light MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 111 of 1865

ASSEMBLY (CYLINDER HEAD) 1 A

Outer valve spring

®

®

Cylinder head r

Side ®>d)

76G01A-079

86U01X-145

86U01X-146

© @ ® ©

© ® © ®

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

3. Install the valve springs and the upper spring seat.

Note

Install the outer valve spring with the closer

pitch toward the cylinder head.

4. Compress the valve spring with the SST; then in-

stall the valve keepers.

5. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Cylinder Head

1. Thoroughly remove all dirt, oil, or other material

from the top of the cylinder block.

2. Place the new cylinder head gasket in position.

3. Install the cylinder head.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80—86

N

m (8.2—8.8 m-kg, 59—64 ft-lb)

86U01X-147

1A—79

Page 130 of 1865

1A INSTALLATION

76G01A-147

86U01X-199

86U01X-200

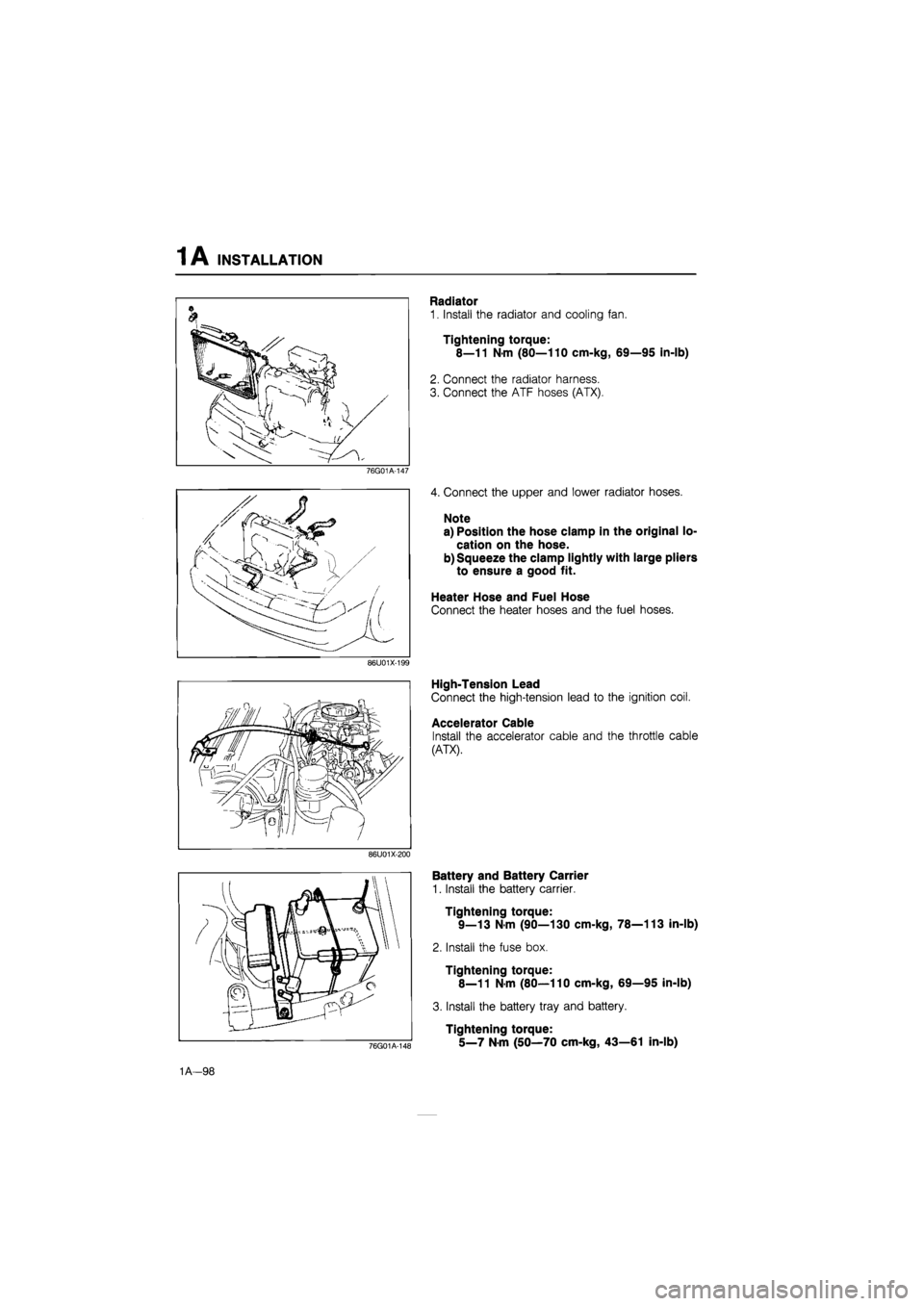

Radiator

1. Install the radiator and cooling fan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Connect the radiator harness.

3. Connect the ATF hoses (ATX).

4. Connect the upper and lower radiator hoses.

Note

a) Position the hose clamp in the original lo-

cation on the hose.

b) Squeeze the clamp lightly with large pliers

to ensure a good fit.

Heater Hose and Fuel Hose

Connect the heater hoses and the fuel hoses.

High-Tension Lead

Connect the high-tension lead to the ignition coil.

Accelerator Cable

Install the accelerator cable and the throttle cable

(ATX).

76G01A-148

Battery and Battery Carrier

1. Install the battery carrier.

Tightening torque:

9—13 N-m (90—130 cm-kg, 78—113 in-lb)

2. Install the fuse box.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

3. Install the battery tray and battery.

Tightening torque:

5_7 Nm (50—70 cm-kg, 43—61 in-lb)

1A—98

Page 139 of 1865

TUNE-UP PROCEDURE 1 B

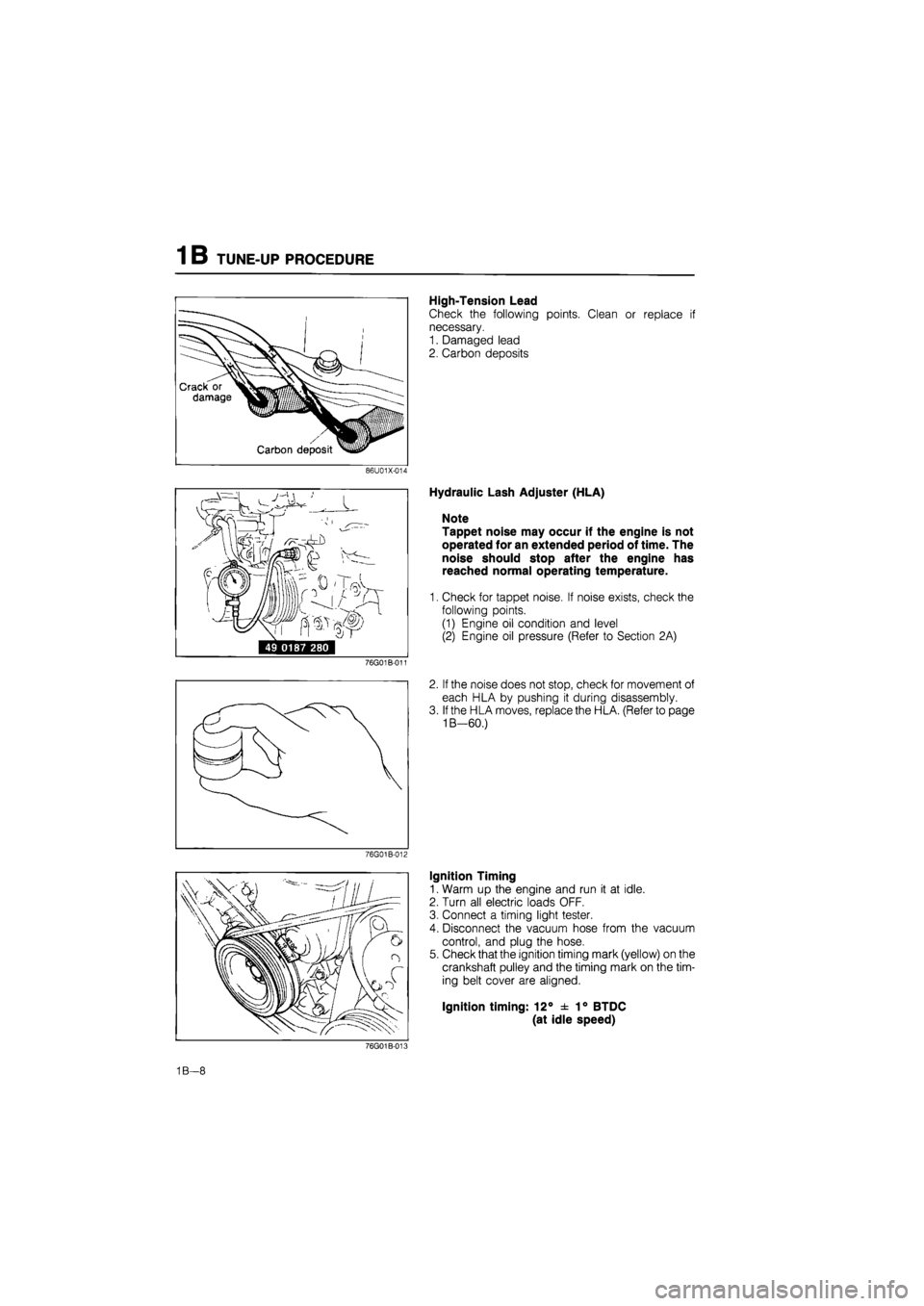

High-Tension Lead

Check the following points. Clean or replace if

necessary.

1. Damaged lead

2. Carbon deposits

86U01X-014

i^rrr ' /

49 0187 280

76G01B-011

76G01B-012

Hydraulic Lash Adjuster (HLA)

Note

Tappet noise may occur if the engine is not

operated for an extended period of time. The

noise should stop after the engine has

reached normal operating temperature.

1. Check for tappet noise. If noise exists, check the

following points.

(1) Engine oil condition and level

(2) Engine oil pressure (Refer to Section 2A)

2. If the noise does not stop, check for movement of

each HLA by pushing it during disassembly.

3. If the HLA moves, replace the HLA. (Refer to page

1B—60.)

Ignition Timing

1. Warm up the engine and run it at idle.

2. Turn all electric loads OFF.

3. Connect a timing light tester.

4. Disconnect the vacuum hose from the vacuum

control, and plug the hose.

5. Check that the ignition timing mark (yellow) on the

crankshaft pulley and the timing mark on the tim-

ing belt cover are aligned.

Ignition timing: 12° ± 1° BTDC

(at idle speed)

76G01B-008

1B—8

Page 150 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

Installation

Install in the reverse order of removal referring to the installation note.

Note a) Position the hose clamp in the original location on the hose.

b) Squeeze the clamp lightly with large pliers to ensure a good fit.

Torque Specifications

8—12 N-m (80—120 cm-kg, 69—104

4—6 N-m (40—60 cm-kg, 35—52 in

15—23 N-m (1.5—2.3 m-kg, 11—17 ft-lb)

7—10 N-m (70—100 cm-kg, 61—87 In-lb)

—11 N-m (80—110 cm-kg, 69—95 In-lb)

37—52 N-m (3.8—5.3 m-kg. 27—38 ft-lb)

80—86 N-m (8.2—8.8 m-kj, 59—64 ft-lb)

~t/—- -19—30 N-m (1.9—3.1 m-kg, g^ 14-22 ft-lb)

\34—44

N-m (3.5—4.5 m-kg, ' 25—33 ft-lb)

19-30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

76G01A-112

1B—19

Page 191 of 1865

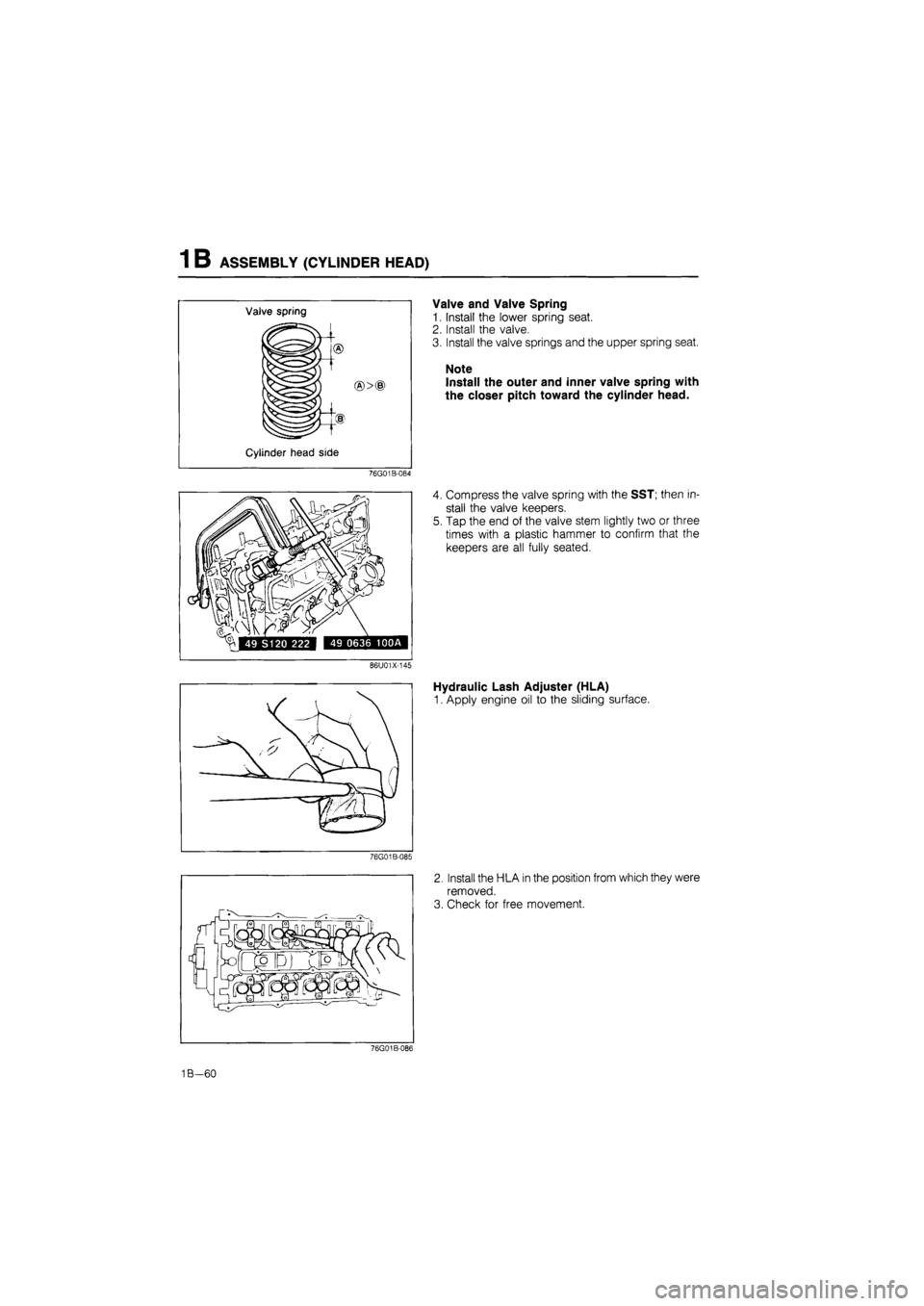

1 B ASSEMBLY (CYLINDER HEAD)

Valve spring

®>®

Cylinder head side

76G01B-084

86U01X-145

76G01B-085

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

3. Install the valve springs and the upper spring seat.

Note

Install the outer and inner valve spring with

the closer pitch toward the cylinder head.

4. Compress the valve spring with the SST; then in-

stall the valve keepers.

5. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Hydraulic Lash Adjuster (HLA)

1. Apply engine oil to the sliding surface.

2. Install the HLA in the position from which they were

removed.

3. Check for free movement.

76G01B-086

1B—60

Page 211 of 1865

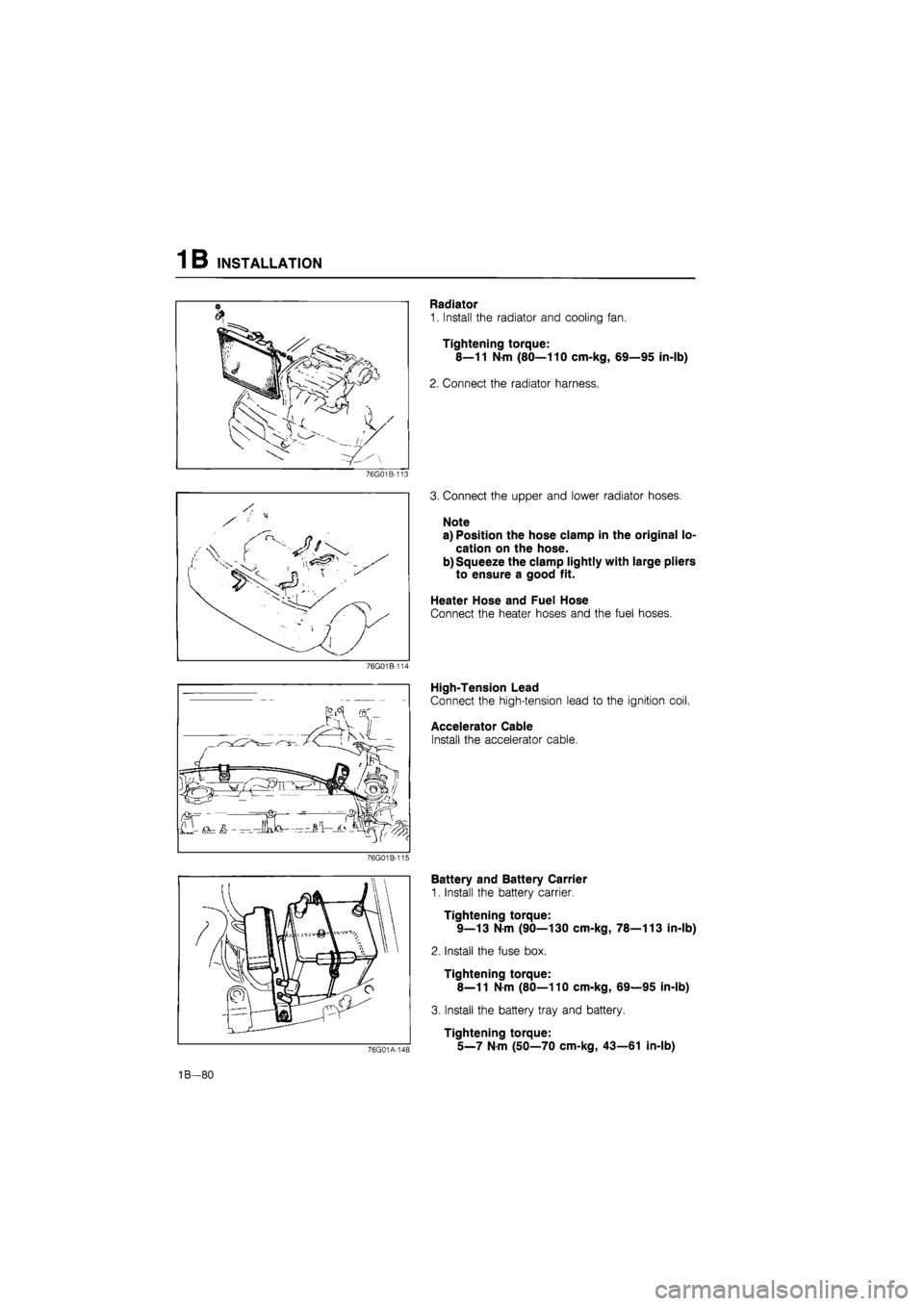

1B INSTALLATION

76G01B-113

76G01B-114

76G01B-115

Radiator

1. Install the radiator and cooling fan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Connect the radiator harness.

3. Connect the upper and lower radiator hoses.

Note

a) Position the hose clamp in the original lo-

cation on the hose.

b) Squeeze the clamp lightly with large pliers

to ensure a good fit.

Heater Hose and Fuel Hose

Connect the heater hoses and the fuel hoses.

High-Tension Lead

Connect the high-tension lead to the ignition coil.

Accelerator Cable

Install the accelerator cable.

76G01A-148

Battery and Battery Carrier

1. Install the battery carrier.

Tightening torque:

9—13 N-m (90—130 cm-kg, 78—113 in-lb)

2. Install the fuse box.

Tightening torque:

8—11

N

m (80—110 cm-kg, 69—95 in-lb)

3. Install the battery tray and battery.

Tightening torque:

5_7

N m

(50—70 cm-kg, 43—61 in-lb)

1B—80

Page 220 of 1865

1C TUNE-UP PROCEDURE

Comprex supercharger

Deflection mm (in)

New 4 0-6.0 (0.16—0.23)

Used 8.0-10 0 (0 31-0.39)

If necessary, loosen the idler lock nut and adjust

the belt deflection by turning the adjust bolt.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

76G01C-011

o

INJECTION TIMING

1. Disconnect the negative battery cable.

2. Release the CSD using the screw driver.

3. Remove the cover on the clutch housing.

4. Turn the flywheel and set the indicator at ATDC.

5. Disconnect the injection pipes from the injection

pump.

76G04D-008

6. Remove the hydraulic head plug from the injec-

tion pump.

7. Mount the SST into the plug hole on the hydraulic

head so the tip of the dial gauge pointer touches

the plunger end of the pump and the dial gauge

indicates approx. 2.0 mm (0.08 in).

76G04D-009

8. Turn the crankshaft slowly counterclockwise to

30-50° BTDC.

9. Make sure the dial indicator pointer no longer

moves by slightly turning the crankshaft.

10. Set the dial gauge scale to Zero at the pointer.

76G04D-010

1C-8

Page 231 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

Installation

Install in the reverse order of removal referring to the installation note.

Note a) Position the hose clamp in the original location on the hose.

b) Squeeze the clamp lightly with large pliers to ensure a good fit.

Torque Specifications

59—69 N m (6.0—7.0 m-kg, 43—51 ft-lb)

55—65 N-m (5.6—6.6 m-kg, 41—48 ft-lb)

7-10 N-m (70—100 cm-kg, 61-87 in-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

8—11 N-m (80—110 cm-kg. 69—95 In-lb)

55—65 N-m i—6.6 m-kg, 48 ft-lb)

—11 N-m (80—110 cm-kg, 69—95 in-lb)

7—10 N-m (70—100 cm-kg, 61—87 in-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

34—49 N-m (3.5—!

\, - 16—27 N-m (1.6—2.8 m-kg, N > 12—20 ft-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

76G01C-242

1C—19

Page 235 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

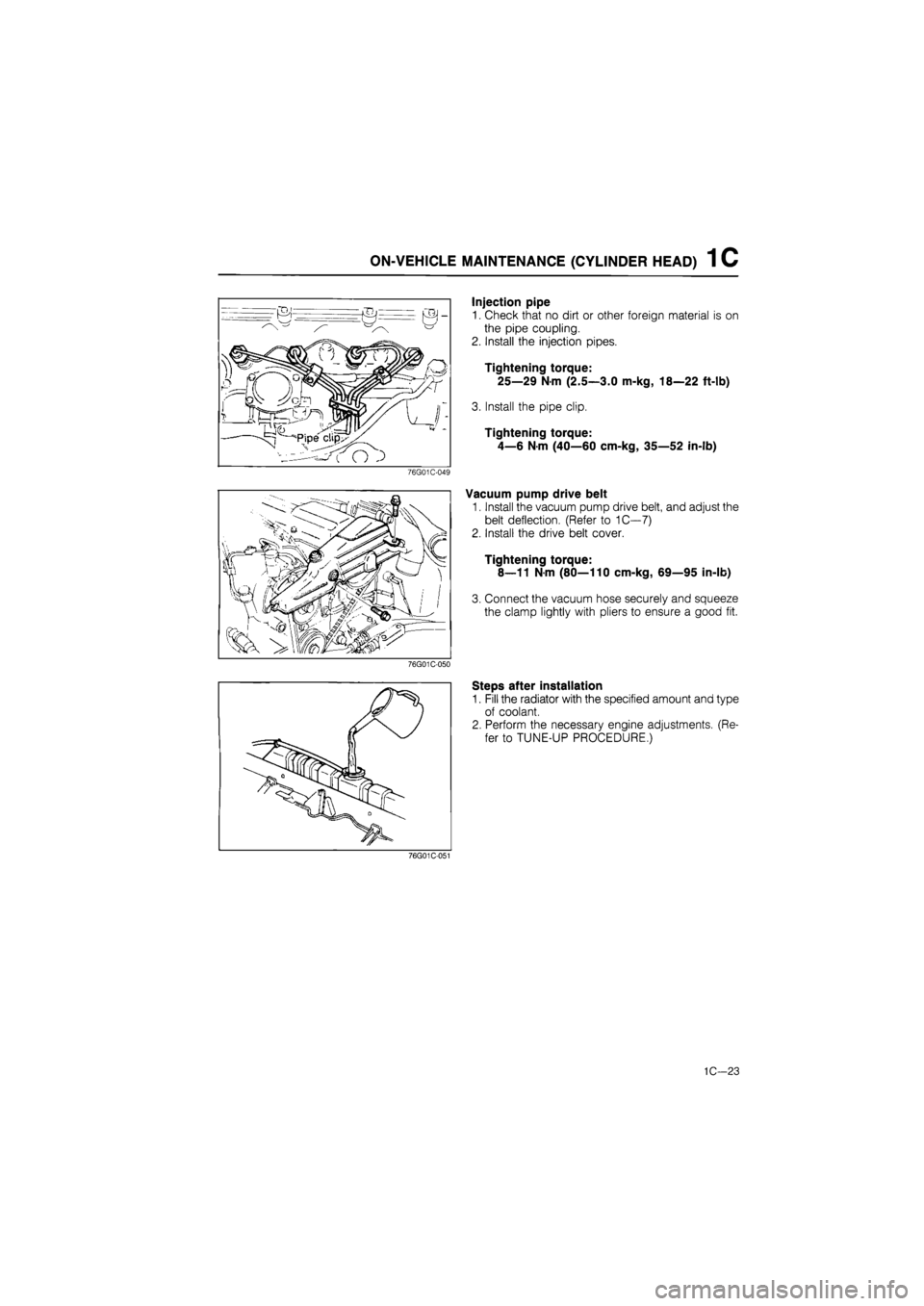

76G01C-049

Injection pipe

1. Check that no dirt or other foreign material is on

the pipe coupling.

2. Install the injection pipes.

Tightening torque:

25—29 Nm (2.5—3.0 m-kg, 18—22 ft-lb)

3. Install the pipe clip.

Tightening torque:

4—6 N-m (40—60 cm-kg, 35—52 in-lb)

Vacuum pump drive belt

1. Install the vacuum pump drive belt, and adjust the

belt deflection. (Refer to 1C—7)

2. Install the drive belt cover.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

3. Connect the vacuum hose securely and squeeze

the clamp lightly with pliers to ensure a good fit.

76G01C-050

Steps after installation

1. Fill the radiator with the specified amount and type

of coolant.

2. Perform the necessary engine adjustments. (Re-

fer to TUNE-UP PROCEDURE.)

76G01C-051

1C—23

Page 286 of 1865

1 C ASSEMBLY (CYLINDER

BLOCK)

76G01C-170

Adjusting

disc

Tappet -

Apply engine oil

4BG01B-150

4BG01B-182

Apply engine oil

1.

Cylinder head bolt

below head length

Valve and Valve Spring

1. Install the lower spring seat.

2. Apply molybdenum disulphide grease to the valve

stem.

3. Install the valve.

4. Install the valve springs and the upper spring seat.

5. Compress the valve spring with the SST; then in-

stall the valve keepers.

6. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Tappet and Adjusting Disc

1. Apply engine oil to the tappets.

2. Install the tappets in the hole.

3. Install the adjusting discs.

Cylinder Head

1. Thoroughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt or grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

76G01C-171

1C-74