torque MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1084 of 1865

7B INSTALLATION

86U07B-449

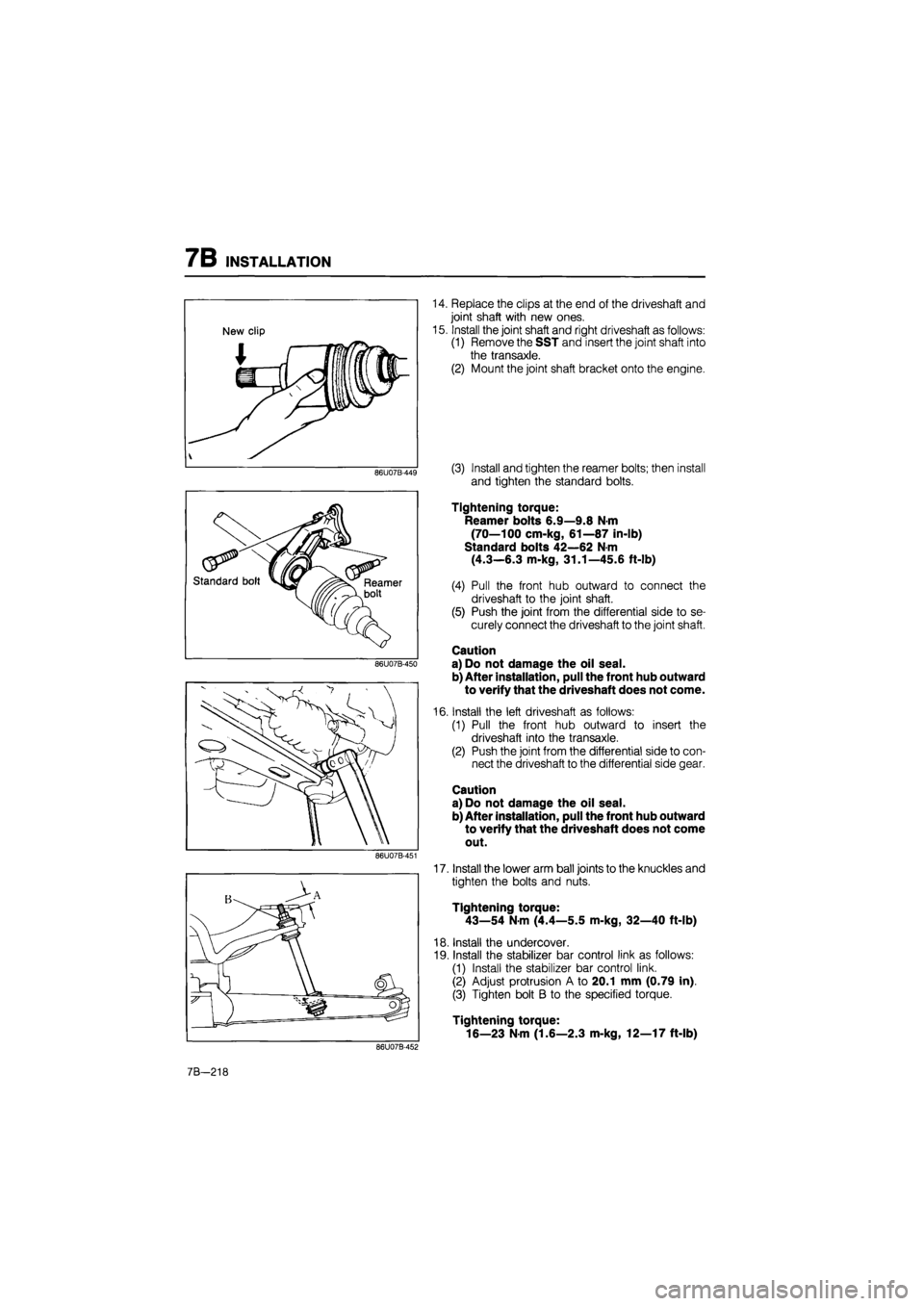

Standard bolt Reamer bolt

86U07B-450

86U07B-451

14. Replace the clips at the end of the driveshaft and

joint shaft with new ones.

15. Install the joint shaft and right driveshaft as follows:

(1) Remove the SST and insert the joint shaft into

the transaxle.

(2) Mount the joint shaft bracket onto the engine.

(3) Install and tighten the reamer bolts; then install

and tighten the standard bolts.

Tightening torque:

Reamer bolts 6.9—9.8 N-m

(70—100 cm-kg, 61—87 in-lb)

Standard bolts 42—62 N-m

(4.3—6.3 m-kg, 31.1—45.6 ft-lb)

(4) Pull the front hub outward to connect the

driveshaft to the joint shaft.

(5) Push the joint from the differential side to se-

curely connect the driveshaft to the joint shaft.

Caution

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to verify that the driveshaft does not come.

16. Install the left driveshaft as follows:

(1) Pull the front hub outward to insert the

driveshaft into the transaxle.

(2) Push the joint from the differential side to con-

nect the driveshaft to the differential side gear.

Caution

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to verify that the driveshaft does not come

out.

17. Install the lower arm ball joints to the knuckles and

tighten the bolts and nuts.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

18. Install the undercover.

19. Install the stabilizer bar control link as follows:

(1) Install the stabilizer bar control link.

(2) Adjust protrusion A to 20.1 mm (0.79 in).

(3) Tighten bolt B to the specified torque.

Tightening torque:

16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

86U07B-452

7B-218

Page 1085 of 1865

INSTALLATION 7B

86U07B-453

86U07B-454

76G07B-198

20. Install the tie-rod ends and cotter pins.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

21. Install the oil cooler outlet and inlet hoses.

22. Install the splash shields.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

23. Install the front wheels.

Tightening torque:

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

24. Connect the throttle cable.

Note

Adjust the throttle cable with the oil pressure

test. (Refer to page 7B—75, 76)

25. Connect the selector cable.

Tightening torque:

Nut

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

Bolts

16—22 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

26. Connect the ground wires to the transaxle case.

Tightening torque:

8—11 N-m (80—115 cm-kg, 69—99 in-lb)

86U07B-456

7B—219

Page 1086 of 1865

7B INSTALLATION

27. Connect the connectors as follows:

(1) Inhibitor switch

(2) Solenoid valve

(3) Pulse generator (G4A-EL)

(4) Fluid temperature switch (G4A-EL)

28. Connect the speedometer cable.

76G07B-199

76G07B-200

76G07B-201

29. Install the fresh air duct. (G4A-HL)

30. Install the air cleaner hose. (G4A-EL)

31. Install the air cleaner assembly; then connect the

air flow meter connector and inlet hose. (G4A-EL)

Tightening torque:

Bolt

31—40 N-m (3.2—4.1 m-kg, 23—30 in-lb)

Nut

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

32. Connect the distributor lead.

33. Install the main fuse block.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

34. Install the battery carrier and battery.

Tightening torque:

31—40 N-m (3.2—4.1 m-kg, 23—30 in-lb)

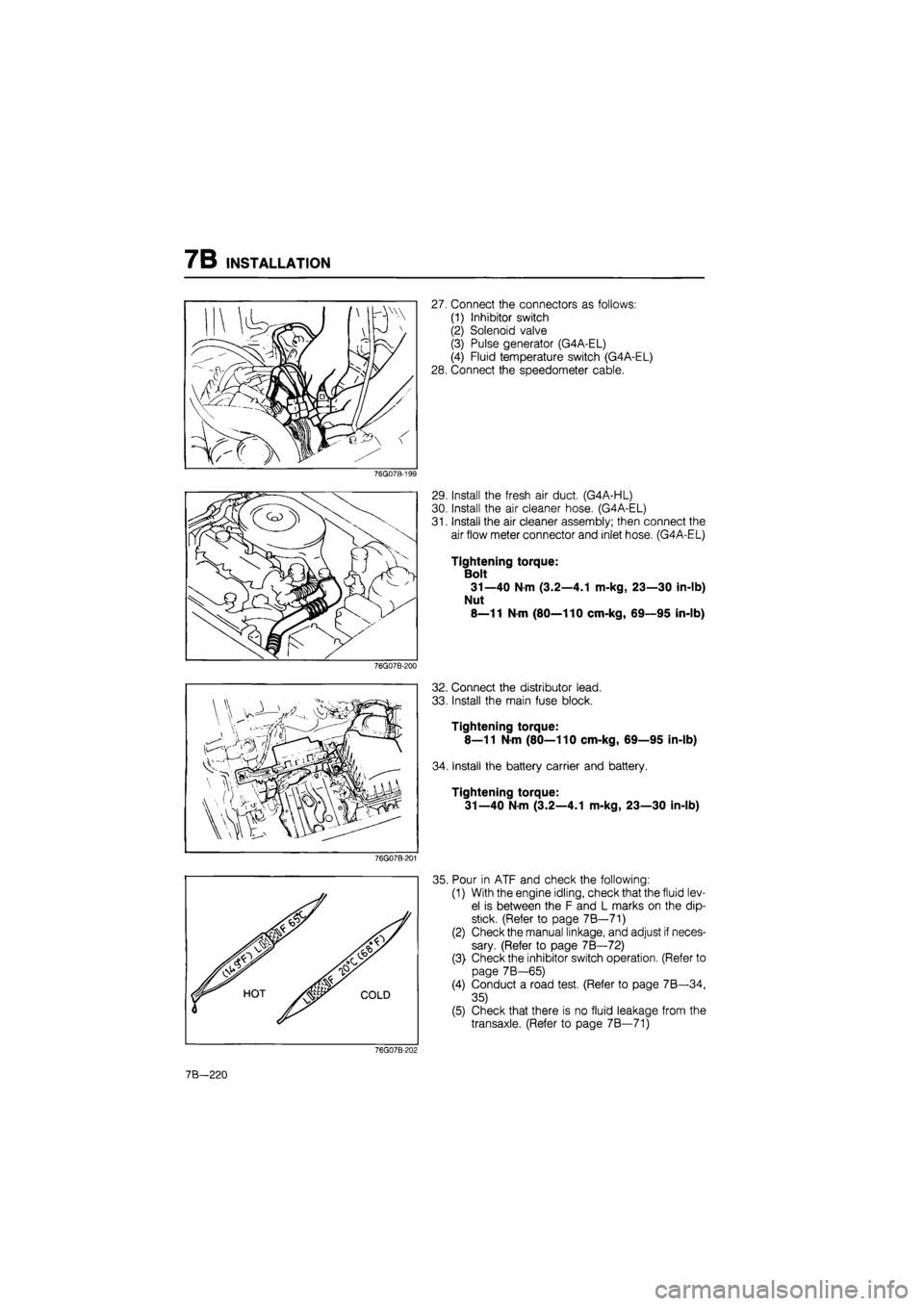

35. Pour in ATF and check the following:

(1) With the engine idling, check that the fluid lev-

el is between the F and L marks on the dip-

stick. (Refer to page 7B—71)

(2) Check the manual linkage, and adjust if neces-

sary. (Refer to page 7B—72)

(3) Check the inhibitor switch operation. (Refer to

page 7B—65)

(4) Conduct a road test. (Refer to page 7B—34,

35)

(5) Check that there is no fluid leakage from the

transaxle. (Refer to page 7B—71)

76G07B-202

7B—220

Page 1087 of 1865

OD

IV) K>

2-4 brake band

—Coasting clutch pressure brake pressure

To oil cooler

N-R accumulator 12-3 accumulator

2-3 Timingr valve 18 Coasting bypass valve Bypass valve Servo control y valve (Blocked)

Pressure modifier valve (Blocked)

3-4 shift valve

Low reducing valve

Pressure regulator valve 3-2 timing valve 3-2 Icapacity valve

Manual valve

Throttle valve

Oil pump

• Throttle pressure

1 Throttle modulated pressure

• Line pressure

I Torque converter pressure Forward clutch pressure\^

Reverse clutch pressure—_____

1-2 accumulator

Throttle back-up valve (Blocked)

-j Throttle J modulator I valve

Apply side 9

Lock-up control valve

-< O

u >

o

o

J3 o

Q >

• m

-< o

3D >

C n

O

O

J3 o

a •C* > • m

-si

CD

Page 1088 of 1865

Apply side 9

Throttle pressure

Throttle modulated pressure

Line pressure

Operating line pressure

1

Torque converter pressure

30 >

Z o m

U)

< O X >

o

o

55

o

0 >

1 m

I Oil pump

Page 1089 of 1865

-vj

ro ro CO

2-4 brake band

Throttle valve

Low and reverse brake pressure [-Coasting clutch pressure|

1-2 accumulator To oil cooler 3r4-Clytch pressure Lock-up control valve

N-R accumulator imulator -3 accumulator

[2-3 Timingf valve Coasting

Bypass valve J Servo control < x ]_ valve (Blocked)

Pressure modifier valve (Blocked)

Throttle modulator valve

Throttle back-up "valve (Blocked) Low reducing valve

Pressure regulator valve 3-2 timing valve 3-2

|

capacity valve

Throttle pressure

Throttle modulated pressure

Line pressure

Torque converter pressure

Forward clutch pressure

Reverse clutch pressure

) Oil pump

Page 1090 of 1865

Apply side 9 Throttle pressure

Throttle modulated pressure

Line pressure

Torque converter pressure

I Oil pump

Page 1091 of 1865

-Nl CD

(V) r\D cn

2-4 brake band

Release side-

Throttle valve

Low and reverse brake pressure Coasting clutch pressure!

•To oil cooler 3-4 clutch pressure:

N-R accumulator accumulator 12-3 accumulator

is [2-3 Timing! valve Coasting bypass valve Bypass valve Servo control * valve (Blocked)

£j] Pressure J modifier I valve x (Blocked)

3-4 shift

|

valve Lp-j Throttle

•

R» modulator I211 valve

Low reducing valve

19 Pressure regulator valve 20 3-2 timing valve sin L

1 n

in ^ * I

S

Manual valve 3-2 D capacity valve

Forward clutch pressure— ^

Reverse clutch pressure

1-2 accumulator

I Throttle pressure

i Throttle modulated pressure

| Line pressure

| Operating line pressure

] Torque converter pressure

Throttle back-up valve (Blocked)

Lock-up control valve

o

3D >

Z o m

to H D m > 3

X -<

D ZJ >

O

O

U O c

o >

• m

w

Page 1092 of 1865

mm

2-4 brake band

Throttle valve

-Coasting clutch pressure| Low and reverse brake pressure

3-4 clutch pressure To oil cooler Lock-up control valve

accumulator N-R accumulator accumulator

valve Coasting bypass valve Bypass valve Servo control x x valve (Blocked)

Pressure modifier valve (Blocked)

Throttle modulator valve

1-2 shift valve

Low reducing valve

(Blocked)

19 Pressure regulator valve 3-2 timing valve 3-2 Jcapacity valve

Manual valve

Apply side

Forward clutch pressure^

Reverse clutch pressure^-

1-2 accumulator

I Oil pump

!•• Throttle pressure

l^M Throttle modulated pressure

i^B Line pressure

HH Operating line pressure

I i Torque converter pressure

Throttle back-up valve

Page 1093 of 1865

CD

ro r\D -vi

2-4 brake band

Release side'

Low and reverse brake pressure /pasting clutch pressure

•To oil cooler issure Lock-up control valve

N-R accumulator imulator }2-3 accumulator

18 Coasting

11 Bypass valve Servo control x valve (Blocked)

Pressure modifier valve (Blocked)

Throttle JBij modulator 2i I valve

3-4 Shift valve

1-2 shift valve

Throttle back-up valve (Blocked) Low reducing valve

19 Pressure regulator valve 20 3-2 timing valve 3-2 capacity valve

Thrott e valve

Forward clutch pressure.

Reverse clutch pressure-^^

1-2 accumulator .

Apply side 9

Oil pump

| Throttle pressure

Throttle modulated pressure

IHH Line pressure

Operating line pressure

I I Torque converter pressure

Manual valve