sensor MAZDA 626 1987 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 527 of 1865

DECELERATION CONTROL SYSTEM 4B

COMPONENT DESCRIPTIONS

Component Function Remarks

Brake light switch Detects braking operation (deceleration);

sends signal to engine control unit

Clutch switch Detects in-gear condition;

sends signal to engine control unit Switch ON when clutch pedal released

Dashpot (MTX) Prevents sudden closing of throttle valve during deceleration or shifting Adjustment speed: 1,900—2,100 rpm

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed in throttle sensor

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Neutral switch Detects in-gear condition; sends signal to engine control unit Switch ON when in-gear

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04B-089

4B—65

Page 528 of 1865

4B DECELERATION CONTROL SYSTEM

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to page 4B—7 and 8.)

Possible

^^ cause

Symptom

Dashpot Water thermo

sensor

Electrical signal

inspection

(Injector)

Possible

^^ cause

Symptom 4B—67 4B—97 4B-66

High idle speed after warming up 1

Runs rough on deceleration 1 3 2

Afterburn in exhaust system 1 3 2

Poor fuel consumption 1 3 2

Fails emission test 1 3 2

76G04B-090

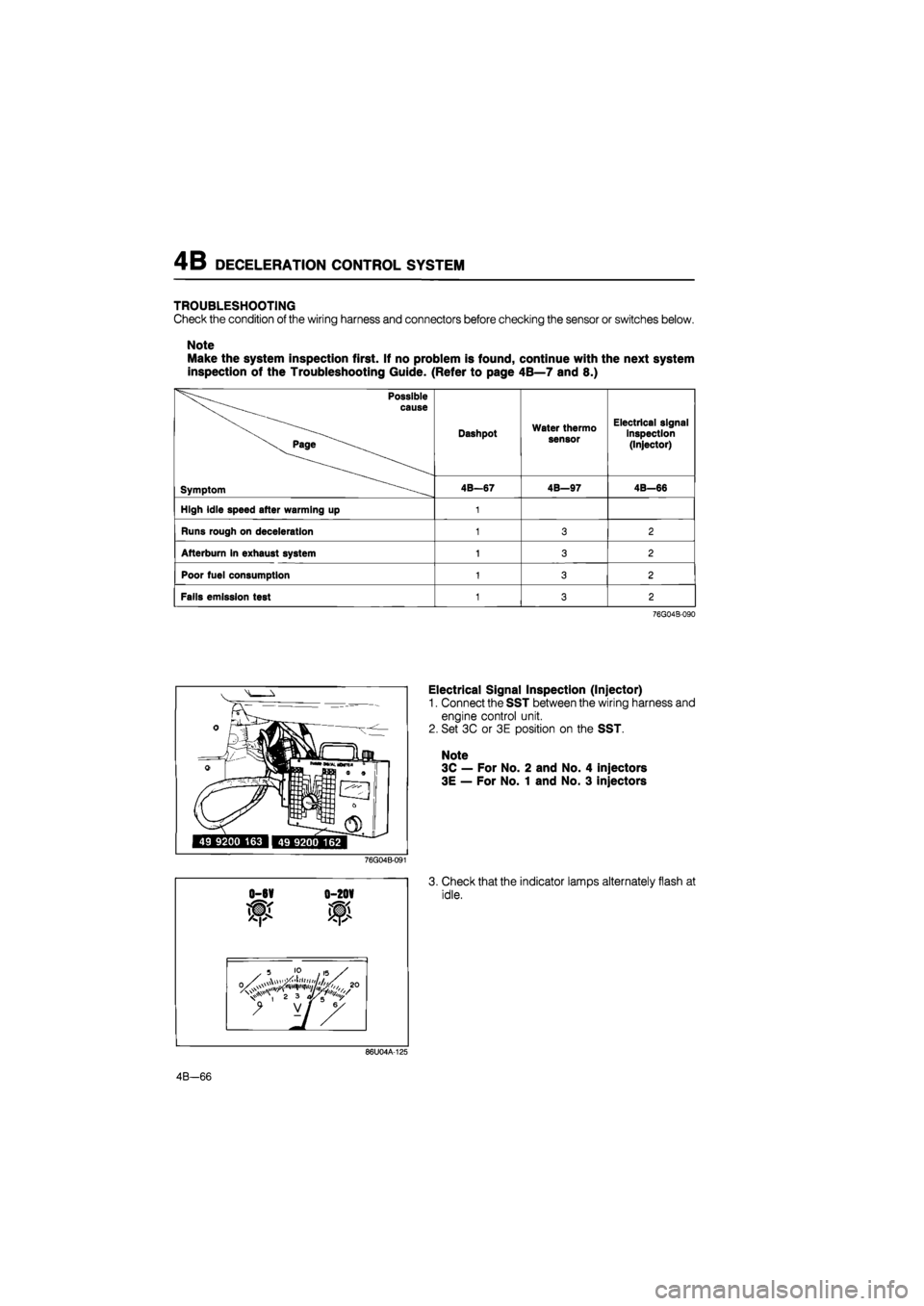

Electrical Signal Inspection (Injector)

1. Connect the SST between the wiring harness and

engine control unit.

2. Set 3C or 3E position on the SST.

Note

3C — For No. 2 and No. 4 injectors

3E — For No. 1 and No. 3 injectors

76G04B-091

0-6V 0-20V

3. Check that the indicator lamps alternately flash at

idle.

86U04A-125

4B—66

Page 531 of 1865

AIR INJECTION SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switch.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause Air control valve Reed valve System inspection

Page 4B—69 4B—70 4B—69

Checking order 2 3 1

76G04B-097

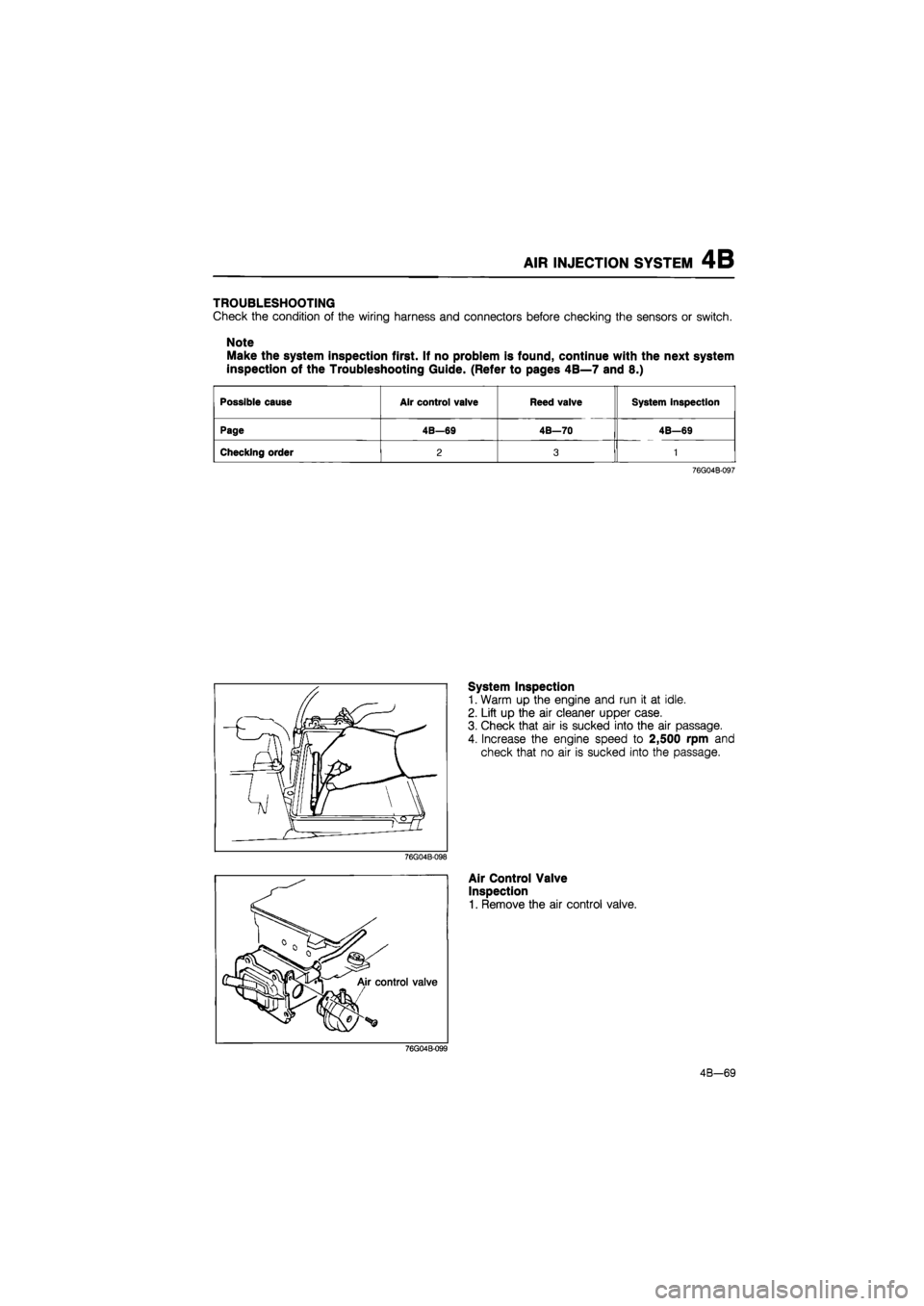

System Inspection

1. Warm up the engine and run it at idle.

2. Lift up the air cleaner upper case.

3. Check that air is sucked into the air passage.

4. Increase the engine speed to 2,500 rpm and

check that no air is sucked into the passage.

Air Control Valve

Inspection

1. Remove the air control valve.

4B-69

Page 533 of 1865

EGR SYSTEM 4B

EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM

EGR modulator valve Solenoid valve (EGR)

86U04A-127

This system introduces exhaust gas into the intake manifold to reduce NOx in the exhaust gas. It oper-

ates depending on the engine load, engine speed (above 1,500 rpm), engine coolant temperature

(above 70°C, 158°F), and radiator coolant temperature (above 17°C, 63°F).

COMPONENT DESCRIPTIONS

Component Function Remarks

EGR control valve Recirculates portion of exhaust gas

EGR modulator valve Controls vacuum acting on EGR control

valve

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (EGR)

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Solenoid valve (EGR) Controls vacuum line to EGR control

valve

Throttle sensor Detects throttle valve opening angle; sends signal to engine control unit Integrated idle switch

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit

ON: above 17°C (63°F)

76G04B-102

4B-71

Page 534 of 1865

4B EGR SYSTEM

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause

Solenoid

valve (EGR)

EGR modula-tor valve

EGR con-trol valve

Water

thermo sensor

Water

thermo switch

Engine control unit

terminal

System in-spection

2N

Page 4B—72 4B—73 4B—73 4B—97 4B—97 4B—90 4B—72

Checking order 3 2 4 6 5 7 1

76G04B-103

86U04A-130

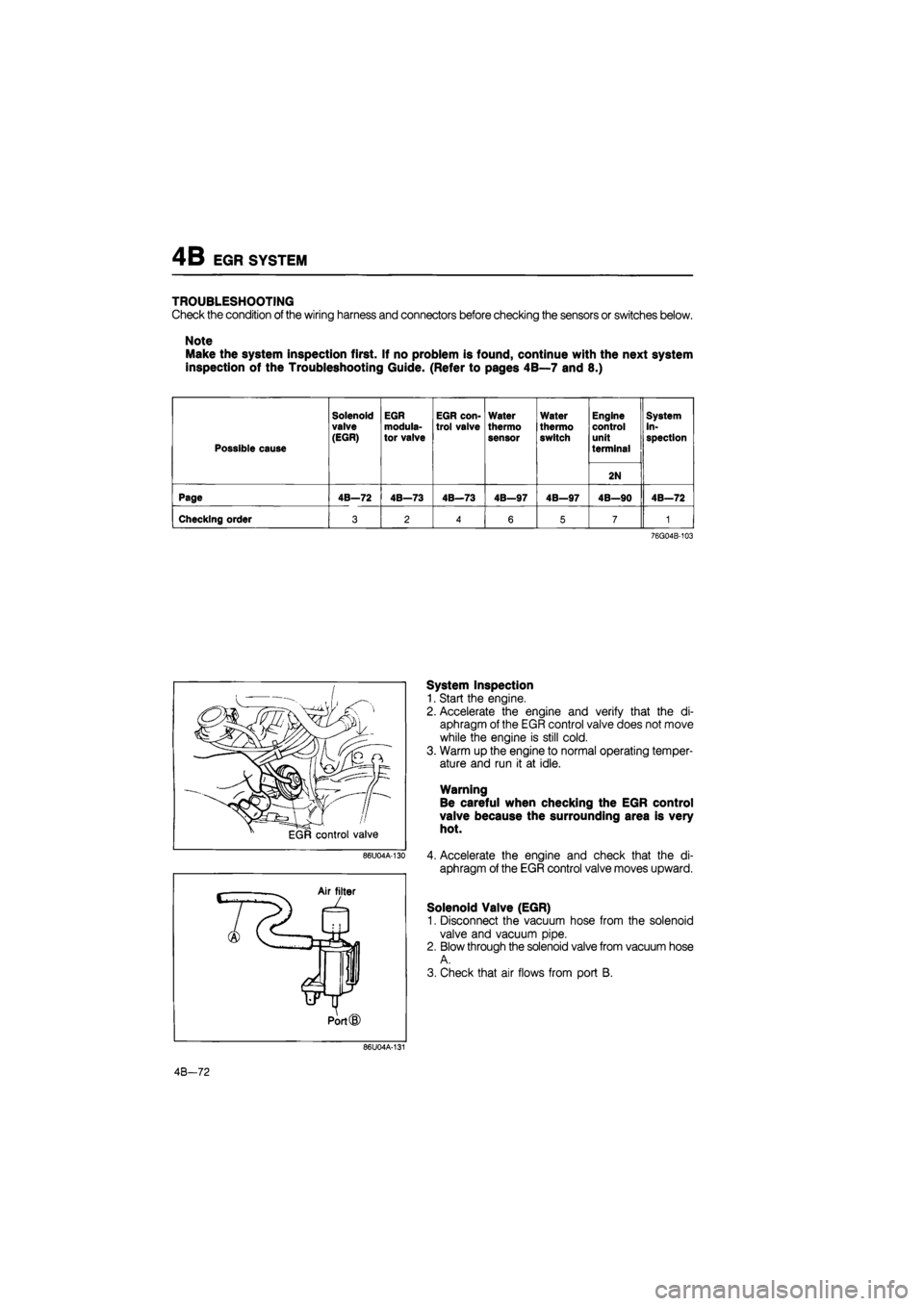

System Inspection

1. Start the engine.

2. Accelerate the engine and verify that the di-

aphragm of the EGR control valve does not move

while the engine is still cold.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve because the surrounding area is very

hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves upward.

Solenoid Valve (EGR)

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-131

4B-72

Page 536 of 1865

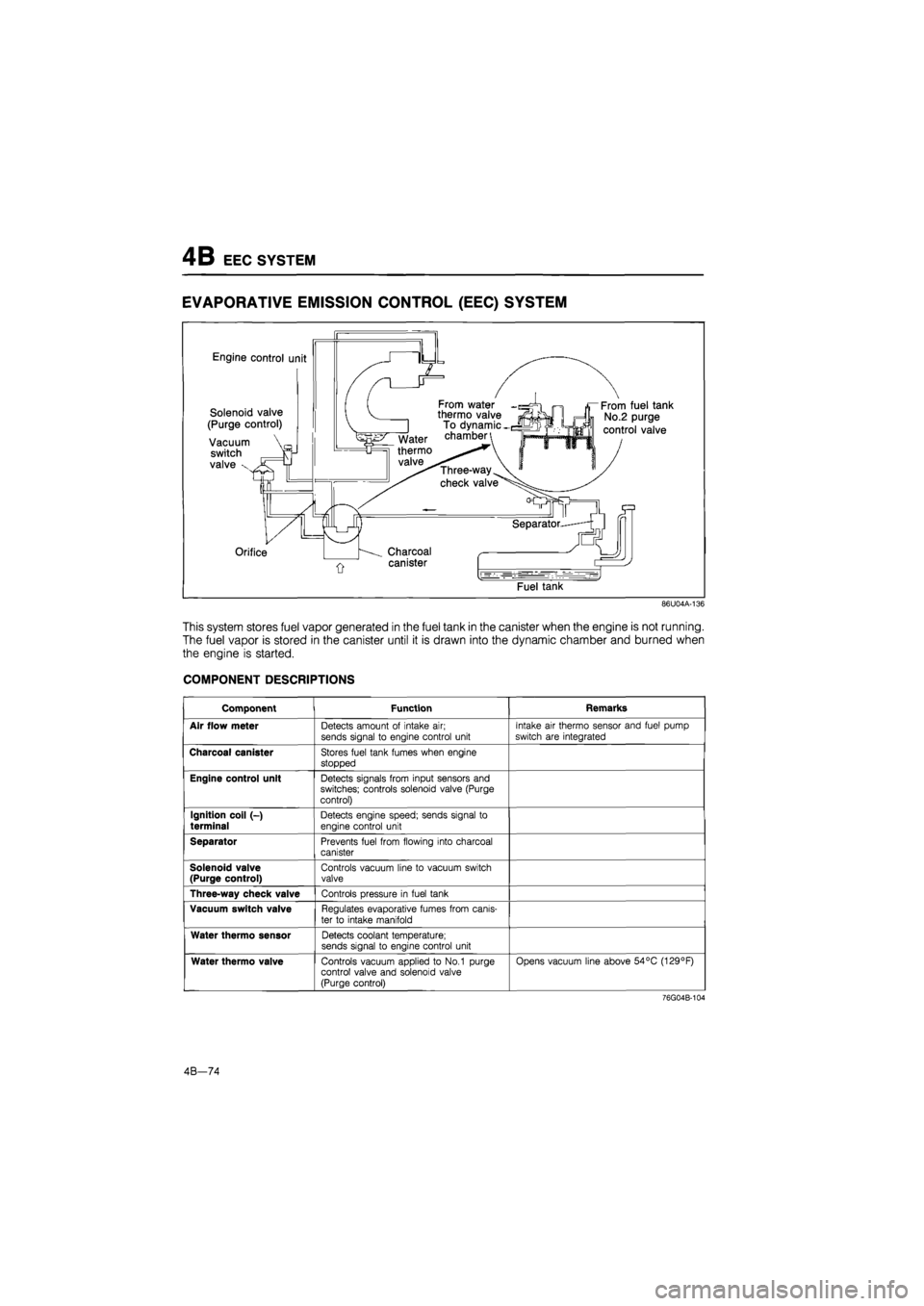

4B EEC SYSTEM

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Engine control unit

Solenoid valve

(Purge control)

Vacuum

switch

valve x

From water thermo valve To dynamic -chamber

Three-way

check valve

Orifice Charcoal

canister

From fuel tank

No.2 purge

control valve

Fuel tank

86U04A-136

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter Detects amount of intake air; sends signal to engine control unit

Intake air thermo sensor and fuel pump

switch are integrated

Charcoal canister Stores fuel tank fumes when engine

stopped

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Purge control)

Ignition coil (-)

terminal Detects engine speed; sends signal to

engine control unit

Separator Prevents fuel from flowing into charcoal canister

Solenoid valve (Purge control) Controls vacuum line to vacuum switch valve

Three-way check valve Controls pressure in fuel tank

Vacuum switch valve Regulates evaporative fumes from canis-

ter to intake manifold

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo valve Controls vacuum applied to No.1 purge control valve and solenoid valve (Purge control)

Opens vacuum line above 54°C (129°F)

76G04B-104

4B—74

Page 537 of 1865

EEC SYSTEM

4B

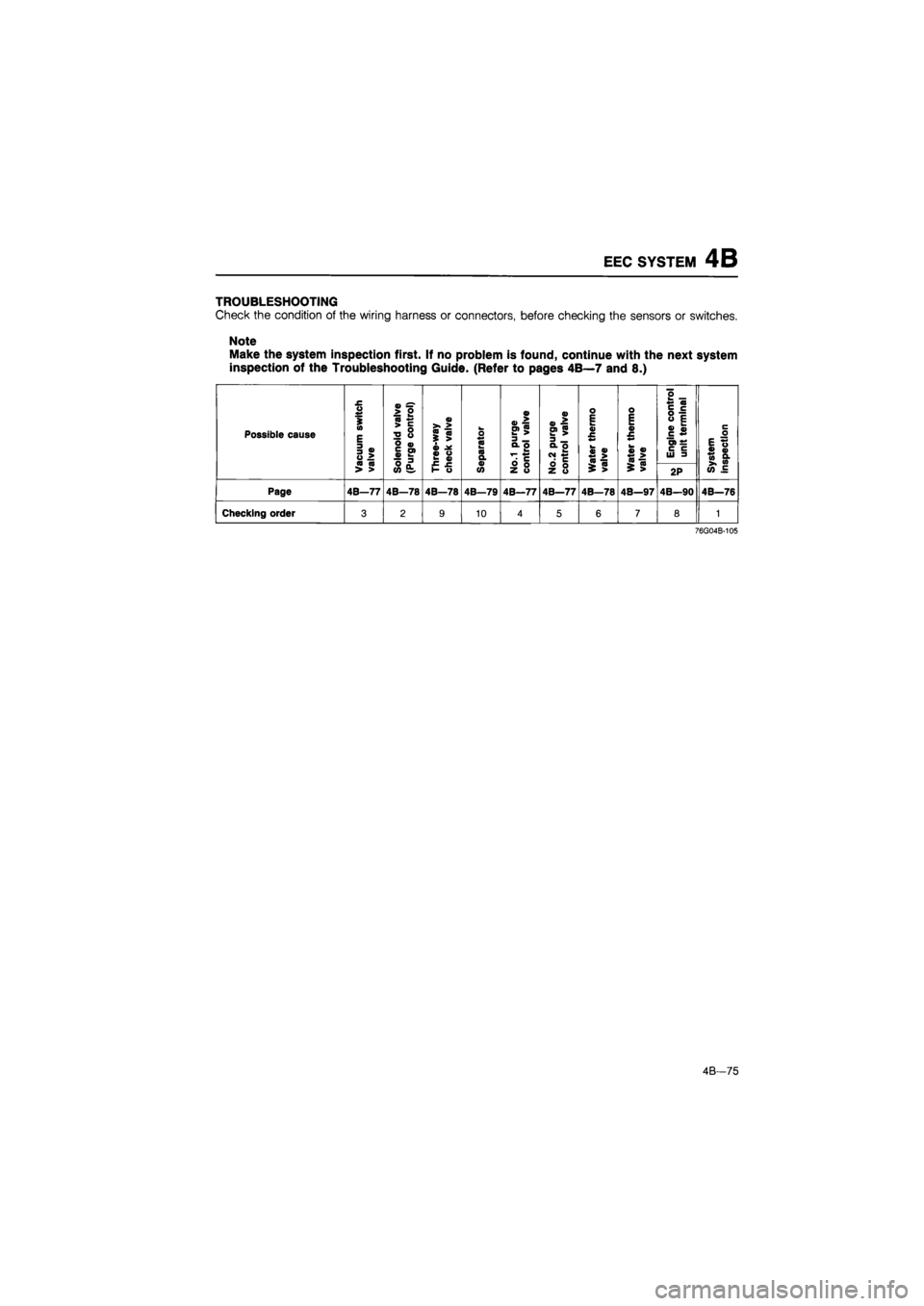

TROUBLESHOOTING

Check

the

condition

of the

wiring harness

or

connectors, before checking

the

sensors

or

switches.

Note

Make the system inspection first.

If no

problem

is

found, continue with

the

next system

inspection

of the

Troubleshooting Guide. (Refer

to

pages 4B—7 and

8.)

Possible cause

Vacuum

switch

valve

Solenoid

valve

(Purge

control)

0)

<0

m

i

>

« «

o

•C

?

o ** «0 a a

No.1

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

o E tm 0) £

«>

0)

^

>

Engine

control

unit

terminal

System inspection Vacuum

switch

valve

Solenoid

valve

(Purge

control)

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

$

>

2P

System inspection

Page 4B—77 4B—78 4B—78 4B—79 4B—77 4B—77 4B—78 4B—97 4B—90 4B—76

Checking order 3 2 9 10 4 5 6 7 8 1

76G04B-105

4B—75

Page 545 of 1865

CONTROL SYSTEM 4B

CONTROL SYSTEM

Atmospheric

pressue sensor

Engine control unit

Brake light switch

Clutch switch

Circuti opening

relay

E/L control unit

Air flow meter

Neutral switch

76G04B-129

The control system consists of the input devices and the engine control unit. The engine control unit

controls the fuel injection amount (EGI), fuel injection pressure, bypass air amount, switch monitor func-

tion, and fail-safe function.

4B—83

Page 546 of 1865

4B CONTROL SYSTEM

RELATIONSHIP CHART

Input Devices and Output Devices

BRAKE LIGHT SWITCH O X X X X X X X X X

ELECTRICAL LOAD CONTROL UNIT X X X X X X X X O X

P/S PRESSURE SWITCH* X X X X X X X X O X

A/C SWITCH O X X X X O O X X O

IGNITION SWITCH

(STA

POSITION) O O X O X X X X O O

INHIBITOR SWITCH o X X X O X X X X O

NEUTRAL

AND

CLUTCH SWITCH o X X X X X X X X O

OXYGEN SENSOR o X X X X X X X X X

WATER THERMO SWITCH (RADIATOR) o X X X O X X X X X

ATMOSPHERIC PRESSURE SENSOR o X X X X O X O O X

INTAKE

AIR

THERMO SENSOR o X X O X X X O O X

WATER THERMO SENSOR o X X O O O X X o X

IDLE SWITCH o o X O X X X X o X

THROTTLE SENSOR o O X X O X X X X O

AIR FLOW METER o X X X X O X X X X

IGNITION COIL o O X O O O X X o O

INPUT

DEVICES

OUTPUT

DEVICES

FUEL

INJECTION

AMOUNT FUEL

INJECTION

TIMING

PRESSURE

REGULATOR

EGR

PURGE

IDLE-UP

(A)*

IDLE-UP

(B)

IDLE-UP

(C)

rr

INPUT

DEVICES

OUTPUT

DEVICES

INJECTOR

AIR

VALVE

SOLENOID

VALVE

AIR

BYPASS

SOLENOID

VALVE

AIR

CONDITIONEI

76G04B-108

4B-84

Page 551 of 1865

CONTROL SYSTEM 4B

Terminal Input Output Connection to Voltage (After warming-up) Remarks Terminal Input Output Connection to IGN: ON Idle Remarks

1P — — — — —

1Q — — — — —

1R — — — — —

1S o Air bypass solenoid valve (Idle-up C) and P/S pressure switch

Battery voltage While solenoid ON (Refer to page 4B—35): below 1.5V

1T — — — — —

1U — — — — —

1V 0 MTX

Neutral and clutch switch

In-gear condition Clutch pedal depressed: battery voltage Clutch pedal released: below 1,5V

Neutral: constant battery voltage

1W O Test connector Test connector grounded: below 1,5V Test connector not grounded: battery voltage Green connector, 1-pin

1X — — — — —

2A o V ref 4.5—5.5V

2B 0 Air flow meter (Vc) 6-10V

2C — — Ground (E2) Approx. OV

2D o Oxygen sensor OV 0-1.OV • Cold engine: 0V at idle • After warming-up: Increase engine speed: 0.5—1.0V Deceleration: 0—0.4V

2E 0 Air flow meter (Vs) Approx. 1.7V Approx. 3—5V Increase engine speed:

voltage increases

2F — -— — —

2G 0 Throttle sensor Accelerator pedal released:

0.4—0.6 V

2H 0 Atmospheric pres-sure sensor At sea level: approx. 4.0V

21 0 Water thermo sensor 0.3—0.6 V Engine coolant temp. 20°C (68°F): approx. 2.5V

2J o Air flow meter (In-

take air thermo

sensor)

Approx. 2.3V at 20°C (68°F)

2K o Solenoid valve (Pres-

sure regulator

control)

For 120 sec. after ignition switch OFF - ON: below 1.5V

For 120 sec. after

starting: below 1.5V

Hot condition: Cool-ant temp, above 70°C (158°F) Intake air temp, above 10°C (50°F)

2K o Solenoid valve (Pres-

sure regulator

control)

Battery voltage Other conditions

2L — — — — —

2M — — —

4B-89