heater MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 1 of 909

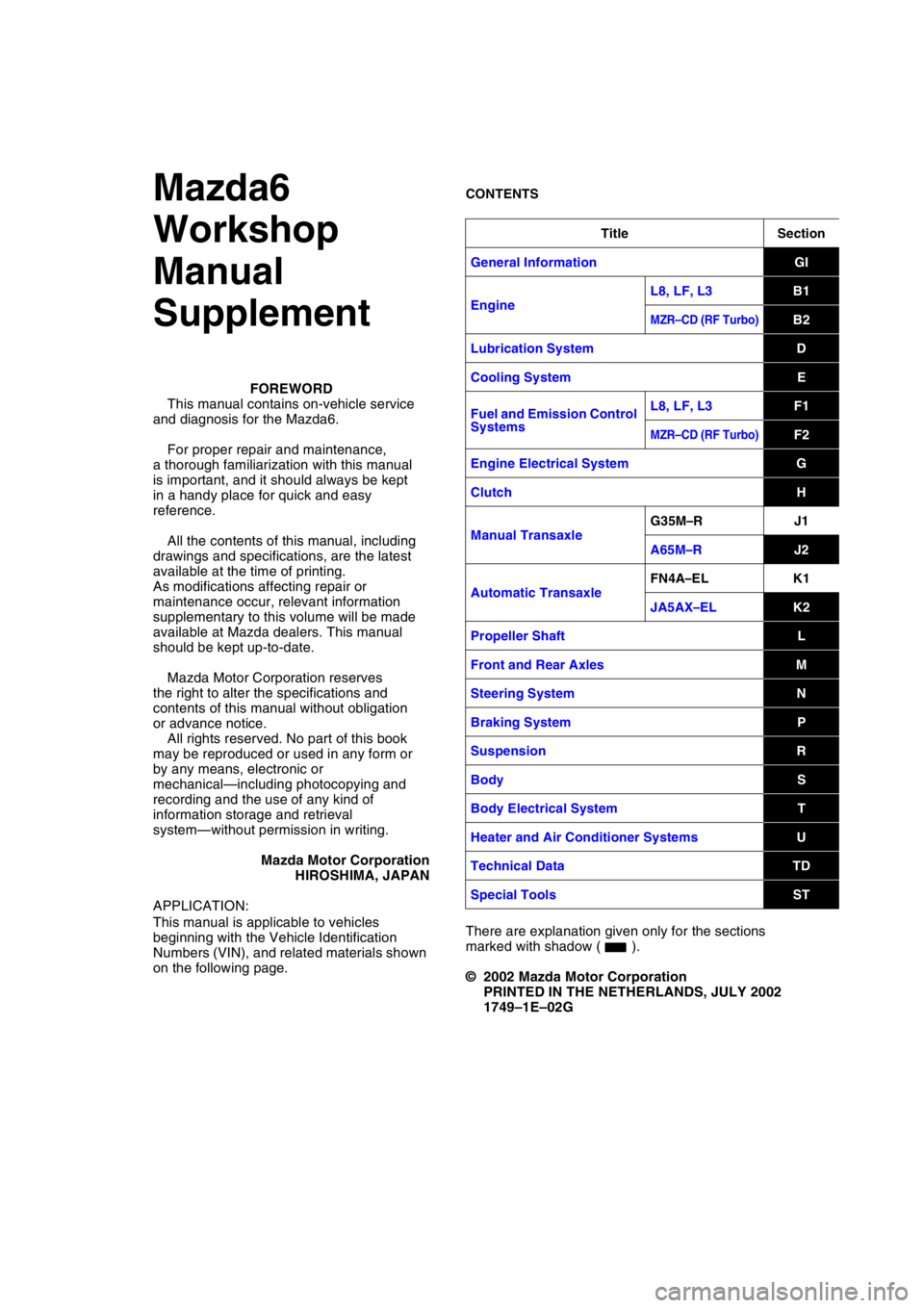

CONTENTSMazda6

Workshop

Manual

Supplement

FOREWORD

This manual contains on-vehicle service

and diagnosis for the Mazda6.

For proper repair and maintenance,

a thorough familiarization with this manual

is important, and it should always be kept

in a handy place for quick and easy

reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Mazda Motor Corporation reserves

the right to alter the specifications and

contents of this manual without obligation

or advance notice.

All rights reserved. No part of this book

may be reproduced or used in any form or

by any means, electronic or

mechanical—including photocopying and

recording and the use of any kind of

information storage and retrieval

system—without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles

beginning with the Vehicle Identification

Numbers (VIN), and related materials shown

on the following page.There are explanation given only for the sections

marked with shadow ( ).

© 2002 Mazda Motor Corporation

PRINTED IN THE NETHERLANDS, JULY 2002

1749–1E–02G

Title Section

General Information

GI

EngineL8, LF, L3

B1

MZR–CD (RF Turbo)B2

Lubrication System

D

Cooling System

E

Fuel and Emission Control

SystemsL8, LF, L3

F1

MZR–CD (RF Turbo)F2

Engine Electrical System

G

Clutch

H

Manual TransaxleG35M

–RJ1

A65M

–RJ2

Automatic TransaxleFN4A

–ELK1

JA5AX

–ELK2

Propeller Shaft

L

Front and Rear Axles

M

Steering System

N

Braking System

P

Suspension

R

Body

S

Body Electrical System

T

Heater and Air Conditioner Systems

U

Technical Data

TD

Special Tools

ST

Page 8 of 909

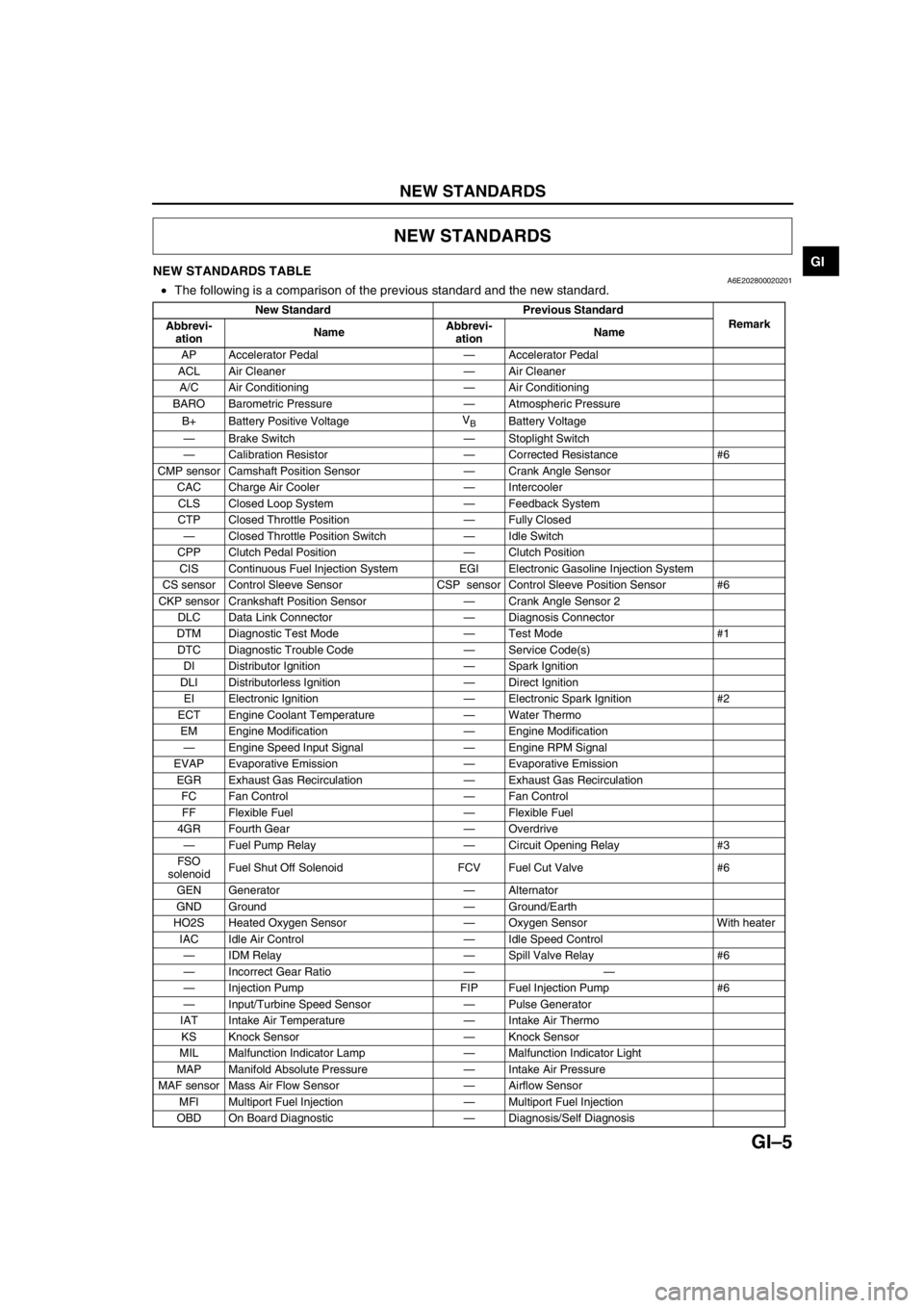

NEW STANDARDS

GI–5

GINEW STANDARDS TABLEA6E202800020201•The following is a comparison of the previous standard and the new standard.

NEW STANDARDS

New Standard Previous Standard

Remark

Abbrevi-

ationNameAbbrevi-

ationName

AP Accelerator Pedal—Accelerator Pedal

ACL Air Cleaner—Air Cleaner

A/C Air Conditioning—Air Conditioning

BARO Barometric Pressure—Atmospheric Pressure

B+ Battery Positive VoltageV

BBattery Voltage

—Brake Switch—Stoplight Switch

—Calibration Resistor—Corrected Resistance #6

CMP sensor Camshaft Position Sensor—Crank Angle Sensor

CAC Charge Air Cooler—Intercooler

CLS Closed Loop System—Feedback System

CTP Closed Throttle Position—Fully Closed

—Closed Throttle Position Switch—Idle Switch

CPP Clutch Pedal Position—Clutch Position

CIS Continuous Fuel Injection System EGI Electronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP sensor Control Sleeve Position Sensor #6

CKP sensor Crankshaft Position Sensor—Crank Angle Sensor 2

DLC Data Link Connector—Diagnosis Connector

DTM Diagnostic Test Mode—Test Mode #1

DTC Diagnostic Trouble Code—Service Code(s)

DI Distributor Ignition—Spark Ignition

DLI Distributorless Ignition—Direct Ignition

EI Electronic Ignition—Electronic Spark Ignition #2

ECT Engine Coolant Temperature—Water Thermo

EM Engine Modification—Engine Modification

—Engine Speed Input Signal—Engine RPM Signal

EVAP Evaporative Emission—Evaporative Emission

EGR Exhaust Gas Recirculation—Exhaust Gas Recirculation

FC Fan Control—Fan Control

FF Flexible Fuel—Flexible Fuel

4GR Fourth Gear—Overdrive

—Fuel Pump Relay—Circuit Opening Relay #3

FSO

solenoidFuel Shut Off Solenoid FCV Fuel Cut Valve #6

GEN Generator—Alternator

GND Ground—Ground/Earth

HO2S Heated Oxygen Sensor—Oxygen Sensor With heater

IAC Idle Air Control—Idle Speed Control

—IDM Relay—Spill Valve Relay #6

—Incorrect Gear Ratio——

—Injection Pump FIP Fuel Injection Pump #6

—Input/Turbine Speed Sensor—Pulse Generator

IAT Intake Air Temperature—Intake Air Thermo

KS Knock Sensor—Knock Sensor

MIL Malfunction Indicator Lamp—Malfunction Indicator Light

MAP Manifold Absolute Pressure—Intake Air Pressure

MAF sensor Mass Air Flow Sensor—Airflow Sensor

MFI Multiport Fuel Injection—Multiport Fuel Injection

OBD On Board Diagnostic—Diagnosis/Self Diagnosis

Page 26 of 909

B1–4

OUTLINE, ENGINE

SUPPLEMENTAL SERVICE INFORMATIONA6E220202000205•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Engine

•Removal/Installation procedure for 4WD has been adopted.

End Of Sie

ENGINE REMOVAL/INSTALLATION (4WD)A6E222401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”.

1. Remove the battery.

2. Remove the battery tray.

3. Remove the radiator.

4. Drain the transaxle oil.

5. Remove the P/S oil pump with the oil hose still connected. Position the P/S oil pump so that it is out of the way.

Use wire or rope to secure.

6. Remove the A/C compressor with the pipes still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure.

7. Remove the propeller shaft from the transfer.

8. Remove the joint shaft. (See M–31 JOINT SHAFT (4WD) DISASSEMBLY/ASSEMBLY.)

9. Remove the front drive shaft (LH) from the transaxle. (See M–39 FRONT DRIVE SHAFT (4WD)

DISASSEMBLY/ASSEMBLY.)

10. Remove the air cleaner, intake air duct, accelerator cable and bracket, and vacuum hose.

11. Remove the ATF hose and selector cable.

12. Remove the vacuum hose and heater hose.

13. Disconnect the fuel hose. (See F1–27 Plastic Fuel Hose Removal Note.) (See F1–28 Plastic Fuel Hose

Installation Note.)

14. Disconnect the wiring harness from the engine side.

15. Remove the three way catalyst (TWC). (See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Start the engine and:

•Inspect for the engine oil, engine coolant, transaxle oil and fuel leakage.

•Verify the ignition timing, idle speed and idle mixture. (See F1–22 IDLE SPEED INSPECTION (4WD).)

19. Perform a road test.

OUTLINE

ENGINE

Page 58 of 909

ENGINE

B2–27

B2

ENGINE REMOVAL/INSTALLATIONA6E232401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant, engine oil, and transaxle oil.

3. Remove the radiator.

4. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the air cleaner and air hose. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

6. Disconnect the fuel hose. (See F2–45 BEFORE REPAIR PROCEDURE.)

7. Remove the front pipe. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the battery and tray. (See G–5 BATTERY REMOVAL/INSTALLATION.)

9. Remove the shift cable, select cable and clutch release cylinder related to the transaxle. (See J2–7 MANUAL

TRANSAXLE REMOVAL/INSTALLATION.)

10. Remove the clutch release cylinder.

11. Remove the vacuum hose and the heater hose.

12. Disconnect the P/S oil pump pressure pipe and P/S oil pump relief hose from the P/S oil pump side. (See N–16

POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/INSTALLATION.)

Note

•The P/S oil pump will not be removed from the engine.

13. Remove the A/C compressor with the pipe still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure it. (See U–11 A/C COMPRESSOR REMOVAL/INSTALLATION.)

14. Remove the joint shaft.

15. Remove the front drive shaft (LH) from the transaxle.

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Fill the engine coolant, engine oil, and transaxle oil.

19. Bleed the air from the fuel line. (See F2–45 AFTER REPAIR PROCEDURE.)

20. Start the engine and:

•Inspect the pulleys and the drive belt for runout and contact.

•Inspect the engine oil, engine coolant transaxle oil, P/S fluid, and fuel for leakage.

•Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

21. Perform a road test.

22. Reinspect the engine oil, engine coolant, transaxle oil, and P/S fluid levels.

ENGINE

Page 79 of 909

E–4

COOLING SYSTEM

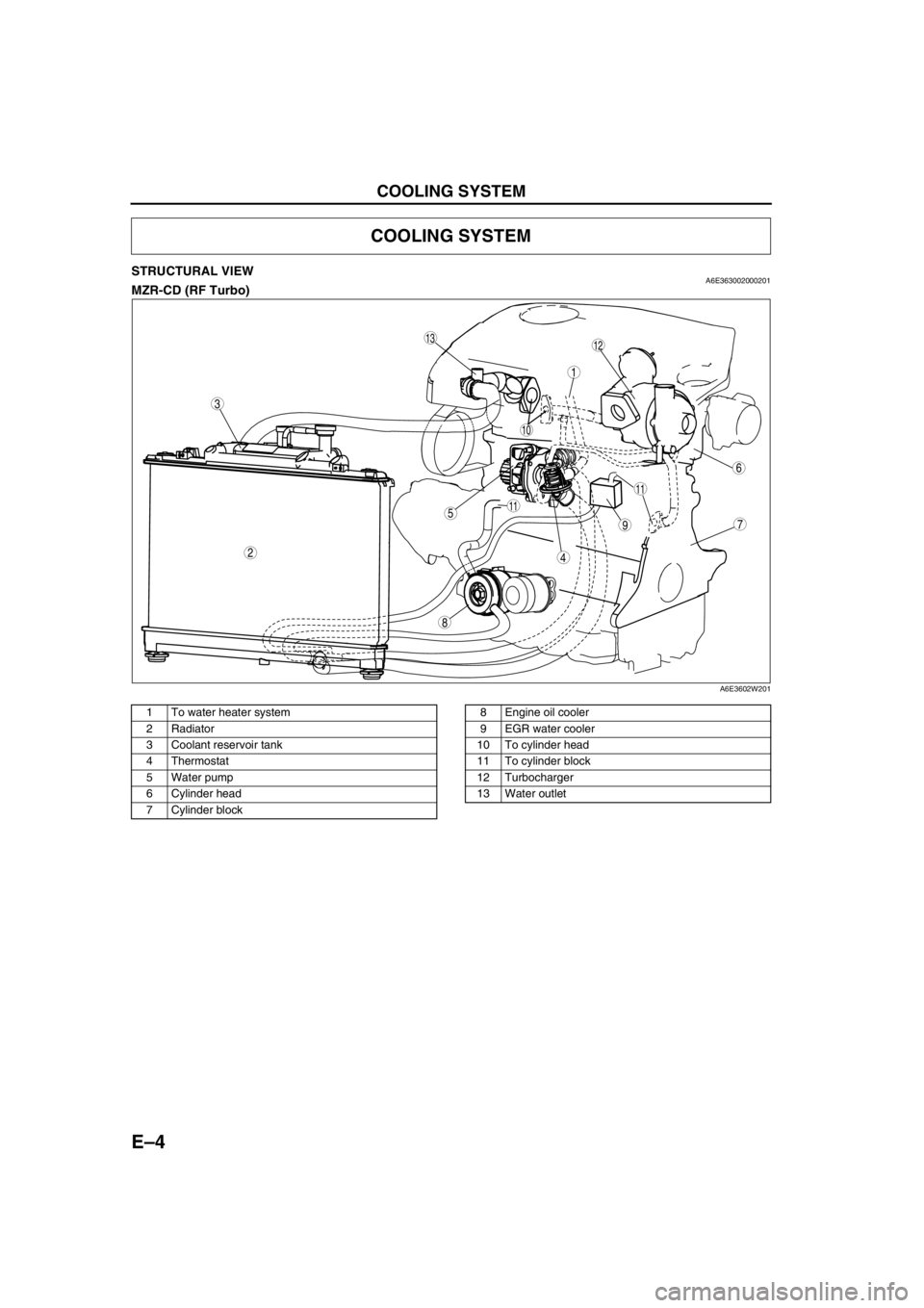

STRUCTURAL VIEWA6E363002000201MZR-CD (RF Turbo)

.

End Of Sie

COOLING SYSTEM

8

75

4

3

1

2

6

10

11

11

9

1312

A6E3602W201

1 To water heater system

2 Radiator

3 Coolant reservoir tank

4Thermostat

5 Water pump

6 Cylinder head

7 Cylinder block8 Engine oil cooler

9EGR water cooler

10 To cylinder head

11 To cylinder block

12 Turbocharger

13 Water outlet

Page 80 of 909

COOLING SYSTEM

E–5

E

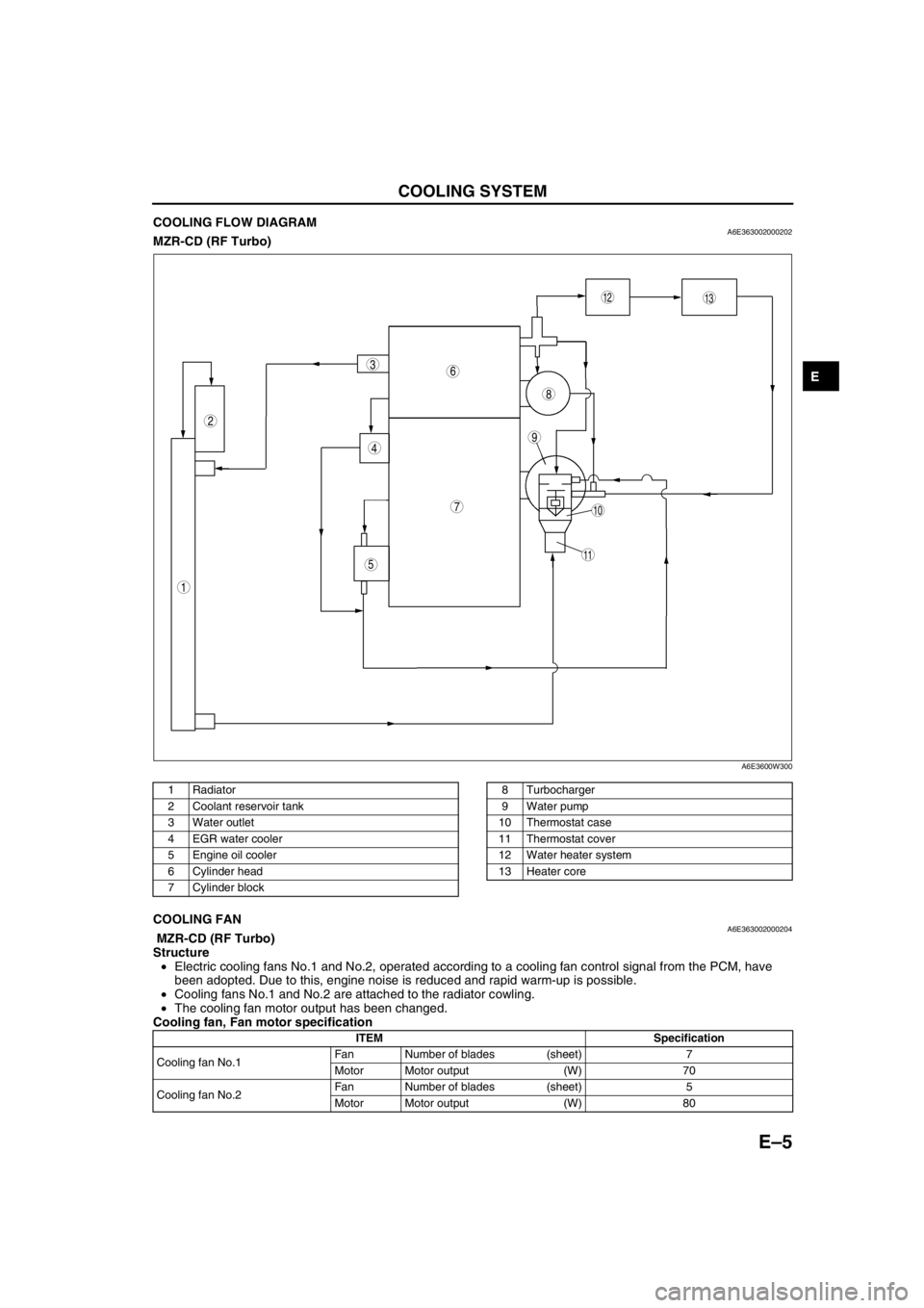

COOLING FLOW DIAGRAMA6E363002000202MZR-CD (RF Turbo)

.

End Of SieCOOLING FANA6E363002000204 MZR-CD (RF Turbo)

Structure

•Electric cooling fans No.1 and No.2, operated according to a cooling fan control signal from the PCM, have

been adopted. Due to this, engine noise is reduced and rapid warm-up is possible.

•Cooling fans No.1 and No.2 are attached to the radiator cowling.

•The cooling fan motor output has been changed.

Cooling fan, Fan motor specification

End Of Sie

9

8

7

5

4

3

1

2

10

13

11

12

6

A6E3600W300

1Radiator

2 Coolant reservoir tank

3 Water outlet

4EGR water cooler

5 Engine oil cooler

6 Cylinder head

7 Cylinder block8 Turbocharger

9 Water pump

10 Thermostat case

11 Thermostat cover

12 Water heater system

13 Heater core

ITEM Specification

Cooling fan No.1Fan Number of blades (sheet) 7

Motor Motor output (W) 70

Cooling fan No.2Fan Number of blades (sheet) 5

Motor Motor output (W) 80

Page 93 of 909

OUTLINE

F1–5

F1

11 Knock sensor

12 CKP sensor

13 CMP sensor

14 Fuel injector No.1

15 Fuel injector No.2

16 Fuel injector No.3

17 Fuel injector No.4

18 IAC valve

19 Oxygen sensor heater (front)

20 Oxygen sensor heater (rear)

21 A/C relay22 Cooling fan relay

23 Cooling fan relay

24 Cooling fan relay

25 TR switch

26 Fuel pump relay

27 Coil

28 Security light

29 Ignition switch

30 Main relay

31 TR switch

32 Starter relay

Page 96 of 909

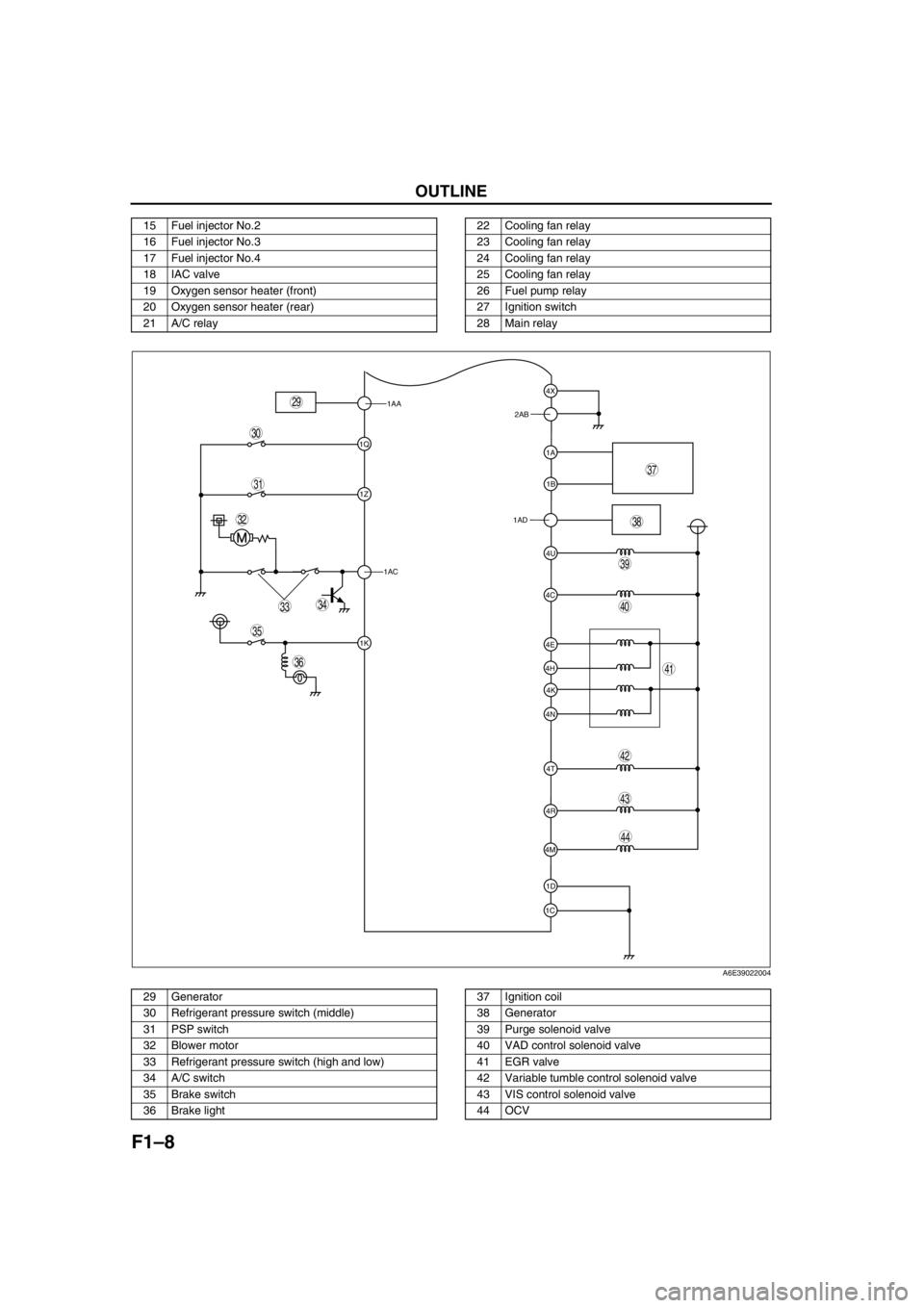

F1–8

OUTLINE

.

15 Fuel injector No.2

16 Fuel injector No.3

17 Fuel injector No.4

18 IAC valve

19 Oxygen sensor heater (front)

20 Oxygen sensor heater (rear)

21 A/C relay22 Cooling fan relay

23 Cooling fan relay

24 Cooling fan relay

25 Cooling fan relay

26 Fuel pump relay

27 Ignition switch

28 Main relay

1AA

1Q

1Z

1AC

1K

1C1D 4M4R 4N4K 4H4E

4T 4C4U 1AD1B 1A 2AB4X

39

38

37

35

36

33

31

32

40

44

43

41

42

34

29

30

A6E39022004

29 Generator

30 Refrigerant pressure switch (middle)

31 PSP switch

32 Blower motor

33 Refrigerant pressure switch (high and low)

34 A/C switch

35 Brake switch

36 Brake light37 Ignition coil

38 Generator

39 Purge solenoid valve

40 VAD control solenoid valve

41 EGR valve

42 Variable tumble control solenoid valve

43 VIS control solenoid valve

44 OCV

Page 103 of 909

CONTROL SYSTEM

F1–15

F1

Output Device

×:Applied

—: Not applied

* : For L3 engine only

End Of Sie

Item SignalMazda6 (GG, GY)

Remark for new model

4WD ATX Unleaded

(RON 90

or above)Current

model

IAC valve IAC×Same as current model

VIC solenoid valve* VIC×—×Same as current model

Variable tumble control

solenoid valveVTCS×Same as current model

Oil control valve (OCV)*Variable valve

timing control×—×Same as current model

Fuel injectorFuel injection

control×Same as current model

Fuel pump relayFuel pump

control×Same as current model

Ignition coil ESA control×Same as current model

EGR valve EGR control×Same as current model

Purge solenoid valve Purge control×Same as current model

BARO factor for Purge control has been

eliminated.

Heated oxygen sensor

heater

(Front, rear)O2S heater

control×Same as current model

Field coil

(Generator terminal D)Generator

control×Same as current model

Cooling fan relayElectric fan

control×Same as current model

A/C relayA/C cut-off

control×Same as current model

Controller area network

(CAN)Information

function×Same as current model

TCM (ATX) information have been

adopted for 4WD ATX model.

Page 106 of 909

F1–18

CONTROL SYSTEM

*1: For MTX model

*2: For 2WD ATX model

*3: For L3 engine

End Of Sie

1 MAF/IAT sensor

2 TP sensor

3 MAP sensor

4 CMP sensor

5 CKP sensor

6 ECT sensor

7 Knock sensor

8 HO2S (front, rear)

9 PSP switch

10 Vehicle speedometer sensor

11

Clutch switch*

1

12

Neutral switch*1

13

TR switch*2

14 Brake switch

15 A/C switch

16 Refrigerant pressure switch

17 Generator (terminal P: generation voltage)

18 Battery

19

VAD control solenoid valve*

3

20 IAC valve

21

VIC solenoid valve*

3

22 Variable tumble control solenoid valve

23

OCV*

3

24 Fuel injector

25 Fuel pump relay

26 Ignition coil

27 Purge solenoid valve

28 EGR valve

29 Oxygen sensor heater (front, rear)

30 A/C relay

31 Cooling fan relay

32 Generator (terminal D: field coil)

33

VAD control*

3

34 IAC

35

VIC*

3

36 VTCS

37

Variable valve timing control*

3

38 Fuel injection control

39 Fuel pump control

40 Electronic spark advance (ESA) control

41 Purge control

42 EGR control

43 Oxygen sensor heater control

44 A/C cut-off control

45 Electrical fan control

46 Generator control