length MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 260 of 1865

1C INSPECTION AND REPAIR

Stem tip

Margin i

thickness

T

Valve face

angle

^45°

76G01C-101

76G01C-102

" & ©

JMFc

•^Caliper gauge

^V^r "M

m

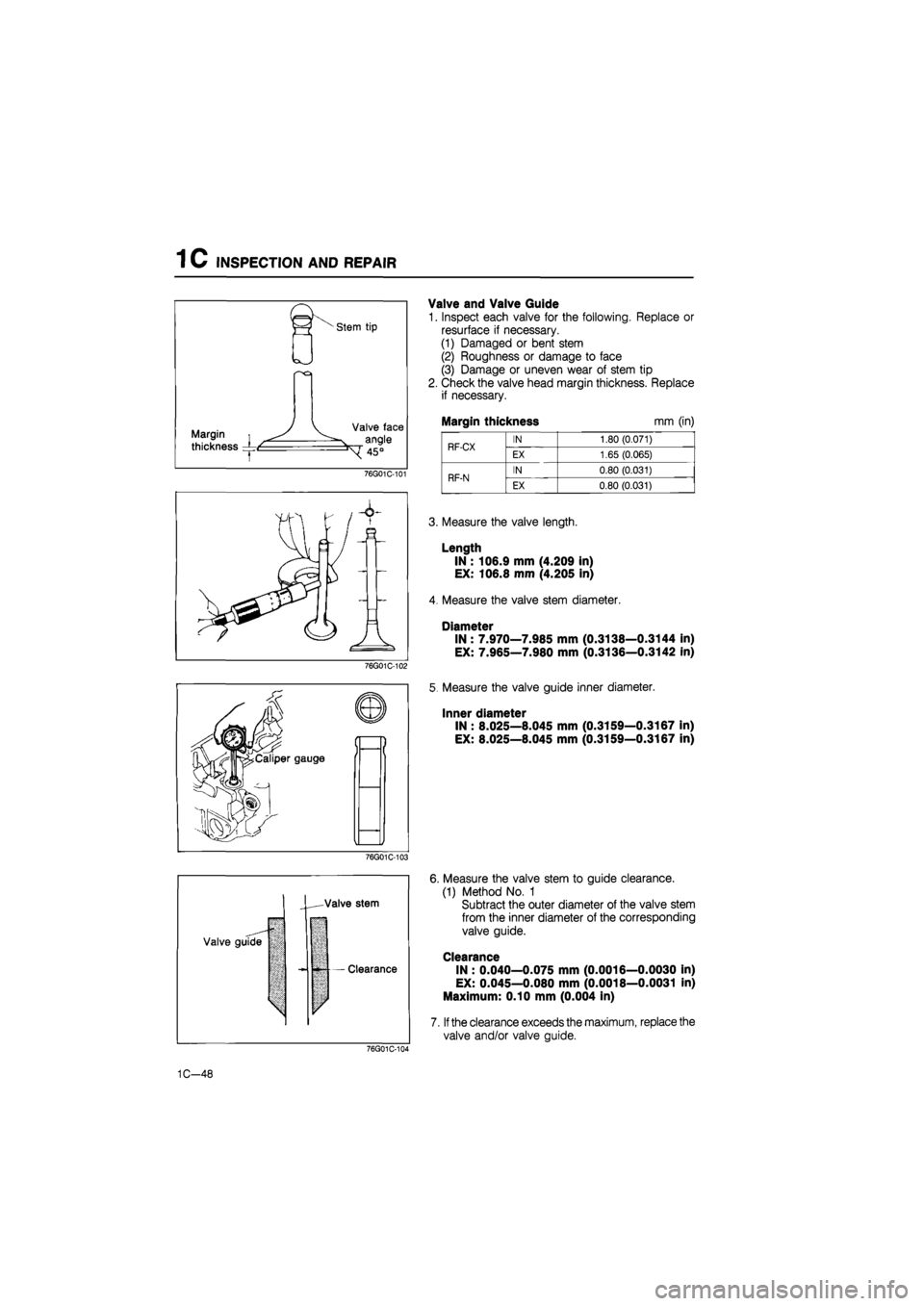

Valve and Valve Guide

1. Inspect each valve for the following. Replace or

resurface if necessary.

(1) Damaged or bent stem

(2) Roughness or damage to face

(3) Damage or uneven wear of stem tip

2. Check the valve head margin thickness. Replace

if necessary.

Margin thickness mm (in)

RF-CX IN 1.80 (0.071) RF-CX EX 1.65 (0.065)

RF-N IN 0.80 (0.031) RF-N EX 0.80 (0.031)

3. Measure the valve length.

Length

IN : 106.9 mm (4.209 in)

EX: 106.8 mm (4.205 in)

4. Measure the valve stem diameter.

Diameter

IN : 7.970—7.985 mm (0.3138—0.3144 in)

EX: 7.965—7.980 mm (0.3136—0.3142 in)

5. Measure the valve guide inner diameter.

Inner diameter

IN : 8.025—8.045 mm (0.3159—0.3167 in)

EX: 8.025—8.045 mm (0.3159—0.3167 in)

76G01C-103

-Valve stem

Valve guide

Clearance

V

6. Measure the valve stem to guide clearance.

(1) Method No. 1

Subtract the outer diameter of the valve stem

from the inner diameter of the corresponding

valve guide.

Clearance

IN : 0.040—0.075 mm (0.0016—0.0030 in)

EX: 0.045—0.080 mm (0.0018—0.0031 in)

Maximum: 0.10 mm (0.004 in)

7.

If

the clearance exceeds the maximum, replace the

valve and/or valve guide.

76G01C-111

1C-48

Page 264 of 1865

INSPECTION AND REPAIR 1C

76G01C-116

76G01C-117

—Angle limit

S//////A 777;////////

Combustion Chamber Insert

1. Inspect the combustion chamber insert for damage

or crack, replace if necessary.

2. Mesure the receded or projected amount of com-

bustion chamber insert from cylinder head surface.

Recession: 0.020 mm (0.0008 in) max.

Projection: 0.005 mm (0.0001 in) max.

If it exceeds the specification, replace the combus-

tion chamber insert and the cylinder head as an as-

sembly.

Valve Spring

1. Inspect each valve spring for cracks or damage.

2. Check the free length and angle. Replace if

necessary.

Free length: 45.11 mm (1.776 in)

Minimum: 44.8 mm (1.764 in)

Angle: 1.6 mm (0.06 in) max.

76G01C-118

Tappet

1. Check the tappet to tappet hole clearance.

(1) Measure the tappet outer diameter.

Diameter:

34.95—34.97 mm (1.3764—1.3768 in)

76G01C-144

1C-52

Page 273 of 1865

INSPECTION AND REPAIR 1C

86U01X-115

Timing Belt Tensioner and Idler Pulley

Check the timing belt tensioner and idler pulley for

smooth rotation and abnormal noise. Replace if

necessary.

Caution

Do not clean the tensioner with cleaning

fluids. If necessary, use a soft rag to wipe it

clean, and avoid scratching it.

Timing Belt Tensioner Spring

Check the free length of the tensioner spring. Replace

if necessary.

Free length:

52.6 mm (2.071 in)

76G01C-251

Timing Belt Pulley and Camshaft Pulley

Inspect the pulley teeth for wear, deformation, or other

damage. Replace if necessary.

Caution

Do not clean the pulley with cleaning fluids.

If necessary, use a rag to wipe it clean.

Timing Belt Cover

Inspect the timing belt covers for damage or cracks.

Replace if necessary.

76G01C-146

1C—61

Page 286 of 1865

1 C ASSEMBLY (CYLINDER

BLOCK)

76G01C-170

Adjusting

disc

Tappet -

Apply engine oil

4BG01B-150

4BG01B-182

Apply engine oil

1.

Cylinder head bolt

below head length

Valve and Valve Spring

1. Install the lower spring seat.

2. Apply molybdenum disulphide grease to the valve

stem.

3. Install the valve.

4. Install the valve springs and the upper spring seat.

5. Compress the valve spring with the SST; then in-

stall the valve keepers.

6. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Tappet and Adjusting Disc

1. Apply engine oil to the tappets.

2. Install the tappets in the hole.

3. Install the adjusting discs.

Cylinder Head

1. Thoroughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt or grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

76G01C-171

1C-74

Page 331 of 1865

OIL

COOLER AND

OIL

FILTER BODY 2B

OIL

COOLER AND

OIL

FILTER BODY

REMOVAL

1. Disconnect the battery negative cable.

2. Drain the engine oil and coolant.

3. Remove in the sequence shown in the figure.

76G02B-012

76G02B-013

1. Idler pulley

2. Water hose

3. Connector bolt

4. Oil cooler

5. Oil filter

6. Oil filter cover

7. Oil filter body

8. Plug

9. Pressure spring

10. Plunger control

11. Relief valve spring

12. Steel ball

INSPECTION

1. Inspect the oil cooler body for cracks or corrod-

ed. If necessary replace it.

2. Check the valves for damage or scoring if neces-

sary replace it.

3. Measure free length of each valve spring. If neces-

sary replace it.

Free length

Relief valve spring: 45.5 mm (1.79 in)

Pressure spring : 54.6 mm (2.15 in)

76G02B-014

2B-7

Page 600 of 1865

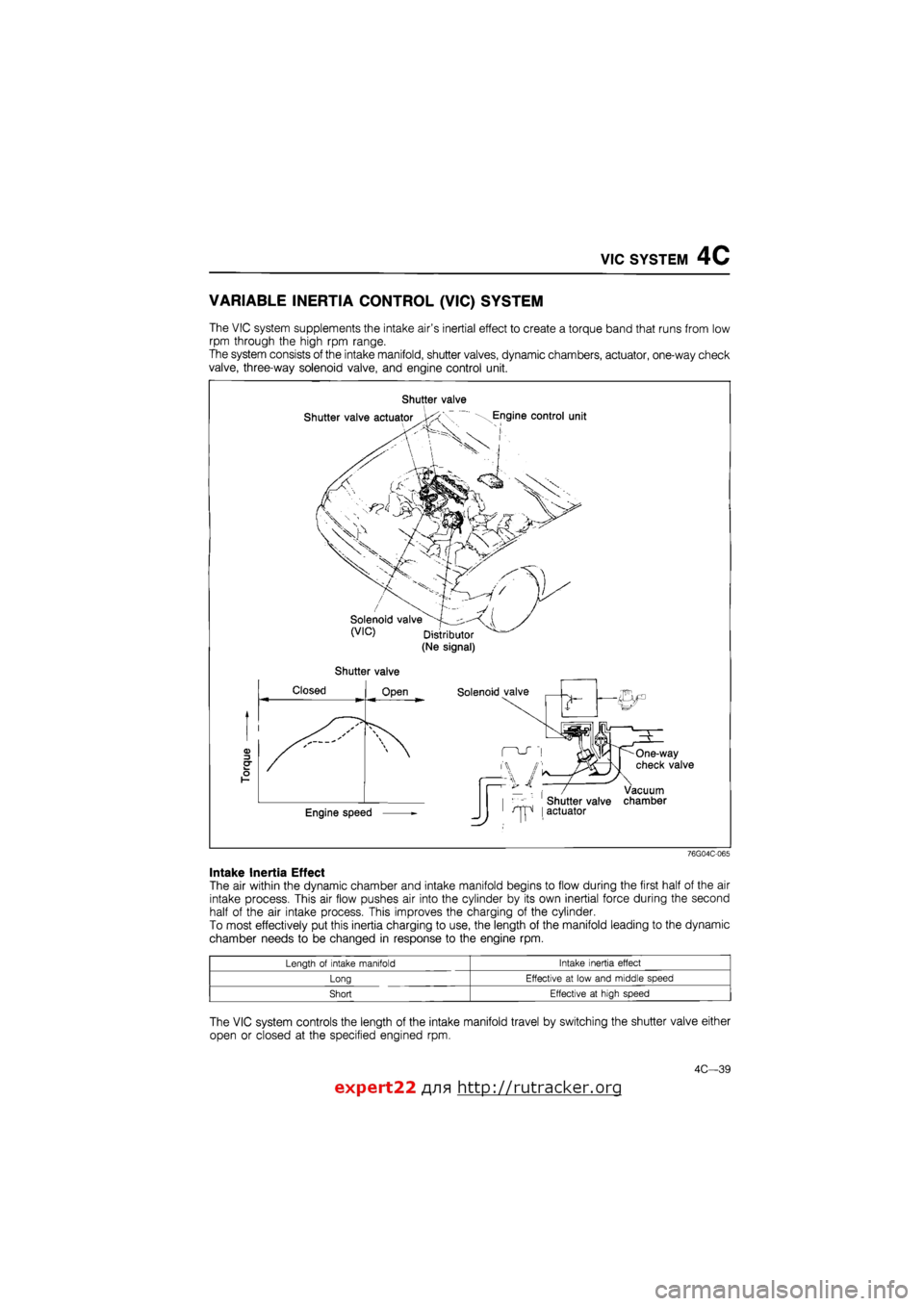

VIC SYSTEM 4C

VARIABLE INERTIA CONTROL

(VIC)

SYSTEM

The VIC system supplements the intake air's inertial effect to create a torque band that runs from low

rpm through the high rpm range.

The system consists of the intake manifold, shutter valves, dynamic chambers, actuator, one-way check

valve, three-way solenoid valve, and engine control unit.

Shutter valve

Shutter valve

76G04C-065

Intake Inertia Effect

The air within the dynamic chamber and intake manifold begins to flow during the first half of the air

intake process. This air flow pushes air into the cylinder by its own inertial force during the second

half of the air intake process. This improves the charging of the cylinder.

To most effectively put this inertia charging to use, the length of the manifold leading to the dynamic

chamber needs to be changed in response to the engine rpm.

Length of intake manifold Intake inertia effect

Long Effective at low and middle speed

Short Effective at high speed

The VIC system controls the length of the intake manifold travel by switching the shutter valve either

open or closed at the specified engined rpm.

expert22 fl/i* http://rutracker.org

4C—39

Page 601 of 1865

7C VIC SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Dynamic chamber Provides chamber for VIC system operation Integrates one-way check valve

Engine control unit Monitors engine rpm, controls solenoid valve Unleaded fuel: ON at above 5200 rpm Leaded fuel: ON at above 5400 rpm

Intake manifold Provides short and long length of intake travel Integrates shutter valve

One-way check valve Holds vacuum in vacuum chamber Installed between dynamic chamber and vacuum chamber

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to control unit Installed in distributor

Solenoid valve (Vlfc) Controls vacuum to shutter valve actuator

Shutter valve Closes short intake port

Shutter valve actuator Actuates shutter valve according to

vacuum from solenoid valve

76G04C-066

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible cause

\Page\.

Symptom

Vacuum chamber (Vacuum leak)

Shutter valve actuator

One-way check valve

Solenoid valve (VIC) Engine control unit (1C)

System

Inspection

Possible cause

\Page\.

Symptom

Vacuum chamber (Vacuum leak)

Shutter valve actuator

One-way check valve Vacuum ' Electric signal | signal

Engine control unit (1C)

System

Inspection

Possible cause

\Page\.

Symptom 4C—42 4C—41 4C—43 4C—42 4C-98 4C—41

Rough idle

During warm up 2 3 4 — — — 1 Rough idle After warming up 2 3 4 — — — 1

Poor acceleration, hesitation,

or lack of power 6 5 7 2 3 4 1

Poor fuel consumption 6 5 7 2 3 4 1

76G04C-067

4C—40

Page 711 of 1865

OUTLINE 5

SPECIFICATIONS

Gasoline Engine

item

Engine

F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE

(DOHC)

Battery

Voltage

Type and capacity

12. Negative ground

(20 hour rate) 34B19L(S) (33 Ah): General 50D20L (50 Ah), 55D23L (60 Ah): ECE

Alternator

Type A.C.

Output V-A 12-70

Regulator type Transistorized (built-in IC regulator)

Regulated voltage 14.1-14.7

Brush length

mm (in) Standard 16.5 (0.650)

Minimum 8.0 (0.315)

Drive belt tension

mm (in)/98 N (10 kg, 22 lb) New: 6-8 (0.24-0.32), Used: 7-9 (0.28-0.35)

Starter

Type Coaxial reduction: Middle East & General (FE • carburetor)

Non-reduction: Others

Output V-kW 12-0.85

Brush length

mm (in)

12-0.95

Standard 17.0 (0.669)

Minimum 11.5 (0.453)

Unleaded fuel

17.0 (0.669)

Others

17.51

Unleaded fuel 11.5(0.453) Others 10,0 (0.394)

12-1.4 12-0.95

17.0 (0.669)

11.5 (0.453)

Ignition timing 6 ± 10 BTDC (Vacuum hose disconnected)

12

±

1° BTDC

(Test connector

grounded)

Distributor

Type Fully transistorized (HEI)

Electronic spark advance

Centrifugal spark advance

(crank angle/engine speed)

degree/rpm

F6

-2-2/1,000 6-10/2,100 14-18/6,100

F8 -2—2/1,000 10-14/2,100 18-22/6,100

FE (8 VALVE)—Carburetor Unleaded fuel

(MTX)-2—2/1,760 12—16/3,360 22—26/5,320 (ATX)-2-2/1,300 12-16/3,360 22-26/5,320

Others

-2—2/1,460 10—14/2,540 22—26/5,540

FE (12 VALVE)—Carburetor -2-2/1,200 10—14/2,400 10—14/4,000 16-20/5,000

FE—Fuel injection (except FE DOHC) -2—2/1,000 10—14/2,600 10—14/4,600 16—20/5,800

Unleaded fuel model 76G05X-503

5-5

Page 712 of 1865

5 OUTLINE

Item

Engine F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE (DOHC)

F6 and F8

-2-2/100 6-10/300

FE (8 VALVE)—Carbu retor Unleaded fuel -2—2/120 8—12/245

Distributor

Vacuum spark advance (Crank angle/Vacuum)

Others (MTX) -2-(ATX) -2--2/100 16-

-2/100 10-

-20/250

-14/200

degree/mmHg (inHg) FE (12 VALVE)—Carburetor

-2-2/120 11-15/300

FE—Fuel injection (except FE DOHC) [A chamber] -2-2/125 18-22/300

[B chamber] -2-2/125 -6 10/200

Spark plug

Type

FE (8 VALVE)*1 NGK: BPR5ES-11, BPR6ES-11 Nippon Denso: W16EXR-U11, W20EXR-U11 Others

NGK: BPR5ES, BPR6ES Nippon Denso: W16EXR-U, W20EXR-U

NGK:

BCPR5E, BCPR6E Nippon

Denso: Q16PR-U, Q20PR-U

Unleaded fuel

NGK: BCPR5E-11 BCPR6E-11 BCPR7E-11

Leaded fuel NGK: BCPR5E BCPR6E

Plug gap mm (in)

0.75-0.85 (0.030-0.033), FE (8 VALVE)*1 1.0-1.1 (0.039-0.043)

0.7-0.8

(0.028-0.031)

1.0-1.1 "

/n noo

n n/9

0.7-0.8 *2 (0.028-0.031)

Firing order 1-3—4-2 76G05X-504

Diesel Engine

——Engine Item RF-N RF-CX

Battery

Voltage V 12, Negative ground Battery Type and capacity

(20 hour rate) 80D26L (65)

50D20L, 50D20R (50)-ECE 80D26L (65)

65D23L, 65D23R (55)

Alternator

Type A.C.

Alternator

Output V-A 12-70 12-75

Alternator

Regulator type Transistorized (built-in IC regulator)

Alternator Regulated voltage V 14.1-14.7 Alternator

Brush length mm (in)

Standard 16.5 (0.650) 21.5 (0.846)

Alternator

Brush length mm (in) Minimum 8.0 (0.315) 8.0 fO.315)

Alternator

Drive belt tension

mm (in)/98 N (10 kg. 92 lb) New: 9-11 (0.35-0.43), Used: 12-14 (0.47-0.55)

Starter

Type Reduction

Starter Output V—kW 12—2.0, 12-2.2 (Cold area) Starter Brush length

mm (in)

Standard 2.0 kW: 17.0 (0.669). 2.2 kW: 18.0 (0.709) Starter Brush length

mm (in) Minimum 2.0 kW: 11.0 (0.453), 2.2 kW: 11.0 (0.453)

Firing order 1-3-4-2

Unleaded fuel model *2 Leaded fuel model

76G05X-505

5-6

Page 792 of 1865

6 CLUTCH PEDAL

INSPECTION

Check the following, and repair or replace any faulty

parts.

1. Worn or damaged pedal bushing

2. Twisted or bent pedal

3. Worn or damaged pedal pad

76G06X-008

INSTALLATION

Install in the reverse order of removal referring to the

installation note.

Installation Note

Apply grease (lithium base, NLGI No.2) to the

bushings.

76G06X-009

ADJUSTMENT

1. Adjust the pedal height. (Refer to page 6—4.)

2. Check the pedal free play, and adjust if necessary.

(Refer to page 6—4.)

3. Adjust the installation length of the assist spring.

The installation length is adjusted by turning nut

A show in the figure and adjusting dimension B.

Standard dimension:

38.6—39.6 (1.520—1.559 in)

76G06X-010

6-6