fuel pressure MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 156 of 1865

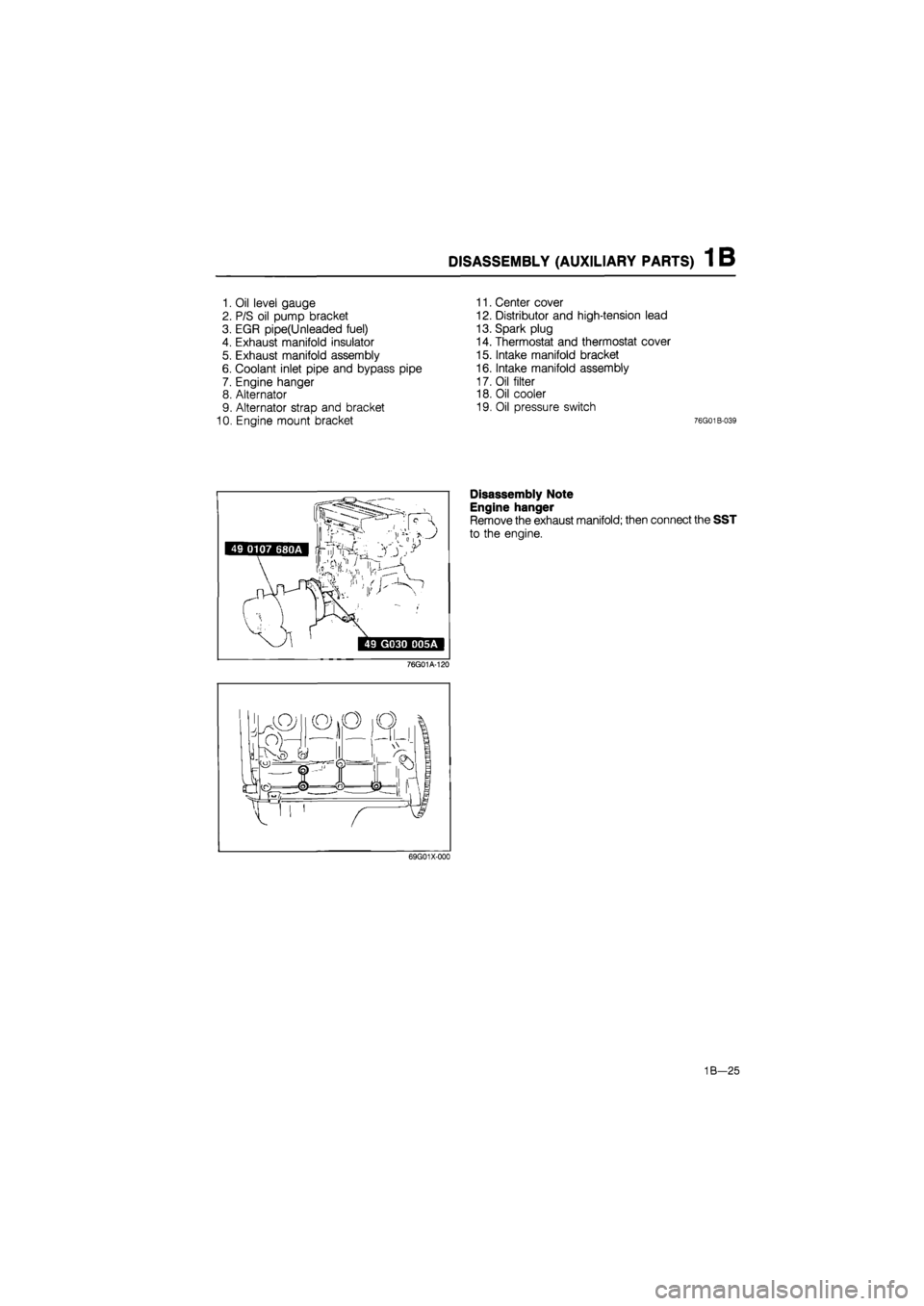

DISASSEMBLY (AUXILIARY PARTS) 1 B

1. Oil level gauge

2. P/S oil pump bracket

3. EGR pipe(Unleaded fuel)

4. Exhaust manifold insulator

5. Exhaust manifold assembly

6. Coolant inlet pipe and bypass pipe

7. Engine hanger

8. Alternator

9. Alternator strap and bracket

10. Engine mount bracket

11. Center cover

12. Distributor and high-tension lead

13. Spark plug

14. Thermostat and thermostat cover

15. Intake manifold bracket

16. Intake manifold assembly

17. Oil filter

18. Oil cooler

19. Oil pressure switch

76G01B-039

49 0107 680A Irf^Ys'^

,v,, I

' ir

>

49 G030 D05A

76G01A-120

Disassembly Note

Engine hanger

Remove the exhaust manifold; then connect the SST

to the engine.

69G01X-000

1B—25

Page 215 of 1865

TROUBLESHOOTING GUIDE 1 C

SPECIFICATIONS

———Engine model

Item ^—_______ RF-CX RF-N

Type Diesel, 4 cycle

Cylinder arrangement and number In line, 4 cylinders

Combustion chamber Swirl chamber

Valve system OHC, belt driven

Displacement cc (cu in) 1,998 (121.9)

Bore and stroke mm (in) 86.0 x 86.0 (3.39 x 3.39)

Compression ratio 21.1 : 1 22.7 : 1

Compression pressure

kPa (kg/cm2, psi)-rpm

Standard 2.943 (30, 427)-200 Compression pressure

kPa (kg/cm2, psi)-rpm Minimum 2.649 (27, 384)-200

Valve timing

IN Open BTDC 13° 13°

Valve timing

IN Close ABDC 15° 39° Valve timing

EX Open BBDC 60° 60° Valve timing

EX Close ATDC 8° 8°

Valve clearance mm (in)

Cold IN 0.25 (0.010)

Valve clearance mm (in)

Cold EX 0.35 (0.014) Valve clearance mm (in) Warm (for ref.)

IN 0.30 (0.012) Valve clearance mm (in) Warm (for ref.) EX 0.40 (0.016)

Idle speed (MTX in neutral) rpm 720

Injection timing ATDC 10 TDC 0°

Injection order 1_3_4_2

76G01C-002

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Difficult starting Malfunction of engine-related components

Burned valve Worn piston, piston ring, or cylinder Failed cylinder head gasket

Replace Replace or repair Replace

1C-48 1C—55,56 1C-16

Difficult starting

Malfunction of fuel system Refer to Section 4D

Difficult starting

Malfunction of Comprex supercharger Refer to Section 4D

Difficult starting

Malfunction of electrical system Refer to Section 5

Poor idling Malfunction of engine-related components Improper valve clearance Poor valve to valve seat contact Failed cylinder head gasket

Adjust Repair or replace Replace

1C-85 1C-50 1C—16

Poor idling

Malfunction of fuel system Refer to Section 4D

Poor idling

Malfunction of Comprex supercharger Refer to Section 4D

Excessive oil consumption

Oil working up Worn piston ring groove or sticking piston ring Worn piston or cylinder

Replace Replace or repair

1C-57 1C—55,56

Excessive oil consumption

Oil working down Worn valve seal Worn valve stem or guide

Replace Replace

1C-24 1C-48

Excessive oil consumption

Oil leakage Refer to Section 2B

76G01C-003

1C—3

Page 222 of 1865

1C ON-VEHICLE INSPECTION

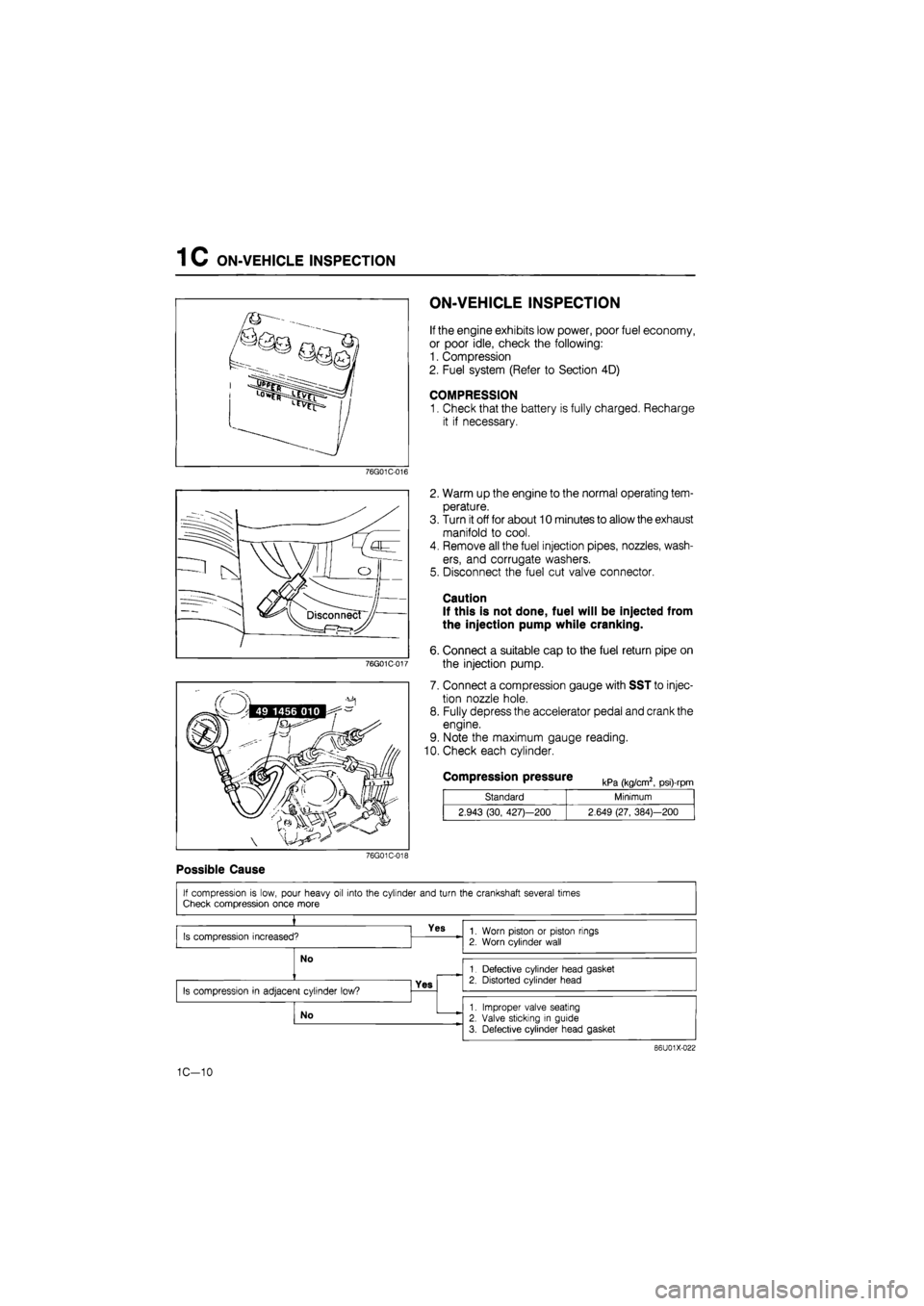

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following:

1. Compression

2. Fuel system (Refer to Section 4D)

COMPRESSION

1. Check that the battery is fully charged, Recharge

it if necessary.

76G01C-016

76G01C-017

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all the fuel injection pipes, nozzles, wash-

ers, and corrugate washers.

5. Disconnect the fuel cut valve connector.

Caution

If this is not done, fuel will be injected from

the injection pump while cranking.

6. Connect a suitable cap to the fuel return pipe on

the injection pump.

7. Connect a compression gauge with SST to injec-

tion nozzle hole.

8. Fully depress the accelerator pedal and crank the

engine.

9. Note the maximum gauge reading.

10. Check each cylinder.

Compression pressure kPa (kg/cm2, psi)-rpm

Standard Minimum

2.943 (30, 427)—200 2.649 (27, 384)—200

76G01C-018

Possible Cause

86U01X-022

1C-10

Page 251 of 1865

DISASSEMBLY (INJECTION PUMP) 1 C

INJECTION PUMP

76G01C-082

1. No.3 engine mount and idler

2. Injection pipe

3. Injection pump

4. Oil level gauge and stay

5. Oil pipe

6. Fuel feed pipe

7. Oil pressure switch

8. Water pipe

9. Water pump

Disassembly Note

Injection pump

Remove the injection pump with its brackets.

If separate them, adjust the injection timing after in-

stalling the timing belt referring to Section 4D.

76G01C-083

1C-39

Page 291 of 1865

ASSEMBLY (INJECTION PUMP) 1 C

Water Pipe

1. Apply a coat of vegetable oil to the O-ring.

2. Install the water pipe.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

3. Connect the water hose.

76G01C-181

^OQOja^q^

cffl-.. M

Oil Pressure Switch

Install the oil pressure switch.

Tightening torque: 12—18 N-m

(1.2—1.8 m-kg, 104—156 in-lb)

76G01C-182

Fuel Feed Pipe and Oil Pipe

1. Install the fuel feed pipe and tighten bolt (A).

Tightening torque:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

2. Install the oil pipe and loosely tighten the bolts (B).

76G01C-183

"m

fa?-^ lA-f! . 11

? - ' ~" ~ -'

Oil Level Gauge

Install the oil level gauge and stay.

Tightening torque:

8—12 N-m (80—120 cm-kg, 69—104 in-lb)

76G01C-184

1C-79

Page 307 of 1865

INSTALLATION 1C

Heater Hose

Connect the heater hoses.

Note

Position the hose clamp in the original loca-

tion on the hose and squeeze the clamp lightly

with large pliers to ensure a good fit.

86U01X-221

Connector Location

Install each harness as shown in the figure.

1. Alternator

2. Boost air temperature sensor (RF-CX)

3. Heat gauge unit

4. Water thermo switch

5. Pick up coil

6. Glow cord

7. Front harness connector and ground

76G01C-222

8. Fuel cut valve

9. Oil pressure switch

10. Starter

11. Water temperature switch

12. Transaxle harness

13. Grounds

1C—95

Page 380 of 1865

OUTLINE 4A

SPECIFICATIONS

F6 & F8 Engine

Engine F6 F8

Specification General Singapore General

ECE,

Hong Kong, &

Singapore

Idle speed

rpm

MTX 800

+58

Idle speed

rpm

ATX 950

t5§

(in N range)|

900 +5§ (in N

range)

CO concentration

%

2.0

± 0.5

(Without secondary

air

injection)

Carburetor

Type Down draft, two barrel

Throat diameter

mm (in)

Primary 30 (1.18) Throat diameter

mm (in)

Secondary 34 (1.34)

Venturi diameter

mm

(in) Primary 23.5 (0.93) Venturi diameter

mm

(in) Secondary 29.0 (1.14)

Main nozzle

mm (in)

Primary 2.6 (0.10) Main nozzle

mm (in)

Secondary 2.8 (0.11)

Main

jet mm (in)

Primary MTX 1.10 (0.0433) 1.09 (0.0429) 1.14 (0.045)

Main

jet mm (in)

Primary ATX 1.10 (0.0433) 1.08 (0.0425) 1.12 (0.044) Main

jet mm (in)

Secondary 1.50 (0.059)

Main

air

bleed mm (in)

Primary MTX 0.60 (0.024) 0.60 (0.024) 0.55 (0.022) Main

air

bleed mm (in)

Primary ATX 0.60 (0.024) 0.80 (0.031) 0.60 (0.024) Main

air

bleed mm (in) Secondary 0.50 (0.020)

Slow

jet mm (in)

Primary 0.48 (0.019) 0.46 (0.018) Slow

jet mm (in)

Secondary 1.00 (0.039) 1.10 (0.043)

Slow

air

bleed mm (in)

Primary No.1 0.80 (0.031)

Slow

air

bleed mm (in)

Primary No.2 1.90 (0.075) Slow

air

bleed mm (in) Secondary No.1 1.00 (0.039) 0.80 (0.031) Slow

air

bleed mm (in) Secondary No.2 0.50 (0.020)

Power

jet mm (in)

0.50 (0.0201

Fast idle adjustment

mm (in)

Clearance between

Drimarv

throttle valve and bore

1.40-1.76 (0.055—0.069) MTX: 0.48-0.64 (0.019-0.025) ATX: 0.56-0.72 (0.022-0.028)

Float level adjustment mm (in)

Max. fuel flow

"L"

Clearance between

flo

44 (17.3)

at and

air

horn without aasket Float level adjustment mm (in) Fuel stop

"H"

12.5(0.49)

Clearance between float and

air

horn without aasket; float lowered

by

own weight

Choke breaker diaphragm mmHg (inHg)

Start 180-240 (7.1—9.5) 100-160 (3.9—6.3) Choke breaker diaphragm mmHg (inHg) Stop 290-350 (11.4—13.8) 220—280 8.7—11.01

Choke opener mmHg (inHg) Start 35-65 (1.4-2.6)

...

35-65 (1.4-2.6) Choke opener mmHg (inHg) Stop

......

130-190 (5.1-7.5) 130-190 (5.1-7.5)

Fuel tank capacity

Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel Dump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8—3.8)

Feeding capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switching Manual Diaphragm type

Element tvoe Oil permeated paper

Fuel specification Leaded regular

76G04A-513

4 A—15

Page 381 of 1865

4A OUTLINE

FE Engine

Engine FE 8Valve FE 12Valve FE 8Valve

Specification General Middle East

ECE, Hong Kong, & Singapore Unleaded fuel

Idle speed

rpm

MTX 800

+5§

850

+5§

Idle speed

rpm

ATX 900

+58 (in N

range)

CO concentration

%

2.0

± 0.5

(Without secondary

air

injection)

Carburetor

Type Down draft,

two

barrel

Throat diameter

mm (in)

Primary 30 (1.18) Throat diameter

mm (in)

Secondary 34 (1.34)

Venturi diameter

mm (in)

Primary 23.5 (0.93) Venturi diameter

mm (in)

Secondary 29.0 (1.14)

Main nozzle

mm (in)

Primary 2.6 (0.10) Main nozzle

mm (in)

Secondary 2.8 (0.11)

Main

jet mm (in)

Primary MTX 1.14 (0.045) 1.09 (0.0429) 1.14 (0.045) 1.09 (0.0429) Main

jet mm (in)

Primary ATX 1.12 (0.044) 1.08 (0.0425) 1.12 (0.044) 1.09 (0.0429) Main

jet mm (in)

Secondary 1.55 (0.061) 1.50 (0.059) 1.55 (0.061) 1.50 (0.059)

Main

air

bleed

mm (in)

Primary MTX 0.50 (0.020) 0.60(0.024) 0.50 (0.020) 0.50 (0.020) Main

air

bleed

mm (in)

Primary ATX 0.55 (0.022) 0.80 (0.031) 0.55 (0.022) 0.50 (0.020) Main

air

bleed

mm (in) Secondary 0.50 (0.020)

Slow

jet mm (in)

Primary 0.46 (0.018)

Slow

jet mm (in)

Secondary MTX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 0.90 (0.035) Slow

jet mm (in)

Secondary ATX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 1.00 (0.039)

Slow

air

bleed

mm (in)

Primary No.1 0.80 (0.031)

Slow

air

bleed

mm (in)

Primary No.2 1.90 (0.075) Slow

air

bleed

mm (in) Secondary No.1 0.80 (0.031) 1.00 (0.039) 0.80 (0.031) 1.00 (0.039)

Slow

air

bleed

mm (in) Secondary No.2 0.50 (0.020)

Power

jet mm (in)

MTX 0.50 (0.020) 0.50 (0.020) Power

jet mm (in)

ATX 0.50 (0.020) 0.40 (0.016)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore

MTX 0.48—0.64

(0.019-0.025) 1.40—1.76

(0.055-0.069)

0.48—0.64

(0.019-0.025) 1.40-1.76

(0.055-0.069)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore ATX 0.56-0.72 (0.022—0.028)

1.40—1.76

(0.055-0.069) 0.56-0.72 (0.022—0.028)

1.40-1.76

(0.055-0.069)

Float level adjust-

ment

mm (in)

Max. fuel flow

"L"

Clearance between

flo

44 (17.3)

at and

air

horn without aasket Float level adjust-

ment

mm (in)

Fuel stop

"H" |

12.5(0.49)

Clearance between float and

air

horn without aasket: float lowered

bv

own weiaht

Choke breaker diaphragm mm-Hg (in-Hg)

Start 100-160 (3.9—6.3) 180—240 (7.1-9.4) 100-160

(3.9-6.3)

180-240

(7.1-9.4) Choke breaker diaphragm mm-Hg (in-Hg) Stop 220—280

(8.7-11.0)

290-350

(11.4-13.8)

220—280

(8.7-11.0)

290-350

(11.4-13.8)

Choke opener mmHg (inHg)

Start 80—120

(3.1-8.7)

30-70 (1.2-2.8) Choke opener mmHg (inHg)

Stop 220-280 (8.7—11.0) 130-190

(5.1-7.5)

Fuel tank capacity

Liters (US aal, Imp aal) 60 (15.9, 13.2)

Fuel DumD

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20—0.27, 2.8-3.8) 20-29 (0.20-0.30, 2.8-4.3)

20-26 (0.20-0.27, 2.8-3.8)

Feedina caDacitv cc/min

feu

in/mini More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switchina Diaphragm Manual Diaphragm Bimetal

Element

tvDe

Oil permeated paper

Fuel specification Leaded super

Unleaded super Leaded regular Leaded super Unleaded super Unleaded regular

76G04G-514

4A—16

Page 400 of 1865

FUEL SYSTEM 4 A

76G04A-048

76G04A-049

FUEL PUMP

Inspection

Fuel pressure

1. Disconnect the hose at the carburetor and connect

a fuel pressure gauge.

2. Disconnect the fuel return hose from the fuel pump

and plug the fuel pump return pipe as shown in

the figure,

3. Measure the pressure while the engine is idling.

Replace the pump, if necessary.

FE & F8 (ECE,

Hong Kong,

Singapore)

Others

Pressure kPa

(kg/cm2, psi)

20—29 (0.2-0.3, 2.8-4.3)

20-26

(0.20-0.27,

2.8-3.8)

Flow rate (volume)

1. Disconnect the carburetor fuel hose and insert the

end into a measuring breaker.

2. Disconnect the fuel return hose from the fuel pump

and plug the fuel pump return pipe as shown in

the figure.

3. Start the engine and measure the amount of fuel

pumped per minute.

Volume: More than 860 cc (52.5 cuin)/min

Removal

1. Remove in the following order.

(1) Fuel outlet hose

(2) Fuel inlet hose

(3) Fuel return hose

(4) Fuel pump

(5) Gasket

(6) Insulator

(7) Gasket

76G04A-050

Installation

Install in the reverse order of removal.

Caution

a) Replace the gasket whenever the fuel pump

is replaced.

b) Be sure to connect the hoses in the correct

positions.

Check for leaks.

76G04A-051

4A—35

expert22 fl/i* http://rutracker.org

Page 436 of 1865

IDLE-UP CONTROL SYSTEM 4 A

FE (Middle East) and F6 (General)

Possible cause

jrvo

diaphragm

3

jrvo

diaphragm

n c o> (0

E 3 3 O

® >

a >

•o o c e

£ O **

S M O

£ O

'i (0 (0

O <

o a

o E W 0)

lm Q.

c a k 4) -

9-5

"S "5 (O > CO < a. DC H Js * OC M

Page 4A—72 4A—74 4A—74 Section 15 4A—75 Section 16

Checking order 1 2 3 4 5 6 7 8

76G04A-136

FE 8Valve—Unleaded Fuel

Posible cause

Engine

control

unit

terminal

Servo

diaphragm

Vacuum

signal

Solenoid

valve £ O **

S CO O

£ U

S <0 U) Relay

(for

A/C) ** n ** w o E «

Refrigerant

pressure

switch

H D I Servo

diaphragm

Vacuum

signal

Solenoid

valve

< a. Relay

(for

A/C)

H Refrigerant

pressure

switch

Page 4A—91 4A—72 4A—74 4A—74 Section 15 4A—75 Section 16

Checking order 9 1 2 3 4 5 6 7 8

76G04A-137

4A—71