steering MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1368 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

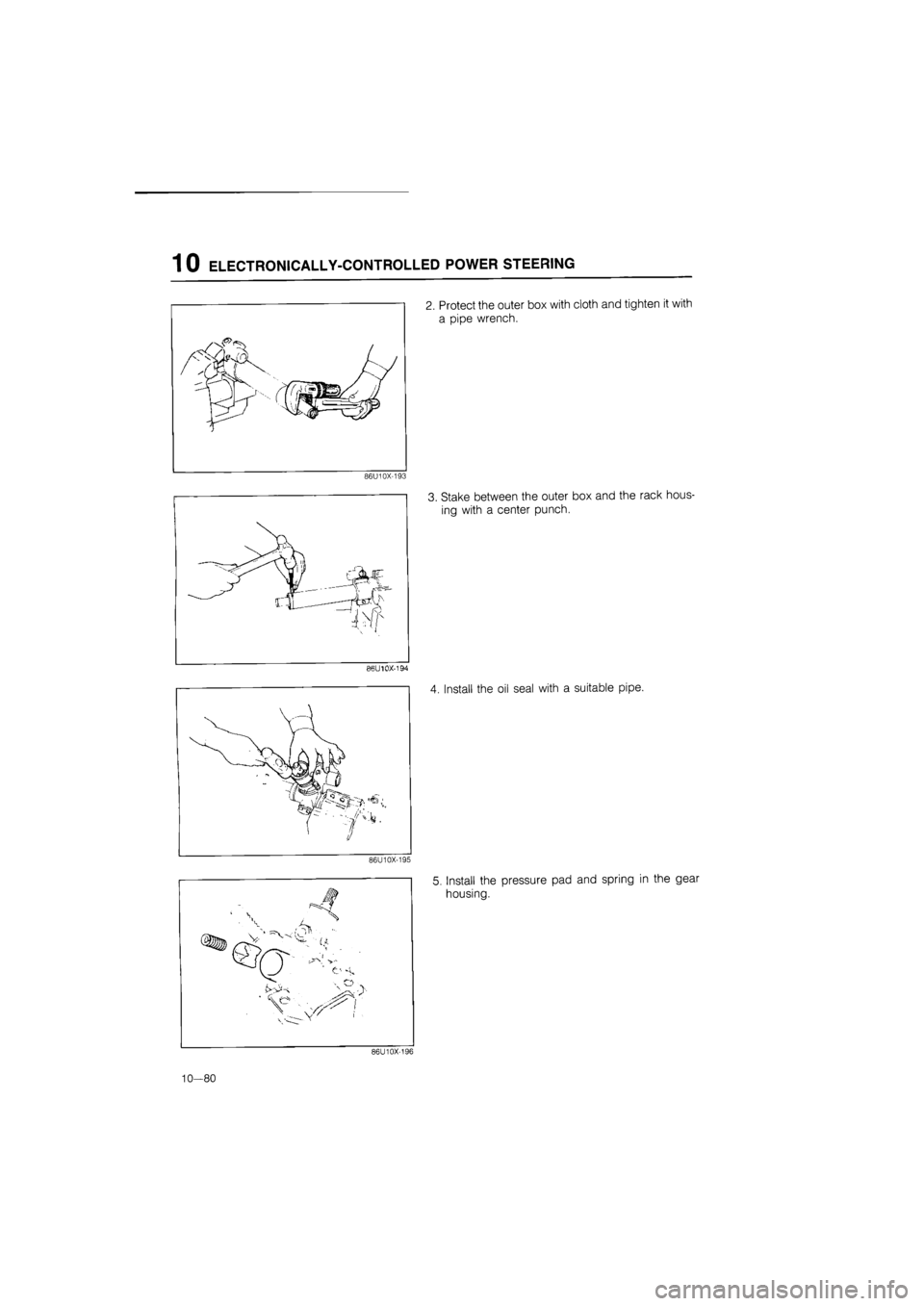

2. Protect the outer box with cloth and tighten it with

a pipe wrench.

86U10X-193

3. Stake between the outer box and the rack hous-

ing with a center punch.

B6U10X-194

4. Install the oil seal with a suitable pipe.

86U10X-195

5. Install the pressure pad and spring in the gear

housing.

86U10X-196

10—80

Page 1369 of 1865

ELECTRONICALLY-CONTROLLED POWER STEERING 1 0

86U10X-197

86U10X-198

86U10X-199

6. Apply thread sealant to the threads of the adjust

cover.

7. Install the adjust cover to the gear housing and

tighten it as specified; then loosen it 35°.

Tightening torque:

4.5—5.5 Nm

(45—55 cm-kg, 39—48 in-lb)

8. Measure the pinion torque with the SST.

Pull scale: 1,000—1,400 g (35.3—49.4 oz)

9. If the pinion torque is not within specification, read-

just the adjust cover.

10. Lock the adjust cover with the locknut.

Tightening torque:

40—50

N

m

(4—5 m-kg, 29—36 ft-lb)

11. Set the rack in a vise and install the washer. Tight-

en the tie-rod.

Tightening torque:

60—80 N-m

(6—8 m-kg, 43—58 ft-lb)

Caution

Insert protective material (such as copper

plates) in the jaws of the vise.

76G10X-040

10—81

Page 1370 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

12. Stake the washer in two places with a punch.

86U10X-201

13. Install the boot. Wrap a new wire around it two

times and twist it 4 to 4.5 times.

Caution

Be sure that the boot is not twisted or dented.

86U10X-202

14. Install the tie-rod ends, aligning them with the marks

made before disassembly.

86U10X-203

15. Install the solenoid valve and pressure switch.

16. Align the oil pipes with the marks made before dis-

assembly, then tighten them.

86U10X-204

10—82

Page 1371 of 1865

OIL PUMP 1 0

OIL PUMP

REMOVAL AND INSTALLATION

1. Jack up the front of the vehicle, and support it with safety stands.

2. Remove in the order shown in the figure, referring to the removal note for specially marked parts.

3. Install in the reverse order of removal.

4. Tighten all nuts and bolts to the specified torque, referring to the figure.

Note

a) The power steering fluid will leak out when the return hose or the pressure hose is dis-

connected. Prepare a suitable container for it to drain into.

b) After installation, inspect the deflection of the oil pump belt and bleed the air from the

system, then check for fluid leakage. 2WS (Gasoline engine)

76G10X-041

4. Bracket

5. Oil pump

6. Oil pump pulley

1. Belt

2. Nut

3. Pipes

10—83

Page 1375 of 1865

ELECTRICAL COMPONENTS OF ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS) 1 0

ELECTRICAL

COMPONENTS

OF

ELECTRONICALLY-CONTROLLED POW-

ER STEERING (ECPS)

CIRCUIT DIAGRAM

J POWER STEERING CONTROL SYSTEM (Electronically-Controlled: FE DOHC Engine Without 4WS) AUTO ADJUSTING SUSPENSION CONTROL SYSTEM (AAS)

MAIN FUSE

IcLJ=.cLLJX..=L1.| T'TTTTT'P LB YL GW GY * B «

I-02

Solenoid Valve

[EM] J-04

Check Connector |F|

VG-j-Ijj-LW

J-05

AAS

Conlorl Unit |R| YR YL GR BY B GY WY WR \LL L LuL I 1 L I T. T TTT T T. T,i B G GW LY WL IT TT TI

J-07 Aclualor (FL) |F] WY WR J-08 Aclualor (FR) [D] WY WR J-09 Aclualor (RL) [R| YL YR J-10 Aclualor

(RR) |R|

Yl YR

86U10X-208

Note

Refer to page 10—4 for the component location.

TROUBLESHOOTING GUIDE

The power steering control unit contains a self-diagnosis function to detect malfunctions within itself,

the ECPS electrical components and circuits.

If a malfunction is detected, the control unit indicates where the problem is located by outputting specific

voltage pulsations at terminal wire (YB) of the check connector.

Troubleshooting of the ECPS system, then, is easily performed by comparing the output pattern with

those of the Diagnosis Table on pages 10—89 and 90. 76G10X-019

TROUBLESHOOTING

How To Use Self-Diagnosis System

By using the control unit's self-diagnosis function and

a voltmeter, malfunctions of the system are easily de-

termined. When diagnosing malfunctions, follow the

steps below.

1. Connect a voltmeter to terminal wire (YB) of the

check connector in the engine compartment.

2. Check the output patterns as described on the fol-

lowing page.

86U10X-209

10—87

Page 1376 of 1865

1 0 ELECTRICAL COMPONENTS OF ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS)

76G10X-020

76G10X-021

Checking Condition

Condition A

1. Turn the ignition switch OFF.

2. Start the engine and let it idle.

3. Turn the steering wheel to the straight-ahead po-

sition, and check the output pattern.

Refer to page 10—89 for other patterns and indi-

cated failure points.

Condition B

1. Turn the ignition switch OFF.

2. Start the engine and let it idle.

3. Turn the steering wheel 45° left and right from the

center, and check the output pattern.

Refer to page 10—89 for other patterns and indi-

cated failure points.

Condition C

1. Turn the ignition switch OFF.

2. Place the vehicle on a chassis roller tester. Block

the rear wheels, and secure it with chains.

3. Start the engine. Put the transmission in gear and

operate the vehicle at more than 10 km/h (6.2

mph).

4.Check the output pattern.

76G10X-022

Normal pattern

4 4V

Normal pattern Normal pattern

uV

Refer to page 10—90 for other patterns and indi-

cated failure points.

Note

For vehicles equipped with ABS, the ABS

warning light may come on. This is not a fail-

ure. The light will go off when turning the ig-

nition switch OFF and back ON.

86U10X-213

10—88

Page 1377 of 1865

ELECTRICAL COMPONENTS OF ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS) 1 0

Diagnosis Table

Condition Output pattern Malfunction Flow chart

No.

4.4V

0V-

10 seconds Power steering sole-noid valve or wiring harness (Control unit to Solenoid valve)

P/S—1

Refer to page

10-91

4.4V

0V-

Wiring harness (Con-

trol unit to Ignition coil) P/S—2 Refer to page 10-91

Steering wheel in straight-ahead po-sition with engine idling.

4.4V

OV-

Steering wheel angle sensor or wiring har-ness (Control unit to Angle sensor)

P/S—3 Refer to page 10-92

4.4V

ov-

Normal operation

Wiring harness (Fuse box to Control unit or Control unit to Body ground)

P/S—5 Refer to page 10—93

OV

10 seconds Power steering sole-

noid valve or wiring

harness (Control unit

to Solenoid valve)

P/S—1 Refer to page 10—91

B Steering wheel turned 45° left and right from center with engine idling

4.4V

0V

Wiring harness (Con-

trol unit to Ignition coil)

P/S—2 Refer to page 10-91

4.4V

0V'

Normal operation

4.4V

0V-

Steering wheel angle

sensor or wiring har-

ness (Control unit to

Angle sensor)

P/S—3 Refer to page 10—92

76G10X-023

10-89

Page 1378 of 1865

1 0 ELECTRICAL COMPONENTS OF ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS)

Condition Output pattern Malfunction Flow chart No.

B Cont'd

OV

Wiring harness (Fuse

box to Control unit or

Control unit to Body

ground)

P/S—5 Refer to page 10-93

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

4.4V —

1 3 s econds Power steering sole-noid valve or wiring harness (Control unit to Solenoid valve)

P/S—1 Refer to page 10-91

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

uv

Power steering sole-noid valve or wiring harness (Control unit to Solenoid valve)

P/S—1 Refer to page 10-91

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

4.4V

n\i

—

Wiring harness (Con-trol unit to Ignition coil) P/S—2 Refer to page 10-91

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

Wiring harness (Con-trol unit to Ignition coil) P/S—2 Refer to page 10-91

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

4.4V

Steering wheel angle sensor or wiring har-ness (Control unit to Angle sensor)

P/S-3 Refer to page 10—92

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

Steering wheel angle sensor or wiring har-ness (Control unit to Angle sensor)

P/S-3 Refer to page 10—92

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

4.4V

Vehicle speed sensor or wiring harness

(Control unit to Meter)

P/S—4 Refer to page 10-92

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

uv

Vehicle speed sensor or wiring harness

(Control unit to Meter)

P/S—4 Refer to page 10-92

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

4.4V

OV —

Normal operation —

C

Front wheels driv-en at more than 10 km/h (6.2 mph)

OV

Wiring harness (Fuse box to Control unit or Control unit to Body ground)

P/S—5 Refer to page 10-93

76G10X-024

10-90

Page 1379 of 1865

ELECTRICAL COMPONENTS

OF

ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS) 1 0

Flow Chart

P/S—1

Failure of solenoid valve or wiring harness (Control unit to Solenoid valve)

Disconnect control unit connector. Check resistance between terminals.

Check voltage between (YL) and D (B) terminal of

control unit connector with engine running

OK

Terminal Resistance

M(LB)—N(LG) 3.5 — 7Q

Check control unit connector, solenoid valve connec-tor, and joint connector for connection, and check output pattern again.

NG

Check the solenoid valve (Refer to page 10—93),

NG

Replace solenoid valve.

P/S-Z Broken wiring harness

(Control unit to Coil)

Terminate of control unit connector with engine running.

NG

Replace control unit.

OK Repair wiring harness (Control unit to Solenoid valve).

Terminal Voltage

L(YL)-D(B) Approx. 12V

NG Repair the wiring harness (Control unit to Ignition

coil).

OK

Replace control unit.

76G10X-025

10—91

Page 1380 of 1865

1 0 ELECTRICAL COMPONENTS OF ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS)

OK

Check for continuity between each terminals of steer-ing angle sensor and control unit harness side con-nector.

Terminal Continuity Angle sensor Control unit Continuity

(G) KG) Yes

(GY) H(GY) Yes

(GW) J(GW) Yes

Repair wiring harness (Control unit to angle sensor).

OK

Replace control unit.

OK

Replace control unit.

76G10X-043

10—92