engine MAZDA 626 1987 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 184 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 B

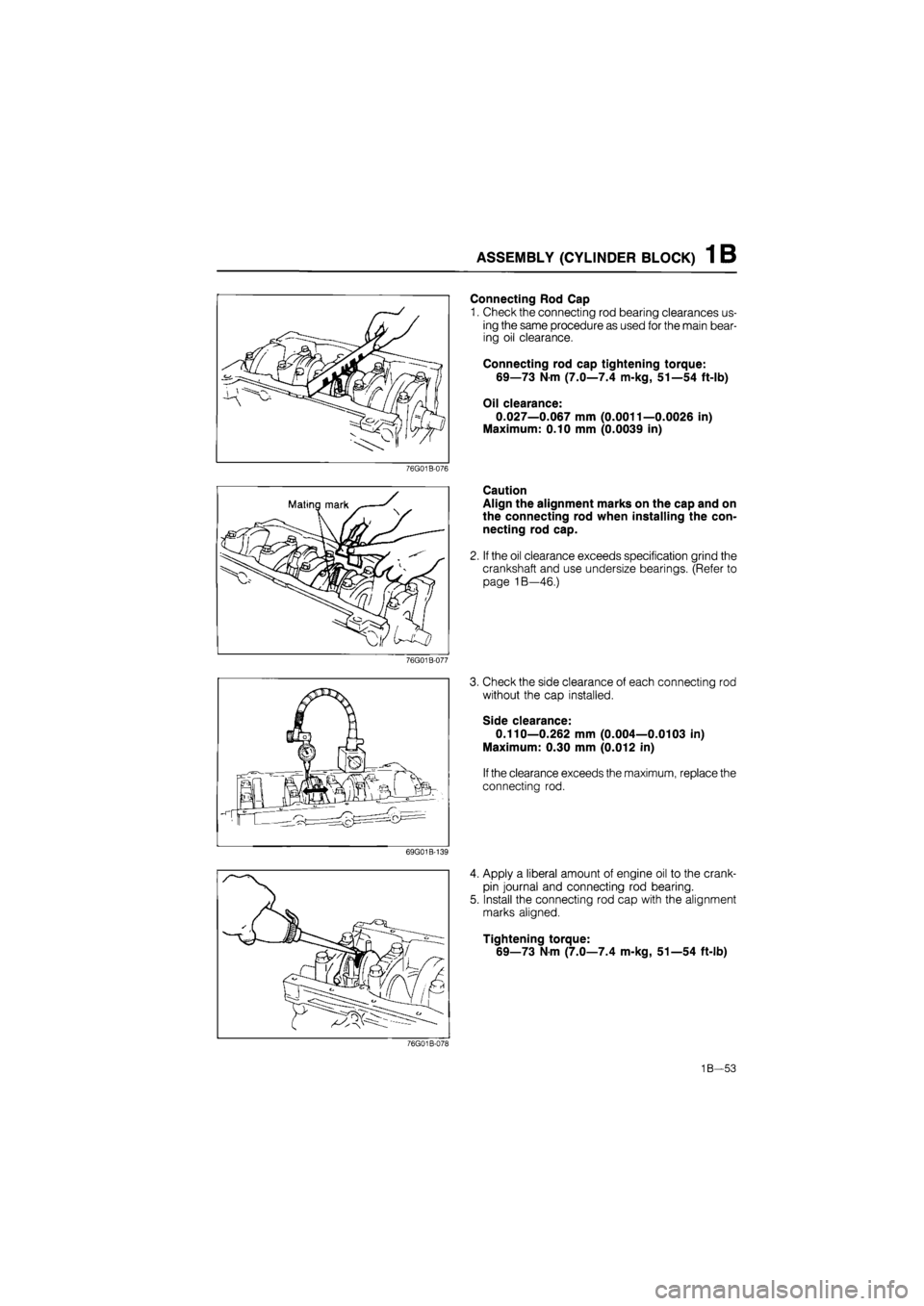

Connecting Rod Cap

1. Check the connecting rod bearing clearances us-

ing the same procedure as used for the main bear-

ing oil clearance.

Connecting rod cap tightening torque:

69—73 Nm (7.0—7.4 m-kg, 51—54 ft-lb)

Oil clearance:

0.027—0.067 mm (0.0011—0.0026 in)

Maximum: 0.10 mm (0.0039 in)

76G01B-076

Caution

Align the alignment marks on the cap and on

the connecting rod when installing the con-

necting rod cap.

2. If the oil clearance exceeds specification grind the

crankshaft and use undersize bearings. (Refer to

page 1B—46.)

76G01B-077

3. Check the side clearance of each connecting rod

without the cap installed.

Side clearance:

0.110—0.262 mm (0.004—0.0103 in)

Maximum: 0.30 mm (0.012 in)

If the clearance exceeds the maximum, replace the

connecting rod.

69G01B-139

4. Apply a liberal amount of engine oil to the crank-

pin journal and connecting rod bearing.

5. Install the connecting rod cap with the alignment

marks aligned.

Tightening torque:

69—73 Nm (7.0—7.4 m-kg, 51—54 ft-lb)

76G01B-078

1B—53

Page 185 of 1865

1 B ASSEMBLY (CYLINDER BLOCK)

CYLINDER BLOCK—II

Torque Specifications

19—25 N m (1.9—2.6 m-kg, 14-19 ft-lb)

7—12 N'm (70—120 cm-kg, 61—104 in-lb)

69G01A-166

Rear Cover

1. Apply engine oil to the rear cover, oil seal and oil

seal lip.

2. Press the oil seal into the rear cover.

4BG01A-158

1B—54

Page 186 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 B

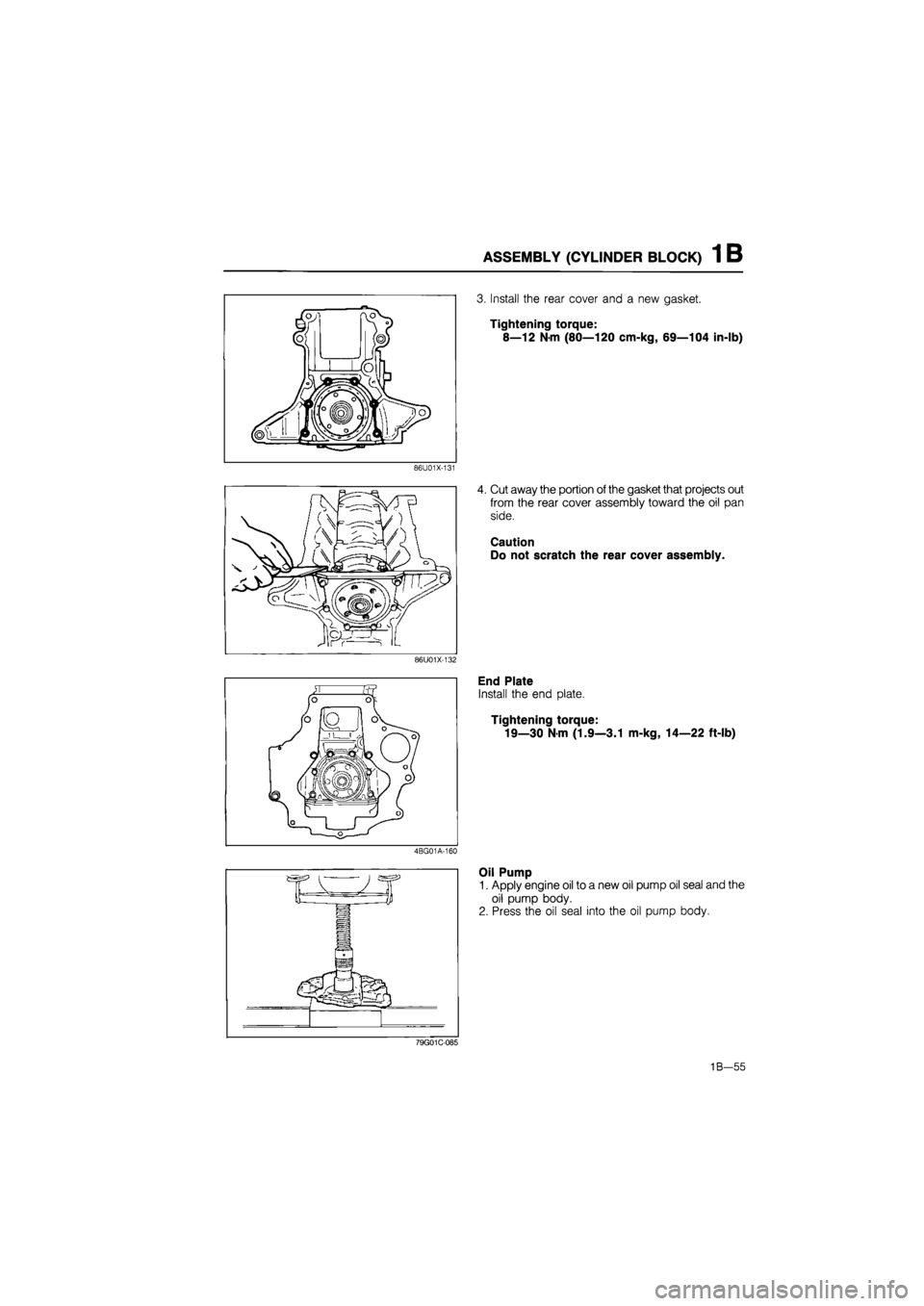

3. Install the rear cover and a new gasket.

Tightening torque:

8—12 N-m (80—120 cm-kg, 69—104 in-lb)

86U01X-131

4. Cut away the portion of the gasket that projects out

from the rear cover assembly toward the oil pan

side.

Caution

Do not scratch the rear cover assembly.

86U01X-132

End Plate

Install the end plate.

Tightening torque:

19—30 Nm (1.9—3.1 m-kg, 14—22 ft-lb)

4BG01A-160

Oil Pump

1. Apply engine oil to a new oil pump oil seal and the

oil pump body.

2. Press the oil seal into the oil pump body.

79G01C-085

1B—55

Page 187 of 1865

1 B ASSEMBLY (CYLINDER BLOCK)

3. Apply engine oil to the oil seal lip.

4. Remove any dirt or other material from the con-

tact surfaces.

5. Apply a continuos bead of silicon sealant to the

contact surface of the oil pump.

Caution

Do not allow any sealant to get into the oil

hole.

86U01X-133

6. Install a new O-ring into the pump body.

7. Install the oil pump.

Tightening torque

(A):

19—25

N

m

(1.9—2.6 m-kg, 14—19 ft-lb)

(§): 37—52

N

m

(3.8—5.3 m-kg, 27—38 ft-lb)

8. Remove any sealant which has been squeezed

out.

76G01A-137

Oil Jet

Install the oil jet as shown in the figure.

Tightening torque: 12—18 Nm

(1.2—1.8 m-kg, 104—156 in-lb)

Caution

The shapes of the No.1, 3 cylinders jet valves

and No.2, 4 jet valves are different.

76G01B-079

Oil Strainer

Install the oil strainer and a new gasket.

Tightening torque:

8—12 Nm (80—120 cm-kg, 69—104 in-lb)

86U01X-136

1B—56

Page 190 of 1865

ASSEMBLY (CYLINDER

BLOCK)

1 B

CYLINDER HEAD

Torque Specifications

18—26 N-m (1.8—2.7 m-kg, 13—20 ft-lb)

8—12 Nm (80—120 cm-kg, 69—104 in-lb)

4—6 Nm (40—60 cm-kg, 35—52 In-lb)

69G01B-152

49 G012 002

Valve Seal

1. Apply engine oil to the inside of the new valve seal.

2. Install the valve seal onto the valve guide with the

SST

76G01 B-083

1B—59

Page 191 of 1865

1 B ASSEMBLY (CYLINDER HEAD)

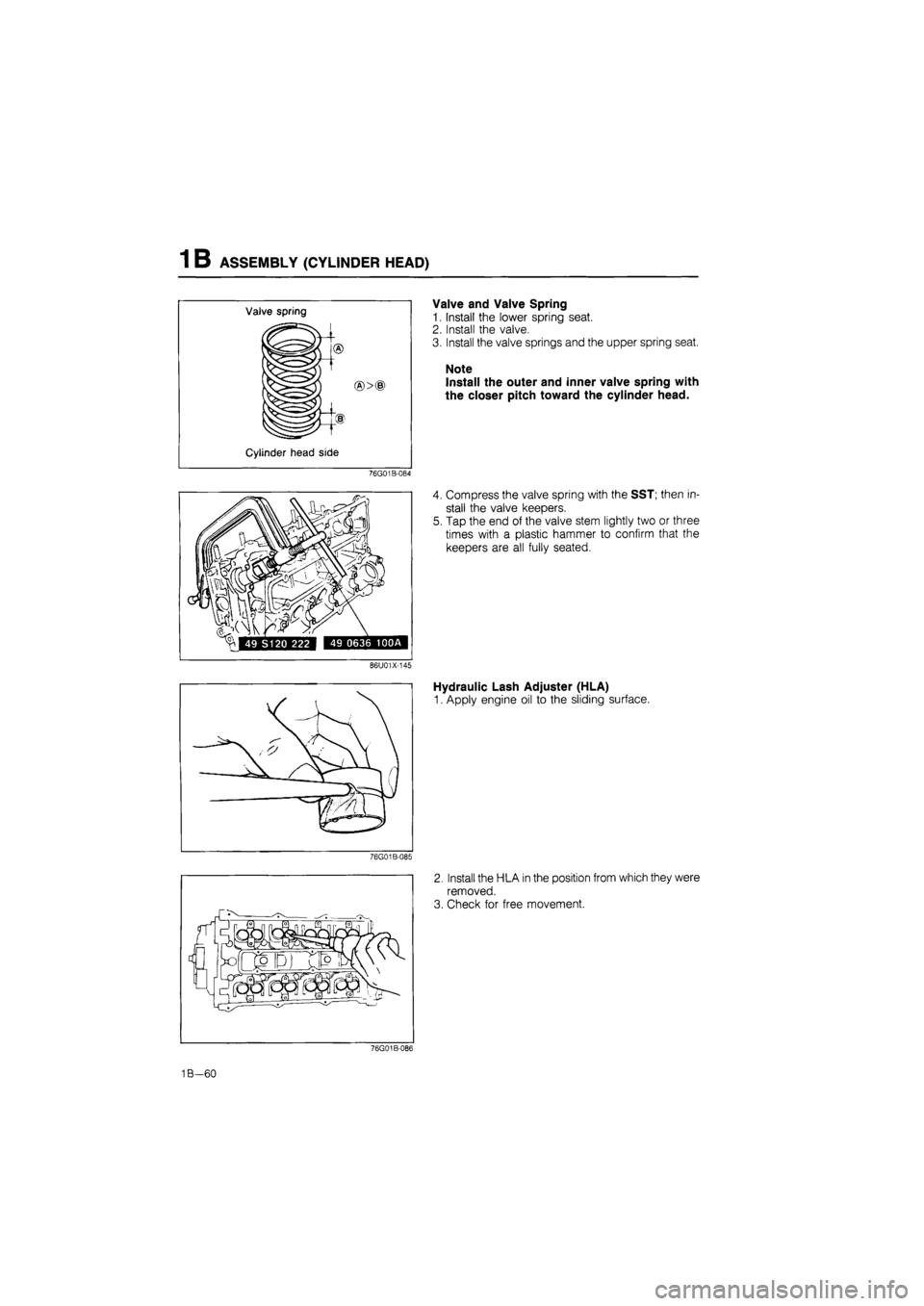

Valve spring

®>®

Cylinder head side

76G01B-084

86U01X-145

76G01B-085

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

3. Install the valve springs and the upper spring seat.

Note

Install the outer and inner valve spring with

the closer pitch toward the cylinder head.

4. Compress the valve spring with the SST; then in-

stall the valve keepers.

5. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Hydraulic Lash Adjuster (HLA)

1. Apply engine oil to the sliding surface.

2. Install the HLA in the position from which they were

removed.

3. Check for free movement.

76G01B-086

1B—60

Page 192 of 1865

ASSEMBLY (CYLINDER HEAD) 1 B

86U01X-146

© ® d> ®

® © ® © (D

86U01X-147

86U01X-148

Cylinder Head

1. Thoroughly remove all dirt, oil, or other material

from the top of the cylinder block.

2. Place the new cylinder head gasket in position.

3. Install the cylinder head.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80—86 Nm (8.2—8.8 m-kg, 59—64 ft-lb)

Camshaft

1. Apply a liberal amount of engine oil to the journals

and bearings.

2. Place the camshaft in position with the dowel pin

facing straight up.

Camshaft Oil Seal

1. Apply liberal amount of clean engine oil to the cam-

shaft oil seal and cylinder head.

2. Install the camshaft oil seal.

76G01B-087

1B-61

Page 193 of 1865

1 B ASSEMBLY (CYLINDER HEAD)

76G01B-088

Camshaft Cap

1. Apply liberal amount of clean engine oil to the cam

lobes and journals.

2. Apply silicon sealant to the front camshaft cap

surface.

3. Position the camshaft caps according to the cap

number and mark.

4. Install the camshaft caps. Tighten the bolts in two

or three steps in the order shown in the figure.

Tightening torque:

18—26 Nm (1.8—2.7 m-kg, 13—20 ft-lb)

Seal Plate

Install the seal plate.

Tightening torque:

8—12

N

m (80—120 cm-kg, 69—104 in-lb)

1B—62

Page 200 of 1865

ASSEMBLY (AUXILIARY PARTS) 1 B

Oil Pressure Switch

Install the oil pressure switch.

Tightening torque: 12—18 N-m

(1.2—1.8 m-kg, 104—156 in-lb)

76G01A-087

Oil Cooler

Install the oil cooler.

Tightening torque:

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

Oil Filter

1. Apply a small amount of engine oil to the rubber

seal of the new filter.

2. Install the oil filter and tighten it by hand until the

rubber seal contacts the base.

3. Then tighten the filter

1

and 1/6 turn with a wrench.

76G01B-099

Intake Manifold Assembly

1. Place the new gasket in position.

2. Install the intake manifold assembly.

3. Tighten the nuts in two or three steps.

Tightening torque:

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

86U01X-167

Intake Manifold Bracket

Install the intake manifold bracket.

Tightening torque:

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

86U01X-168

expert22 fl/ia http://rutracker.org

1B-69

Page 201 of 1865

1 B ASSEMBLY (AUXILIARY PARTS)

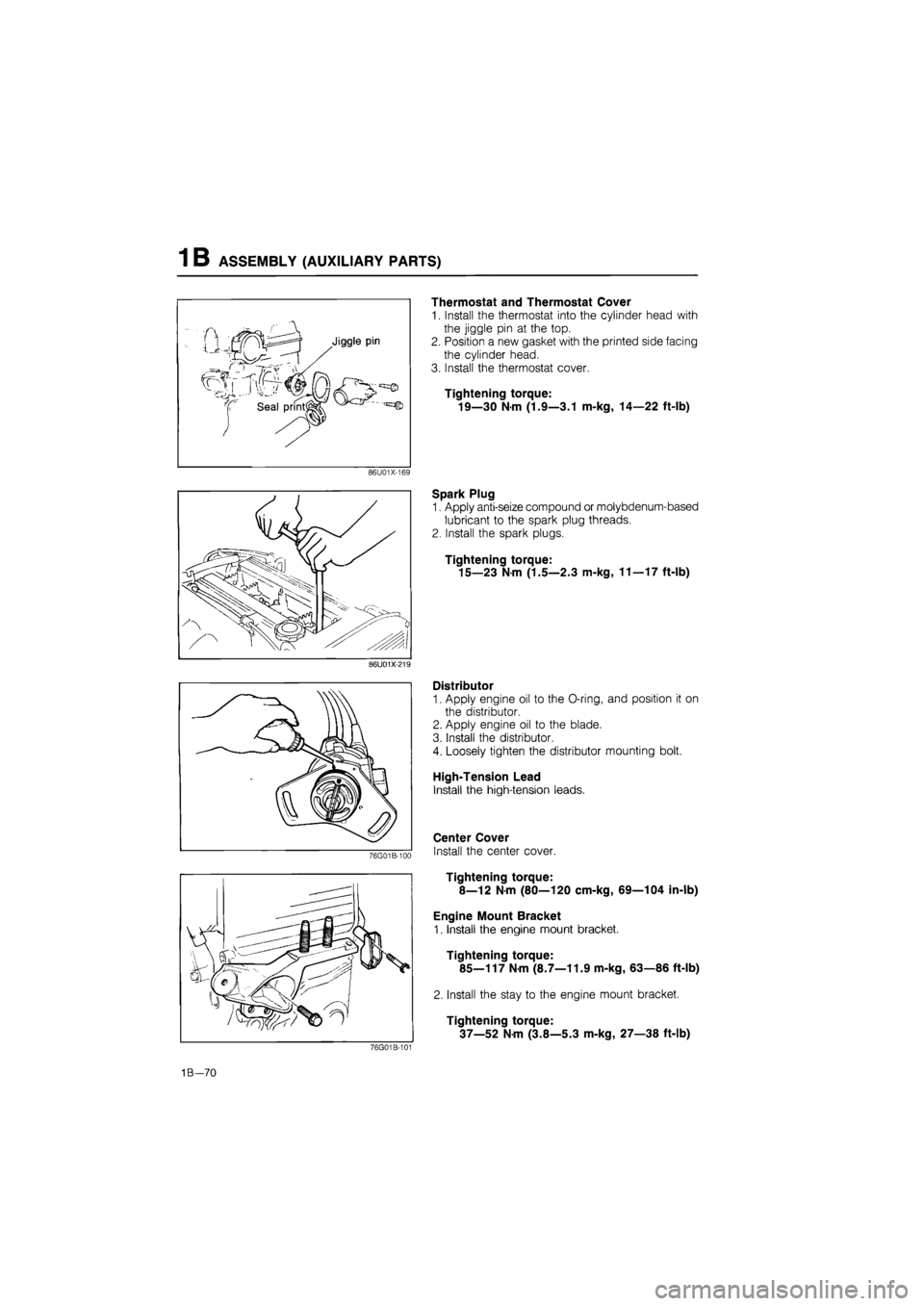

Thermostat and Thermostat Cover

1. Install the thermostat into the cylinder head with

the jiggle pin at the top.

2. Position a new gasket with the printed side facing

the cylinder head.

3. Install the thermostat cover.

Tightening torque:

19—30 Nm (1.9—3.1 m-kg, 14—22 ft-lb)

86U01X-169

Spark Plug

1. Apply anti-seize compound or molybdenum-based

lubricant to the spark plug threads.

2. Install the spark plugs.

Tightening torque:

15—23

N

m (1.5—2.3 m-kg, 11—17 ft-lb)

86U01X-219

1B—70

Distributor

1. Apply engine oil to the O-ring, and position it on

the distributor.

2. Apply engine oil to the blade.

3. Install the distributor.

4. Loosely tighten the distributor mounting bolt.

High-Tension Lead

Install the high-tension leads.

Center Cover

Install the center cover.

Tightening torque:

8—12 Nm (80—120 cm-kg, 69—104 in-lb)

Engine Mount Bracket

1. Install the engine mount bracket.

Tightening torque:

85—117

N m

(8.7—11.9 m-kg, 63—86 ft-lb)

2. Install the stay to the engine mount bracket.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)