to approximately 10 V.

7. Verify that the voltage between the PCM

terminals 10 (accelerator position detection

signal) and 91 is within the specification.

•If the circuit is okay, replace the idle switch.

Specification

0.85—1.15 V (Target value: 1.0 V)

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•Signal circuit

—Idle switch terminal A and PCM terminal 31

•GND circuit

—Idle switch terminal B and GND

Short circuit

•Signal circuit

—Idle switch terminal A and PCM terminal 31 to

GND

End Of Sie

ACCELERATOR POSITION SENSOR

IDLE SWITCHPCM B

A

C

D

A

B31 10

90

88

91

A6E40702037

IDLE SWITCH

HARNESS SIDE CONNECTOR

A

B

A6E40702038

Page 223 of 909

CONTROL SYSTEM

F2–71

F2

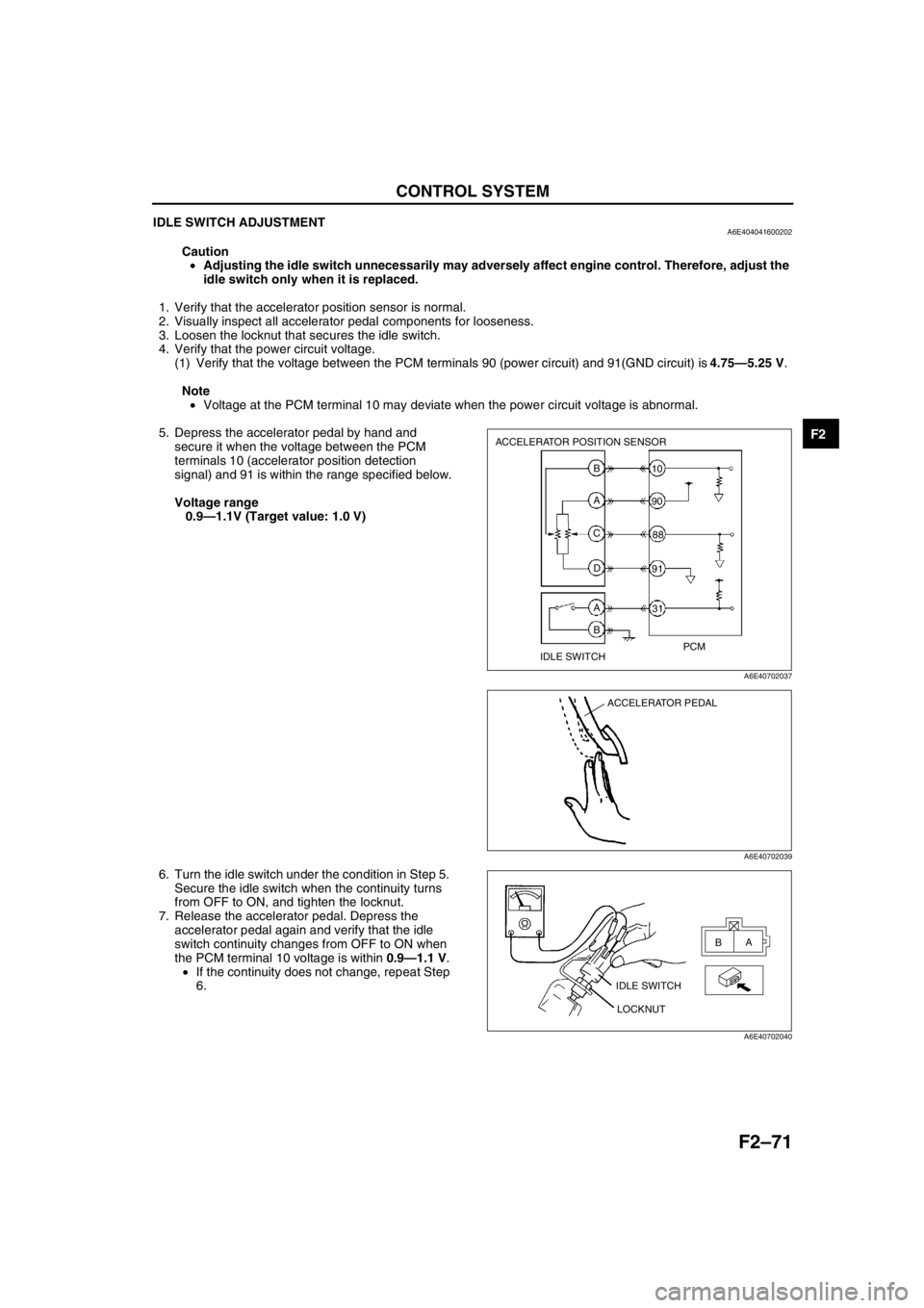

IDLE SWITCH ADJUSTMENTA6E404041600202

Caution

•Adjusting the idle switch unnecessarily may adversely affect engine control. Therefore, adjust the

idle switch only when it is replaced.

1. Verify that the accelerator position sensor is normal.

2. Visually inspect all accelerator pedal components for looseness.

3. Loosen the locknut that secures the idle switch.

4. Verify that the power circuit voltage.

(1) Verify that the voltage between the PCM terminals 90 (power circuit) and 91(GND circuit) is 4.75—5.25 V.

Note

•Voltage at the PCM terminal 10 may deviate when the power circuit voltage is abnormal.

5. Depress the accelerator pedal by hand and

secure it when the voltage between the PCM

terminals 10 (accelerator position detection

signal) and 91 is within the range specified below.

Voltage range

0.9—1.1V (Target value: 1.0 V)

6. Turn the idle switch under the condition in Step 5.

Secure the idle switch when the continuity turns

from OFF to ON, and tighten the locknut.

7. Release the accelerator pedal. Depress the

accelerator pedal again and verify that the idle

switch continuity changes from OFF to ON when

the PCM terminal 10 voltage is within 0.9—1.1 V.

•If the continuity does not change, repeat Step

6.

End Of Sie

ACCELERATOR POSITION SENSOR

IDLE SWITCHPCM B

A

C

D

A

B31 10

90

88

91

A6E40702037

ACCELERATOR PEDAL

A6E40702039

IDLE SWITCH

LOCKNUTA

B

A6E40702040