engine oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 286 of 1865

1 C ASSEMBLY (CYLINDER

BLOCK)

76G01C-170

Adjusting

disc

Tappet -

Apply engine oil

4BG01B-150

4BG01B-182

Apply engine oil

1.

Cylinder head bolt

below head length

Valve and Valve Spring

1. Install the lower spring seat.

2. Apply molybdenum disulphide grease to the valve

stem.

3. Install the valve.

4. Install the valve springs and the upper spring seat.

5. Compress the valve spring with the SST; then in-

stall the valve keepers.

6. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Tappet and Adjusting Disc

1. Apply engine oil to the tappets.

2. Install the tappets in the hole.

3. Install the adjusting discs.

Cylinder Head

1. Thoroughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt or grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

76G01C-171

1C-74

Page 287 of 1865

ASSEMBLY (CYLINDER

BLOCK)

1 C

6. Apply engine oil to the cylinder head bolts.

7. Tighten the cylinder head bolts.

(1) Tighten the bolts to the specified torque, in or-

der shown in the figure.

Tightening torque:

29 Nm (3.0 m-kg, 22 ft-lb)

4BG01B184

(2)Make paint marks on the bolt heads, as shown

in the figure.

(3)With the paint marks as a reference point, turn

the cylinder head bolts another 90°

(90°—105°) in the tightening direction. Tight-

en them in the order.

(4)Then tighten them once again 90°

(90°—105°) in the tightening order.

Caution

Be absolutely sure to tighten all bolts in the

order.

4BG01 B-185

Camshaft

1. Apply engine oil to the camshaft and journal part

of the cylinder head.

2. Set the seal cap.

3. Apply a coat of sealant (1016 77 739) to the area

shown in the figure.

4. Install the camshaft so that the key groove faces

directly upward.

4BG01 B-186

5. Install the camshaft caps according to the number

and

^

mark,

and loosely tighten the camshaft cap

nuts.

76G01C-172

1C—75

Page 288 of 1865

1 C ASSEMBLY (CYLINDER HEAD)

6. Apply a coat of engine oil to the new oil seal lip

and insert it.

76G01C-253

76G01C-173

Glow cord

Glow plug

76G01C-174

7. Tighten the camshaft cap nuts evenly in order

shown in the figure.

Tighten torque:

20—26

N m

(2.0—2.7 m-kg, 14—20 ft-lb)

Note

The adjustment of the valve clearance should

be made only after the camshaft pulley injec-

tion pump pulley and timing belt have been

installed.

Glow Plug and Glow Cord

1. Install the glow plugs.

Tightening torque:

15—20 Nm (1.5—2.0 m-kg, 11—15 ft-lb)

2. Install the glow cord.

Tightening torque:

0.8—1.5 Nm (8.0—15 cm-kg, 7—13 in-lb)

Injection Nozzle and Leak Pipe

1. Install the new corrugated washers and the new

copper gaskets in position.

2. Install the injection nozzles.

Tightening torque:

59—69 Nm (6.0—7.0 m-kg, 43—51 ft-lb)

Note

The corrugated washers and copper gaskets

must be replaced with new ones each time the

injection nozzles are removed.

3. Install the leak pipe.

Tightening torque:

31—44

N m

(3.2—4.5 m-kg, 23—33 ft-lb)

76G01C-175

1C—76

Page 300 of 1865

1 C ASSEMBLY (AUXILIARY PARTS)

76G01C-205

76G01C-206

76G01C-207

o e-

Oil Cooler Assembly

1. Clean the contact surfaces of the cylinder block

and oil filter assembly.

2. Install new O-rings, and apply a coat of engine oil.

3. Install the oil cooler assembly.

Tightening torque:

Bolt A: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

4. Connect the water hose.

Oil Filter

1. Install the oil filter cover.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Apply a coat of engine oil to the filter rubber seal.

3. Install the oil filter until the rubber seal contacts the

oil cooler by hand. Then tighten it a 7/6 turn fur-

ther with a band type wrench.

Alternator

1. Install the alternator.

Tightening torque:

Bolt A: 19—26 N m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

2. Install the alternator drive belt, and adjust the belt

deflection. (Refer to page 1C—7)

76G01C-208

1C—88

expert22 ajia http://rutracker.org

Page 302 of 1865

1 C ASSEMBLY (AUXILIARY PARTS)

76G01C-213

76G01C-214

Comprex Supercharger Insulator

Install the comprex supercharger insulator.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Air Funnel Assembly

1. Install the air funnel assembly.

Tightening torque:

Bolt A: 19—26

N

m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 3—4

N

m

(35—45 cm-kg, 30—39 ft-lb)

2. Connect the actuator vacuum tube.

76G01C-215

Vacuum Pump

1. Install the vacuum pump with bracket.

Tightening torque:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

2. Connect the oil pipe and hose.

Tightening torque:

12—18 N-m (1.2—1.8 m-kg, 104—156 ft-lb)

3. Install the drive belt, and adjust the belt deflection.

(Refer to page 1C—7)

PCV Hose

Install the PCV hose.

I! Jfc)' j

.CSD water hose

ilJJM: !

76G01C-216

CSD Water Hose

1. Remove the engine from the engine hanger.

2. Tighten the oil pipe mounting bolts.

Bolt A: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Bolt B: 12—18 N-m

(1.2—1.8 m-kg, 104—156 ft-lb)

3. Install the CSD water hose.

Tightening torque:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

1C-90

Page 311 of 1865

INSTALLATION 1C

Accelerator Cable

Install the accelerator cable.

76G01C-235

76G01C-236

Engine Oil

Add the specified amount and type of engine oil. (Re-

fer to Section 2B)

Coolant

Close the drain plug, fill the radiator and reservoir tank

with the specified amount and type of coolant. (Re-

fer to Section 3B)

Check Engine Condition

1. Check for leaks.

2. Perform engine adjustments if necessary.

3. Perform a road test.

4. Recheck the oil and coolant levels.

1C—99

Page 312 of 1865

LUBRICATION SYSTEM

(GASOLINE ENGINE)

OUTLINE 2A— 2

LUBRICATION CIRCUIT (DOHC) 2A— 2

LUBRICATION CIRCUIT (SOHC) 2A— 3

SPECIFICATIONS 2A— 4

TROUBLESHOOTING GUIDE 2A— 4

INSPECTION 2A— 5

ENGINE OIL 2A— 5

OIL PRESSURE 2A— 5

ENGINE OIL 2A— 5

REPLACEMENT 2A— 5

OIL FILTER 2A— 6

REPLACEMENT 2A— 6

OIL COOLER 2A— 6

REMOVAL AND INSTALLATION 2A— 6

OIL PAN 2A— 7

REMOVAL 2A— 7

INSPECTION 2A— 8

INSTALLATION 2A— 8

OIL PUMP 2A— 9

REMOVAL 2A— 9

DISASSEMBLY 2A—11

INSPECTION 2A—11

ASSEMBLY 2A—13

INSTALLATION 2A—13

76G02A-001

Page 315 of 1865

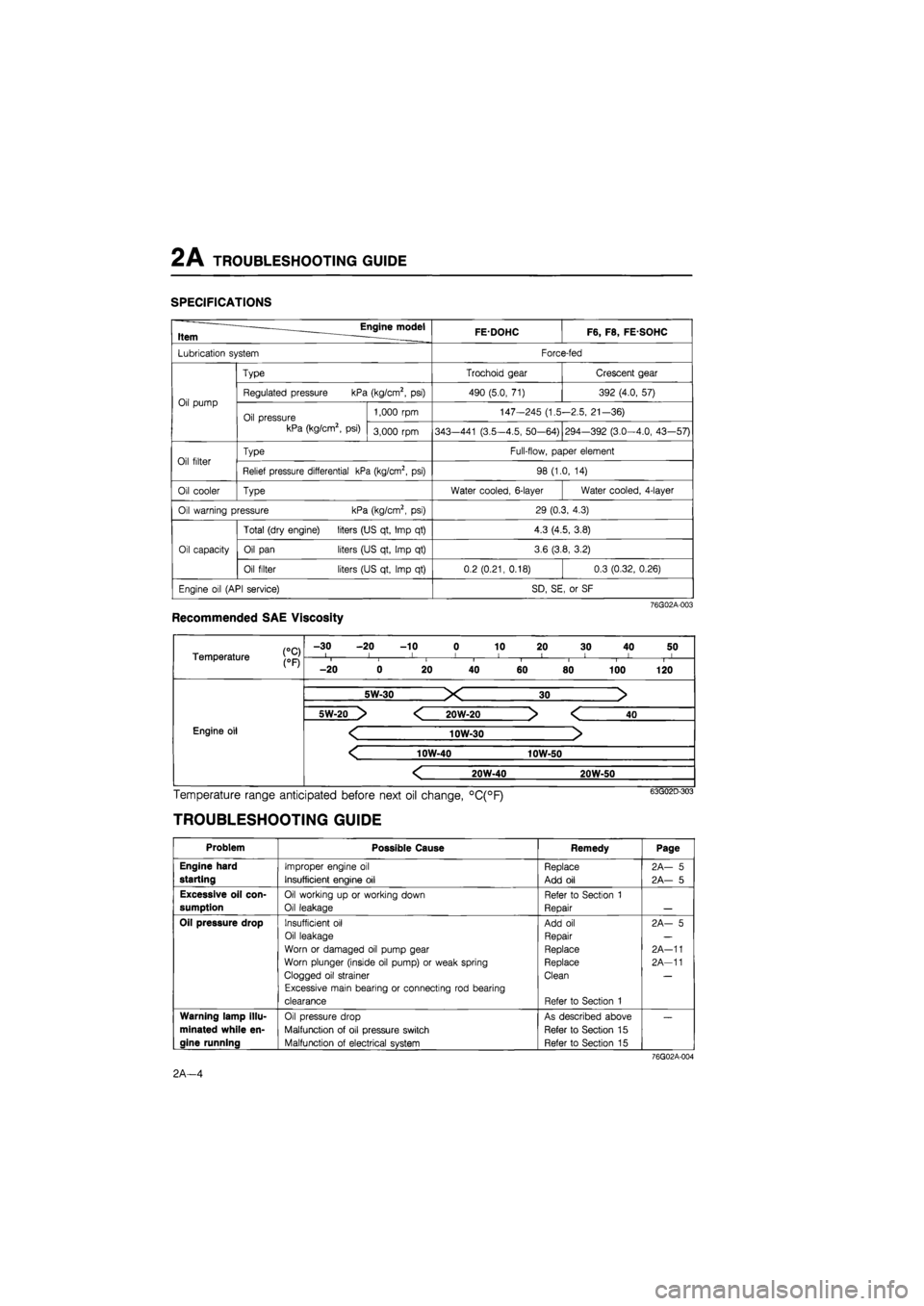

2 A TROUBLESHOOTING GUIDE

SPECIFICATIONS

Engine model Item . FEDOHC F6, F8, FE SOHC

Lubrication system Force-fed

Oil pump

Type Trochoid gear Crescent gear

Oil pump Regulated pressure kPa (kg/cm2, psi) 490 (5.0, 71) 392 (4.0, 57) Oil pump

Oil pressure kPa (kg/cm2, psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pump

Oil pressure kPa (kg/cm2, psi) 3,000 rpm 343—441 (3.5-4.5, 50-64) 294-392 (3.0-4.0, 43—57)

Oil filter Type Full-flow, paper element Oil filter Relief pressure differential kPa (kg/cm2, psi) 98 (1.0, 14)

Oil cooler Type Water cooled, 6-layer Water cooled, 4-layer

Oil warning pressure kPa (kg/cm2, psi) 29 (0.3, 4.3)

Oil capacity

Total (dry engine) liters (US qt, Imp qt) 4.3 (4.5, 3.8)

Oil capacity Oil pan liters (US qt, Imp qt) 3.6 (3.8, 3.2) Oil capacity

Oil filter liters (US qt, Imp qt) 0.2 (0.21, 0.18) 0.3 (0.32, 0.26)

Engine oil (API service) SD, SE, or SF

76G02A-003

Recommended SAE Viscosity

Temperature j0pj

-30 -20 -10 0 10 20 30 40 50 I l I I 1 < ! I I Temperature j0pj i i i i I i 1 1

-20 0 20 40 60 80 100 120

Engine oil Engine oil

5W-30 X 30 >

Engine oil Engine oil

5W-20 > < 20W-20 > < 40

Engine oil < 10W-30 > Engine oil

< 10W-40 10W-50

Engine oil Engine oil

< 20W-40 20W-50

Engine oil

Temperature range anticipated before next oil change, °C(°F)

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine oil

Insufficient engine oil

Replace

Add oil

2A— 5

2A— 5

Excessive oil con-

sumption

Oil working up or working down

Oil leakage

Refer to Section 1

Repair

Oil pressure drop Insufficient oil

Oil leakage

Worn or damaged oil pump gear

Worn plunger (inside oil pump) or weak spring

Clogged oil strainer

Excessive main bearing or connecting rod bearing

clearance

Add oil

Repair

Replace

Replace

Clean

Refer to Section 1

2A- 5

2A-11

2A-11

Warning lamp illu-

minated while en-

gine running

Oil pressure drop

Malfunction of oil pressure switch

Malfunction of electrical system

As described above

Refer to Section 15

Refer to Section 15

76G02A-004

2A—4

Page 316 of 1865

INSPECTION, ENGINE OIL 2A

86U02X-004

INSPECTION

ENGINE OIL

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temper-

ature and stop it.

3. Wait for five minutes.

4. Remove the oil level gauge and check the oil lev-

el and condition.

5. Add or replace oil if necessary.

Note

The distance between the L and F marks on

the level gauge represents 1.0 liter (1.06 US

qt, 0.88 Imp qt).

OIL PRESSURE

1. Remove the oil pressure switch.

69G02A-006

76G02A-005

86U02X-006

2. Screw the SST into the pressure switch installa-

tion hole.

3. Warm up the engine to normal operating tem-

perature.

4. Run the engine at 3,000 rpm, and note the gauge

reading.

Oil pressure:

343—441 kPa

(3.5—4.5 kg/cm2, 50—64 psi)...DOHC 2g4 392 kPa

(3.0—4.0 kg/cm2, 43—57 psi)...SOHC

5. If the pressure is not as specified, check for the

cause, and repair if necessary.

(Refer to Troubleshooting Guide.)

ENGINE OIL

REPLACEMENT

1. Warm up the engine to the normal operating tem-

perature and stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

Warning

Be careful when draining, the oil is very hot.

2A-5

Page 317 of 1865

2A OIL FILTER, OIL COOLER

j

F

k

4

4. Install the drain plug and a new gasket.

5. Refill the engine with the specified type and amount

of oil.

6. Refit the oil filler cap.

Oil pan capacity:

3.6 liters (3.8 US qt, 3.2 Imp qt)

7. Recheck the oil level after the engine has been run.

76G02A-006

TbJ

r

86U02X-008

76G02A-007

0

A

if \ lO

/O

f \ 11 • V jJ

VJ f .fa,-

n D

©

76G02A-008

OIL FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface

on the engine.

3. Apply a small amount of engine oil to the rubber

seal of the new filter.

Warning

Be careful that the engine and filter are very

hot.

4. (DOHC)

Install the oil filter until the rubber seal contacts the

base and then tighten the filter

1

and

1

/6 turn with

a wrench.

(SOHC)

Install the oil filter and tighten it by hand only. Do

not use a wrench.

5. Start the engine and inspect around the filter seal

for leaks.

6. Check the oil level and add oil if necessary.

Oil filter capacity:

0.20 liters (0.21 US qt, 0.18 Imp qt)...DOHC

0.30 liters (0.32 US qt, 0.26 Imp qt)...SOHC

OIL

COOLER

(DOHC, 12-valve,

ECE

8-valve)

REMOVAL AND INSTALLATION

Remove in the sequence shown in the figure.

Install in the reverse order of removal.

1. Water hose

2. Oil filter

3. Nut

4. Oil cooler

Nut tightening torque:

29—39

N

m (3.0—4.0 m-kg, 22—29 ft-lb)

2A-6