engine oil MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 38 of 1865

1A TUNE-UP PROCEDURE

76G01A-102

76G01A-103

76G01A-104

TUNE-UP PROCEDURE

Tune the engine according to the procedures

described below.

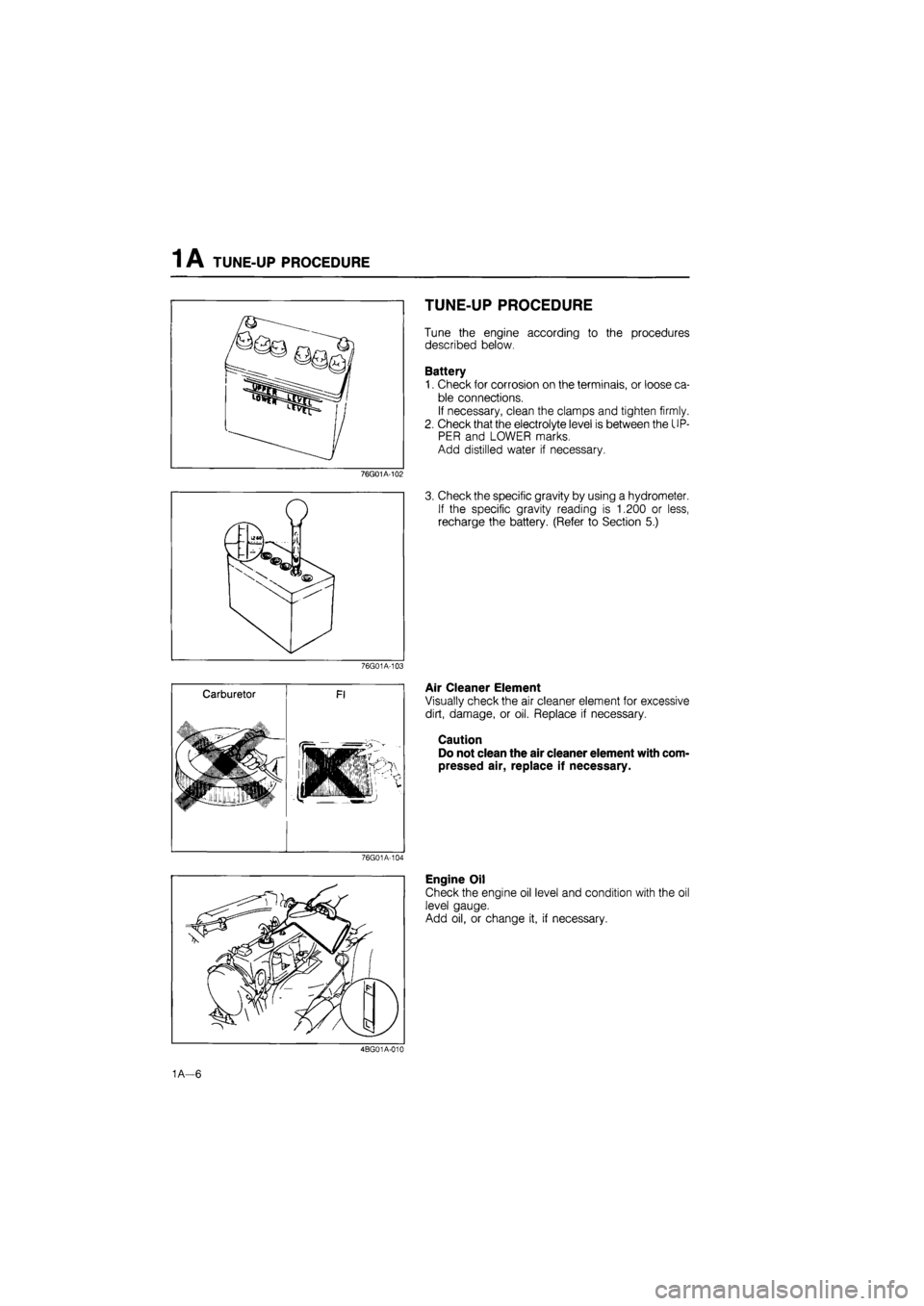

Battery

1. Check for corrosion on the terminals, or loose ca-

ble connections.

If necessary, clean the clamps and tighten firmly.

2. Check that the electrolyte level is between the UP-

PER and LOWER marks.

Add distilled water if necessary.

3. Check the specific gravity by using a hydrometer.

If the specific gravity reading is 1.200 or less,

recharge the battery. (Refer to Section 5.)

Air Cleaner Element

Visually check the air cleaner element for excessive

dirt, damage, or oil. Replace if necessary.

Caution

Do not clean the air cleaner element with com-

pressed air, replace if necessary.

Engine Oil

Check the engine oil level and condition with the oil

level gauge.

Add oil, or change it, if necessary.

76G01A-019

1A—6

Page 41 of 1865

TUNE-UP PROCEDURE 1A

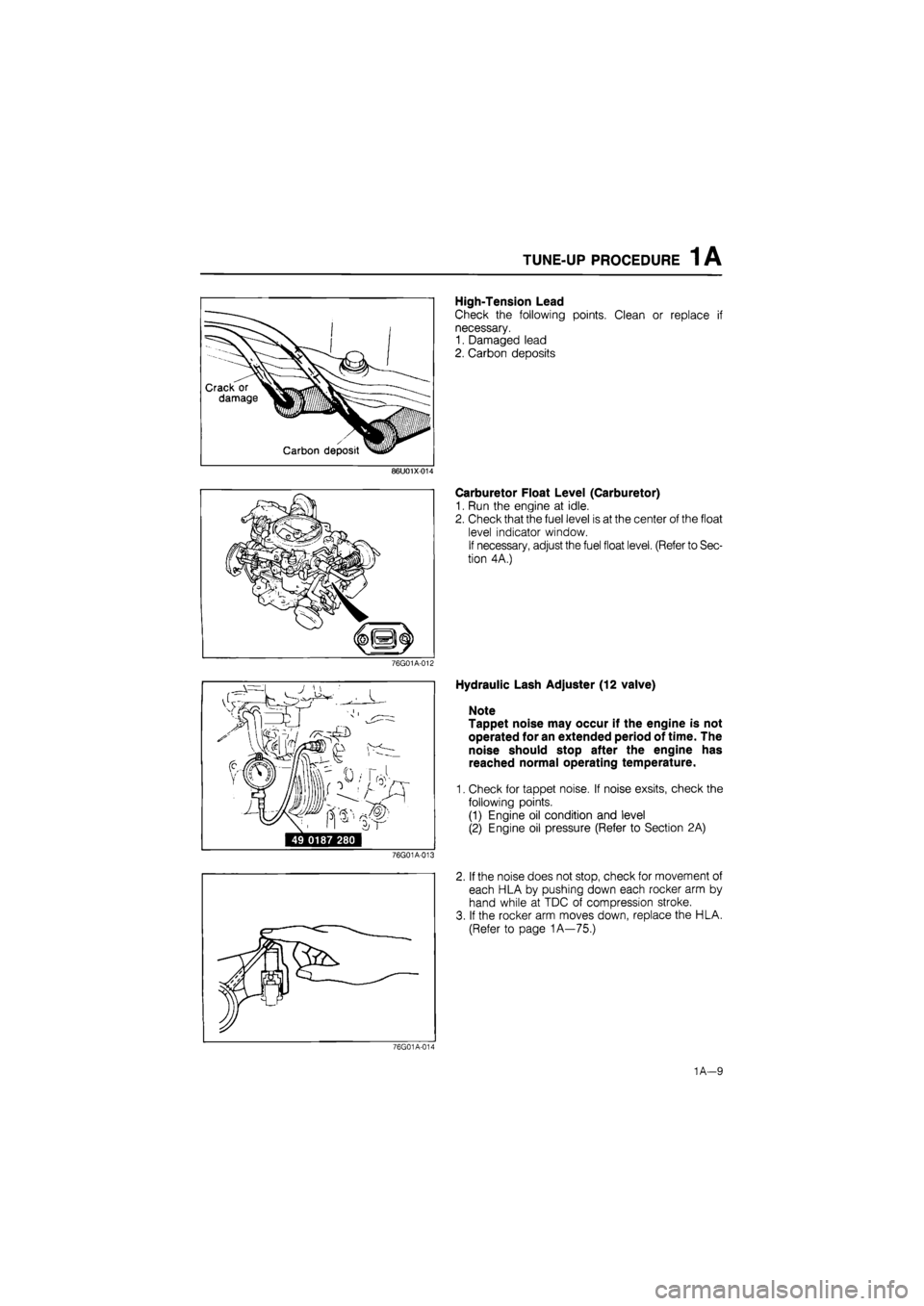

High-Tension Lead

Check the following points. Clean or replace if

necessary.

1. Damaged lead

2. Carbon deposits

86U01X-014

76G01A-012

49 0187 280

76G01A-013

Carburetor Float Level (Carburetor)

1. Run the engine at idle.

2. Check that the fuel level is at the center of the float

level indicator window.

If necessary, adjust the fuel float level. (Refer to Sec-

tion 4A.)

Hydraulic Lash Adjuster (12 valve)

Note

Tappet noise may occur if the engine is not

operated for an extended period of time. The

noise should stop after the engine has

reached normal operating temperature.

1. Check for tappet noise. If noise exsits, check the

following points.

(1) Engine oil condition and level

(2) Engine oil pressure (Refer to Section 2A)

2. If the noise does not stop, check for movement of

each HLA by pushing down each rocker arm by

hand while at TDC of compression stroke.

3. If the rocker arm moves down, replace the HLA.

(Refer to page 1A—75.)

76G01A-014

1

A—9

Page 45 of 1865

ON-VEHICLE INSPECTION 1 A

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following points.

1. Ignition system (Refer to Section 5)

2. Compression

3. Fuel system (Refer to Section 4)

COMPRESSION

1. Check that the battery is fully charged. Recharge

if necessary.

76G01A-107

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all spark plugs.

5. Disconnect the primary wire connector from the

ignition coil.

86U01X-020

6. Connect a compression gauge to No.

1

spark plug

hole.

7. Fully depress the accelerator pedal and crank the

engine.

8. Note the maximum gauge reading.

9. Check each cylinder.

Compression pressure kPa (kg/cm2, psi)-rpm

Standard Minimum

F6 1,128 (11.5, 164)—270 790 (8.1, 114)—270

F8-FE 1,275 (13.0, 185)—270 893 (9.1, 129)—270

FE 12-valve 1,422 (14.5, 206)—280 996 (10.2, 144)—280

76G01A-023

Possible Cause

86U01X-022

1A—13

Page 47 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

Removal note

Timing belt tensioner

1. Turn the crankshaft to align the mating mark of the

camshaft pulley with the front housing timing mark.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

2. Remove the tensioner.

76G01A-025

Timing belt

Mark the timing belt rotation for proper reinstallation

if it is reused.

Caution

Be careful not to allow oil, grease, or water

on the belt.

86U01X-024

Inspection

Inspect the following parts.

(Refer to page 1A—60, 61.)

1. Timing belt

2. Timing belt tensioner and spring

3. Timing belt idler pulley

4. Timing belt pulley

5. Camshaft pulley

76G01A-026

1A—15

Page 49 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 A

76G01A-027

76G01B-024

76G01A-028

/Jf

ry.

2. Check that the mating mark of the camshaft pul-

ley is aligned with the timing mark. If it is not

aligned, turn the camshaft to align.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

3. Install the timing belt tensioner and spring. Tem-

porarily secure it with the spring fully extended.

Caution

Do not damage the pulleys when securing the

tensioner pulley.

4. Install the timing belt. (Keep the tension side of belt

as tight as possible).

Caution

a) If the timing belt is being reused, it must be

reinstalled to rotate in the original direction.

b) Check that there is no oil, grease, or dirt on

the timing belt.

5. Loosen the tensioner lock bolt.

6. Turn the crankshaft twice in the direction of rota-

tion, and align the mating marks.

7. Check that the timing marks are correctly aligned.

If not aligned, remove the timing belt tensioner and

timing belt, and repeat steps 1—6.

69G01B-027

1A-17

Page 56 of 1865

1 A ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

Installation note

Cylinder head

1. Thoroughly remove all dirt and oil from the top of

the cylinder block with a rag.

2. Place a new cylinder head gasket in position.

86U01X-035

®

CD

© (8)

3. Set the cylinder head in place.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80—86 N-m (8.2—8.8 m-kg, 59—64 ft-lb)

86U01X-036

Cylinder head cover

1. Apply silicon sealant to the shaded area shown in

the figure.

2. Install the cylinder head cover.

Tightening torque:

6—8

N

m (60—80 cm-kg, 52—69 in-lb)

86U01X-037

Timing belt

1. Align the mating mark of the camshaft pulley with

the front housing timing mark.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

2. Install the timing belt. (Refer to TIMING BELT of

ON-VEHICLE MAINTENANCE.)

76G01A-034

1A—24

Page 57 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 A

76G01A-035

Engine harness connector

Install the engine harness connectors.

Distributor

1. Apply engine oil to the O-ring, and position it on

the distributor.

2. Apply engine oil to the blade or gear.

3. Align the mating marks as shown in the figure

...8-valve.

4. Install the distributor with the marks facing straight

up.

5. Loosely tighten the distributor mounting bolt.

1. IG coil

2. Engine ground

3. Water tempera-

ture sensor

4. Water thermo

switch

5. Oxygen sensor

(Fl)

6. Injection harness

(Fl)

7. F/l solenoid

valve (Fl)

8. Throttle sensor

(Fl)

76G01A-113

Steps After Installation

1. Fill the radiator with the specified amount and type

of coolant.

2. Perform the necessary engine adjustments. (Re-

fer to TUNE-UP PROCEDURE.)

1

A—25

Page 62 of 1865

1 A ON-VEHICLE MAINTENANCE (VALVE SEAL)

Installation note

Valve seal

1. Apply engine oil to the inside of the new valve seal.

2. Push it on gently with the SST.

86U01X-049

Valve spring

Cylinder head side

Valve spring

1. (12-valve)

Install the valve spring with the narrower pitch to-

ward the cylinder head side.

(8-valve)

Install the outer valve spring with the narrower pitch

toward the cylinder head side.

2. Install the valve keepers, and tap the end of the

valve stem lightly two or three times with a plastic

hammer to confirm that the keepers are all fully

seated.

76G01A-038

12-valve Rocker arm, rocker arm shaft

1. Remove the rocker arm shafts and camshaft caps.

2. (12-valve)

Assemble the rocker arms and springs to the shaft.

Note

a) The intake side shaft has twice as many oil

holes as the exhaust side shaft.

b) The stepped ends are the rear sides of both

intake and exhaust shafts.

76G01A-039

(8-valve)

Assemble the camshaft caps, rocker arms, and

springs, to the shafts.

Caution

Be sure both rocker arm shaft oil holes (in the

center camshaft cap) face each other.

76G01A-040

1A—30

Page 63 of 1865

ON-VEHICLE MAINTENANCE (VALVE SEAL) 1 A

Camshaft

1. Apply sealant to the shaded areas as shown in the

figure.

76G01A-041

2. Apply engine oil to the camshaft journals.

3. Install the camshaft with its dowel pin upward.

76G01A-042

12-valve

© © (D

Rocker arm and shaft assembly

(12-valve)

1. Install the camshaft caps.

2. Install the rocker arm and shaft assemblies on the

cylinder head, and tighten them in three steps in

the order shown in the figure.

Tightening torque:

18—26 Nm (1.8—2.7 m-kg, 13—20 ft-lb)

76G01A-043

Caution

Be careful that the rocker arms or spacers do

not get caught between the shaft and cam-

shaft cap.

86U01X-052

1A—31

Page 64 of 1865

ON-VEHICLE MAINTENANCE (VALVE SEAL) 1 A

76G01A-044

86U01X-212

76G01A-045

(8-valve)

Install the rocker arm and shaft assemblies on the cyl-

inder head and tighten them in three steps in the or-

der shown in the figure.

Tightening torque:

18—26 N-m (1.8—2.7 m-kg, 13—20 ft-lb)

Front housing

1. Replace the oil seal in the front housing.

2. Apply engine oil to the oil seal lip.

3. Install the front housing along with a new gasket.

Tightening torque:

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

Rear housing

Install the rear housing along with a new gasket.

Tightening torque:

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

Camshaft pulley

1. Install the camshaft pulley so that the mating mark

is aligned with the camshaft dowel pin straight up.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

2. Tighten the lock bolt.

Tightening torque:

47—65 N-m (4.8—6.6 m-kg, 35—48 ft-lb)

Timing belt

Install the timing belt. (Refer to TIMING BELT of ON-

VEHICLE MAINTENANCE.)

86U01X-052

1A—32