engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 274 of 1865

1 C ASSEMBLY (CYLINDER BLOCK)

ASSEMBLY

1. Clean all parts before reinstallation.

2. Apply new engine oil to all sliding and rotating parts.

3. Replace plain bearings if they are peeling, burned, or otherwise damaged.

4. Tighten all bolts and nuts to the specified torques.

Caution

Do not reuse gaskets or oil seals.

CYLINDER BLOCK—I

Torque Specifications

69G01A-139

1C—62

Page 275 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

Cavity

"F" mark

o

/-Matching mark

76G01C-147

76G01C-252

Top ring and — 90° •v. Second ring expanders. •v. Second ring

457//

iW

\ /

-J^/ \Oil ring

4BG01B-153

RF-CX RF-N

—ll Br1 &Top

GO [IP 2nd

fa? r® oil

Piston ring

Connecting Rod

1. Align the piston cavity and matching mark in the

large end of the connecting rod.

2. Apply engine oil to the circumference of each pis-

ton pin and to the small end of each connecting

rod.

3. Insert a snap ring into one of the piston pin holes

in the piston.

4. Install the piston pin using the SST.

5. Connect the piston and connecting rod by the pis-

ton pin, and lock the snap ring.

Note

Heat the piston to 50—70°C (120—170°F) for

installation.

Piston Ring

1. Apply a liberal coat of engine oil to the piston rings.

2. Install the oil ring expander and the oil ring.

3. Install the second ring.

4. Install the top ring.

5. Align the piston ring end gaps, as shown in the

figure.

Caution

The rings must be mounted so the "R" or "N"

marks face upward.

76G01C-148

1C—63

Page 277 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

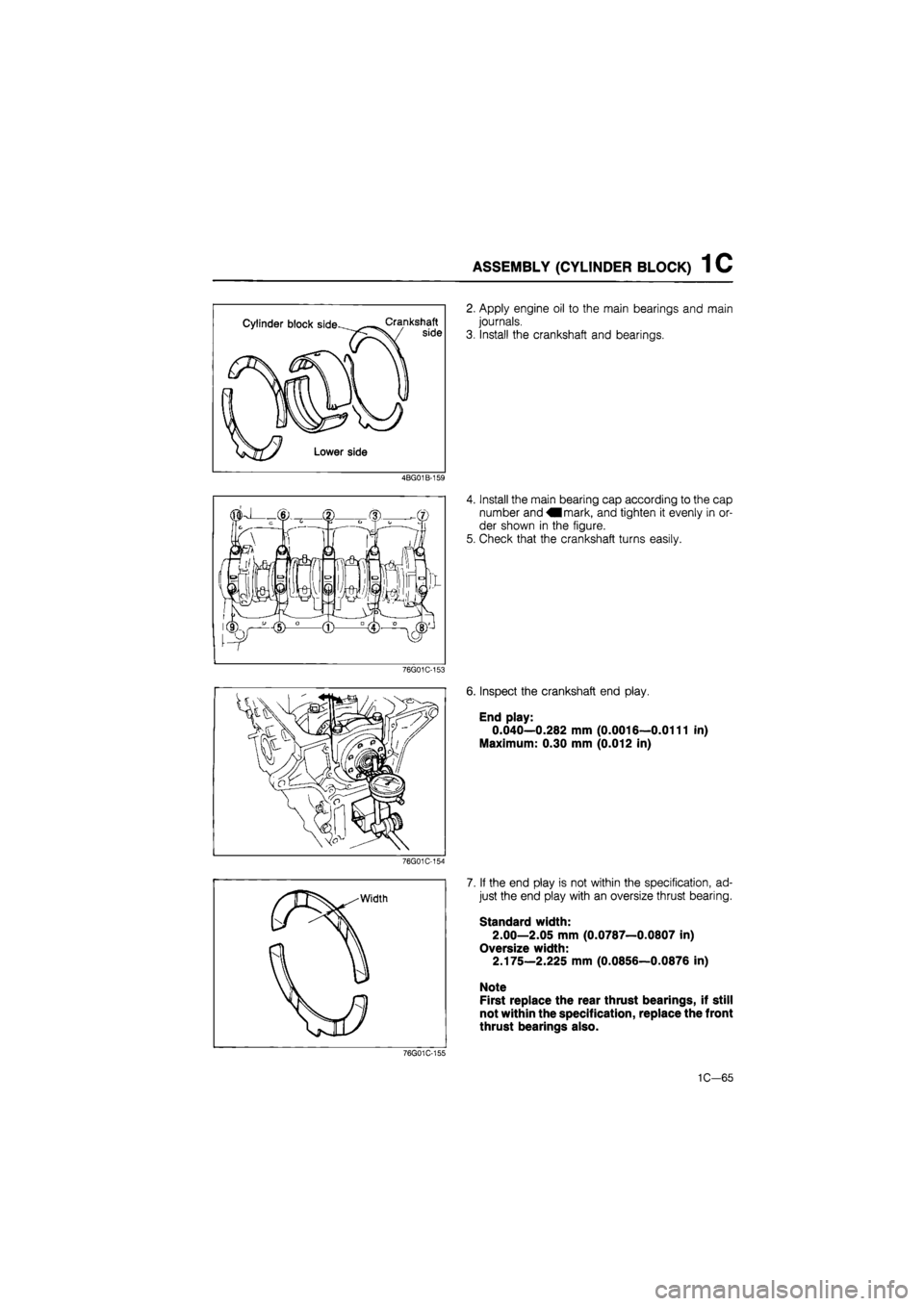

Cylinder block side Crankshaft side

Lower side

4BG01B-159

2. Apply engine oil to the main bearings and main

journals.

3. Install the crankshaft and bearings.

4. Install the main bearing cap according to the cap

number and mark, and tighten it evenly in or-

der shown in the figure.

5. Check that the crankshaft turns easily.

76G01C-153

6. Inspect the crankshaft end play.

End play:

0.040—0.282 mm (0.0016—0.0111 in)

Maximum: 0.30 mm (0.012 in)

76G01C-154

76G01C-155

7. If the end play is not within the specification, ad-

just the end play with an oversize thrust bearing.

Standard width:

2.00—2.05 mm (0.0787—0.0807 in)

Oversize width:

2.175—2.225 mm (0.0856—0.0876 in)

Note

First replace the rear thrust bearings, if still

not within the specification, replace the front

thrust bearings also.

1C-65

Page 278 of 1865

1C ASSEMBLY (CYLINDER BLOCK)

Pilot Bearing

1. Apply engine oil to the outer circumference of the

bearing.

2. Set a piece of pipe (outer diameter 30—34 mm,

1.18—1.34 in) against the outer race of the bear-

ing, then tap it evenly into the crankshaft.

3. Lubricate the bearing with grease.

76G01C-156

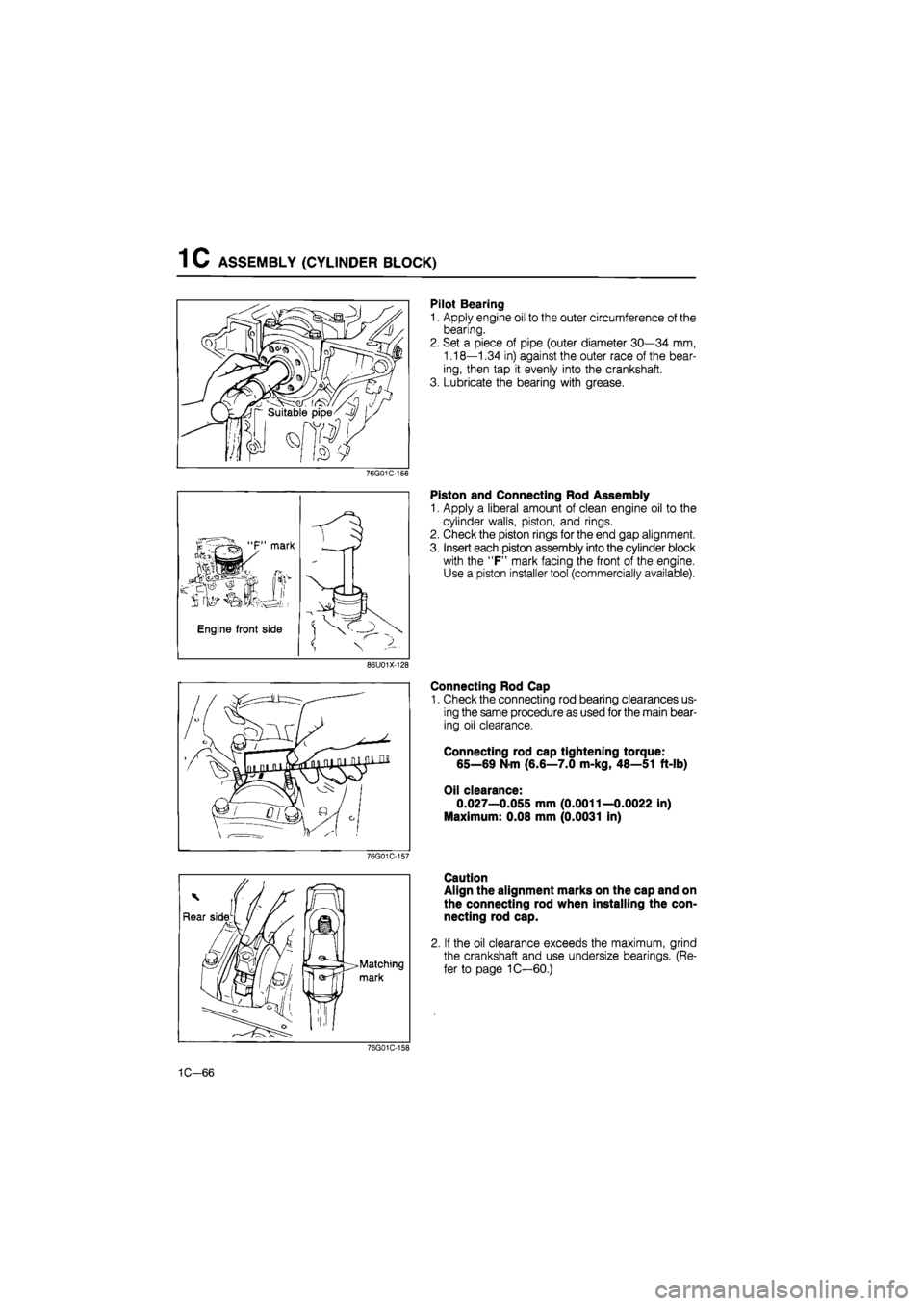

Piston and Connecting Rod Assembly

1. Apply a liberal amount of clean engine oil to the

cylinder walls, piston, and rings.

2. Check the piston rings for the end gap alignment.

3. Insert each piston assembly into the cylinder block

with the "F" mark facing the front of the engine.

Use a piston installer tool (commercially available).

86U01X-128

Connecting Rod Cap

1. Check the connecting rod bearing clearances us-

ing the same procedure as used for the main bear-

ing oil clearance.

Connecting rod cap tightening torque:

65—69 N-m (6.6—7.0 m-kg, 48—51 ft-lb)

Oil clearance:

0.027—0.055 mm (0.0011—0.0022 in)

Maximum: 0.08 mm (0.0031 in)

76G01C-157

Caution

Align the alignment marks on the cap and on

the connecting rod when installing the con-

necting rod cap.

If the oil clearance exceeds the maximum, grind

the crankshaft and use undersize bearings. (Re-

fer to page 1C—60.)

76G01C-158

1C-66

Page 279 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

3. Check the side clearance of each connecting rod

without the cap installed.

Side clearance:

0.11—0.262 mm (0.0043—0.0103 in)

Maximum: 0.30 mm (0.012 in)

If the clearance exceeds the maximum, replace the

connecting rod.

76G01C-159

4. Apply a liberal amount of engine oil to the crank-

pin journal and connecting rod bearing.

5. Install the connecting rod cap with the alignment

marks aligned.

Tightening torque:

65—69 Nm (6.6—7.0 m-kg, 48—51 ft-lb)

86U01X-130

Oil jet

Install the oil jet into the cylinder block.

Tightening torque: 12—18 N-m

(1.2—1.8 m-kg, 104—156 in-lb)

76G01C-160

1C-67

Page 280 of 1865

1 C ASSEMBLY (CYLINDER BLOCK)

CYLINDER BLOCK—II

Torque Specifications

179—193 N m (18.3—19.7 m-kg, 132—142 ft-lb)

—

I iu

uii-nn, 69—95 in-tb)

69G01A-166

Rear Cover

1. Apply engine oil to the rear cover, oil seal and oil

seal lip.

2. Press the oil seal into the rear cover.

4BG01A-158

1C-68

Page 281 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

86U01X-131

86U01X-132

76G01C-161

3. Install the rear cover and a new gasket.

Tightening torque:

8—12 Nm (80—120 cm-kg, 69—104 in-lb)

4. Cut away the portion of the gasket that projects out

from the rear cover assembly toward the oil pan

side.

Caution

Do not scratch the rear cover assembly.

End Plate

Install the end plate.

Tightening torque:

19—26

N

m (1.9—2.6 m-kg, 14—19 ft-lb)

Oil Pump

1. Apply engine oil to a new oil pump oil seal and the

oil pump body.

2. Press the oil seal into the oil pump body.

79G01C-085

1C-69

Page 282 of 1865

1 C ASSEMBLY (CYLINDER BLOCK)

86U01X-133

76G01C-162

76G01C-163

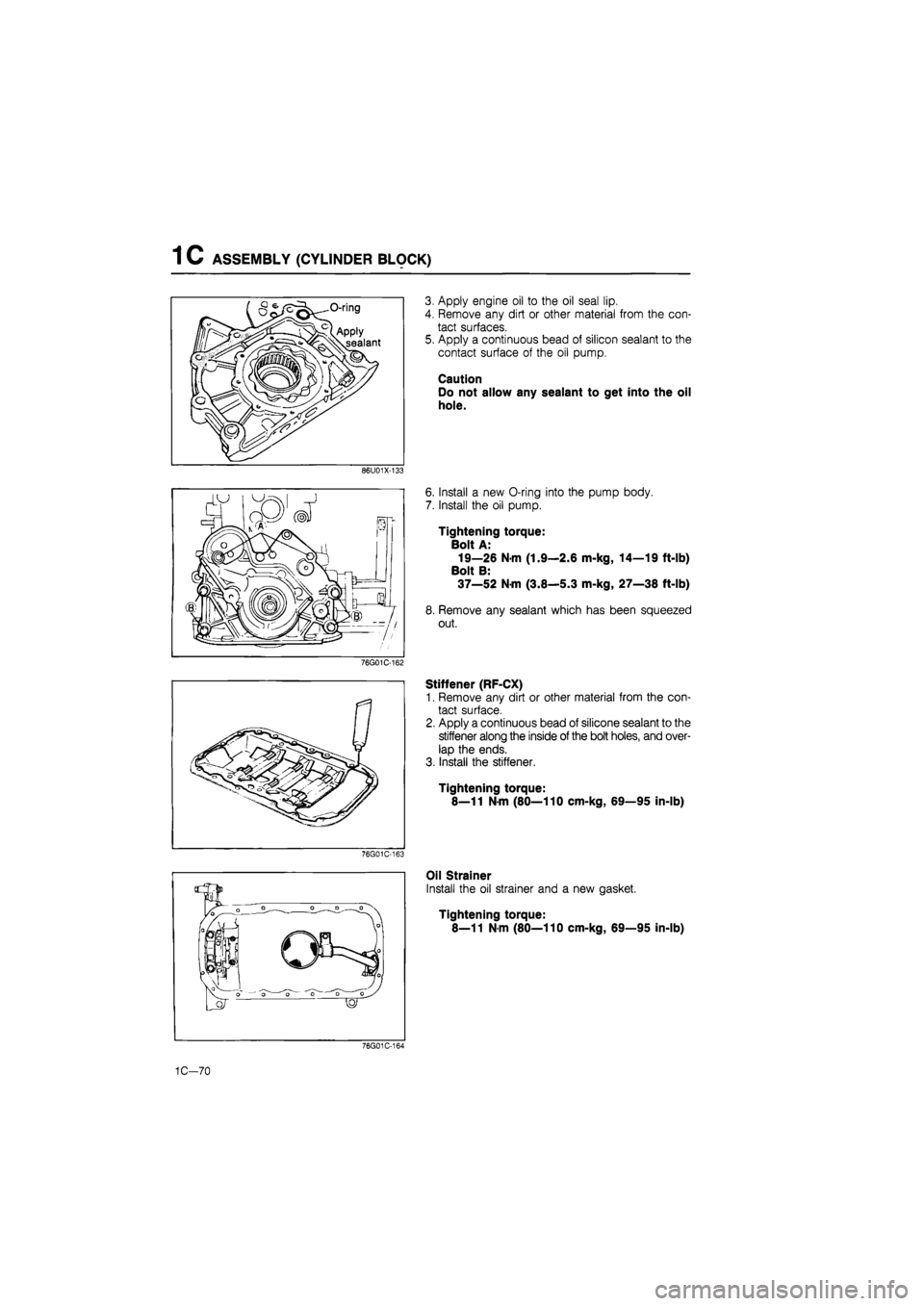

3. Apply engine oil to the oil seal lip.

4. Remove any dirt or other material from the con-

tact surfaces.

5. Apply a continuous bead of silicon sealant to the

contact surface of the oil pump.

Caution

Do not allow any sealant to get into the oil

hole.

6. Install a new O-ring into the pump body.

7. Install the oil pump.

Tightening torque:

Bolt A:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B:

37—52 Nfli (3.8—5.3 m-kg, 27—38 ft-lb)

8. Remove any sealant which has been squeezed

out.

Stiffener (RF-CX)

1. Remove any dirt or other material from the con-

tact surface.

2. Apply a continuous bead of silicone sealant to the

stiffener along the inside of the bolt holes, and over-

lap the ends.

3. Install the stiffener.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Oil Strainer

Install the oil strainer and a new gasket.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

76G01C-171

1C-70

Page 285 of 1865

ASSEMBLY (CYLINDER HEAD) 1 C

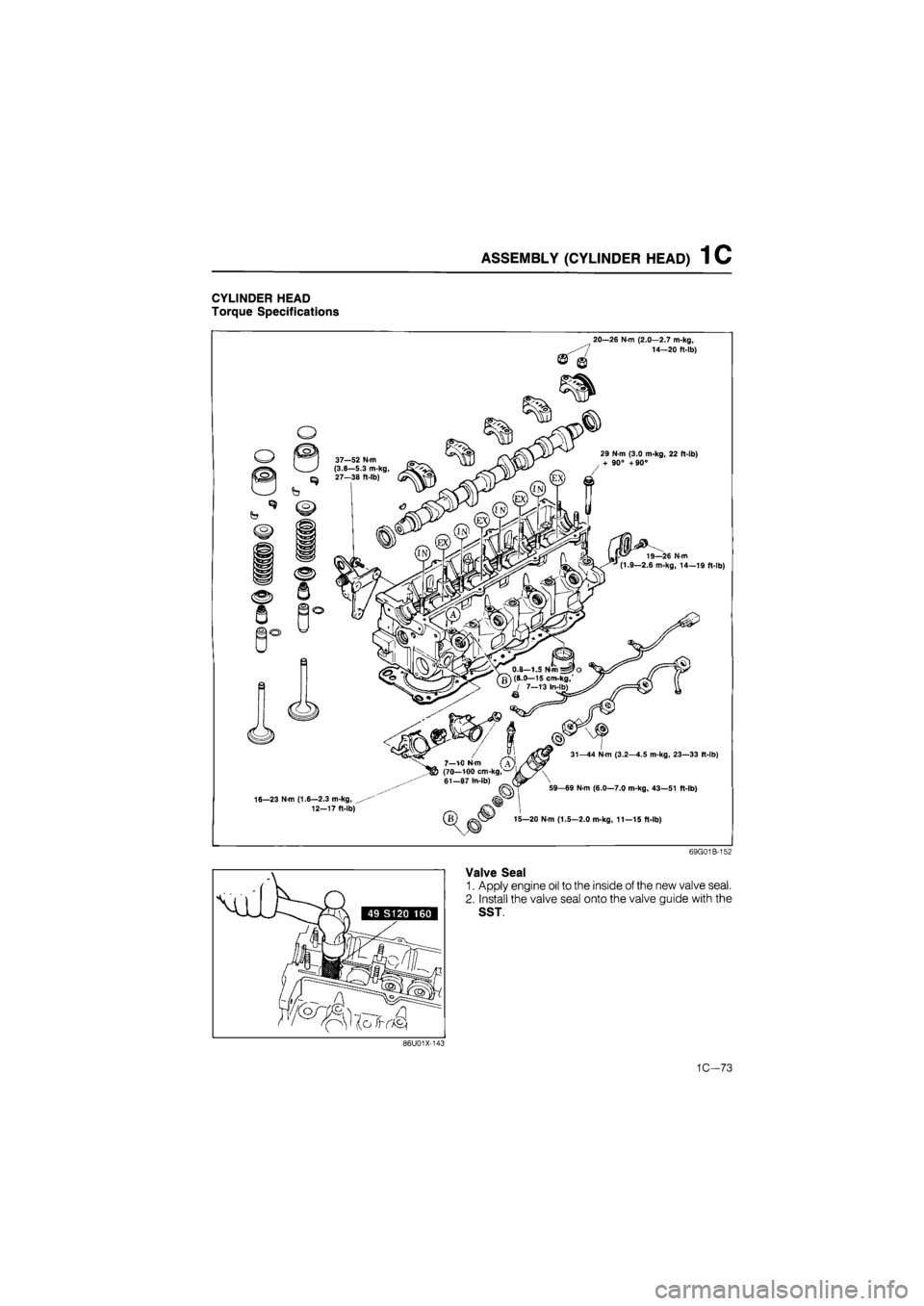

CYLINDER HEAD

Torque Specifications

20—26 N-m (2.0—2.7 m-kg, 14—20 ft-lb)

o

29 N-m (3.0 m-kg, 22 ft-lb) + 90° +90°

b

b

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

16—23 N-m (1.6—2.3 m-kg, 12-17 ft-lb)

31—44 N-m (3.2—4.5 m-kg, 23—33 ft-lb)

59—69 N-m (6.0—7.0 m-kg, 43—51 ft-lb)

15—20 N-m (1.5—2.0 m-kg, 11—15 ft-lb)

69G01 B-152

Valve Seal

1. Apply engine oil to the inside of the new valve seal.

2. Install the valve seal onto the valve guide with the

SST.

86U01X-143

1C—73

Page 286 of 1865

1 C ASSEMBLY (CYLINDER

BLOCK)

76G01C-170

Adjusting

disc

Tappet -

Apply engine oil

4BG01B-150

4BG01B-182

Apply engine oil

1.

Cylinder head bolt

below head length

Valve and Valve Spring

1. Install the lower spring seat.

2. Apply molybdenum disulphide grease to the valve

stem.

3. Install the valve.

4. Install the valve springs and the upper spring seat.

5. Compress the valve spring with the SST; then in-

stall the valve keepers.

6. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Tappet and Adjusting Disc

1. Apply engine oil to the tappets.

2. Install the tappets in the hole.

3. Install the adjusting discs.

Cylinder Head

1. Thoroughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt or grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

76G01C-171

1C-74