ECU MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 197 of 1865

1 B ASSEMBLY (TIMING BELT)

69G01B-165

76G01B-095

79G01C-097

Timing Belt Idler Pulley

Install the timing belt idler pulley.

Tightening torque:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

Timing Belt Tensioner

1. Install the timing belt tensioner and tensioner

spring.

2. Tentatively secure the tensioner with the spring fully

extended.

Timing Belt

1. Install the timing belt so that there is no looseness

at the tension side, and at the two camshaft pulleys.

Caution

a) If the timing belt is being reused, it must be

reinstalled to rotate in the original direction.

b) Check that there is no oil, grease, or dirt on

the timing belt.

2. Loosen the tensioner lock bolt.

3. Turn the crankshaft twice in the direction of rotation.

4. Check that the mating marks are correctly aligned.

If not aligned, remove the timing belt and tension-

er, and repeat the above-mentioned procedure.

5. Turn the crankshaft to align the S mark of the right

side camshaft pulley with seal plate mating mark.

6. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)

76G01B-096

1B-66

Page 205 of 1865

1B INSTALLATION

ENGINE INSTALLATION

Install the engine and transaxle assembly.

Warning: Be sure the vehicle is securely supported.

Torque Specifications

67—93

N m

(6.8—9.5 m-kg, 49—69 ft-lb)

85—117

N m

(8.7—11.9 m-kg, 63—86 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

8-11 N-m (80—110 cm-kg, 69—95 In-lb)

[;> )

16—27

N-m

(1.6—2.8 m-kg, 12—20 ft-lb)

37—63 N-m (3.8—6.4 m-l 27—46 ft-ll

37—52 N-m (3.8—5.3 m-kg 27—38 ft-lb)

64—89 N-m (6.5—9.1 m-kg, 47—66 ft-lb)

36—54 N-m (3.7—5.5 m-kg, 27—40 ft-lb)

-31—46 N-m (3.2—4.7 m-kg, 23—34 ft-lb)

31—46 N-m (3.2-4.7 m-kg, 23—34 ft-lb)

39—59 N-m (4.0—6.0 m-kg, 29—43 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

31—46 N-m (3.2—4.7 m 23—34 ft-lb)

19—25 N-m (1.9—2.6 m-kg, 14-

19—25 N-m (1.9—2.6 m

16—23 N-m (1.6—2.3 m-l

5—7 N-m (50—70 cm-kg, 43—61 in-lb)

-16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

9—13 N-m (90—130 cm-kg, 78—113 In-lb)

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

,68—118 N-m .0—12.0 m-kg 65—87 ft-lb)

43-54 N-m (4.4—5.5 m-kg, 32-40 tl-lb)

8—11

N-m

(80—110 cm-kg, 69—95 In-lb)

86U01X-180

1B—74

Page 207 of 1865

1B INSTALLATION

86U01X-184

86U01X-185

86U01X-186

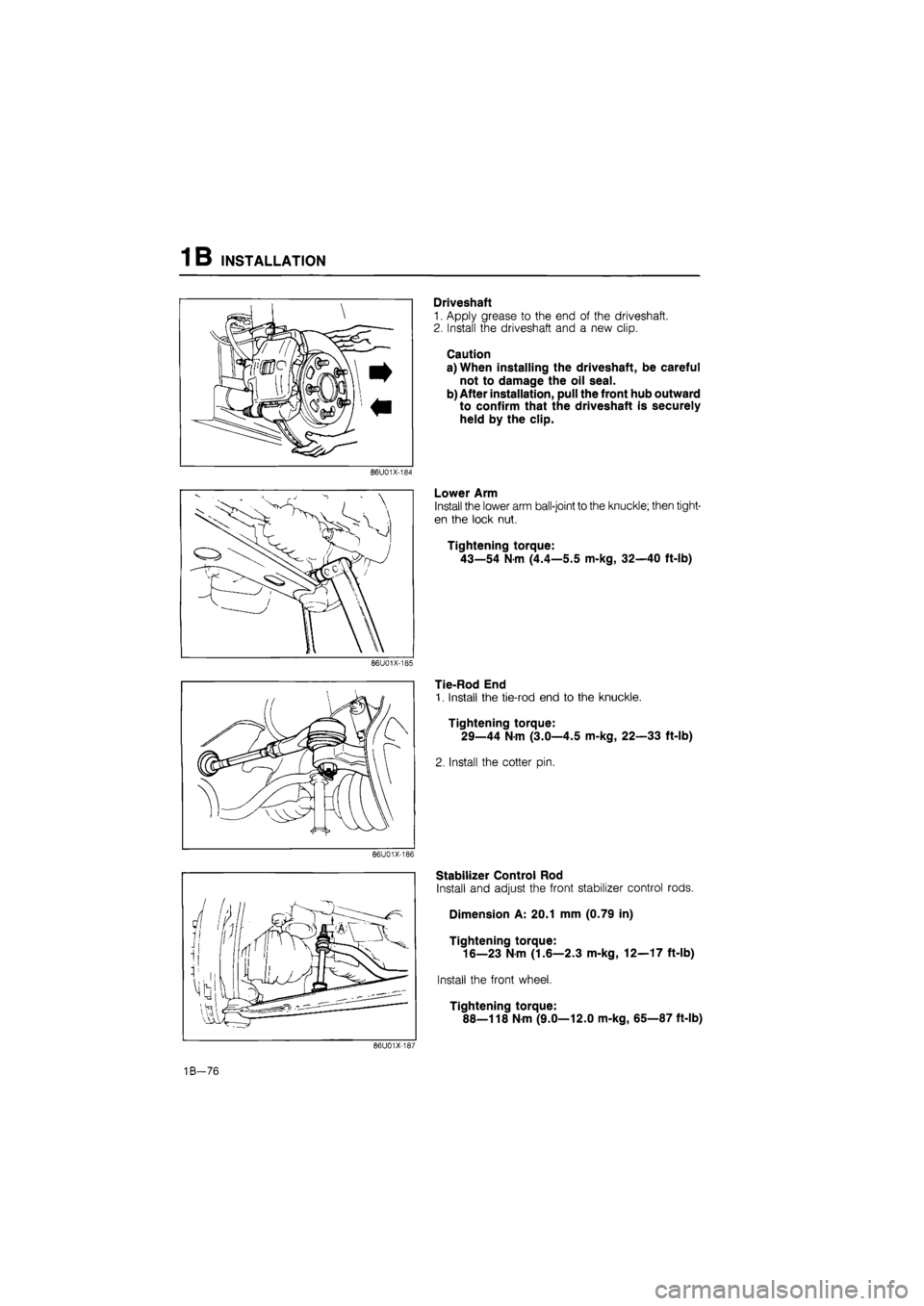

Driveshaft

1. Apply grease to the end of the driveshaft.

2. Install the driveshaft and a new clip.

Caution

a) When installing the driveshaft, be careful

not to damage the oil seal.

b) After installation, pull the front hub outward

to confirm that the driveshaft is securely

held by the clip.

Lower Arm

Install the lower arm ball-joint to the knuckle; then tight-

en the lock nut.

Tightening torque:

43—54 Nm (4.4—5.5 m-kg, 32—40 ft-lb)

Tie-Rod End

1. Install the tie-rod end to the knuckle.

Tightening torque:

29—44 Nm (3.0—4.5 m-kg, 22—33 ft-lb)

2. Install the cotter pin.

Stabilizer Control Rod

Install and adjust the front stabilizer control rods.

Dimension A: 20.1 mm (0.79 in)

Tightening torque: 16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

Install the front wheel.

Tightening torque:

88—118 Nm (9.0—12.0 m-kg, 65—87 ft-lb)

86U01X-180

1B—76

Page 226 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 C

2. Install the timing belt tensioner and spring.

3. Temporarily secure the tensioner with it shifted

outwards.

63G01D-330

4. Install the timing belt.

Caution

a) The timing belt must be reinstalled in the

same direction of previous rotation, if it is

to be reused.

b) Be sure that there is no oil, grease, or dirt

on the timing belt.

76G01C-024

Install the idler pulley.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27-38 ft-lb)

Remove the affixing bolts from the injection pulley.

76G01C-025

7. Loosen the tensioner lock bolt.

8. Turn the crankshaft twice in the direction of rota-

tion (clockwise).

Caution

Do not rotate reverse direction.

9. Check that each timing mark is correcty aligned.

If not aligned, remove the timing belt. Repeat step

1-8.

76G01C-030

1C-14

Page 235 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

76G01C-049

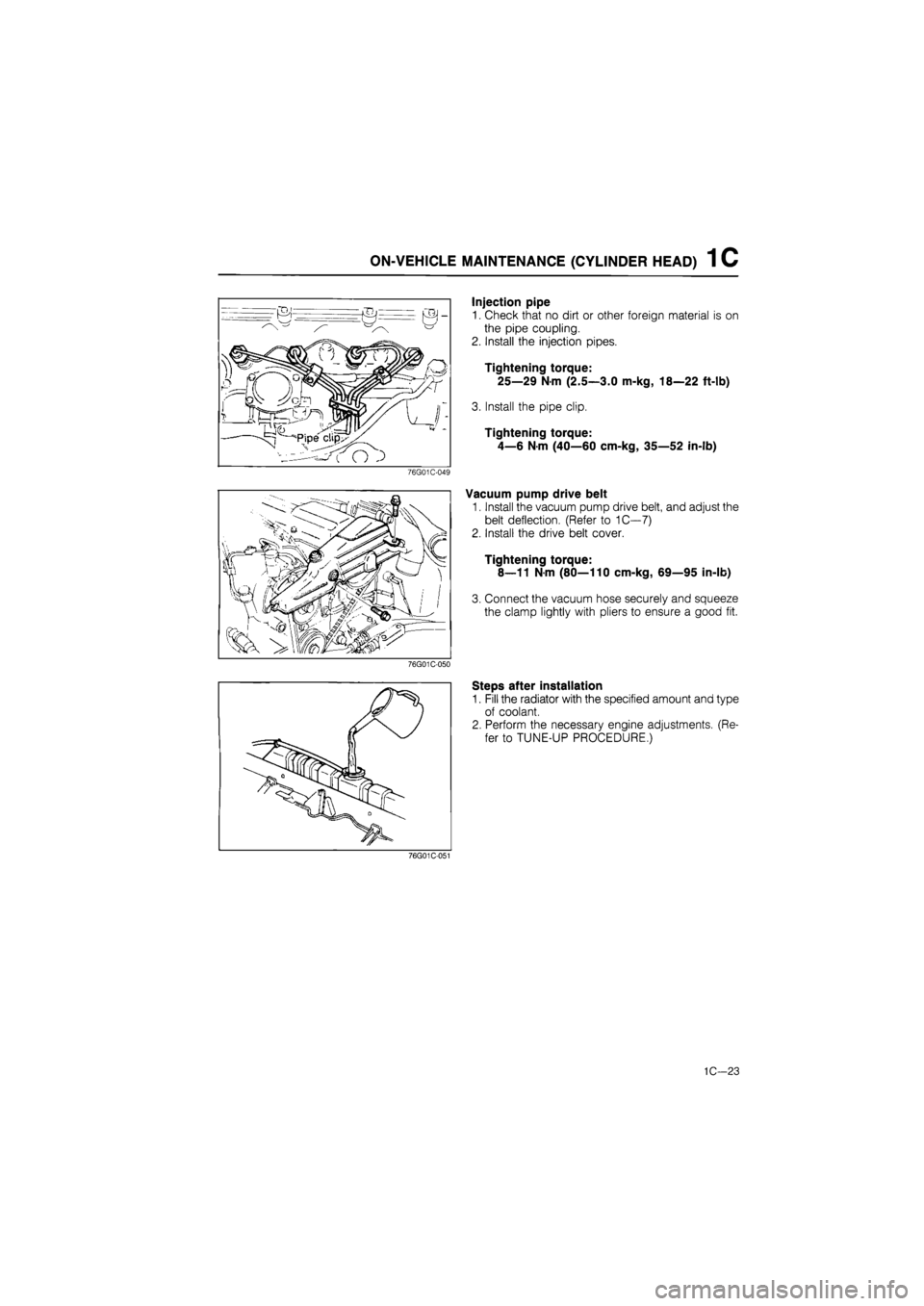

Injection pipe

1. Check that no dirt or other foreign material is on

the pipe coupling.

2. Install the injection pipes.

Tightening torque:

25—29 Nm (2.5—3.0 m-kg, 18—22 ft-lb)

3. Install the pipe clip.

Tightening torque:

4—6 N-m (40—60 cm-kg, 35—52 in-lb)

Vacuum pump drive belt

1. Install the vacuum pump drive belt, and adjust the

belt deflection. (Refer to 1C—7)

2. Install the drive belt cover.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

3. Connect the vacuum hose securely and squeeze

the clamp lightly with pliers to ensure a good fit.

76G01C-050

Steps after installation

1. Fill the radiator with the specified amount and type

of coolant.

2. Perform the necessary engine adjustments. (Re-

fer to TUNE-UP PROCEDURE.)

76G01C-051

1C—23

Page 244 of 1865

1C REMOVAL

76G01C-244

76G01C-072

67U01X-029

Removal Note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep fire and open flame away from the fuel

area.

After disconnecting the fuel hoses, plug them to avoid

fuel leakage.

Clutch release cylinder

Remove the clutch release cylinder with the pipe still

connected; then avoid the cylinder.

P/S pump, A/C compressor

Remove the P/S pump and A/C compressor with the

hoses still connected to them, secure the pump and

compressor as shown in the figure.

Driveshaft

Remove the driveshafts. (Refer to Section 9.) Slide

the SST into the transaxle.

86U01X-060

1C-32

Page 295 of 1865

ASSEMBLY (TIMING BELT) 1 C

63G01D-431

76G01C-191

76G01C-192

Timing Belt Tensioner

1. Install the tensioner spring onto the tensioner.

2. Install the tensioner assembly.

3. Temporarily secure it so the tensioner is shifted

outward.

Timing Belt

1. Return the crankshaft about 45° to the timing mark

on the oil pump housing.

2. Check that the timing marks of the camshaft pul-

ley and the injection pump pulley align with the tim-

ing marks on the seal plate.

3. Install the timing belt in the sequence shown in the

figure.

Caution

The timing belt must be reinstalled in the same

direction of rotation for continued durability.

76G01C-200

1C—83

Page 304 of 1865

1C INSTALLATION

ENGINE INSTALLATION

Install the engine and transaxle assembly.

Warning: Be sure the vehicle is securely supported.

Torque Specifications

67-93 N-m {6.6—9.5 m-kg, 49—69 ft-Sb)

8—11 Nm (80—110 cm-kg,„ 69—95 in-lb)

85—117 N m (8.7—11.9 m-kg, 63—G6 ft-lb) S—11 N-m (80—110em-kg, 69—95 In-lb)

5—7 N-m (50—70 cm-kg, 43—61 in-lb)

67—93 N-m (6,8—9,5 m-kg, 49—69 ft-lb)

55—80 N-m (5.6—8.2 m-kg, 41—59 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

43—62 N-m (4.3—6.3 m-kg, 14—22 ft-lb)

7—10 N-m (70—100 cm-kg, 60—86 in-lb)

37—52 N-m (3.6—5.3 m-kg, 27—38 ft-lb)

34—49 N-m (3.5—5.0 m-kg, 25—36 ft-lb)

31—40 N-m 9 (3.2-4.1 m-kg, 23—30 ft-lb)

'8—11 N-m (80—110 cm-kg, 69—95 in-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

-IS* 88—118 N-m ^-(9.0—12.0 m-kg, 65—87 ft-lb) 8—11 N-m (80—110 cm-kg, 69—95 In-lb)

86U01X-180

1C—92

Page 306 of 1865

1C INSTALLATION

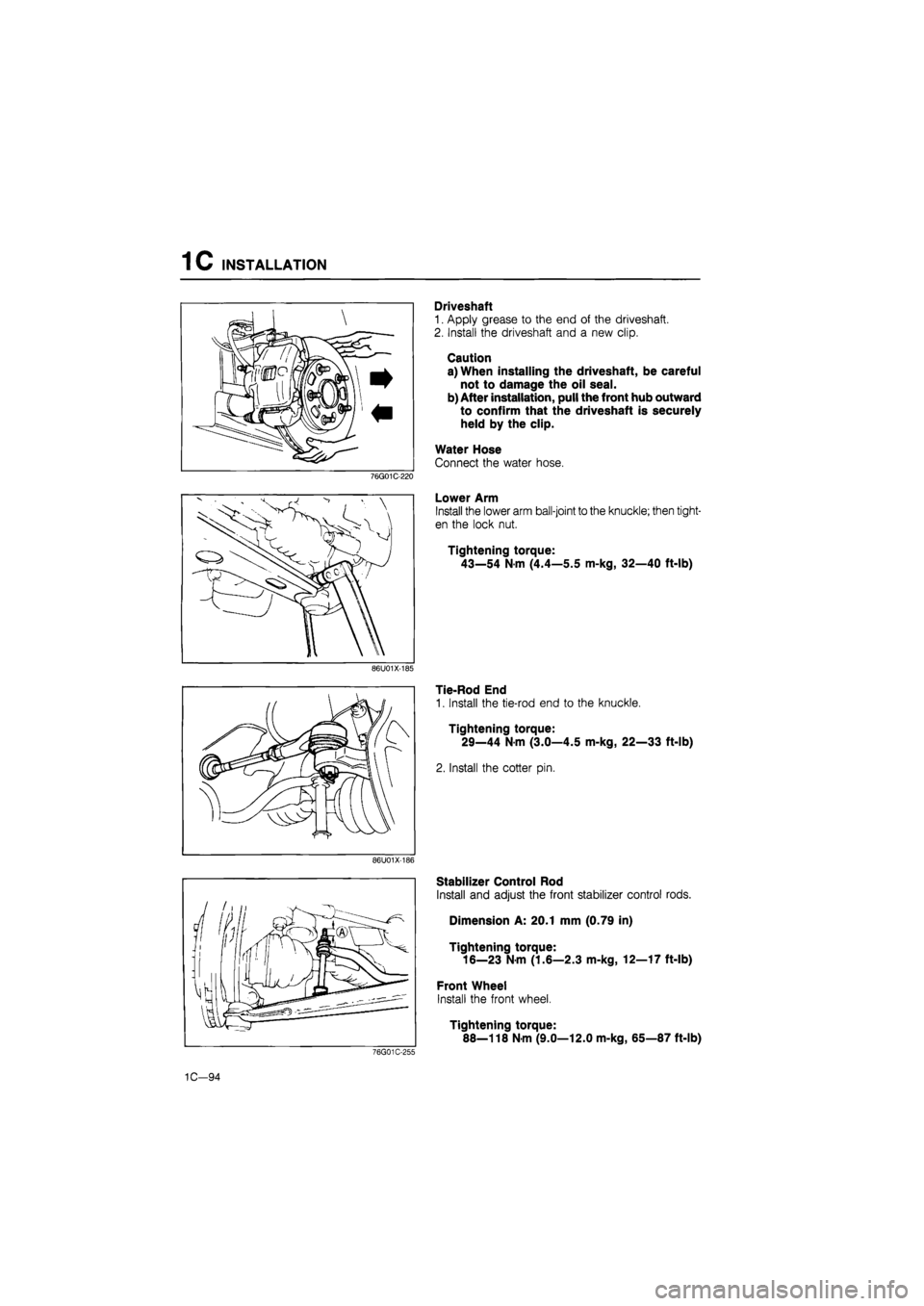

Driveshaft

1. Apply grease to the end of the driveshaft.

2. Install the driveshaft and a new clip.

Caution

a) When installing the driveshaft, be careful

not to damage the oil seal.

b) After installation, pull the front hub outward

to confirm that the driveshaft is securely

held by the clip.

Water Hose

Connect the water hose.

76G01C-220

Lower Arm

Install the lower arm ball-joint to the knuckle; then tight-

en the lock nut.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

86U01X-185

Tie-Rod End

1. Install the tie-rod end to the knuckle.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

2. Install the cotter pin.

86U01X-186

76G01C-255

Stabilizer Control Rod

Install and adjust the front stabilizer control rods.

Dimension A: 20.1 mm (0.79 in)

Tightening torque: 16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

Front Wheel

Install the front wheel.

Tightening torque:

88—118 N-m (9.0—12.0 m-kg, 65—87 ft-lb)

1C—94

Page 309 of 1865

INSTALLATION 1C

76G01C-227

P/S Oil Pump

1. Install the P/S oil pump.

Tightening torque:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

2. Install the P/S oil pump pully. (Refer to section 10)

Tightening torque:

55—59 Nm (5.6—6.0 m-kg, 41—43 ft-lb)

3. Set the pipe bracket in position.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

4. Install the drive belt and adjust the belt deflection.

(Refer to page 1C—7)

5. Install the drive belt cover.

Tightening torque:

8—11

N

m (80—110 cm-kg, 69—95 in-lb)

76G01C-228

Fuel Hose

Install the fuel hose.

Note

Be careful of the red marks on the hose.

76G01C-229

76G01C-230

Intercooler Pipe and Hose

1. Install the intercooler pipe and hose.

Tightening torque:

19—26 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

2. Install the brake vacuum pipe.

Tightening torque:

8—11

N

m (80—110 cm-kg, 69—95 in-lb)

3. Connect the brake vacuum hose securely and

squeeze the clamp lightly with pliers to ensure a

good fit.

1C-97