Rear brake MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 893 of 1865

TROUBLESHOOTING (G4A-EL) 7B

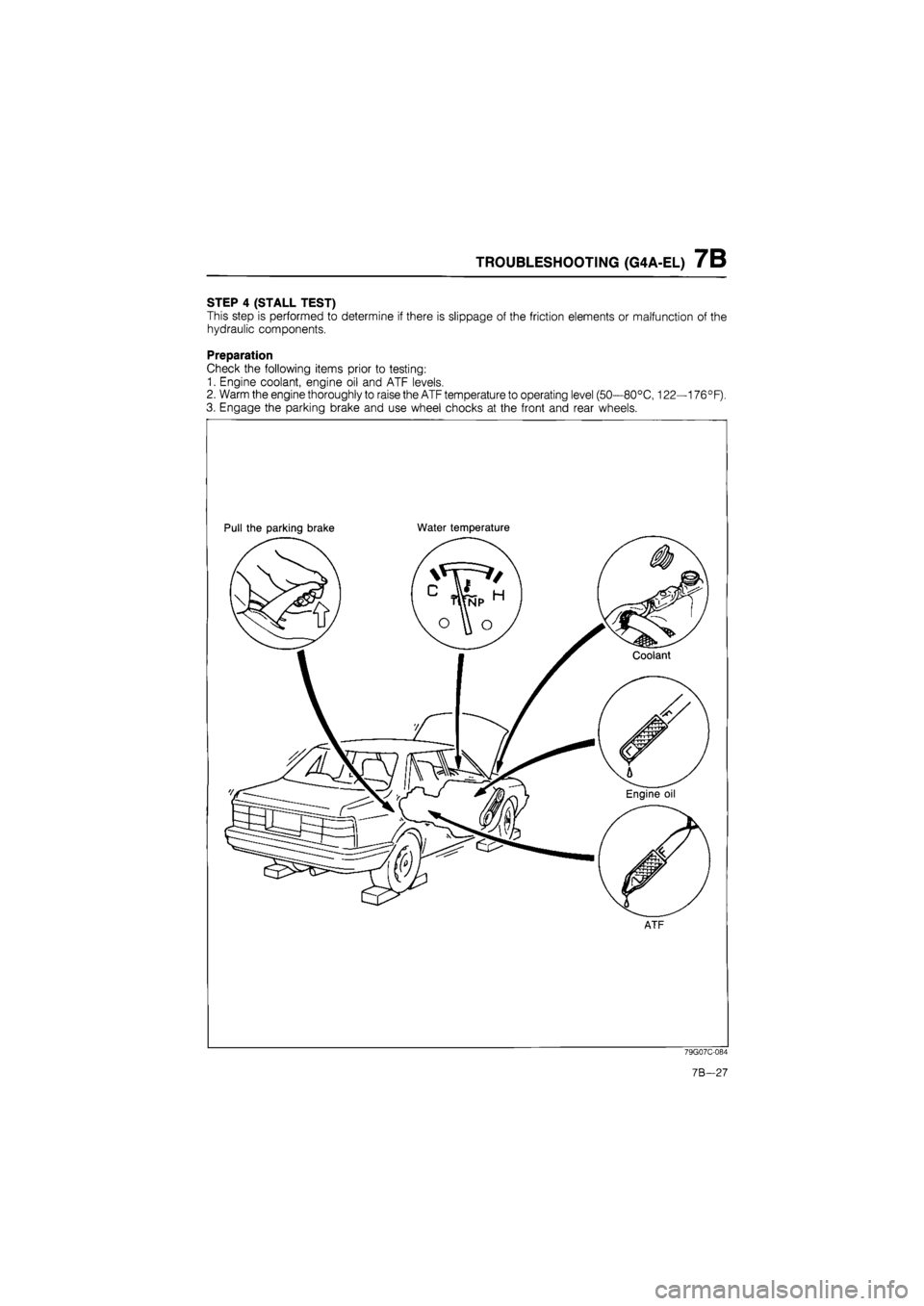

STEP 4 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Engage the parking brake and use wheel chocks at the front and rear wheels.

Pull the parking brake Water temperature

ATF

79G07C-084

7B-27

Page 915 of 1865

TROUBLESHOOTING (G4A-HL) 7B

STEP 3 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Engage the parking brake and use wheel chocks at the front and rear wheels.

Pull the parking brake Water temperature

ATF

83U07B-038

7B—49

Page 1002 of 1865

7B INSPECTION AND REPAIR

CONTROL VALVE BODY (G4A-EL)

Precaution

(1) Pay close attention when handling the control valve because it consists of the most precise and

delicate parts of the transaxle.

(2) Neatly arrange the removed parts in order to avoid mixing up similar parts.

(3) Disassemble the control valve assembly and thoroughly clean it when the clutch and/or brake bands

are burned, and/or when the automatic transaxle fluid is degenerated.

Components I

Front and premain control body

6—8 N-m (66—80 cm-kg, 57—69 in-lb)

1.1-2 Solenoid valve

2. 2-3 Solenoid valve

3. Bolts

4. Front control body

5. Front/premain front gasket

6. Premain separator

7. Front/premain rear gasket

8. Premain control body

9. Premain/main front gasket

10. Main separator

76G07B-141

7B—136

Page 1021 of 1865

INSPECTION AND REPAIR 7B

CONTROL VALVE BODY (G4A-HL)

Precaution

(1) Pay close attention when handling the control valve because it consists df the most precise and

delicate parts of the transaxle.

(2) Neatly arrange the removed parts in order to avoid mixing up similar parts.

(3) Disassemble the control valve assembly and thoroughly clean it when the clutch and/or brake bands

are burned, and/or when the automatic transaxle fluid is degenerated.

Components I

Front and premain control body

6—8 Nm ® (66—80 cm-kg, 57—69 In-lb)

1. Lock-up solenoid valve

2. Front control body

3. Front/premain front gasket

4. Premain separator

5. Front/premain rear gasket

6. Premain control body

7. Premain/main front gasket

8. Main separator

76G07B-163

7B—155

Page 1115 of 1865

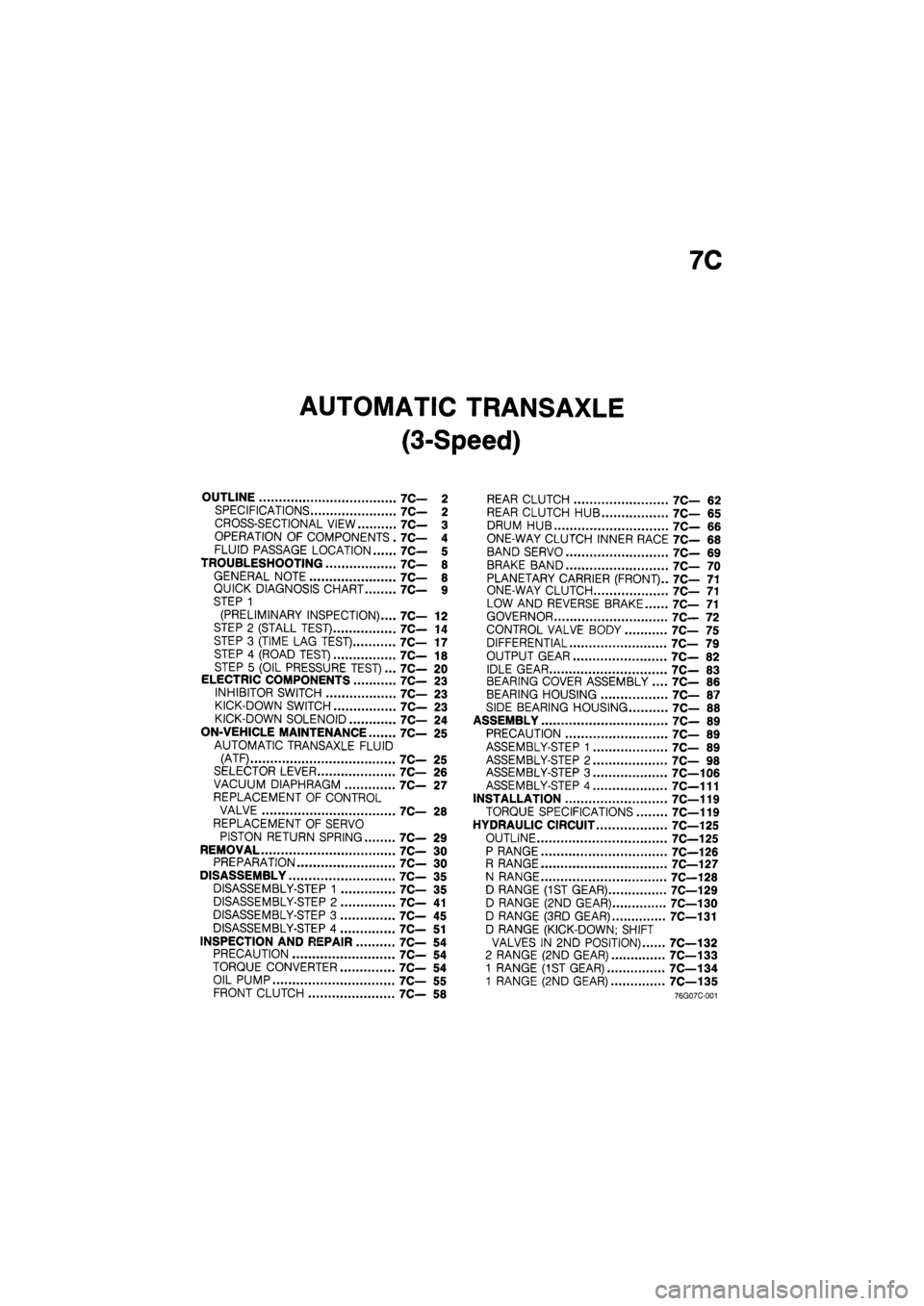

7C

AUTOMATIC TRANSAXLE

(3-Speed)

OUTLINE 7C— 2

SPECIFICATIONS 7C— 2

CROSS-SECTIONAL VIEW 7C— 3

OPERATION OF COMPONENTS . 7C— 4

FLUID PASSAGE LOCATION 7C— 5

TROUBLESHOOTING 7C— 8

GENERAL NOTE 7C— 8

QUICK DIAGNOSIS CHART 7C— 9

STEP 1

(PRELIMINARY INSPECTION).... 7C— 12

STEP 2 (STALL TEST) 7C— 14

STEP 3 (TIME LAG TEST) 7C— 17

STEP 4 (ROAD TEST) 7C— 18

STEP 5 (OIL PRESSURE TEST)... 7C— 20

ELECTRIC COMPONENTS 7C— 23

INHIBITOR SWITCH 7C— 23

KICK-DOWN SWITCH 7C— 23

KICK-DOWN SOLENOID 7C— 24

ON-VEHICLE MAINTENANCE 7C- 25

AUTOMATIC TRANSAXLE FLUID

(ATF) 7C— 25

SELECTOR LEVER 7C— 26

VACUUM DIAPHRAGM 7C— 27

REPLACEMENT OF CONTROL

VALVE 7C— 28

REPLACEMENT OF SERVO

PISTON RETURN SPRING 7C— 29

REMOVAL 7C— 30

PREPARATION 7C— 30

DISASSEMBLY 7C— 35

DISASSEMBLY-STEP 1 7C— 35

DISASSEMBLY-STEP 2 7C— 41

DISASSEMBLY-STEP 3 7C— 45

DISASSEMBLY-STEP 4 7C— 51

INSPECTION AND REPAIR 7C- 54

PRECAUTION 7C— 54

TORQUE CONVERTER 7C— 54

OIL PUMP 7C— 55

FRONT CLUTCH 7C— 58

REAR CLUTCH 7C— 62

REAR CLUTCH HUB 7C— 65

DRUM HUB 7C— 66

ONE-WAY CLUTCH INNER RACE 7C— 68

BAND SERVO 7C— 69

BRAKE BAND 7C— 70

PLANETARY CARRIER (FRONT).. 7C— 71

ONE-WAY CLUTCH 7C— 71

LOW AND REVERSE BRAKE 7C— 71

GOVERNOR 7C— 72

CONTROL VALVE BODY 7C— 75

DIFFERENTIAL 7C— 79

OUTPUT GEAR 7C— 82

IDLE GEAR 7C— 83

BEARING COVER ASSEMBLY .... 7C— 86

BEARING HOUSING 7C— 87

SIDE BEARING HOUSING 7C— 88

ASSEMBLY 7C— 89

PRECAUTION 7C— 89

ASSEMBLY-STEP 1 7C— 89

ASSEMBLY-STEP 2 7C— 98

ASSEMBLY-STEP 3 7C—106

ASSEMBLY-STEP 4 7C—111

INSTALLATION 7C—119

TORQUE SPECIFICATIONS 7C—119

HYDRAULIC CIRCUIT 7C—125

OUTLINE 7C—125

P RANGE 7C—126

R RANGE 7C—127

N RANGE 7C—128

D RANGE (1ST GEAR) 7C—129

D RANGE (2ND GEAR) 7C—130

D RANGE (3RD GEAR) 7C—131

D RANGE (KICK-DOWN; SHIFT

VALVES IN 2ND POSITION) 7C—132

2 RANGE (2ND GEAR) 7C—133

1 RANGE (1ST GEAR) 7C—134

1 RANGE (2ND GEAR) 7C—135

76G07C-001

Page 1116 of 1865

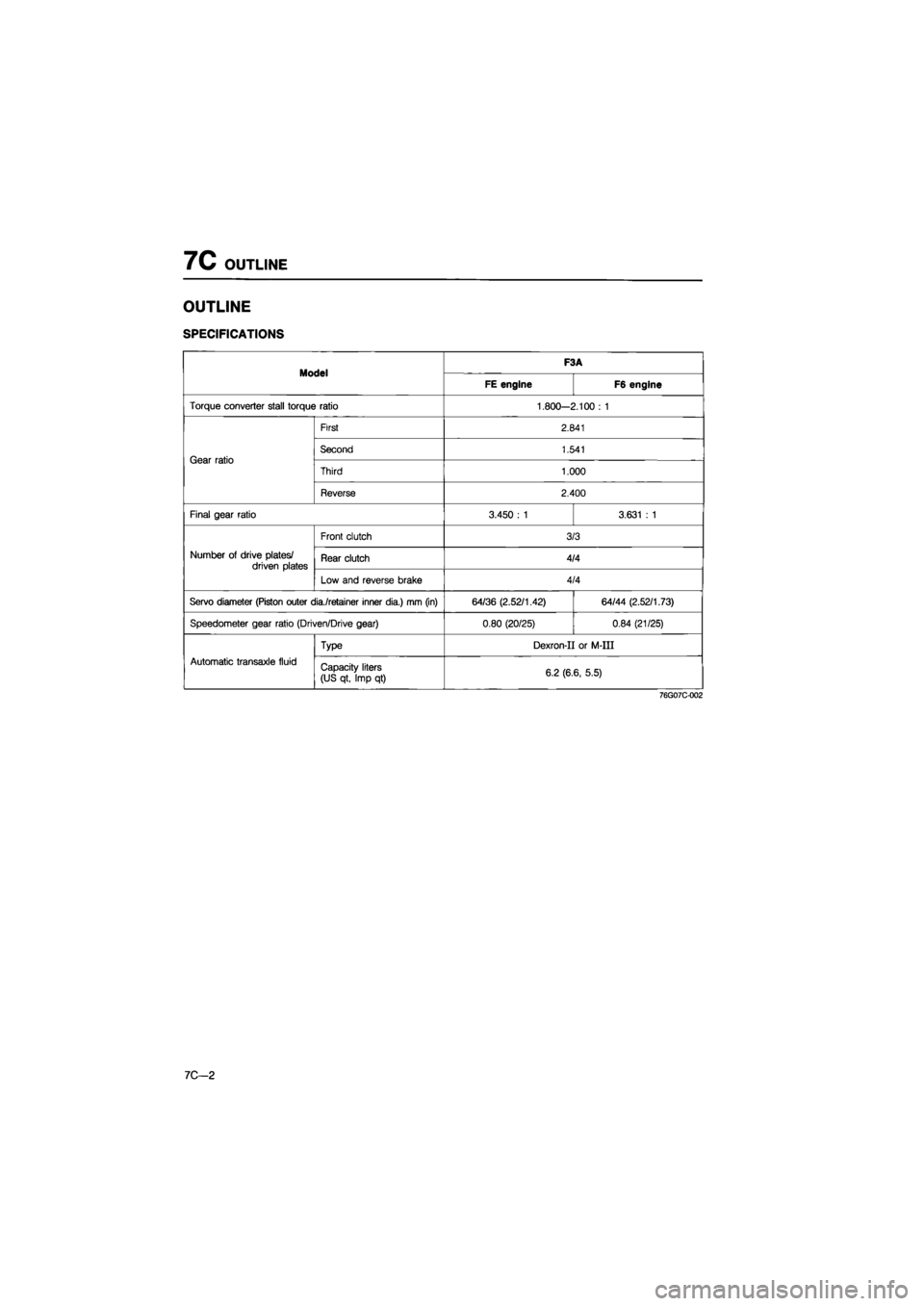

7C OUTLINE

OUTLINE

SPECIFICATIONS

Model F3A Model FE engine F6 engine

Torque converter stall torque ratio 1.800-2.100 : 1

Gear ratio

First 2.841

Gear ratio Second 1.541 Gear ratio

Third 1.000

Gear ratio

Reverse 2.400

Final gear ratio 3.450 : 1 3.631 : 1

Number of drive plates/ driven plates

Front clutch 3/3

Number of drive plates/ driven plates Rear clutch 4/4 Number of drive plates/ driven plates

Low and reverse brake 4/4

Servo diameter (Piston outer dia./retainer inner dia.) mm (in) 64/36 (2.52/1.42) 64/44 (2.52/1.73)

Speedometer gear ratio (Driven/Drive gear) 0.80 (20/25) 0.84 (21/25)

Automatic transaxle fluid

Type Dexron-II or M-III

Automatic transaxle fluid Capacity liters

(US qt, Imp qt) 6.2 (6.6, 5.5)

76G07C-002

7C—2

Page 1117 of 1865

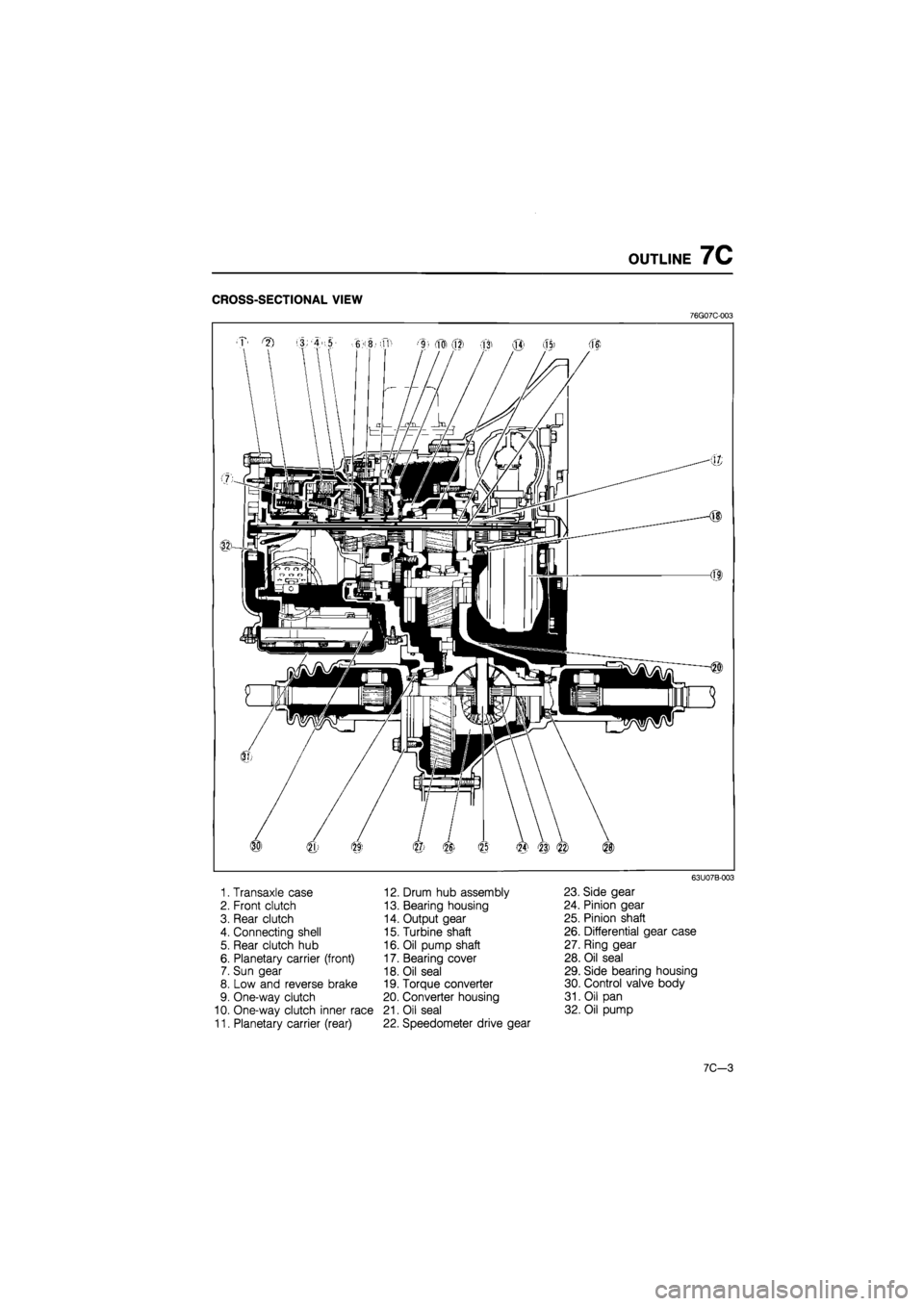

OUTLINE 7C

CROSS-SECTIONAL VIEW

76G07C-003

1. Transaxle case

2. Front clutch

3. Rear clutch

4. Connecting shell

5. Rear clutch hub

6. Planetary carrier (front)

7. Sun gear

8. Low and reverse brake

9. One-way clutch

10. One-way clutch inner race

11. Planetary carrier (rear)

12. Drum hub assembly

13. Bearing housing

14. Output gear

15. Turbine shaft

16. Oil pump shaft

17. Bearing cover

18. Oil seal

19. Torque converter

20. Converter housing

21. Oil seal

22. Speedometer drive gear

63U07B-003

23. Side gear

24. Pinion gear

25. Pinion shaft

26. Differential gear case

27. Ring gear

28. Oil seal

29. Side bearing housing

30. Control valve body

31. Oil pan

32. Oil pump

7C-3

Page 1118 of 1865

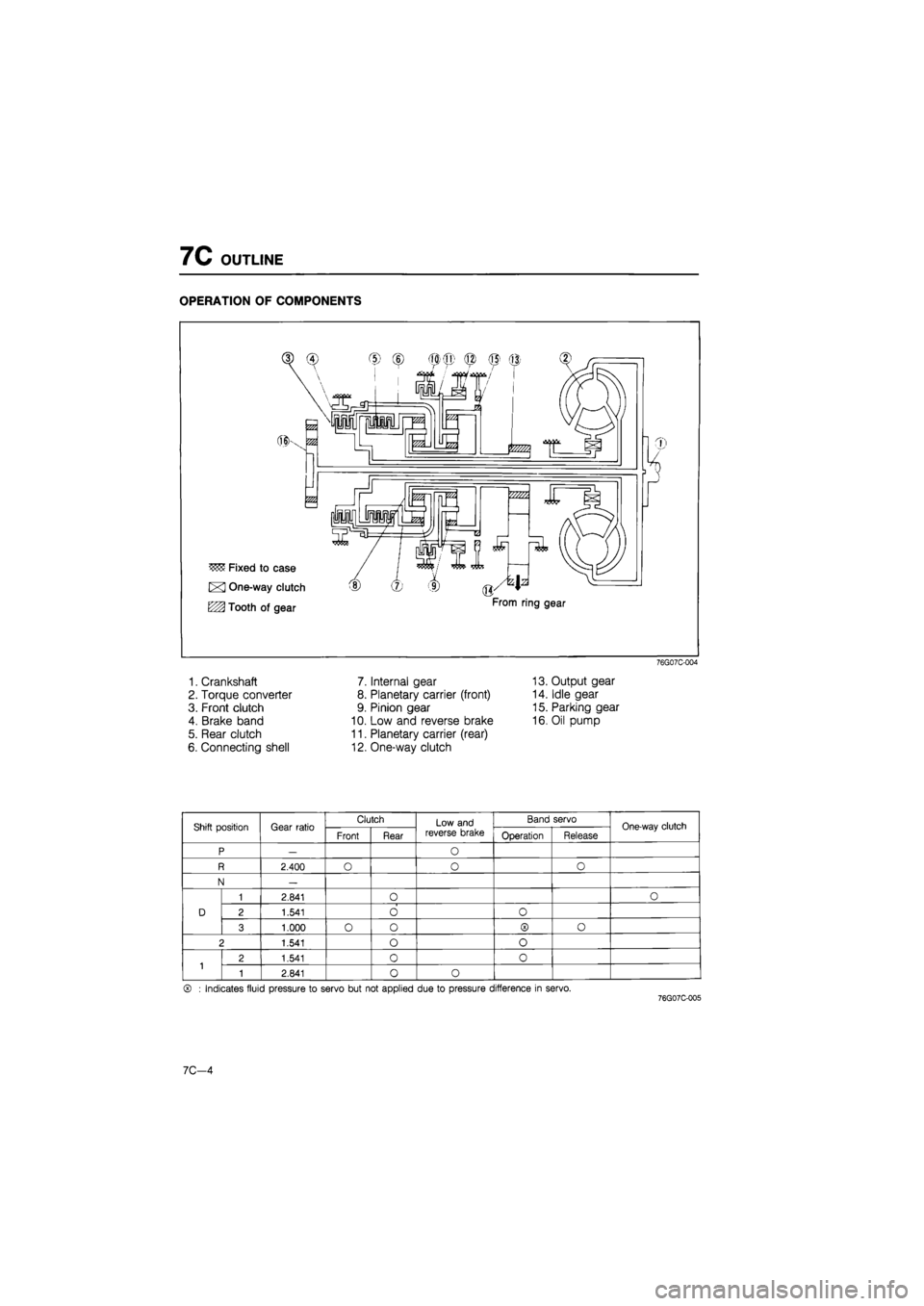

7C OUTLINE

OPERATION OF COMPONENTS

76G07C-004

1. Crankshaft 7. Internal gear 13. Output gear

2. Torque converter 8. Planetary carrier (front) 14. Idle gear

3. Front clutch 9. Pinion gear 15. Parking gear

4. Brake band 10. Low and reverse brake 16. Oil pump

5. Rear clutch 11. Planetary carrier (rear)

6. Connecting shell 12. One-way clutch

Shift position Gear ratio Clutch Low and reverse brake

Band servo One-way clutch Shift position Gear ratio Front Rear

Low and reverse brake Operation Release One-way clutch

P — O

R 2.400 O o O

N —

D

1 2.841 O O

D 2 1.541 O O D

3 1.000 O o ® o

2 1.541 o o

1 2 1.541 0 0 1 1 2.841 0 o

® : Indicates fluid pressure to servo but not applied due to pressure difference in servo. 76G07C-005

7C-4

Page 1120 of 1865

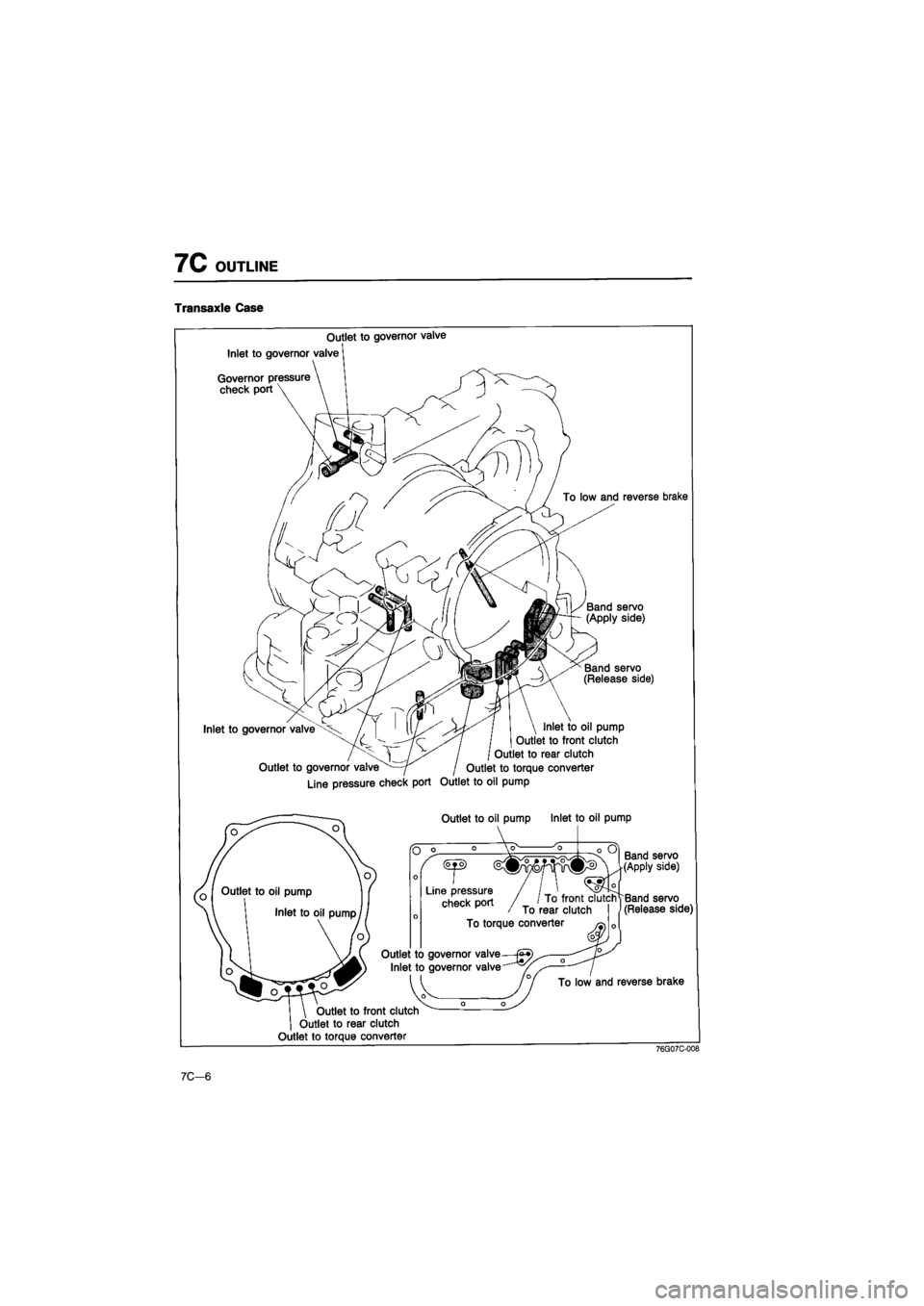

7C OUTLINE

Transaxle Case

Outlet to governor valve

Inlet to governor valve'

Governor pressure

check port

To low and reverse brake

Band servo (Apply side)

Band servo (Release side)

Inlet to governor valve Inlet to oil pump

Outlet to front clutch

Outlet to rear clutch

Outlet to governor valve j Outlet to torque converter

Line pressure check port Outlet to oil pump

Outlet to oil pump Inlet to oil pump

Outlet to front clutch

Outlet to rear clutch

Outlet to torque converter

Band servo (Apply side)

Band servo (Release side)

Outlet to governor valve—

Inlet to governor valve

reverse brake

76G07C-008

7C—6

Page 1123 of 1865

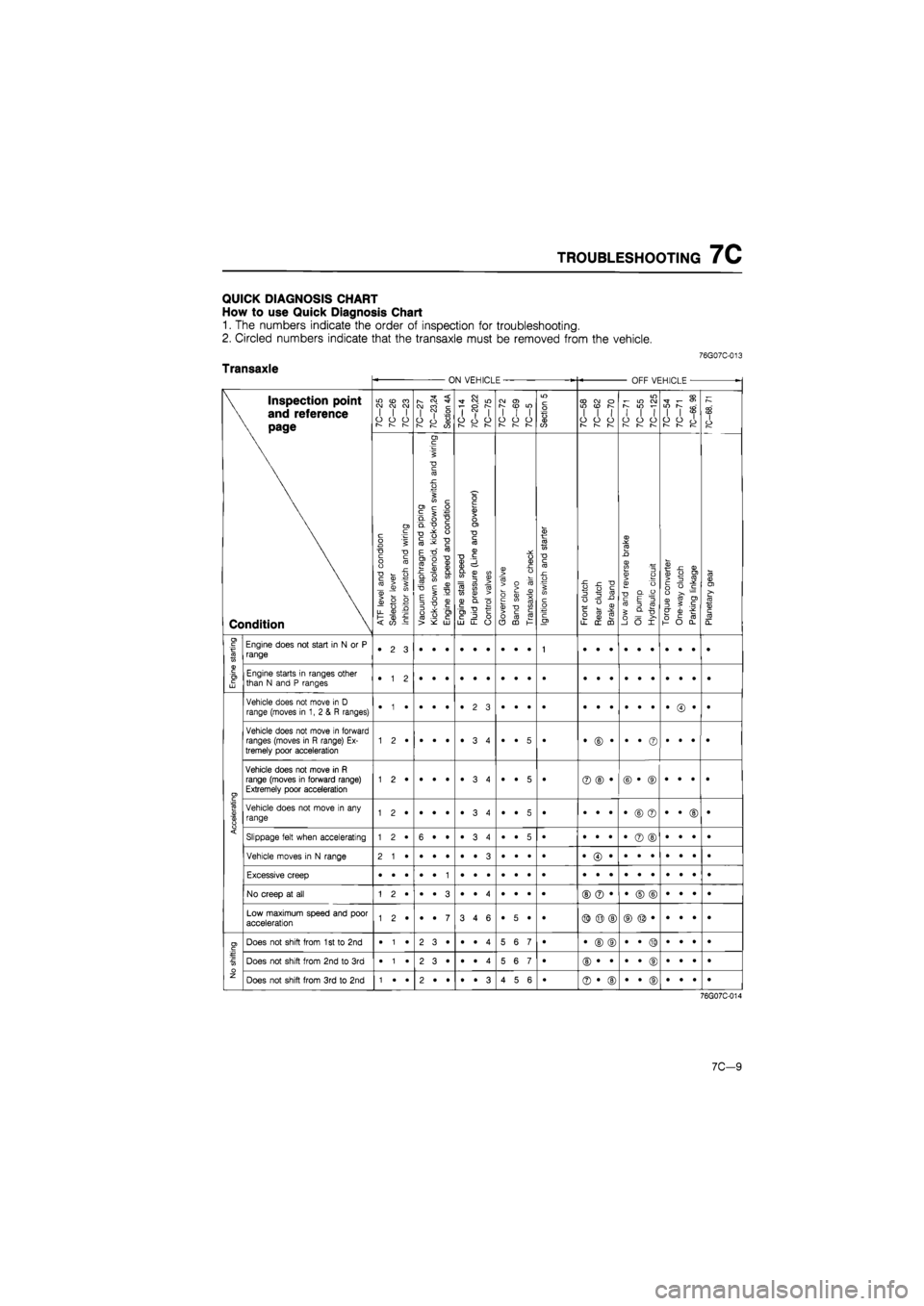

TROUBLESHOOTING

7C

QUICK DIAGNOSIS CHART

How

to use

Quick Diagnosis Chart

1.

The

numbers indicate

the

order

of

inspection

for

troubleshooting.

2. Circled numbers indicate that

the

transaxle must

be

removed from

the

vehicle.

76G07C-013

Transaxle ON VEHICLE OFF VEHICLE

•

\ Inspection point

\

and

reference

\ page

Condition

7C-25

7C-26

7C-23

10—21

7C—23,24

Section

4A

7C-14

7C—20,22

10—lb

10-12 10—69

7C—5

Section

5

7C—58

7C-62

7C-70

7C-71

7C-55

7C-125

7C-54 7C-71

7C-66,

98

7C-68,

71

\ Inspection point

\

and

reference

\ page

Condition

ATF

level

and

condition

Selector

lever

Inhibitor

switch

and

wiring

^

Vacuum

diaphragm

and

piping

|

Kick-down

solenoid,

kick-down

switch

and

wiring

Engine

idle

speed

and

condition

Engine

stall

speed

Fluid

pressure

(Line

and

governor)

Control

valves

Governor

valve

Band

servo

Transaxle

air

check

Ignition

switch

and

starter

Front

clutch

Rear

clutch

Brake

band

Low

and

reverse

brake

Oil

pump Hydraulic

circuit

Torque

converter

One-way

clutch

Parking

linkage

Planetary

gear

I

Engine

starting

Engine does

not

start

in

N or P

range •

2 3

1

Engine

starting

Engine starts

in

ranges other than

N

and P

ranges •

1 2

Accelerating

Vehicle does

not

move

in

D

range (moves

in 1, 2 & R

ranges) •

• •

•

Accelerating

Vehicle does

not

move

in

forward ranges (moves

in R

range)

Ex-

tremely poor acceleration •

• 5

• •

© •

•

• ©

•

• •

•

Accelerating

Vehicle does

not

move

in R

range (moves

in

forward range) Extremely poor acceleration 1

2 •

•

• •

•

3 4

•

• 5

• ©

© •

©

• ©

•

• •

•

Accelerating

Vehicle does

not

move

in any

range 1

2 •

•

• •

•

3 4

•

• 5

• •

• •

•

© ©

•

• ©

•

Accelerating Slippage felt when accelerating 1

2 •

6

• •

•ST

CO

•

•

• 5

• •

• •

•

© ©

•

• •

• Accelerating

Vehicle moves

in

N

range

Accelerating

Excessive creep

Accelerating

No creep

at all

©

© •

•

© ©

•

• •

•

Accelerating

Low maximum speed

and

poor acceleration 1

2 •

•

• 7

3

4 6

•

5 •

• ©

© ©

No shifting

Does

not

shift from

1

st to 2nd

•

1 •

2

3 •

•

• 4

5

6 7

• •

© ©

•

• ©

•

• •

•

No shifting

Does

not

shift from

2nd to 3rd

•

1 •

2

3 •

•

• 4

5

6 7

•

No shifting

Does

not

shift from

3rd to 2nd

1

• •

2

• •

•

• 3

4

5 6

• ©

• ©

•

• ©

•

• •

•

76G07C-014

7C-9