sensor MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 594 of 1865

INTAKE AIR SYSTEM 4C

76G04C-054

76G04C-055

76G04C-056

Removal Note

Water hose

Before disconnecting the water hose, drain two liters

of engine coolant.

Delivery pipe assembly.

1. Separate the fuel return pipe from the delivery pipe

assembly.

2. Remove the delivery pipe assembly and the fuel

return pipe.

PARTS INSPECTION

Air Cleaner Element

1. Check the condition of the air cleaner element.

2. Blow out the dust with compressed air, if

necessary.

Caution

a) The air cleaner must be replaced at the in-

tervals outlined in the maintenance

schedule.

b) Never drive the vehicle without the air

cleaner element, otherwise, damage to the

air flow sensor (hot wire) will occur.

c) Never use an oil permeated air cleaner ele-

ment, otherwise, contamination of the hot

wire will occur.

4C—33

Page 601 of 1865

7C VIC SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Dynamic chamber Provides chamber for VIC system operation Integrates one-way check valve

Engine control unit Monitors engine rpm, controls solenoid valve Unleaded fuel: ON at above 5200 rpm Leaded fuel: ON at above 5400 rpm

Intake manifold Provides short and long length of intake travel Integrates shutter valve

One-way check valve Holds vacuum in vacuum chamber Installed between dynamic chamber and vacuum chamber

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to control unit Installed in distributor

Solenoid valve (Vlfc) Controls vacuum to shutter valve actuator

Shutter valve Closes short intake port

Shutter valve actuator Actuates shutter valve according to

vacuum from solenoid valve

76G04C-066

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible cause

\Page\.

Symptom

Vacuum chamber (Vacuum leak)

Shutter valve actuator

One-way check valve

Solenoid valve (VIC) Engine control unit (1C)

System

Inspection

Possible cause

\Page\.

Symptom

Vacuum chamber (Vacuum leak)

Shutter valve actuator

One-way check valve Vacuum ' Electric signal | signal

Engine control unit (1C)

System

Inspection

Possible cause

\Page\.

Symptom 4C—42 4C—41 4C—43 4C—42 4C-98 4C—41

Rough idle

During warm up 2 3 4 — — — 1 Rough idle After warming up 2 3 4 — — — 1

Poor acceleration, hesitation,

or lack of power 6 5 7 2 3 4 1

Poor fuel consumption 6 5 7 2 3 4 1

76G04C-067

4C—40

Page 606 of 1865

ISC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

A/C switch Detects air conditioner operation; sends

signal to engine control unit Switch ON when air conditioner

operating

Air valve When cold, supplies bypass air into dy-namic chamber • Engine speed increased to shorten warm-up period • Thermo wax type

• Installed in BAC valve

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

E/L control unit Detects that E/L is being applied; sends

signal to engine control unit

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Idle speed control)

Idle switch Detects when throttle valve fully closed;

sends signal to engine control unit

Installed on throttle body

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

P/S pressure switch Detects P/S operation; sends signal to engine control unit Switch ON when steering wheel turned right or left

Solenoid valve (Idle speed control) Controls bypass air amount • Controlled by duty signal from engine control unit • Installed in BAC valve

• Operates idle-up

Test connector For initial idle speed adjustment • Gerrn, 1-pin

• Idle speed feedback control cancelled when connector grounded

Water thermo sensor Detects coolant temperature; sends

signal to engine control unit

76G04C-078

4C—45

Page 607 of 1865

4C

ISC

SYSTEM

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible cause

\Page

Symptom

Air valve P/S pres-sure switch

Solenoid

valve (Idle

speed

control)

Water

thermo

sensor

Engine control unit terminal System

In-

spection

Possible cause

\Page

Symptom

Air valve P/S pres-sure switch

Solenoid

valve (Idle

speed

control)

Water

thermo

sensor

1L 1W 2Q

System

In-

spection

Possible cause

\Page

Symptom 4C—47 4C—97 4C—48 4C—107 4C—98 4C—46

Engine

stalls

During warm up 2 — 3 4 — 5 6 1 Engine

stalls After warm up — 4 2 — 3 5 6 1

Rough

idle

During warm up 2 — 3 — — 4 5 1 Rough

idle After warm up 4 2 — 3 5 6 1

High idle speed after warm up 2 5 3 — 4 6 7 1

Runs rough on deceleration — — 2 — — 3 4 1

Afterburn in exhaust system 2 — 3 — — 4 5 1

Falls emission test 2 3 — — 4 5 1

76g04c-079

System Inspection

(Air valve)

1. Ground the test connector (Green, 1-pin) with a

jumper wire.

2. Disconnect the ISC valve connector (Gray, 2-pin)

at idle while the engine is cold.

3. Note the engine speed and reconnect the con-

nector.

4. Warm up the engine to the normal operating tem-

perature and disconnect the connector again.

5. Check that the engine speed is lower than that

when cold.

4C—46

Page 611 of 1865

4C FUEL SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Air flow sensor Detects amount of intake air;

sends signal to engine control unit

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

Engine control unit Detects signals from input sensors and switches; controls injector and fuel pump operations

Fuel filter Filters fuel

Fuel pump Provides fuel to injectors • Operates while engine running

• Installed in fuel tank

Fuel pump control unit (4WS) Monitors fuel level in left section; controls transfer pump operation

G signal pick-up Detects No.1 cylinder TDC; sends signal to engine control unit Installed in distributor

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed on throttle body

Ignition switch (ST position) Sends engine cranking signal to engine control unit

Injector Injects fuel into intake port • Controlled by signals from engine control unit • High-ohmic injector

Intake air thermo sensor Detects intake air temperature; send signal to engine control unit

Control relay Supplies electric current to injectors fuel pump and engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

Oxygen sensor (Unleaded fuel) Detects oxygen concentration; sends signal to engine control unit

• Zirconia ceramic and platinum coating • Integrated heater coil

Pressure regulator Adjusts fuel pressure supplied to injectors

Pulsation damper Absorbs fuel pulsation

Throttle sensor Detects throttle valve opening angle;

sends signal to engine control unit

Installed on throttle body

Transfer pump (4WS) Pumps fuel from the left to the right side Controlled by fuel pump control unit

Transfer pump switch (4WS) Detects fuel level in left section;

sends signal to control unit

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch (Unleaded fuel) Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04C-088

4C-50

Page 612 of 1865

FUEL SYSTEM

4C

TROUBLESHOOTING

Checking the condition of the wiring harness and connectors before checking the sensors or switches.

Note

If

no

problem

is

found, continue with inspection

of the

next system

of

Troubleshooting

Guide. (Refer

to

page 4C—10,

and 11)

Possible cause 0 CO £ O ** CO £ O "5

Page

o CO c 0> (A

S o c

w O M C

.fc <0 "o

^ o w c 0) <0 c « o>

Im O CO c w w

0>

!

41 10 o E k 0) £ **

d>

5 <0 O E ^ 0) £

w 0

Fuel

pump

Injector Fuel

pressure

Engine control

unit terminal

a. E 3 a

a> » c

Transfer

pump

sv

(4WS)

ha c o o

if Qj

«> S£

< g. X O £ 1-ID a 5

Fuel

pump

Injector Fuel

pressure

1Q 3C,3E 3F,3H 3B ID k_ H

Transfer

pump

sv

(4WS) 3

C

U.

3

Symptom *C—103 4C—110 4C—107 4C—104 4C—107 4C—106 4C-56 4C-57 4C-54 4C-98 40-59

Hard start

or

won't start (Cranks

OK)

— — —-— g — 1 7 — 2 8 6 3 4 5

Engine During warm

up

4 — — — 3 — — 2 1 — 5 — — — —

stalls After warm

up

1 — — — — — — 3 2 — 4 — — — —

Rough During warm

up

5 — — — 3 — — 2 1 — 4 — — — —

a> 3 Idle After warm

up

1 6 — — 4 — — 3 2 — 5 — — — —

•o a> •o (0 a> c -»

Poor acceleration, hesi-tation,

or

lack

of

power 1 — — 3 5 — — 4 2 — 6 — — — — •o a> •o (0 a> c -» Runs

rough on

deceleration 1 — — — — — — 2 — — 3 — — — —

Afterburn on deceleration 1 — — — — — — 2 — — 3 — — — —

Poor fuel consumption 6 — 5 — 4 — — 2 1 — 3 — — — —

Engine stalls

or

runs rough after hot starting 1 5 — — — — — 3 2 — 4 — — — —

Falls emission test — — 1 — — 2 — 3 — — 4 — — — —

Hard start

or

won't

start (Cranks

OK)

— — — — 9 — 1 7 — 2 8 6 3 4 5

Engine During warm

up

4 — — — 3 — — 2 1 — 5 — — — —

stalls After warm

up

1 — — — — — — 3 2 — 4 — — — —

Rough During warm

up

— — — 3 — — 2 1 — 4 — — — —

a> 3 Idle After warm

up

1 6 — — 4 — — 3 2 — 5 — — — —

•o a> •o a

Poor acceleration, hesi-tation,

or

lack

of

power 1 — — — 4 — — 3 2 — 5 — — — —

a> Runs rough on deceleration 1 — — — — — — 2 — — 3 — — — —

Afterburn on deceleration 1 — — — — — — 2 — — 3 — — — —

Poor fuel consumption 5 — — — 4 — — 2 1 — 3 — — — —

Engine stalls

or

runs rough after

hot

staring 1 5 — — — — — 3 2 — 4 — — — —

Falls emission test 1 ?

76G04C-089

4C—51

Page 630 of 1865

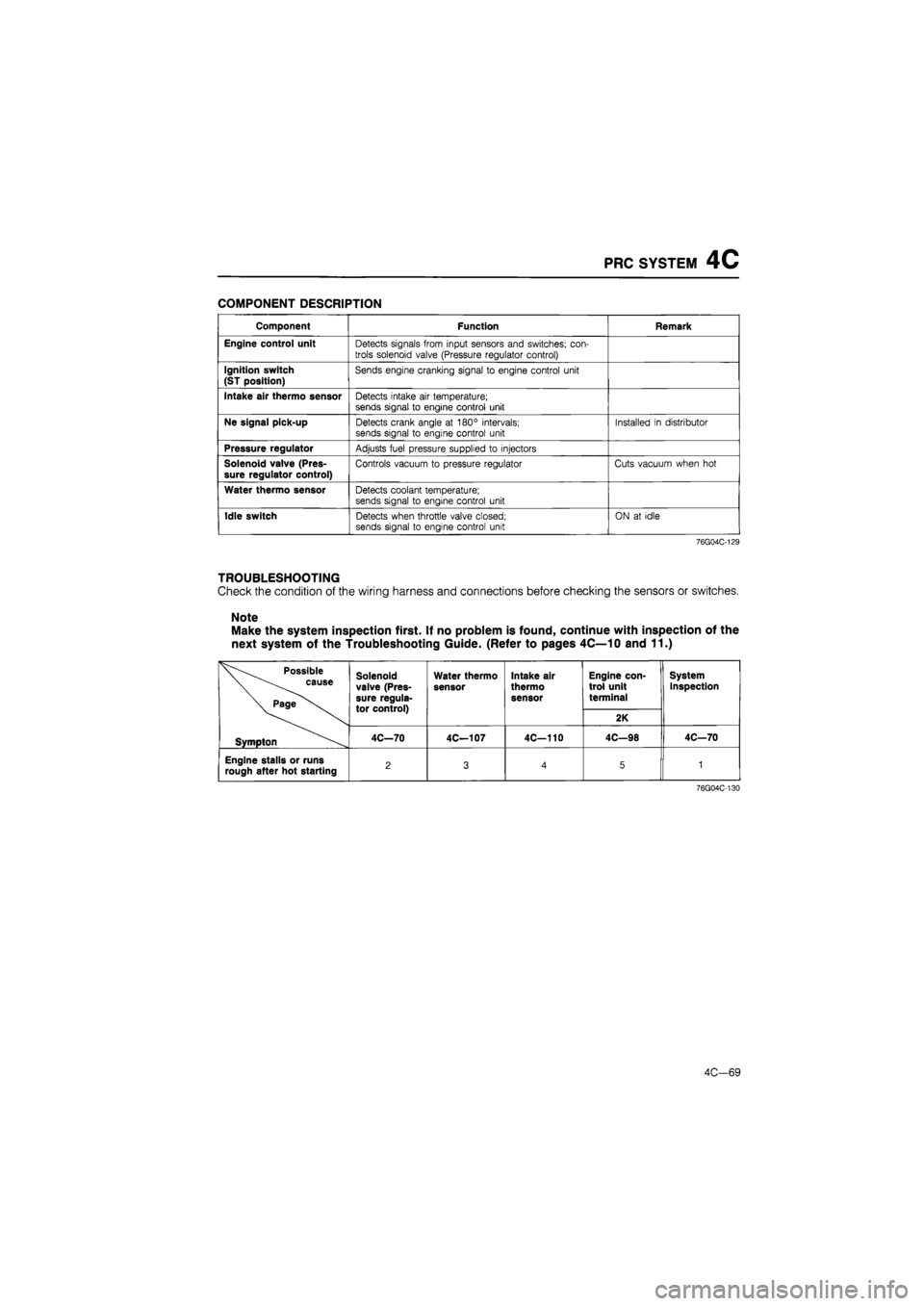

PRC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

Engine control unit Detects signals from input sensors and switches; con-trols solenoid valve (Pressure regulator control)

Ignition switch

(ST position)

Sends engine cranking signal to engine control unit

Intake air thermo sensor Detects intake air temperature; sends signal to engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Pressure regulator Adjusts fuel pressure supplied to injectors

Solenoid valve (Pres-

sure regulator control)

Controls vacuum to pressure regulator Cuts vacuum when hot

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Idle switch Detects when throttle valve closed; sends signal to engine control unit ON at idle

76G04C-129

TROUBLESHOOTING

Check the condition of the wiring harness and connections before checking the sensors or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible

\ cause

\ Page

Solenoid valve (Pres-sure regula-tor control)

Water thermo

sensor

Intake air

thermo

sensor

Engine con-trol unit terminal

System inspection Solenoid valve (Pres-sure regula-tor control) 2K

Symplon 4C—70 4C—107 4C-110 4C—98 4C—70

Engine stalls or runs rough after hot starting 2 3 4 5 1

76G04C-130

4C-69

Page 631 of 1865

4C PRC SYSTEM

System Inspection

1. Connect the SST to the engine. (Refer to page

4C-53.)

2. Start the engine.

76G04C-131

Hi?

Jpll ssil

Water thermo sensor ^^^Tta^e air thermo sensor

76G04C-132

Operating time Fuel line pressure kPa (kg/cm2, psi)

After starting: for 120 sec. 235-275 (2.4-2.8, 34-40)

After 120 sec. 186-226 (1.9-2.3, 27-33)

3. Warm up the engine to normal operating temper-

ature and stop the engine.

Warning

Be careful when disconnecting the water ther-

mo sensor connector because the surround-

ing area is very hot.

4. Disconnect the water thermo sensor connector.

Connect a resistor (200 fl) to the sensor connector.

5. Heat the intake air thermo sensor to above specifi-

cation.

Specification: 30°C (86°F)....unleaded fuel

50°C (122°F)....leaded fuel

6. Restart the engine.

7. Check the fuel line pressure and operating times

as shown in the chart.

76G04C-133

Solenoid Valve (Pressure Regulator Control)

Inspection

1. Disconnect the vacuum hose from the vacuum

pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

76G04C-134

4C—70

Page 633 of 1865

4C DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

Distributor

(Ne signal)

Idle switch

QSO-Water thermo sensor

=5

A/C switch

Engine control unit

Detection of

fuel cut

condition Determi-

nation of

fuel cut

speed

* *

1

T

No.3

I

No.4

No.2

The fuel cut system is provided as a deceleration control system.

This system is to improve fuel consumption.

86U04A-121

4C—72

Page 634 of 1865

DECELERATION CONTROL SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remarks

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit ON at idle

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

76G04C-135

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to page 4C—10 and 11.)

Possible cause Water thermo sensor System inspection

Page 4C—107 4C—74

Checking order 2 1

76G04C-136

4C-73