light MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 574 of 1865

TROUBLESHOOTING WITH SST 4C

49 H018 9A1

negative battery cable

^ll

Test connector: (Green, 1 pin)

86U04A-015

Ignition switch:

ON

for six

seconds

76G04C-014

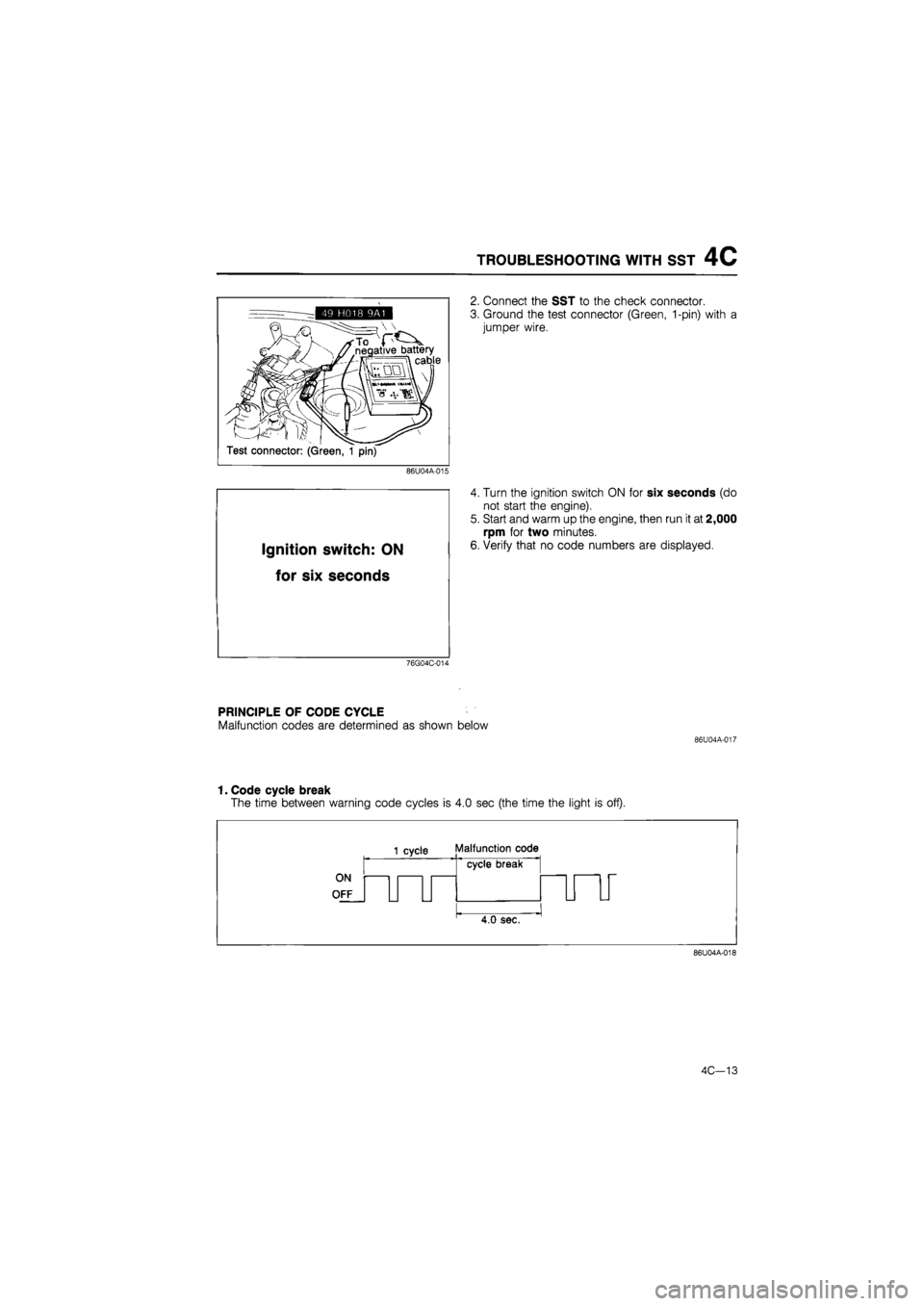

2. Connect the SST to the check connector.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

4. Turn the ignition switch ON for six seconds (do

not start the engine).

5. Start and warm up the engine, then run it at 2,000

rpm for two minutes.

6. Verify that no code numbers are displayed.

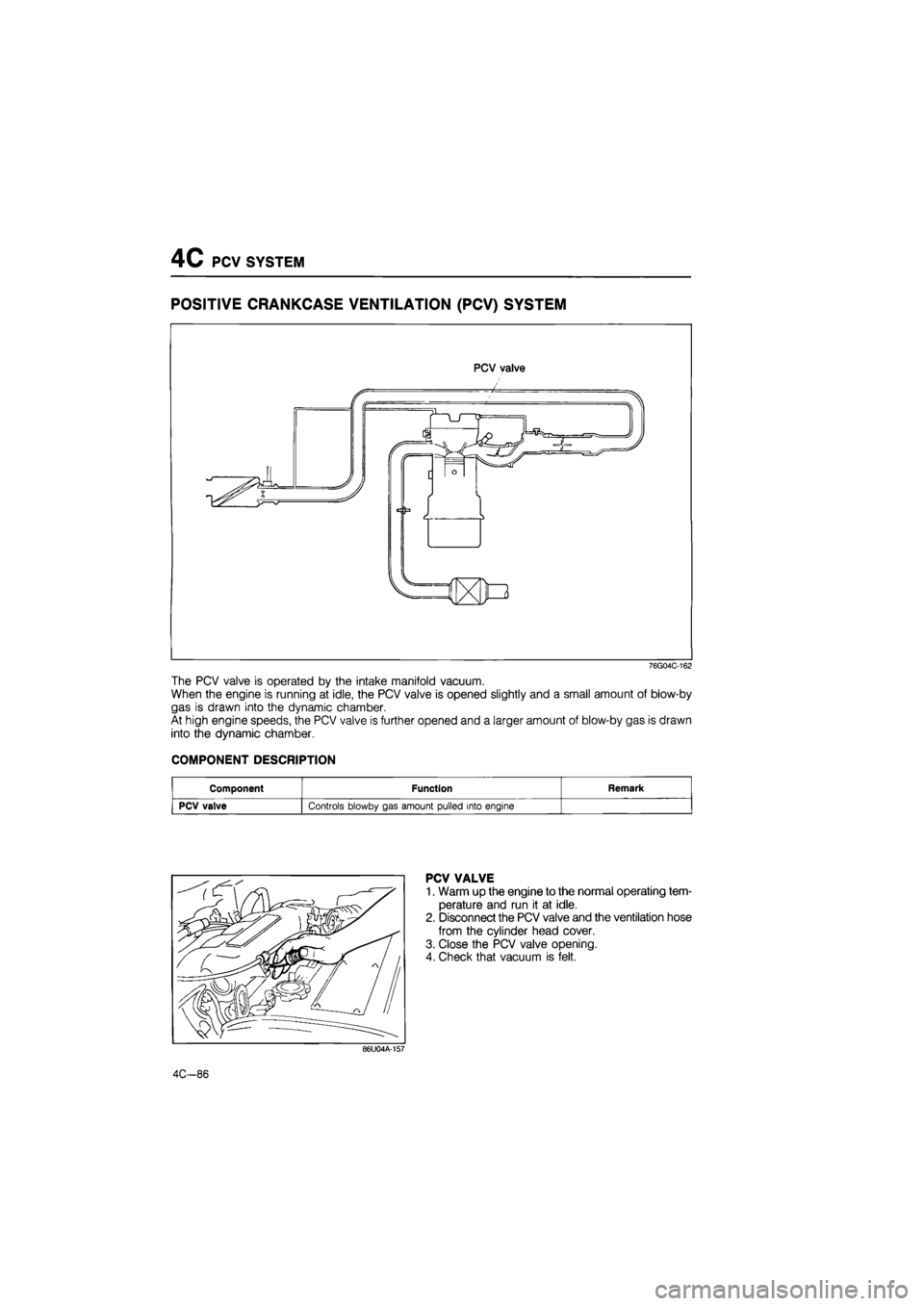

PRINCIPLE OF CODE CYCLE

Malfunction codes are determined as shown below

86U04A-017

1. Code cycle break

The time between warning code cycles is 4.0 sec (the time the light is off).

ON

OFF

1 cycle Malfunction code

cycle break

4.0 sec.

86U04A-018

4C—13

Page 575 of 1865

4C TROUBLESHOOTING WITH SST

2. Second digit of malfunction code (ones position)

The digit in the ones position of the malfunction code represents the number of times the buzzer

is on 0.4 sec during one cycle.

ON

OFF

1 cycle Malfunction code

1 2 3 cycle break

Malfunction

code: 03

n^j

0.4 0.4 sdc. sec.

4.0 sec.

76G04C-015

3. First digit of malfunction code (tens position)

The digit in the tens position of the malfunction code represents the number of times the buzzer

is on 1.2 sec during one cycle.

It should also be noted that the light goes off for 1.6 sec. between the long and short pulses of

the buzzer.

1 cycle Malfunction code

1 2

~U 0.4

1.2 sec. sec h

1 2|

flfl

First digit

1.6 sec.

cycle break

Malfunction

code: 22

nr

4.0 sec.

Second

digit

76G04C-016

CODE NUMBER

Malfunction display

Sensor or

subsystem Self-diagnosis Fail-safe Malfunction

code no.

Malfunction code output signal pattern

Sensor or

subsystem Self-diagnosis Fail-safe

02 o°nfJLJJL

Ne signal No Ne signal from crank angle sensor during craking

03 oppJUllUl

G signal No G signal Cancels sequencial

injection

05

Knock sensor (only

leaded fuel)

Open or short circuit • Retards ignition timing 4°

76G04C-017

4C—14

Page 586 of 1865

SWITCH MONITOR FUNCTION 4C

SWITCH MONITOR FUNCTION

Individual switches can be monitored by the SST (Self-Diagnosis checker 49 G018 9A0 or Digital

code checker 49 9200 180).

Note

The test connector must be grounded and the ignition switch ON (engine stopped).

Engine control unit

76G04C-035

Switch Self-Diagnosis Checker (Monitor lamp) Remark Switch Light ON Light OFF Remark

Clutch switch Pedal released Pedal depressed In gear

Neutral switch In gear Neutral Clutch pedal released

Idle switch Pedal depressed Pedal released —

Headlight switch ON OFF —

Rear defroster switch ON OFF —

Blower switch ON OFF Blower motor position: "3" or "4"

Water thermo switch (Elec-trical fan) Terminal disconnected Terminal connected While fan not operating

4C—25

Page 588 of 1865

SWITCH MONITOR FUNCTION 4C

Idle switch

76G04C-039

Blower switch

76G04C-040

Headlight switch

76G04C-041

Rear defroster switch

76G04C-042

4C—27

Page 608 of 1865

ISC SYSTEM 4C

76G04C-081

76G04C-082

Cooling fan switch

Rear defroster switch

Head light switch

Blower motor switch

ISC "valve

76G04C-083

(ISC valve)

6. Connect the ISC valve connector.

Note

a) Make sure that the initial idle speed is set

to specification.

b) All accessory must be OFF.

7. Again disconnect the ISC valve connector (engine

at normal operating temperature).

8. Check that the engine speed decreases.

9. Reconnect the ISC valve connector.

10 Remove the jumper wire from the test connector

and make sure that the idle speed is within specifi-

cations.

(Load Test)

11. Apply power steering, electrical, and air conditioner

loads and check that the idle speed is controlled

to within specifications.

Load Idle speed

P/S 750 ± 50

E/L 800 ± 50

A/C 800 ± 50

E/L and A/C 800 ± 50

BAC Valve

Air valve

1. Remove the BAC valve from the throttle body.

2. Blow air through the valve from port A and check

that air comes out of port B when the BAC valve

is cold..

3. If not correct, replace the BAC valve.

Note

Refer to "Installation" on this page for the

BAC valve installation.

86U04A-063

4C—47

Page 647 of 1865

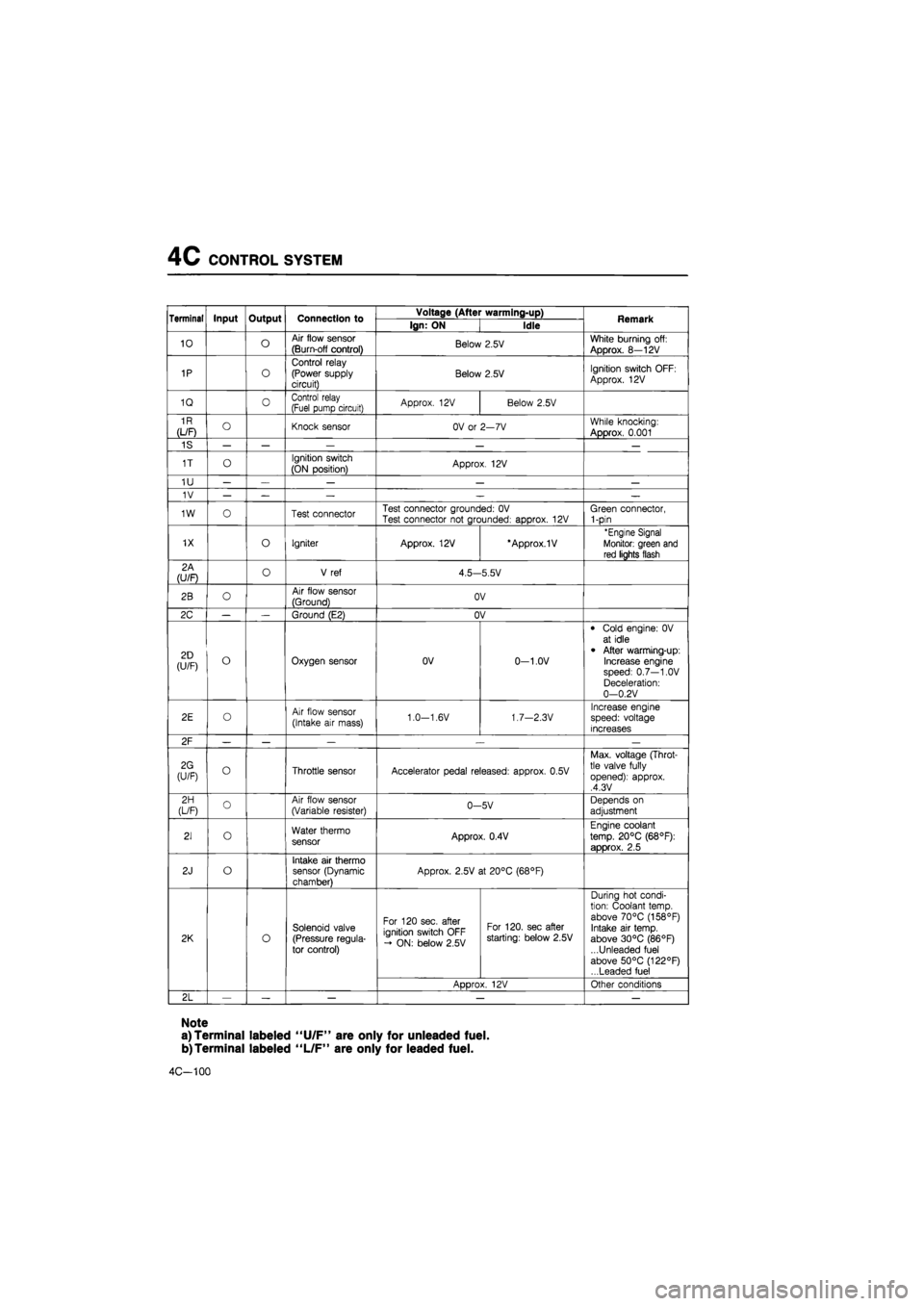

4C PCV SYSTEM

POSITIVE CRANKCASE VENTILATION

(PCV)

SYSTEM

PCV valve

76G04C-162

The PCV valve is operated by the intake manifold vacuum.

When the engine is running at idle, the PCV valve is opened slightly and a small amount of blow-by

gas is drawn into the dynamic chamber.

At high engine speeds, the PCV valve is further opened and a larger amount of blow-by gas is drawn

into the dynamic chamber.

COMPONENT DESCRIPTION

Component Function Remark

PCV valve Controls blowby gas amount pulled into engine

PCV VALVE

1. Warm up the engine to the normal operating tem-

perature and run it at idle.

2. Disconnect the PCV valve and the ventilation hose

from the cylinder head cover.

3. Close the PCV valve opening.

4. Check that vacuum is felt.

86U04A-157

4C-86

Page 660 of 1865

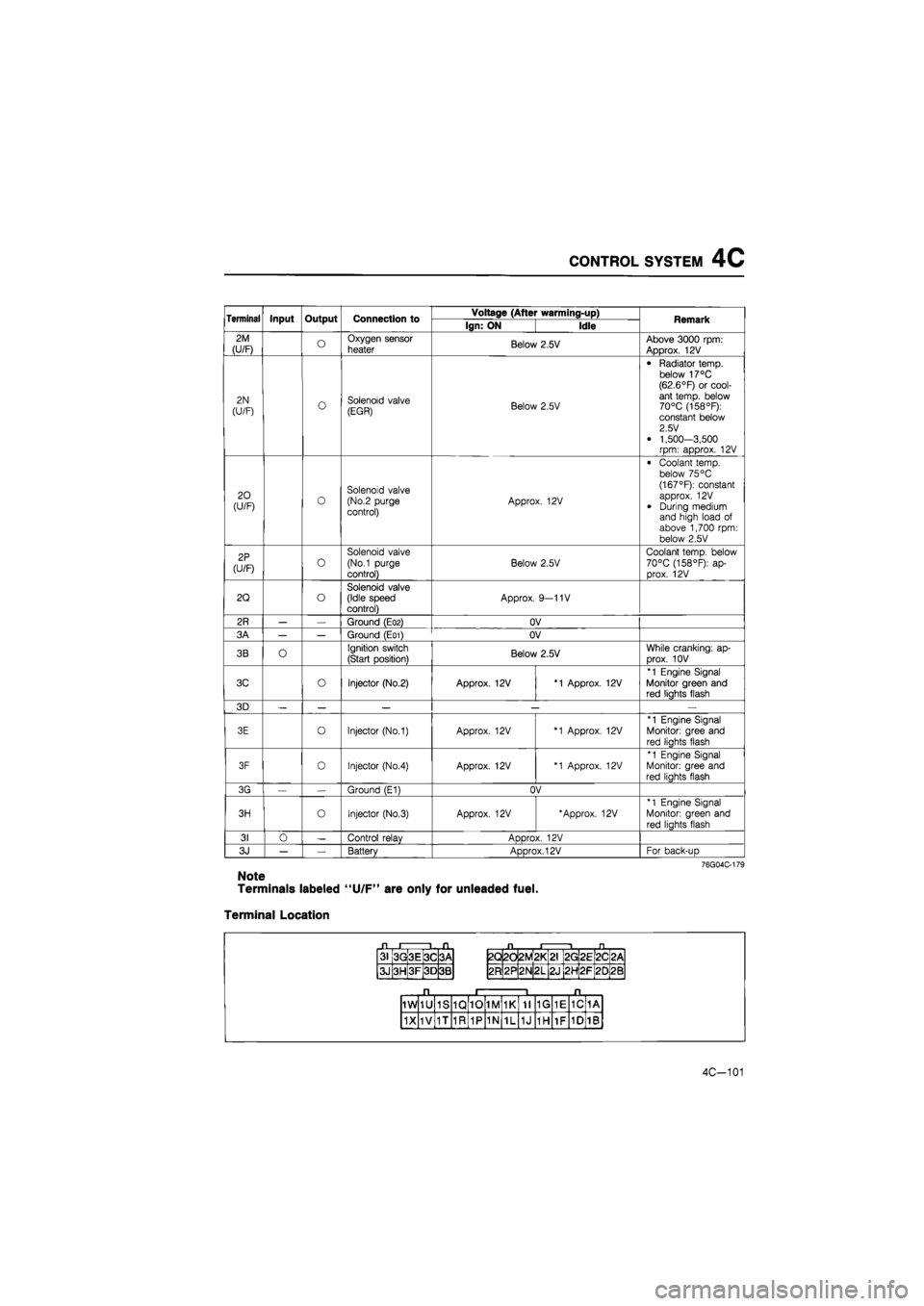

CONTROL SYSTEM 4C

Terminal Voltage

If the input and output devices wiring are normal, but the engine control unit terminal voltage is incor-

rect, replace the engine control unit.

Terminal Input Output Connection to Voltage (After warming-up) Remark Terminal Input Output Connection to Ign: ON Idle Remark

1A — — — — — —

1B o Self-Diagnosis Checker (Code No.)

For 3sec. after ignition switch OFF ->• ON: below 2.5V (Buzzer sounds) After 3sec.: approx. 12V (Buzzer does not sound)

• Using Self-Diagnosis Check-er and test con-nector grounded • Buzzer sounds: below 2.5V • Buzzer does not sound: approx. 12V

1C o

Solenoid valve (Variable inertia control) Approx. 12V

Above 5200 rpm (Unleaded fuel) or 5400 rpm (Leaded fuel): Below 2.5V

1D o Self-Diagnosis Checker (Monitor lamp)

For 3sec.after igni-tion switch OFF -» ON:

approx. 5V (light il-luminates)

After 3sec.: approx. 12V (light does not illuminate)

(Test connector grounded) approx. 5V (Test connector not grounded) Monitor lamp ON: approx. 5V Monitor lamp OFF: approx. 12V

With Self-Diagnosis

Checker

1E O Idle switch Accelerator pedal released: OV

Accelerator pedal depressed: approx. 12V

1F o A/C relay A/C switch ON: below 2.5V

A/C switch OFF: approx. 12V Blower motor ON

1G O Neutral or clutch switch

In-gear condition Clutch pedal depressed: approx. 12V Clutch pedal released: OV

MTX (Neutral: con-stant approx. 12V)

1H

(U/F) o Water thermo

switch

Approx. 12V Radiator temp.: be-low 17°C (63°R 1H

(U/F) o Water thermo

switch OV Radiator temp.:

above 17°C (63°F)

11 o Electrical load control unit E/L switch ON: below 2.5V

E/L switch OFF: approx. 10—12V

Electrical load: Rear defroster switch

Headlight switch Blower motor switch (3rd & 4th position) Electrical fan switch

1J — — — — —

1K o P/S pressure

switch

Constant approx.

12V

P/S ON: below 2.5V P/S OFF: approx. 12V

1L o A/C switch A/C switch ON: below 2.5V A/C switch OFF: aDDrox. 12V Blower motor: ON

1M o Distributor

(Ne signal) OV or 5V Approx. 2.0V

1N o Distributor (G signal) OV or 5V Approx. 1.2V

Note

Terminals labeled "U/F" are only for unleaded fuel.

4C-99

Page 661 of 1865

4C CONTROL SYSTEM

Terminal Input Output Connection to Voltage (After warming-up) Remark Terminal Input Output Connection to Ign: ON Idle Remark

10 o Air flow sensor

(Burn-off control) Below 2.5V White burning off:

Approx. 8—12V

1P o

Control relay (Power supply circuit) Below 2.5V Ignition switch OFF:

Approx. 12V

1Q 0 Control relay (Fuel pump circuit) Approx. 12V Below 2.5V

1R

(L/F) O Knock sensor OV or 2—7V While knocking:

Approx. 0.001

1S — — — — —

1T o Ignition switch

(ON position) Approx. 12V

1U — — — — —

1V — — — — —

1W o Test connector Test connector grounded: OV Test connector not grounded: approx. 12V Green connector, 1-pin

1X o Igniter Approx. 12V *Approx.1V 'Engine Signal

Monitor: green and

red lights flash

2A (U/F) o V ref 4.5—5.5V

2B o Air flow sensor

(Ground) OV

2C — — Ground (E2) OV

2D (U/F) o Oxygen sensor OV 0-1.0V

• Cold engine: 0V at idle

• After warming-up: Increase engine speed: 0.7—1.0V Deceleration: 0—0.2V

2E o Air flow sensor

(Intake air mass) 1.0—1.6V 1.7—2.3V Increase engine speed: voltage increases

2F — — — .— —

2G (U/F) o Throttle sensor Accelerator pedal released: approx. 0.5V

Max. voltage (Throt-tle valve fully opened): approx. ,4.3V

2H (L/F) o Air flow sensor (Variable resister) 0-5V Depends on

adjustment

21 o Water thermo sensor Approx. 0.4V

Engine coolant

temp. 20°C (68°F):

approx. 2.5

2J o Intake air thermo sensor (Dynamic chamber)

Approx. 2.5V at 20°C (68°F)

2K o

Solenoid valve (Pressure regula-tor control)

For 120 sec. after ignition switch OFF - ON: below 2.5V

For 120. sec after starting: below 2.5V

During hot condi-tion: Coolant temp, above 70°C (158°F) Intake air temp, above 30°C (86°F) ...Unleaded fuel above 50°C (122°F) ...Leaded fuel

2K o

Solenoid valve (Pressure regula-tor control)

ADDrox. 12V Other conditions

2L — — — — —

Note

a) Terminal labeled "U/F" are only for unleaded fuel.

b)Terminal labeled "L/F" are only for leaded fuel.

4C-100

Page 662 of 1865

CONTROL SYSTEM 4C

Terminal Input Output Connection to Voltage (After warming-up) Remark Terminal Input Output Connection to Ign: ON Idle Remark

2M

(U/F) o Oxygen sensor

heater Below 2.5V Above 3000 rpm: Approx. 12V

2N

(U/F) o Solenoid valve (EGR) Below 2.5V

• Radiator temp, below 17°C (62.6°F) or cool-ant temp, below 70°C (158°F): constant below 2.5 V

• 1,500-3,500 rpm: approx. 12V

20 (U/F) 0 Solenoid valve (No.2 purge control) Approx. 12V

• Coolant temp, below 75 °C (167°F): constant approx. 12V

• During medium and high load of above 1,700 rpm: below 2.5V

2P

(U/F) o

Solenoid valve

(No.1 purge

control)

Below 2.5V

Coolant temp, below 70°C (158°F): ap-prox. 12V

2Q o Solenoid valve (Idle speed control) Approx. 9—11V

2R — — Ground (E02) OV

3A — — Ground (E01) OV

3B O Ignition switch

(Start position) Below 2.5V While cranking: ap-

Drox. 10V

3C o Injector (No.2) Approx. 12V *1 Approx. 12V

*1 Engine Signal Monitor green and red liahts flash

3D — — — — —

3E o Injector (No.1) Approx. 12V *1 Approx. 12V

*1 Engine Signal

Monitor: gree and

red liahts flash

3F 0 Injector (No.4) Approx. 12V *1 Approx. 12V

*1 Engine Signal Monitor: gree and red liahts flash

3G — Ground (E1) OV

3H o Injector (No.3) Approx. 12V 'Approx. 12V *1 Engine Signal

Monitor: green and

red lights flash

31 0 — Control relav ADDrox. 12V

3J — — Battery Approx. 12V For back-uD

76G04C-179

Note

Terminals labeled "U/F" are only for unleaded fuel.

Terminal Location

31 3G 3E 3C 3A

3J 3H 3F 3D 3B

2Q 2d 2M *

L

2G 2E 2C <

CM

2R 2P 2N 2L 2J 2H 2F 20 2B

1W 1U 1S 1Q 10 1M 1K 11 1G 1E 1C 1A

1X 1V 1T 1R 1P 1N 1L 1J 1H 1F 1D 1B

4C-101

Page 663 of 1865

4C CONTROL SYSTEM

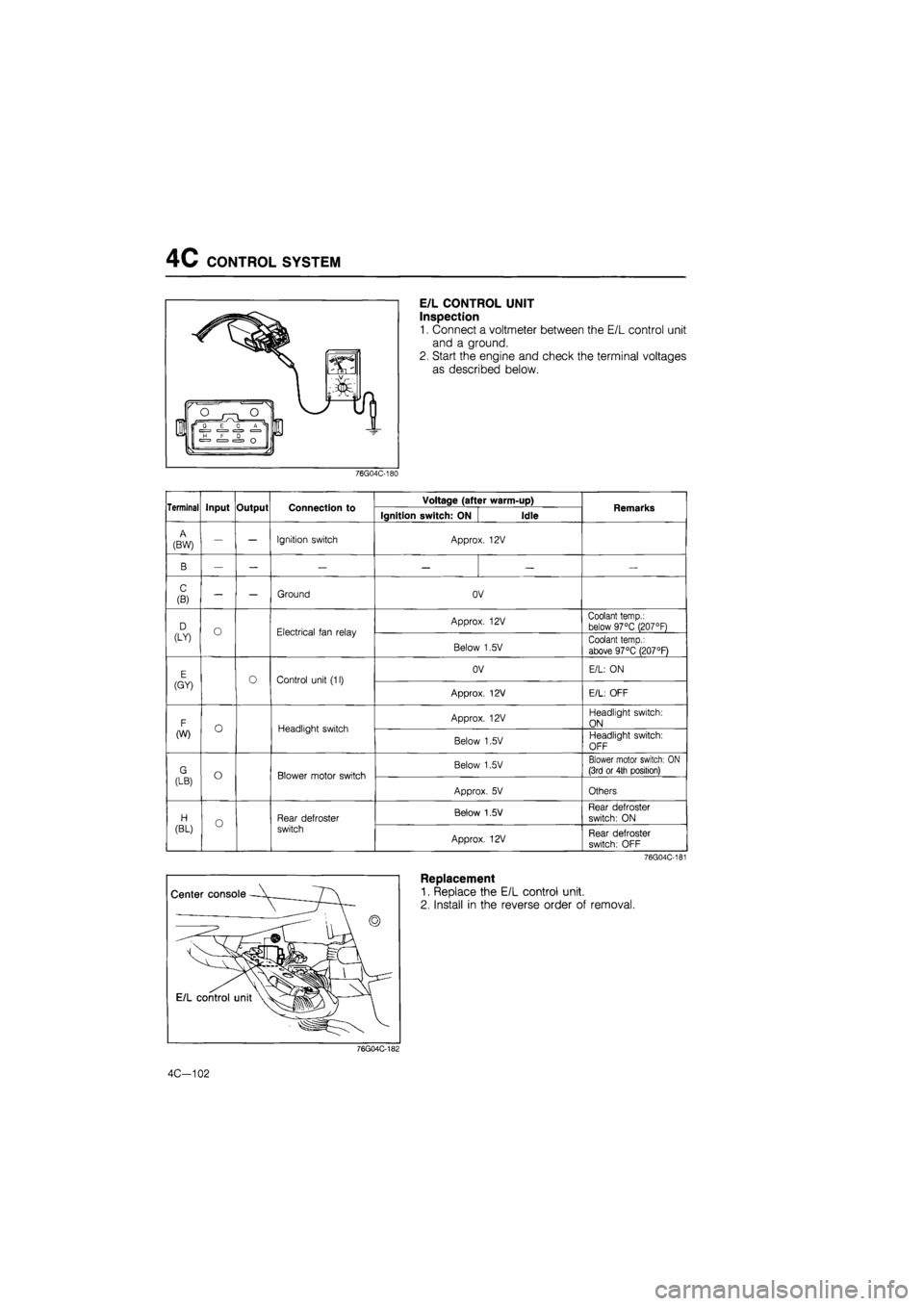

E/L CONTROL UNIT

Inspection

1. Connect a voltmeter between the E/L control unit

and a ground.

2. Start the engine and check the terminal voltages

as described below.

76G04C-180

Terminal Input Output Connection to Voltage (after warm-up) Remarks Terminal Input Output Connection to Ignition switch: ON Idle Remarks

A

(BW) — — Ignition switch Approx. 12V

B — — — — — —

C

(B) — — Ground OV

D (LY) O Electrical fan relay Approx. 12V Coolant temp.: below 97°C (207°F) D (LY) O Electrical fan relay

Below 1,5V Coolant temp.:

above 97°C (207°F)

E (GY) Control unit (11) OV E/L: ON E (GY) Control unit (11)

Approx. 12V E/L: OFF

F (W) O Headlight switch Approx. 12V Headlight switch:

ON F (W) O Headlight switch

Below 1,5V Headlight switch:

OFF

G (LB) o Blower motor switch Below 1.5V Blower motor switch: ON (3rd or 4th position) G (LB) o Blower motor switch

Approx. 5V Others

H

(BL) o Rear defroster

switch

Below 1.5 V Rear defroster

switch: ON H

(BL) o Rear defroster

switch Approx. 12V Rear defroster switch: OFF

76G04C-181

Replacement

1. Replace the E/L control unit.

2. Install in the reverse order of removal.

76G04C-182

4C—102