parking brake MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 915 of 1865

TROUBLESHOOTING (G4A-HL) 7B

STEP 3 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Engage the parking brake and use wheel chocks at the front and rear wheels.

Pull the parking brake Water temperature

ATF

83U07B-038

7B—49

Page 937 of 1865

ON-VEHICLE MAINTENANCE 7B

ON-VEHICLE MAINTENANCE

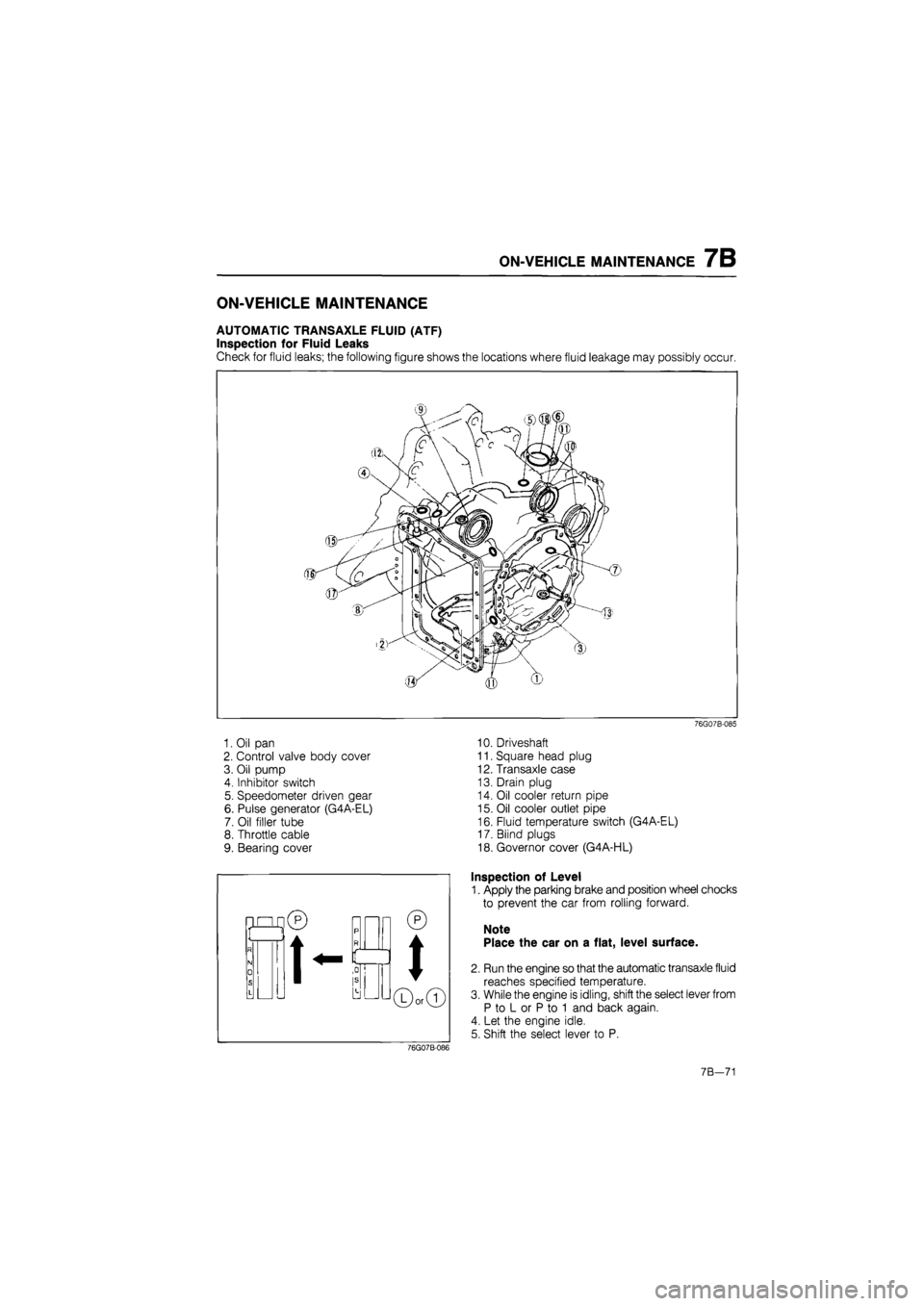

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator (G4A-EL)

7. Oil filler tube

8. Throttle cable

9. Bearing cover

76G07B-085

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch (G4A-EL)

17. Blind plugs

18. Governor cover (G4A-HL)

Inspection of Level

1. Apply the parking brake and position wheel chocks

to prevent the car from rolling forward.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches specified temperature.

3. While the engine is idling, shift the select lever from

P to L or P to 1 and back again.

4. Let the engine idle.

5. Shift the select lever to P.

76G07B-086

7B—71

Page 965 of 1865

DISASSEMBLY 7B

DISASSEMBLY-STEP 3

Component

86U07B-151

1. Transaxle case

2. Output shell

3. Snap ring

4. Spring and retainer assembly

5. Low and reverse brake piston

6. Plug, washer, spring, and detent ball

7. Bracket

8. Manual shaft and manual plate

9. Actuator support

10. Parking assist lever

11. Parking pawl

7B—99

Page 1118 of 1865

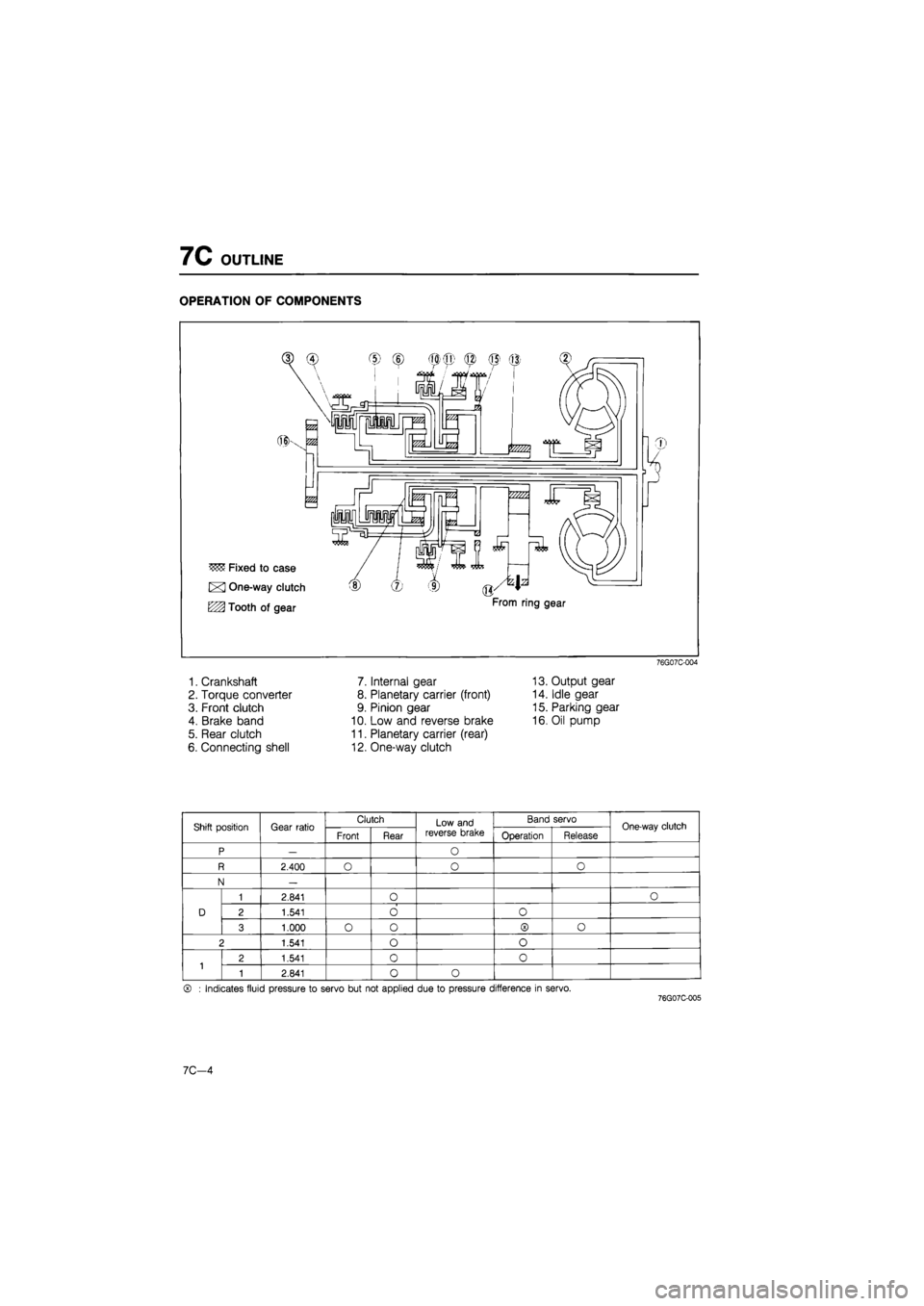

7C OUTLINE

OPERATION OF COMPONENTS

76G07C-004

1. Crankshaft 7. Internal gear 13. Output gear

2. Torque converter 8. Planetary carrier (front) 14. Idle gear

3. Front clutch 9. Pinion gear 15. Parking gear

4. Brake band 10. Low and reverse brake 16. Oil pump

5. Rear clutch 11. Planetary carrier (rear)

6. Connecting shell 12. One-way clutch

Shift position Gear ratio Clutch Low and reverse brake

Band servo One-way clutch Shift position Gear ratio Front Rear

Low and reverse brake Operation Release One-way clutch

P — O

R 2.400 O o O

N —

D

1 2.841 O O

D 2 1.541 O O D

3 1.000 O o ® o

2 1.541 o o

1 2 1.541 0 0 1 1 2.841 0 o

® : Indicates fluid pressure to servo but not applied due to pressure difference in servo. 76G07C-005

7C-4

Page 1123 of 1865

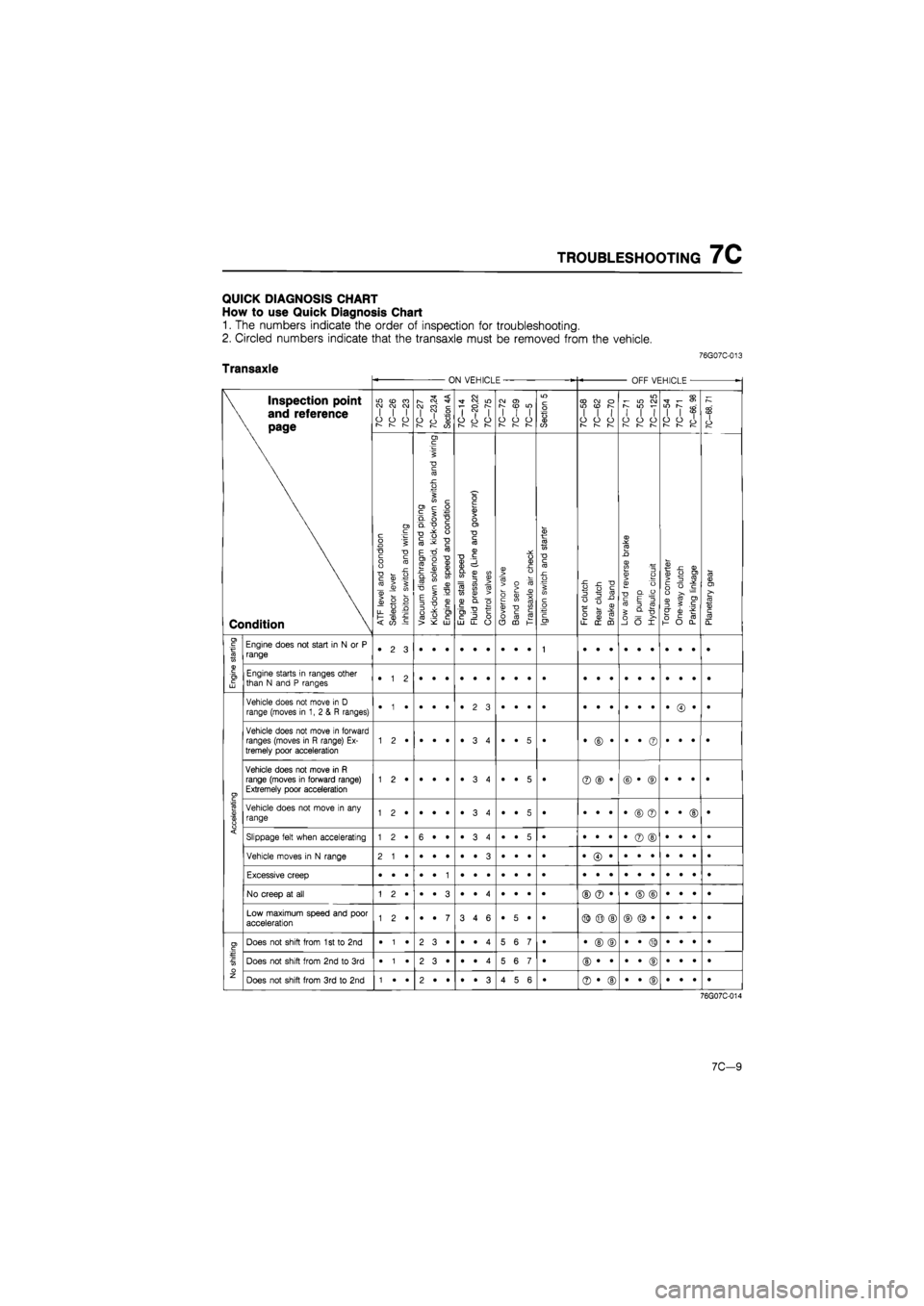

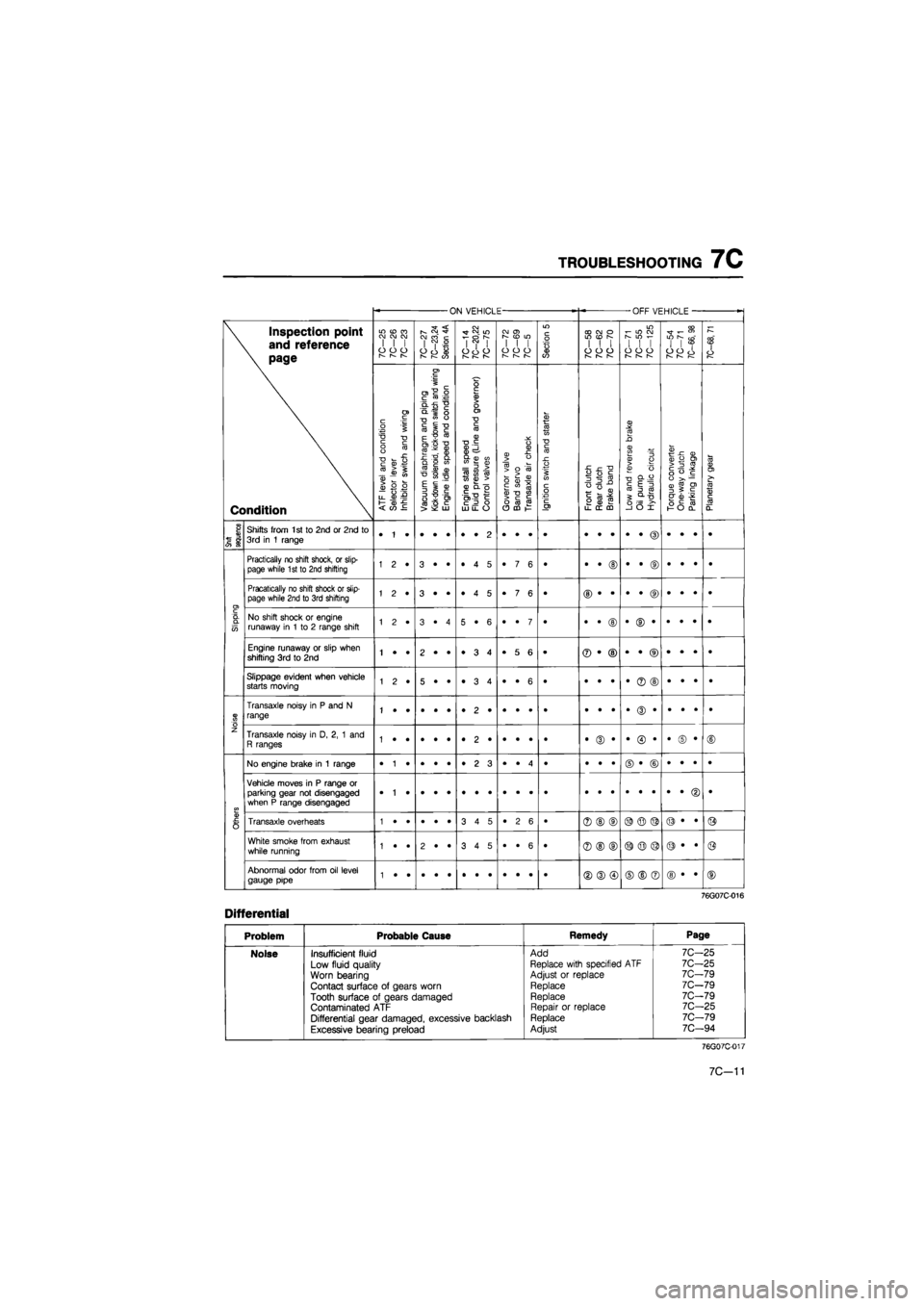

TROUBLESHOOTING

7C

QUICK DIAGNOSIS CHART

How

to use

Quick Diagnosis Chart

1.

The

numbers indicate

the

order

of

inspection

for

troubleshooting.

2. Circled numbers indicate that

the

transaxle must

be

removed from

the

vehicle.

76G07C-013

Transaxle ON VEHICLE OFF VEHICLE

•

\ Inspection point

\

and

reference

\ page

Condition

7C-25

7C-26

7C-23

10—21

7C—23,24

Section

4A

7C-14

7C—20,22

10—lb

10-12 10—69

7C—5

Section

5

7C—58

7C-62

7C-70

7C-71

7C-55

7C-125

7C-54 7C-71

7C-66,

98

7C-68,

71

\ Inspection point

\

and

reference

\ page

Condition

ATF

level

and

condition

Selector

lever

Inhibitor

switch

and

wiring

^

Vacuum

diaphragm

and

piping

|

Kick-down

solenoid,

kick-down

switch

and

wiring

Engine

idle

speed

and

condition

Engine

stall

speed

Fluid

pressure

(Line

and

governor)

Control

valves

Governor

valve

Band

servo

Transaxle

air

check

Ignition

switch

and

starter

Front

clutch

Rear

clutch

Brake

band

Low

and

reverse

brake

Oil

pump Hydraulic

circuit

Torque

converter

One-way

clutch

Parking

linkage

Planetary

gear

I

Engine

starting

Engine does

not

start

in

N or P

range •

2 3

1

Engine

starting

Engine starts

in

ranges other than

N

and P

ranges •

1 2

Accelerating

Vehicle does

not

move

in

D

range (moves

in 1, 2 & R

ranges) •

• •

•

Accelerating

Vehicle does

not

move

in

forward ranges (moves

in R

range)

Ex-

tremely poor acceleration •

• 5

• •

© •

•

• ©

•

• •

•

Accelerating

Vehicle does

not

move

in R

range (moves

in

forward range) Extremely poor acceleration 1

2 •

•

• •

•

3 4

•

• 5

• ©

© •

©

• ©

•

• •

•

Accelerating

Vehicle does

not

move

in any

range 1

2 •

•

• •

•

3 4

•

• 5

• •

• •

•

© ©

•

• ©

•

Accelerating Slippage felt when accelerating 1

2 •

6

• •

•ST

CO

•

•

• 5

• •

• •

•

© ©

•

• •

• Accelerating

Vehicle moves

in

N

range

Accelerating

Excessive creep

Accelerating

No creep

at all

©

© •

•

© ©

•

• •

•

Accelerating

Low maximum speed

and

poor acceleration 1

2 •

•

• 7

3

4 6

•

5 •

• ©

© ©

No shifting

Does

not

shift from

1

st to 2nd

•

1 •

2

3 •

•

• 4

5

6 7

• •

© ©

•

• ©

•

• •

•

No shifting

Does

not

shift from

2nd to 3rd

•

1 •

2

3 •

•

• 4

5

6 7

•

No shifting

Does

not

shift from

3rd to 2nd

1

• •

2

• •

•

• 3

4

5 6

• ©

• ©

•

• ©

•

• •

•

76G07C-014

7C-9

Page 1124 of 1865

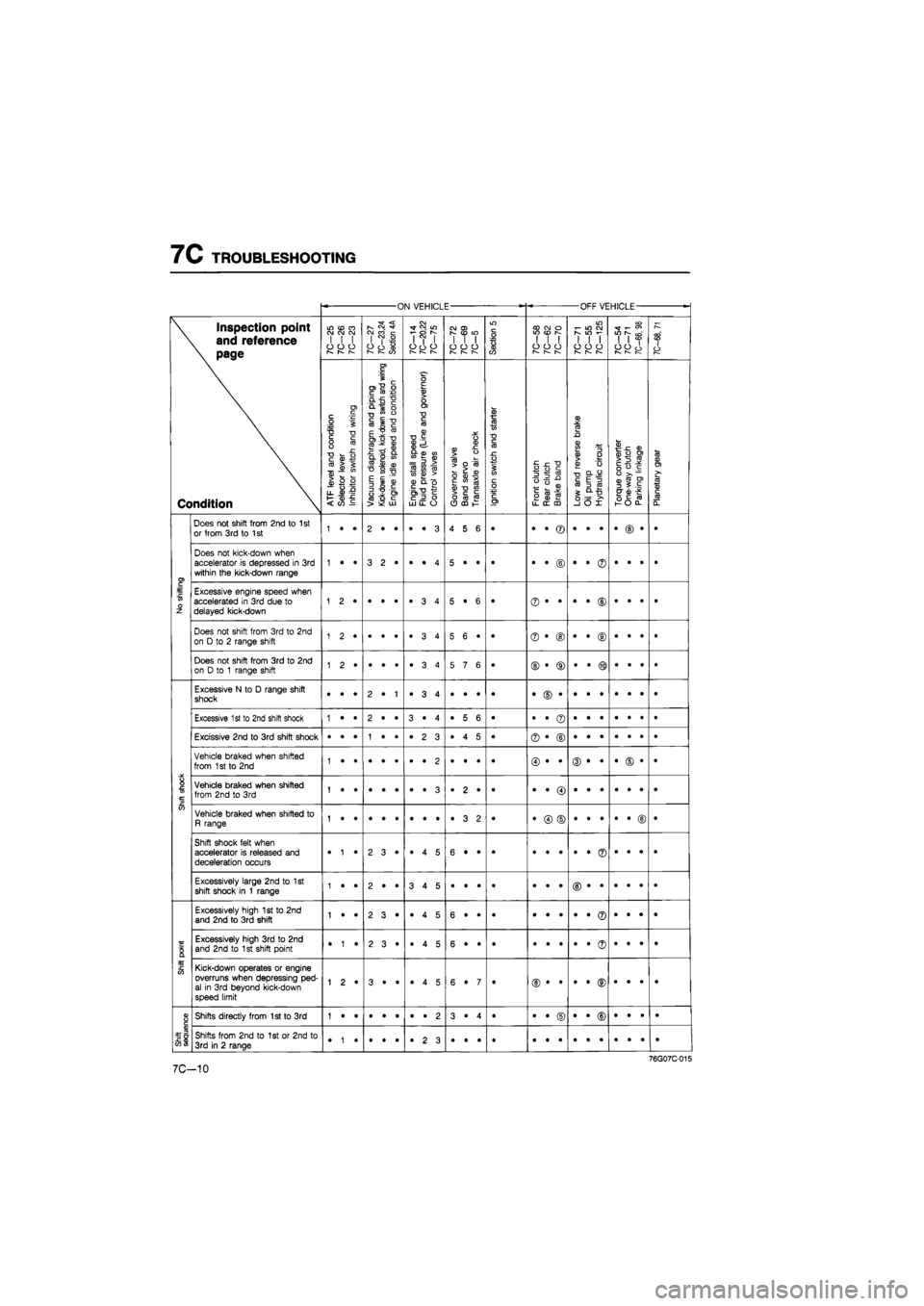

7C TROUBLESHOOTING

ON VEHICLE OFF VEHICLE

-

\ Inspection point

\ and reference

\ page

Condition

LO

(O

CO CJ OJ CM I

I I

O

O

CJ

r-~

r—

7C-27

7C—23,24

Section

4A

7C—14

7C—20,22

7C-75

CO

O)

I

I I

o

o o

r—

r—

Section

5

CO CO

o

WON I

I I

o

o o

1— 1—

m i-

in co

S

IO

i-

1

1 1

o

o o

—

I—

7C—54

7C-71

7C-66,

98

7C—68,

71

\ Inspection point

\ and reference

\ page

Condition

A.TF

level

and

condition

Selector

lever

Inhibitor

switch

and

wiring

Vacuum

diaphragm

and

piping

Kick-down

solenoid,

kick-down

switch

and

wiring

Engine

idle

speed

and

condition

Engine

stall

speed

Fluid

pressure

(Line

and

governor)

Control

valves

Governor

valve

Band

servo

Transaxle

air

check

Ignition

switch

and

starter

Front

clutch

Rear

clutch

Brake

band

Low

and

reverse

brake

Oil pump Hydraulic

circuit

Torque

converter

One-way

clutch

Parking

linkage

Planetary

gear

No

shifting

Does

not

shift from 2nd

to

1

st or from

3rd to

1

st 1

• •

2

• •

•

• 3

4

5 6

•

No

shifting

Does

not

kick-down when accelerator

is

depressed

in 3rd

within

the

kick-down range 1

• •

3

2*

•

• 4

5

• •

• •

• ©

•

• ©

•

• •

•

No

shifting

Excessive engine speed when accelerated

in 3rd

due

to

delayed kick-down 5

• 6

• ©

• •

•

• ©

•

• •

• No

shifting

Does

not

shift from

3rd to 2nd

on

D to

2

range shift 1

2 •

5

6 •

• ©

• ®

•

• ®

•

• •

•

No

shifting

Does

not

shift from

3rd to 2nd

on

D to 1

range shift 5

7 6

• ©

• ®

•

• ®

•

• •

•

Shift

shock

Excessive

N to

D

range shift shock •

• •

2

• 1

•

3 4

•

• •

• •

© •

•

• •

•

• •

•

Shift

shock

Excessive

1

st

to

2nd shift shock 1

• •

2

• •

3

• 4

•

5 6

• •

• ©

•

• •

•

• •

•

Shift

shock

Excissive 2nd

to 3rd

shift shock •

• •

1

• •

•

2 3

•

4 5

• ©

• ©

Shift

shock

Vehicle braked when shifted from

1

st

to 2nd

Shift

shock

Vehicle braked when shifted from 2nd

to 3rd

1

• •

•

• •

•

• 3

.

2 •

•

Shift

shock

Vehicle braked when shifted

to

R range 1

• •

•

• •

•

• •

•

3 2

• •

© ©

•

• •

•

• ©

•

Shift

shock

Shift shock felt when accelerator

is

released

and

deceleration occurs •

1 •

2

3*

•

4 5

6

• •

• •

• •

•

• ©

•

• *

•

Shift

shock

Excessively large 2nd

to 1st

shift shock

in 1

range 1

• •

2

• •

3

4 5

•

• •

•

Shift

point

Excessively high

1st to 2nd

and 2nd

to

3rd shift 1

• •

2

3 •

•

4 5

6

• •

•

Shift

point

Excessively high

3rd to 2nd

and

2nd to

1

st shift point •

1 •

2

3 •

•

4 5

6

• •

• •

• •

•

• ©

•

• •

•

Shift

point

Kick-down operates

or

engine overruns when depressing

ped-

al

in 3rd

beyond kick-down speed limit

1

2 •

3

• •

•

4 5

6

• 7

•

Shift

sequence

Shifts directly from 1st

to 3rd

1

• •

•

• •

•

• 2

3

• 4

• •

• ©

•

• ©

•

• •

•

Shift

sequence

Shifts from

2nd to 1st or

2nd

to

3rd

in

2

range •

1 •

•

• •

•

2 3

•

• •

•

7C-10

Page 1125 of 1865

TROUBLESHOOTING

7C

ON VEHICLE -OFF VEHICLE

-

\ Inspection point

\

and

reference

\ page

Condition

in cd

ra

CM CM CM

I

I I

o

o o

I—

r~—

r—

7C—27

7C—23,24

Section

4A

7C—14

7C—20,22

7C-75

CM

0>

[—

CO

LO I

I I

O

O O

r^ r—

Section

5

CD CM

O

in (D

s

I

I I

o

o o

r—

r^

w

CM

r-

m f-

I

I I

o

o o

r-— I—

r-—

7C—54

7C-71

7C—66,

98

7C-68,

71 \ Inspection point

\

and

reference

\ page

Condition

ATR

level

and

condition

Selector

lever

Inhibitor

switch

and

wiring

Vacuum

diaphragm

and

piping

Kick-down

solenoid,

kick-down

switch

and

wiring

Engine

idle

speed

and

condition

Engine

stall

speed

Fluid

pressure

(Line

and

governor)

Control

valves

Governor

valve

Band

servo

Transaxle

air

check

Ignition

switch

and

starter

Front

clutch

Rear

clutch

Brake

band

Low

and

reverse

brake

Oil

pump

Hydraulic

circuit

Torque

converter

One-way

clutch

Parking

linkage

Planetary

gear

Snift

sequence

Shifts from

1st to

2nd

or

2nd

to

3rd

in 1

range

Slipping

Practically

no

shift shock,

or

slip-page while 1st

to

2nd shifting 1

2 •

3

• •

•

4 5

•

7 6

• •

• ©

•

• ©

•

• •

•

Slipping

Pracatically

no

shift shock

or

slip-page while 2nd

to

3rd shifting 1

2 •

3

• •

•

4 5

•

7 6

•

Slipping

No shift shock

or

engine runaway

in 1 to 2

range shift 1

2 •

3

• 4

5

• 6

•

• 7

• •

• ©

•

© •

•

• •

•

Slipping

Engine runaway

or

slip when shifting

3rd to 2nd

1

• •

2

• •

•

3 4

•

5 6

• ®

• ©

•

• ®

•

• •

•

Slipping

Slippage evident when vehicle starts moving 1

2 •

5

• •

•

3 4

•

• 6

• •

• •

•

® ©

•

• •

•

Noise

Transaxle noisy

in P and N

range

Noise

Transaxle noisy

in D, 2, 1 and

R ranges •

(D •

•

© •

•

© •

©

Others

No engine brake

in 1

range •

1 •

•

• •

•

2 3

•

• 4

• •

• •

©

• ©

•

• •

•

Others

Vehicle moves

in P

range

or

parking gear

not

disengaged when

P

range disengaged

•

Others

Transaxle overheats 3

4 5

•

2 6

• ®

©

(D ©

© ©

©

• •

©

Others

White smoke from exhaust while running 1

• •

2

• •

3

4 5

•

• 6

• ®

© ©

©

© ©

©

• •

@

Others

Abnormal odor from

oil

level gauge pipe ©

® ©

©

© ®

©

• •

©

76G07C-016

Differential

Problem Probable Cause Remedy Page

Noise Insufficient fluid Add 7C—25

Low fluid quality Replace with specified

ATF

7C-25

Worn bearing Adjust

or

replace 7C-79

Contact surface

of

gears worn Replace 7C-79

Tooth surface

of

gears damaged Replace 7C-79

Contaminated

ATF

Repair

or

replace 7C-25

Differential gear damaged, excessive backlash Replace 7C-79

Excessive bearing preload Adjust 7C—94

76G07C-017

7C—11

Page 1126 of 1865

7C TROUBLESHOOTING

STEP 1 (PRELIMINARY INSPECTION)

In this step, the main points related to the automatic transaxle are checked. These items must be kept

in the correct condition at all times in order to assure proper operation of the automatic transaxle.

1. Automatic Transaxle Fluid (ATF)

Check ATF level and condition. (Refer to page 7C—25.)

2. Selector Lever

Check selector lever position and adjust it if necessary. (Refer to page 7C—26.)

76G07C-018

3. Oil Leakage

Check for oil leakage.

(1) Warm up the ATF.

(2) Apply the parking brake and block the wheels

to prevent the vehicle from rolling.

(3) Shift the selector lever to R range.

(4) Check if oil leaks from the noted oil seals or

gaskets.

(5) If oil leaks, replace the seal or gasket.

76G07C-019

7C-12

Page 1128 of 1865

7C TROUBLESHOOTING

STEP 2 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Set the parking brake and block the front and rear of the wheels.

Pull the parking brake Water temperature

ATF

7C—14

76G07C-024

Page 1139 of 1865

ON-VEHICLE MAINTENANCE 7C

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Kick-down solenoid

2. Vacuum diaphragm

3. Manual shaft

4. Speedometer driven gear

5. Oil level tube

6. Governor cover

7. Governor

8. Oil pan

9. Oil pump

10. Inhibitor switch

11. Transaxle case

12. Oil pump

13. Square head plugs

14. Bearing cover

15. Drive shaft

76G07C-041

©

i

©

[JdQ©

I

Inspection of Level

1. Apply the parking brake and block the wheels to

prevent the vehicle from rolling.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches operating temperature.

3. While the engine is idling, shift the select lever from

P to 1 and back again.

4. Let the engine idle.

5.Shift the select lever to P.

76G07C-042

7C-25