torque MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1480 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

86U11X-170

86U11X-171

Removal of Front Wheel Speed Sensor

1. Remove the wheel and tire.

2. Remove the parts shown in the figure, and remove

the sensor from the knuckle.

Installation of Front Wheel Speed Sensor

1. Install the sensor to the knuckle.

Tightening torque:

16—23 N m (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

The left and right sensors are not interchange-

able. L or R is indicated on the bracket.

2. Install the sensor harness bracket onto the knuckle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

3. Push the sensor harness through the splash shield

and secure it with the clip.

4. Install the sensor harness bracket to the body.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

Verify that the harness is not twisted and does

not contact the shock absorber or body when

the steering wheel is turned.

5. Connect the sensor connector.

6. Install the wheel and tire.

86U11X-172

11-88

Page 1481 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

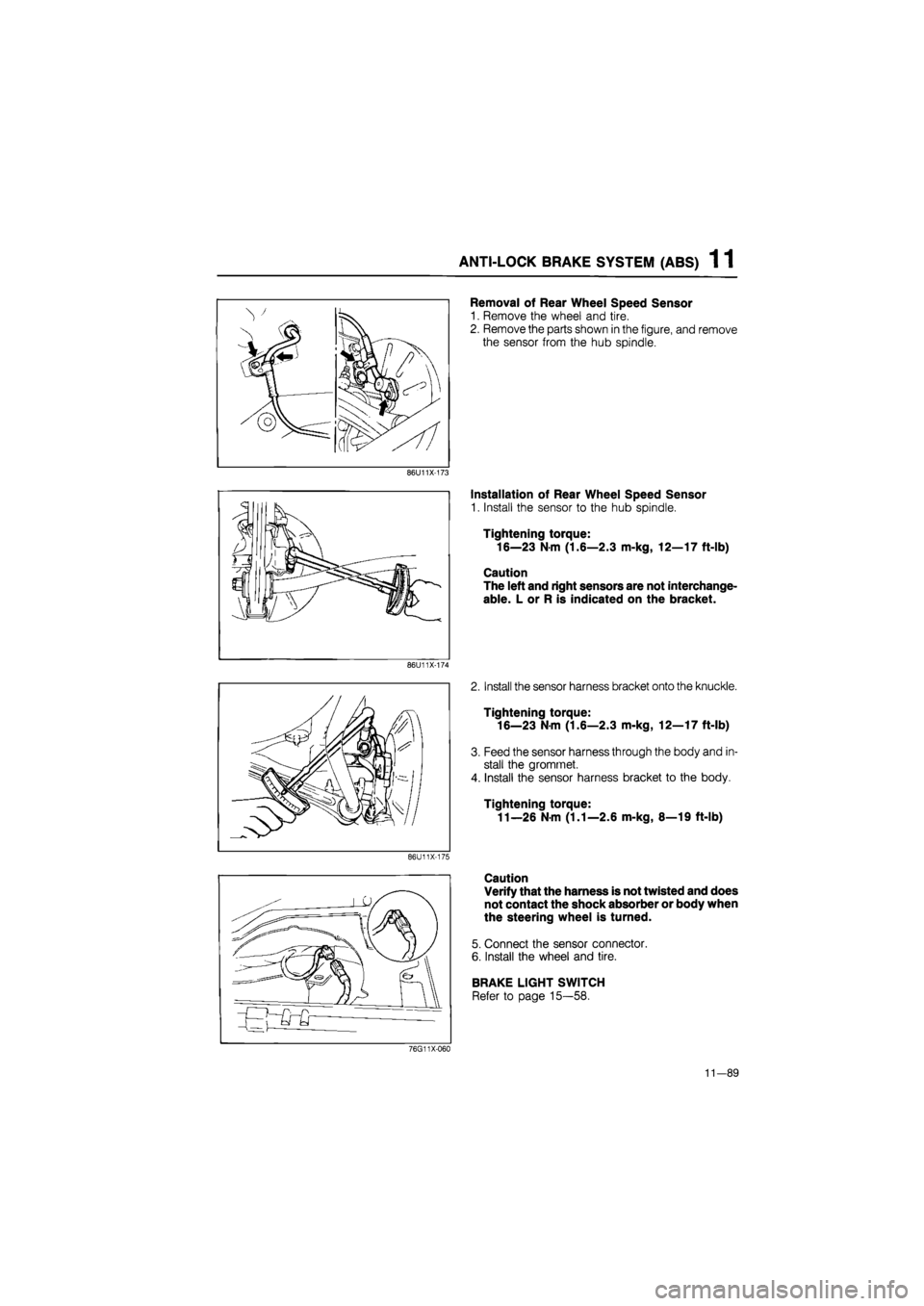

Removal of Rear Wheel Speed Sensor

1. Remove the wheel and tire.

2. Remove the parts shown in the figure, and remove

the sensor from the hub spindle.

86U11X-173

86U11X-174

86U11X-175

Installation of Rear Wheel Speed Sensor

1. Install the sensor to the hub spindle.

Tightening torque:

16—23 N m (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

The left and right sensors are not interchange-

able. L or R is indicated on the bracket.

2. Install the sensor harness bracket onto the knuckle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

3. Feed the sensor harness through the body and in-

stall the gromrnet.

4. Install the sensor harness bracket to the body.

Tightening torque:

11—26 N m (1.1—2.6 m-kg, 8—19 ft-lb)

Caution

Verify that the harness is not twisted and does

not contact the shock absorber or body when

the steering wheel is turned.

5. Connect the sensor connector.

6. Install the wheel and tire.

BRAKE LIGHT SWITCH

Refer to page 15—58.

76G11X-060

11-89

Page 1483 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

Installation of Front Sensor Rotor

Install in the reverse order of removal, referring

Torque specifications

Removal note

Sensor rotor

Tap the sensor rotor off the drive shaft with a chisel.

to installation note for the specially marked parts.

Installation note

Sensor rotor

Press the sensor rotor onto the driveshaft with the

SST.

Caution

Install the sensor rotor with chamfered edge

toward the driveshaft.

11—91

Page 1485 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

Installation of Rear Sensor Rotor

Install in the reverse order of removal, referring to installation note for the specially marked parts.

Torque specifications

86U11X-184

Installation

Sensor rotor

Press the sensor rotor onto the hub with the SST.

86U11X-185

Locknut

1. Install and tighten the locknut.

2. Stake a new locknut securely in the driveshaft

groove.

Caution

Do not use a pointed tool for staking.

3. Check that the hub rotates freely by hand.

86U11X-186

11—93

Page 1490 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

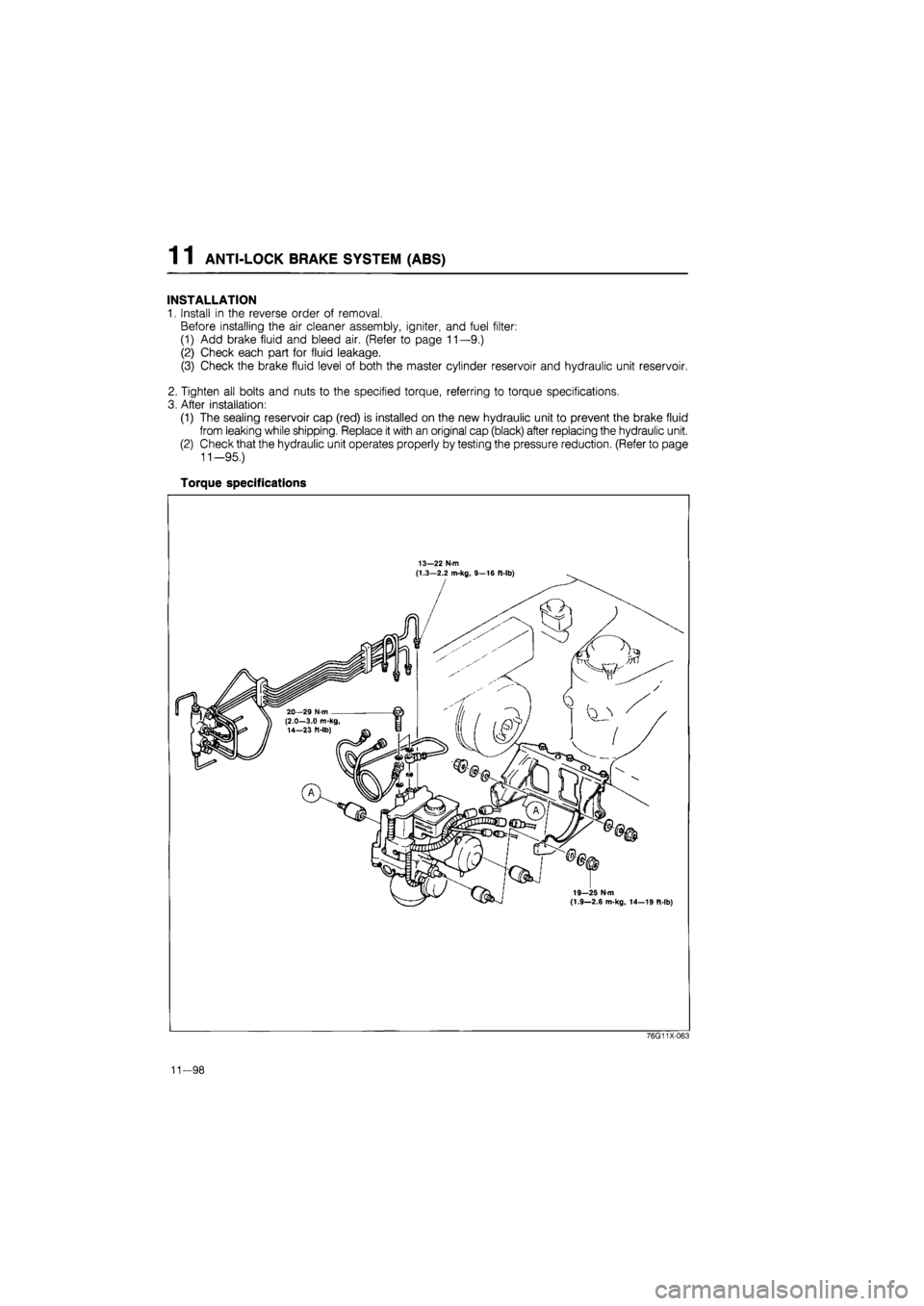

INSTALLATION

1. Install in the reverse order of removal.

Before installing the air cleaner assembly, igniter, and fuel filter:

(1) Add brake fluid and bleed air. (Refer to page 11—9.)

(2) Check each part for fluid leakage.

(3) Check the brake fluid level of both the master cylinder reservoir and hydraulic unit reservoir.

2. Tighten all bolts and nuts to the specified torque, referring to torque specifications.

3. After installation:

(1) The sealing reservoir cap (red) is installed on the new hydraulic unit to prevent the brake fluid

from leaking while shipping. Replace it with an original cap (black) after replacing the hydraulic unit.

(2) Check that the hydraulic unit operates properly by testing the pressure reduction. (Refer to page

11-95.)

Torque specifications

11-98

Page 1496 of 1865

WHEELS AND TIRES 1 2

WHEEL BALANCE

If a wheel becomes unbalanced or if a tire is replaced

or repaired, the wheel must once again be balanced

to within specification.

Maximum unbalance (at rim edge): g (oz)

13 inch-wheel 11 (0.39)

14 inch-wheel 10 (0.35)

15 inch-wheel 9 (0.32)

76G12X-005

Balance

weight

Outside

Balance

weight

86U12X-011

Caution

a) Do not use more than two balance weights

on the inner or outer side of the wheel, if

the total weight exceeds 100 g (3.5 oz), re-

balance after moving the tire around on the

rim.

b) Attach the balance weights tightly so that

they do not protrude more than 3 mm (0.12

in) beyond the wheel edge.

c) Select suitable balance weights for steel or

aluminum alloy wheels.

d)Do not use an on-car balancer on ATX

models. Use of this type of balancer may

cause clutch damage.

WHEEL MOUNTING

Tighten the lug nuts to the specified torque in a criss-

cross fashion.

Tightening torque:

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

Caution

a) The wheel-to-hub contact surfaces must be

clean.

b) Never apply oil to the nuts, bolts, or wheels;

doing so might cause looseness or seizure

of the lug nuts.

86U12X-012

SPECIAL NOTE

Regarding wheels and tires:

1. Do not use wheels or tires other than the specified types.

2. Aluminum wheels are easily scratched. When washing them, use a soft cloth, never a wire brush.

If the vehicle is steam cleaned, do not allow boiling water to contact the wheels.

3. If alkaline compounds (such as salt water or road salts), get on aluminum wheels, wash them as

soon as possible to prevent damage. Use only a neutral detergent.

86U12X-013

12-5

Page 1510 of 1865

FRONT SHOCK ABSORBER AND SPRING 1 3

FRONT SHOCK ABSORBER AND SPRING

REMOVAL AND INSTALLATION

1. Jack up the front of the vehicle and support it with safety stands.

2. Remove in the sequence shown in the figure, referring to the removal note for specially marked parts.

3. Install in the reverse order of removal, referring to the installation note for specially marked parts.

4. Tighten all nuts and bolts to the specified torque, referring to the figure.

.CD

46—63 N m (4.7—6.4 m-kg, 34—46 ft-lb)

8—11 Nm (80—110 cm-kg, 69—95 In-lb)

93-117 N-m . (9.5-11.9 m-kg, 69—86 ft-lb)

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

11—25 N-m (1.1—2.6 m-kg, 8.0—19 ft-lb)

1. Lug nut

2. Wheel and tire

3. Clip

4. Harness and bracket bolt

(ABS)

5. Rubber cap

6. Actuator (AAS)

7. Nuts and bolts (Ignition coil

bracket)

76G13X-012

8. Bolt and nut

9. Nut

10. Shock absorber assembly

11. Seat

86U13X-010

Removal Note

ABS Harness bracket

Remove the ABS harness and bracket.

13—13

Page 1511 of 1865

1 3 FRONT SHOCK ABSORBER AND SPRING

AAS actuator

1. Disconnect the AAS actuator connector.

2. Remove the AAS actuator.

86U13X-011

Shock absorber clinch bolts and nuts

1. Remove the shock absorber clinch bolts and nuts.

2. Remove the shock absorber upper mounting nuts.

76G13X-013

Installation Note

Mounting block

Install the mounting block to the suspension tower

with the white mark facing the front-inside direction.

Tightening torque: 46—63 N-m

(4.7—6.4 m-kg, 34—46 ft-lb)

86U13X-013

Shock absorber clinch bolts and nuts

Install the clinch bolts and nuts.

Tightening torque: 93—117

N

m

(9.5—11.9 m-kg, 69—86 ft-lb)

86U13X-014

13—14

Page 1512 of 1865

FRONT SHOCK ABSORBER AND SPRING 1 3

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the sequence shown in the figure, referring to the disassembly note for specially

marked parts.

2. Inspect all components and parts, referring to inspection note.

3. Assemble in the reverse order of disassembly, referring to the assembly note for specially marked

parts.

4. Tighten all nuts and bolts to the specified torque, referring to the figure.

76G13X-014

1. Nut

2. Actuator bracket

3. Mounting block

4. Bearing

5. Spring upper seat

6. Spring seat

7. Dust boot

8. Bound stopper

9. Coil spring

10. Shock absorber

13—15

Page 1514 of 1865

FRONT SHOCK ABSORBER AND SPRING 1 3

Assembly Note

1. Set the SST in a vise

2. Secure the shock absorber in the SST.

3. Install the bound stopper and dust boot to the

shock absorber.

4. Install the compressed coil spring (compressed

with SST).

5. Install the rubber seat, spring upper seat, bearing

and mounting block.

86U13X-021

6. Remove the SST.

7. Secure the mounting block in a vise.

Caution

Use copper or aluminum plates in the jaws of

a vice.

8. Tighten the piston rod upper nut.

Tightening torque:

64—84 Nm (6.5—8.2 m-kg, 47—59 ft-lb)

Caution

Check that the spring is well seated in the up-

per seats.

13—17