engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 218 of 1865

1C TUNE-UP PROCEDURE

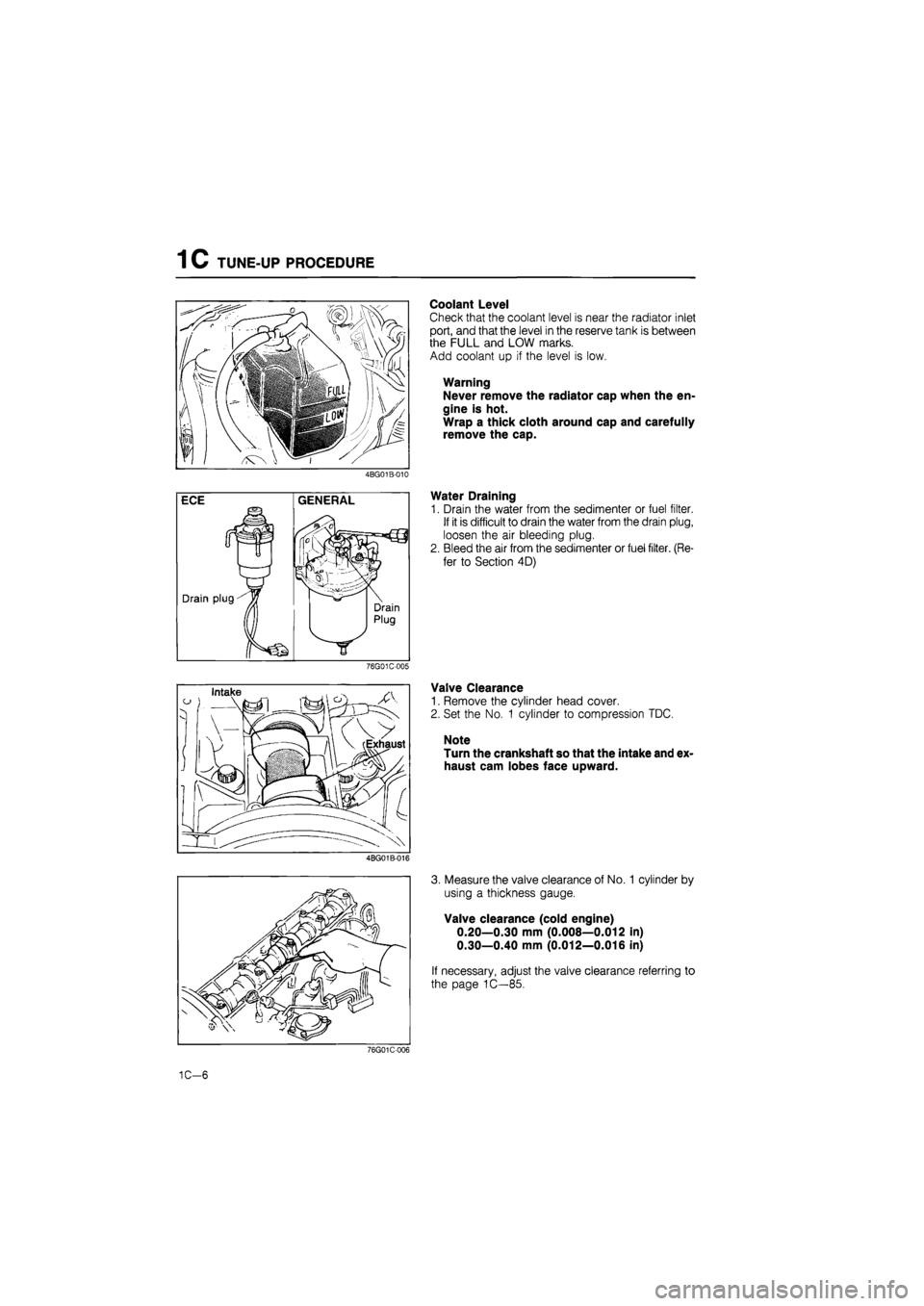

Coolant Level

Check that the coolant level is near the radiator inlet

port, and that the level in the reserve tank is between

the FULL and LOW marks.

Add coolant up if the level is low.

Warning

Never remove the radiator cap when the en-

gine is hot.

Wrap a thick cloth around cap and carefully

remove the cap.

4BG01B-010

Water Draining

1. Drain the water from the sedimenter or fuel filter.

If it is difficult to drain the water from the drain plug,

loosen the air bleeding plug.

2. Bleed the air from the sedimenter or fuel filter. (Re-

fer to Section 4D)

76G01C-005

Valve Clearance

1. Remove the cylinder head cover.

2. Set the No. 1 cylinder to compression TDC.

Note

Turn the crankshaft so that the intake and ex-

haust cam lobes face upward.

4BG01B-016

3. Measure the valve clearance of No. 1 cylinder by

using a thickness gauge.

Valve clearance (cold engine)

0.20—0.30 mm (0.008—0.012 in)

0.30—0.40 mm (0.012—0.016 in)

If necessary, adjust the valve clearance referring to

the page 1C—85.

76G01C-006

1C-6

Page 221 of 1865

TUNE-UP PROCEDURE 1C

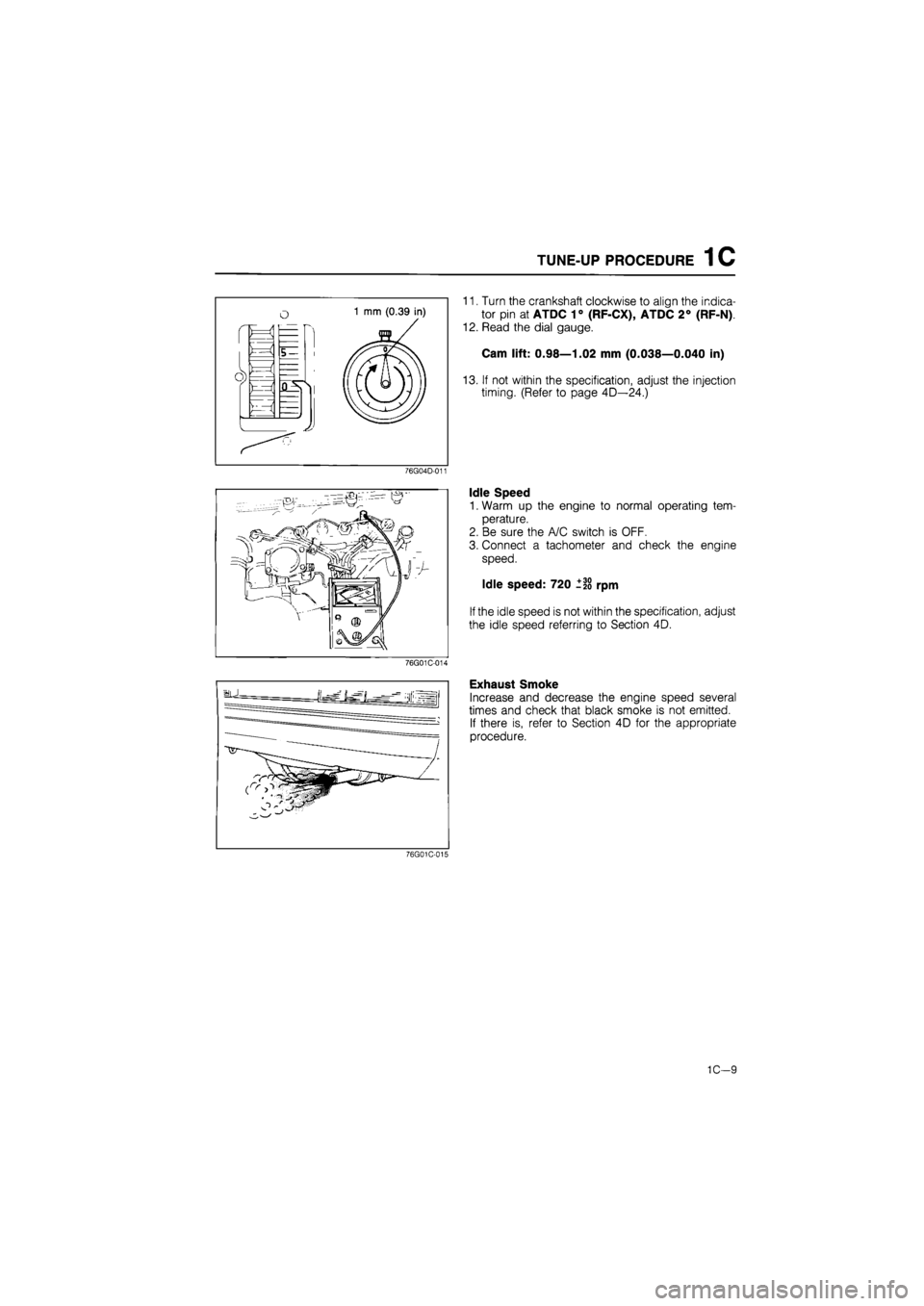

11. Turn the crankshaft clockwise to align the indica-

tor pin at ATDC 1° (RF-CX), ATDC 2° (RF-N)

12. Read the dial gauge.

Cam lift: 0.98—1.02 mm (0.038—0.040 in)

13. If not within the specification, adjust the injection

timing. (Refer to page 4D—24.)

76G04D-011

Idle Speed

1. Warm up the engine to normal operating tem-

perature.

2. Be sure the A/C switch is OFF.

3. Connect a tachometer and check the engine

speed.

Idle speed: 720 ±20 rpm

If the idle speed is not within the specification, adjust

the idle speed referring to Section 4D.

76G01C-014

Exhaust Smoke

Increase and decrease the engine speed several

times and check that black smoke is not emitted.

If there is, refer to Section 4D for the appropriate

procedure.

76G01C-015

1C—9

Page 222 of 1865

1C ON-VEHICLE INSPECTION

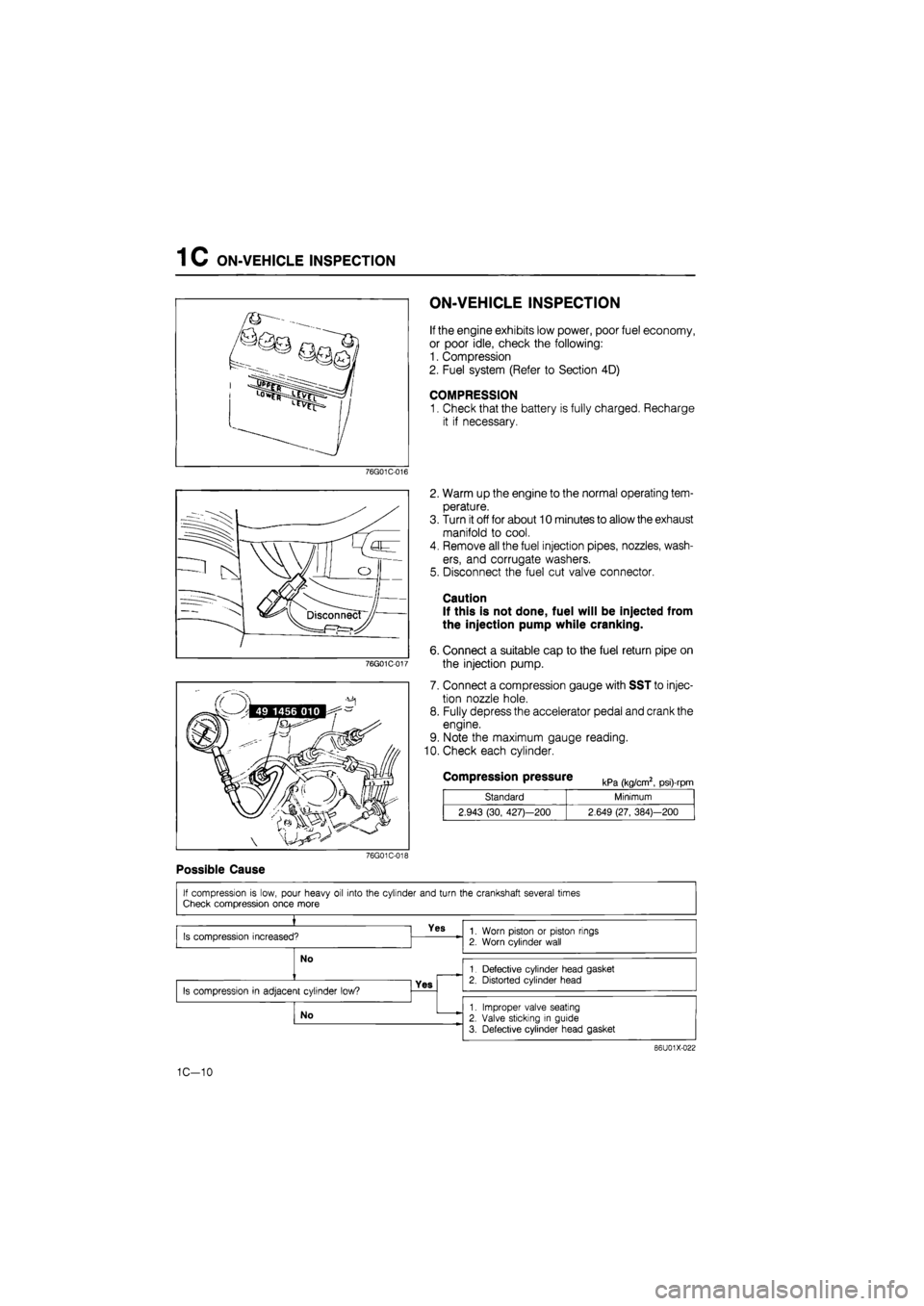

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following:

1. Compression

2. Fuel system (Refer to Section 4D)

COMPRESSION

1. Check that the battery is fully charged, Recharge

it if necessary.

76G01C-016

76G01C-017

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all the fuel injection pipes, nozzles, wash-

ers, and corrugate washers.

5. Disconnect the fuel cut valve connector.

Caution

If this is not done, fuel will be injected from

the injection pump while cranking.

6. Connect a suitable cap to the fuel return pipe on

the injection pump.

7. Connect a compression gauge with SST to injec-

tion nozzle hole.

8. Fully depress the accelerator pedal and crank the

engine.

9. Note the maximum gauge reading.

10. Check each cylinder.

Compression pressure kPa (kg/cm2, psi)-rpm

Standard Minimum

2.943 (30, 427)—200 2.649 (27, 384)—200

76G01C-018

Possible Cause

86U01X-022

1C-10

Page 223 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 C

ON-VEHICLE MAINTENANCE

TIMING BELT

Removal

1. Disconnect the nagative battery cable.

2. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01C-019

1. Engine side cover

2. A/C and alternator drive belt

3. Crankshaft pulley

4. Left and right timing belt cover

5. Alternator idle pulley

6. Idler pulley

7. No.3 engine mount

8. Timing belt

9. Timing belt tensioner and spring

Note

Loosen the No.3 engine mount nuts and lower the engine to remove the crankshaft pulley.

1C-11

Page 224 of 1865

1 C ON-VEHICLE MAINTENANCE (TIMING BELT)

76G01C-020

76G01C-238

Kww

76G01C-021

Removal note

Timing belt

1. Aligh the timing marks of each pulleys.

2. Affix the injection pump pulley to the bracket us-

ing two bolts (35—40 mm, 1.4—1.6 in).

Caution

a) Do not turn in the reverse direction of en-

gine revolution.

b) After removing the timing belt, do not ro-

tate the crankshaft pulley or camshaft

pulley.

3. Make the forward direction arrow on the timing belt.

Note

Direction arrow is to reassemble the timing

belt in the same direction.

4. Loosen the timing belt tensioner bolt.

5. Shift the tensioner outwards as far as possible, and

temporarily tighten it.

6. Suspend the engine with chain block on the front

engine hanger.

7. Remove the No.3 engine mount.

8. Remove the timing belt.

Caution

Do not allow any oil or grease on the timing

belt.

Inspection and Repair

Inspect the following parts. (Refer to page 1C—60,

61).

1. Timing belt

2. Timing belt tensioner and spring

3. Timing belt idler pulley

4. Timing belt pulley

76G01C-022

1C—12

Page 227 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 C

76G01C-027

76G01C-028

76G01C-029

Checking

point

Idler pulley

Crankshaft pulley zQi A/C

Checking point compressor

76G01C-030

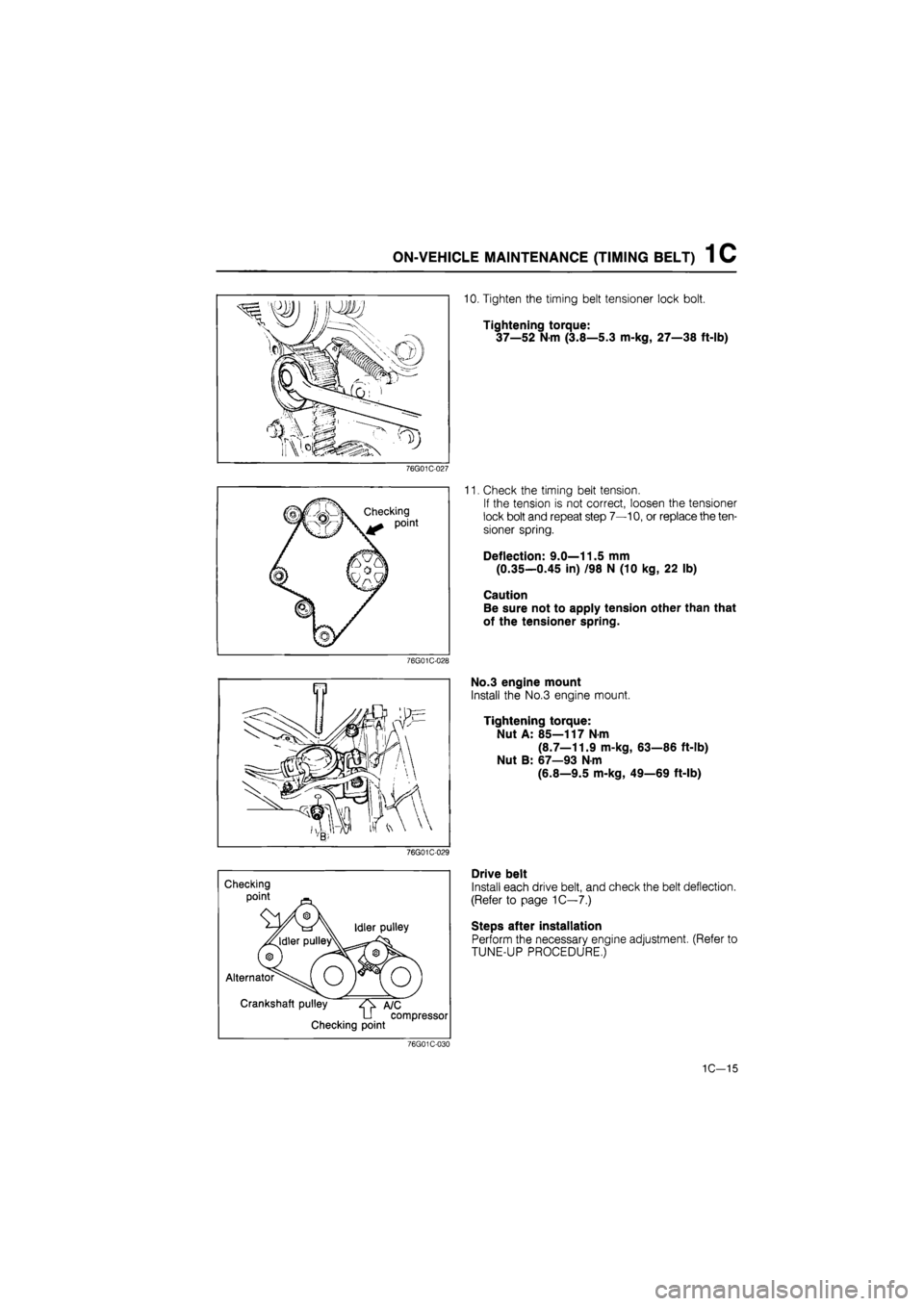

10. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)

11. Check the timing belt tension.

If the tension is not correct, loosen the tensioner

lock bolt and repeat step 7—10, or replace the ten-

sioner spring.

Deflection: 9.0—11.5 mm

(0.35—0.45 in) /98 N (10 kg, 22 lb)

Caution

Be sure not to apply tension other than that

of the tensioner spring.

No.3 engine mount

Install the No.3 engine mount.

Tightening torque:

Nut A: 85—117 N-m

(8.7—11.9 m-kg, 63—86 ft-lb)

Nut B: 67—93 N-m

(6.8—9.5 m-kg, 49—69 ft-lb)

Drive belt

Install each drive belt, and check the belt deflection.

(Refer to page 1C—7.)

Steps after installation

Perform the necessary engine adjustment. (Refer to

TUNE-UP PROCEDURE,)

1C-15

Page 228 of 1865

1 C ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

CYLINDER HEAD

Removal

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01C-031

1. Accelerator cable

2. Air cleaner

3. Brake vacuum pipe

4. Intercooler pipe and hose*

5. Drive belt cover

6. Vacuum pump drive belt

7. Fuel hose

8. Water temperature switch

connector

9. Glow plug connector

10. Water thermo switch con-

nector

11. Heat gauge unit connector

12. Boost air temperature sen-

sor connector*

13. Injection pipes

14. Upper radiator hose

15. Water hose

(thermostat—FIR)

16. Oil level gauge and stay

bolt

17. Oil pipe bolt

18. Timing belt (Refer to page

1C—11)

19. Cylinder head cover

20. Camshaft pulley

21. Rear camshaft pulley

76G01C-032

22. Injection pump pulley

23. Seal plate

24. Water hose and pipe

25. Comprex supercharger

drive belt*

26. Heat insulator*

27. Exhaust manifold stay

28. Front exhaust pipe

29. Cylinder head bolt

30. Cylinder head

31. Cylinder head gasket

32. Comprex supercharger*

33. Exhaust manifold

34. Intake manifold

Note

* marked parts are equipped only for the RF-CX.

1C-16

Page 232 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

76G01C-037

Apply engine oil

/

Cylinder head bolt

below head length

76G01C-038

(8) (4; D (5)

® ®

76G01C-039

3m-kg

(21.7ft-lb

Installation

Cylinder head

1. Throughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt and grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

6. Apply engine oil to the threads and the seat face

of the cylinder head bolts.

7. Tighten the cylinder head bolts.

(1) Tighten the bolts to the specified torque, in the

order shown in the figure.

Tightening torque:

29 N-m (3.0 m-kg, 22 ft-lb)

(2) Make paint marks on the bolt heads, as shown

in the figure.

(3) With the paint marks as a reference point, turn

the cylinder head bolts another 90°

(90°—105°) in the tightening direction. Tight-

en them in the order.

(4) Then tighten them once again 90°

(90°—105°) in the tightening order.

Caution

Be absolutely sure that the bolts are tightened

in the proper order.

76G01C-044

1C—20

Page 235 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

76G01C-049

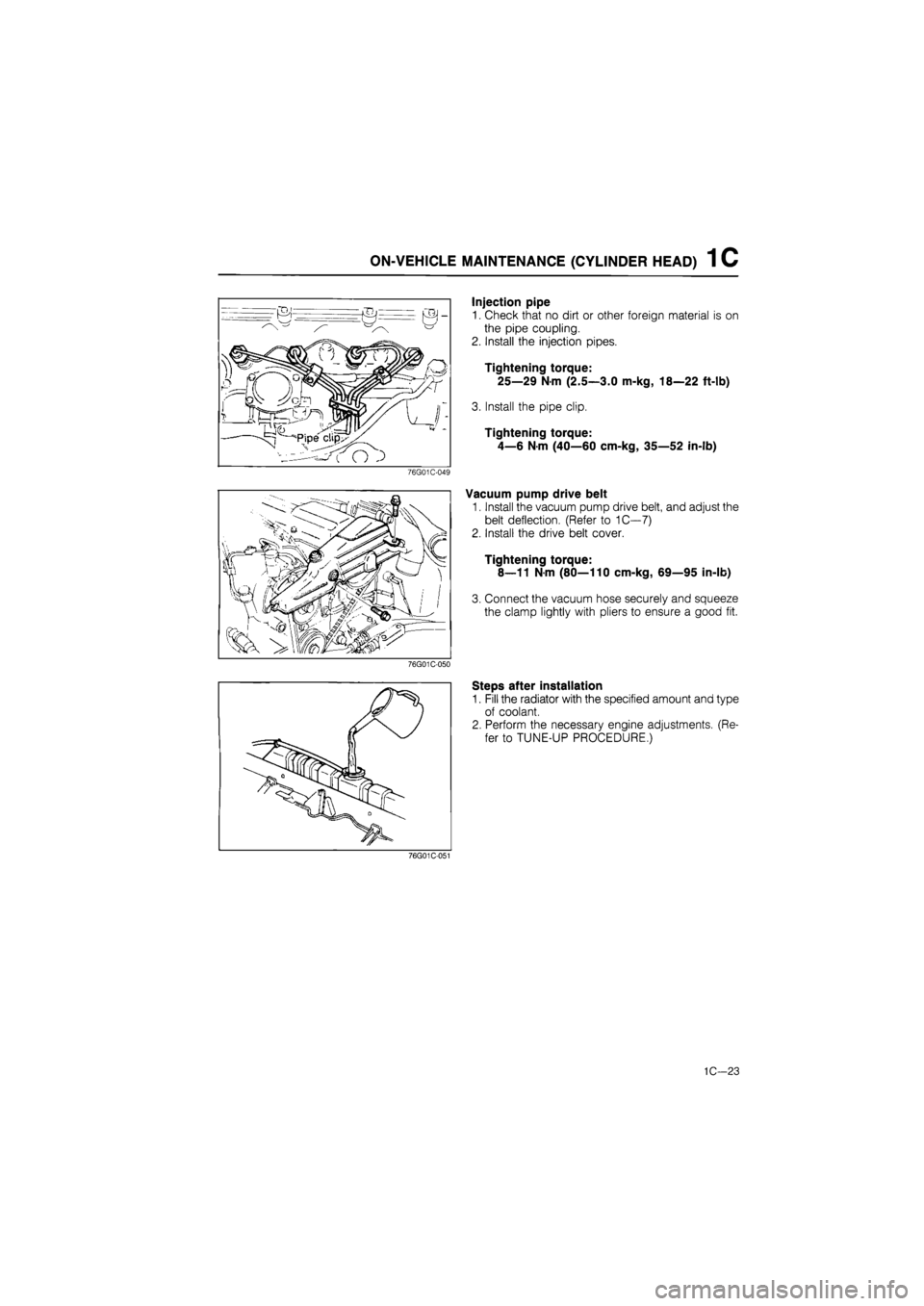

Injection pipe

1. Check that no dirt or other foreign material is on

the pipe coupling.

2. Install the injection pipes.

Tightening torque:

25—29 Nm (2.5—3.0 m-kg, 18—22 ft-lb)

3. Install the pipe clip.

Tightening torque:

4—6 N-m (40—60 cm-kg, 35—52 in-lb)

Vacuum pump drive belt

1. Install the vacuum pump drive belt, and adjust the

belt deflection. (Refer to 1C—7)

2. Install the drive belt cover.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

3. Connect the vacuum hose securely and squeeze

the clamp lightly with pliers to ensure a good fit.

76G01C-050

Steps after installation

1. Fill the radiator with the specified amount and type

of coolant.

2. Perform the necessary engine adjustments. (Re-

fer to TUNE-UP PROCEDURE.)

76G01C-051

1C—23

Page 239 of 1865

ON-VEHICLE MAINTENANCE (VALVE SEAL) 1 C

Installation

Install in the reverse order of removal referring to the installation note.

Torque Specifications

20—26 N-m (2.0—2.7 m-kg, 14—20 ft-lb)

N-m (5.6—6.6 m-kg, ft-lb)

55—65 N m (5.6—6.6 m-kg, 41—48 ft-lb)

76G01C-243

Installation note

Valve seal

1. Apply engine oil to the inside of the new valve seal.

2. Push it on gently with the SST.

86U01X-049

1C—27