MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 941 of 1865

ON-VEHICLE MAINTENANCE 7B

'mfm^i! kfOl iff t—

76G07B-093

76G07B-094

Main fuse block (G4A-EL)

Install the main fuse block.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

Battery carrier

Install the battery carrier.

Tightening torque:

31—40 Nm (3.2—4.1 m-kg, 23—30 ft-lb)

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks. (Refer to page

7 B—71)

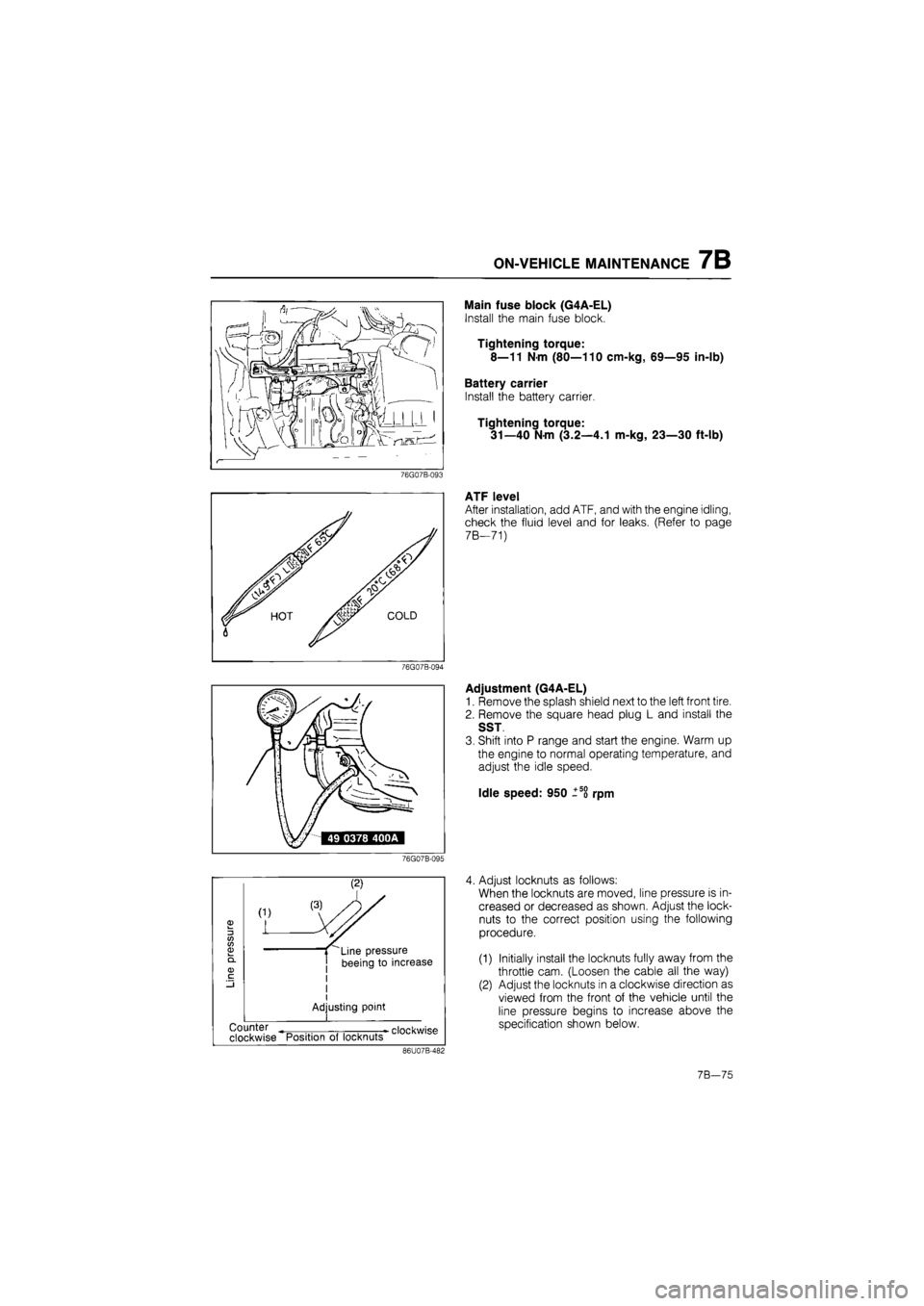

Adjustment (G4A-EL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug L and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 950 ±5o rpm

76G07B-095

3 CO CO 03

(1)

L

Line pressure

beeing to increase

I

Adjusting point

•

clockwise Counter

clockwise Position of locknuts

86U07B-482

4. Adjust locknuts as follows:

When the locknuts are moved, line pressure is in-

creased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

line pressure begins to increase above the

specification shown below.

7B—75

Page 942 of 1865

7B ON-VEHICLE MAINTENANCE

Line pressure decreases

Line pressure increases

86U07B-483

Protector

-7 / Throttle cable

86U07B-080

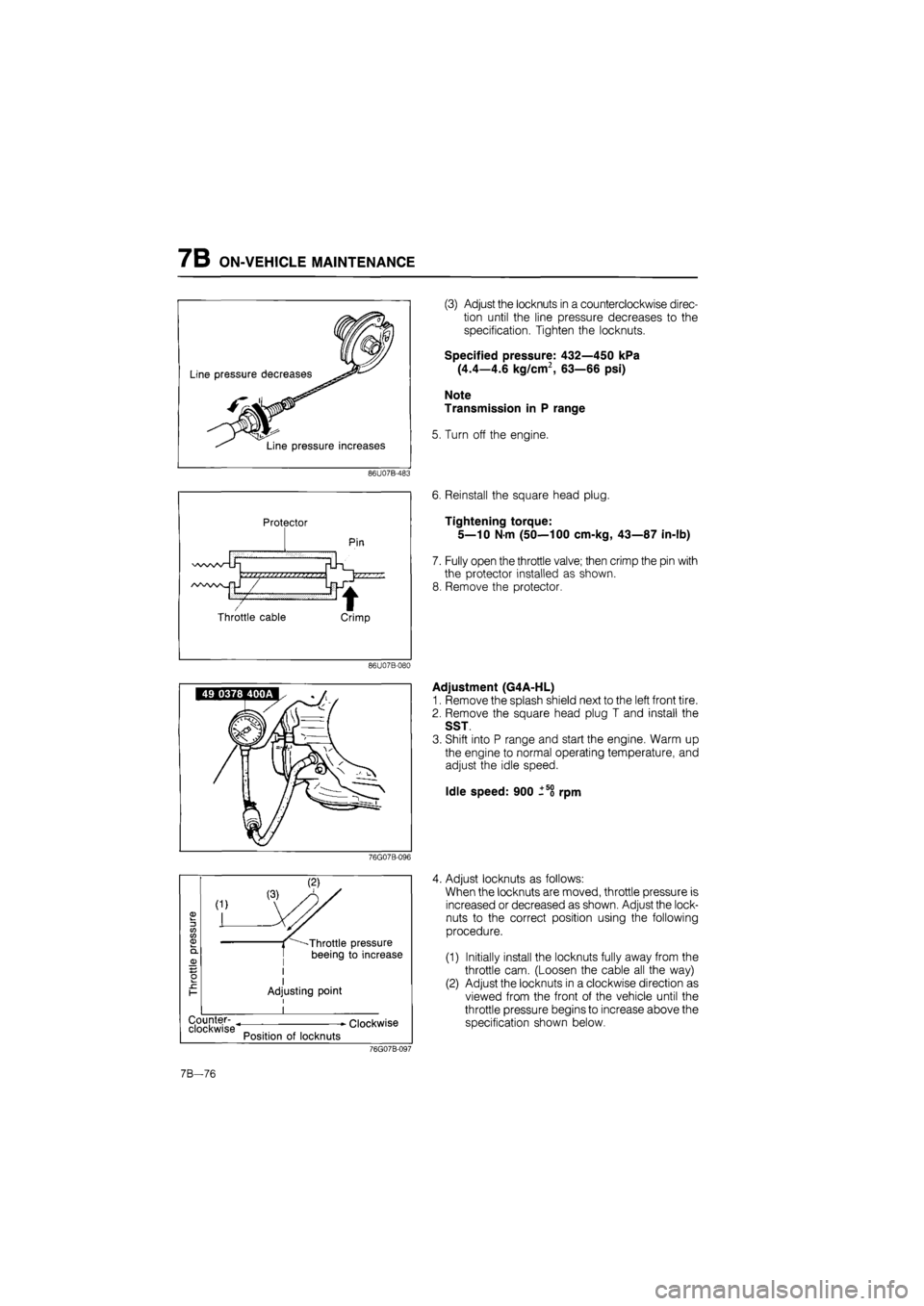

(3) Adjust the locknuts in a counterclockwise direc-

tion until the line pressure decreases to the

specification. Tighten the locknuts.

Specified pressure: 432—450 kPa

(4.4—4.6 kg/cm2, 63—66 psi)

Note

Transmission in P range

5. Turn off the engine.

6. Reinstall the square head plug.

Tightening torque:

5—10 N m (50—100 cm-kg, 43—87 in-lb)

7. Fully open the throttle valve; then crimp the pin with

the protector installed as shown.

8. Remove the protector.

Adjustment (G4A-HL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug T and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 900 -5o rpm

76G07B-096

3 tn tn

L

Counter- ^ clockwise

Throttle pressure

beeing to increase

I Adjusting point

Position of locknuts

Clockwise

4. Adjust locknuts as follows:

When the locknuts are moved, throttle pressure is

increased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

throttle pressure begins to increase above the

specification shown below.

76G07B-097

7B—76

Page 943 of 1865

ON-VEHICLE MAINTENANCE 7B

Line pressure decreases

Line pressure increases

76G07B-098

Protector

NAAA/V^

/NA/w^nJ

Throttle cable Crimp

86U07B-080

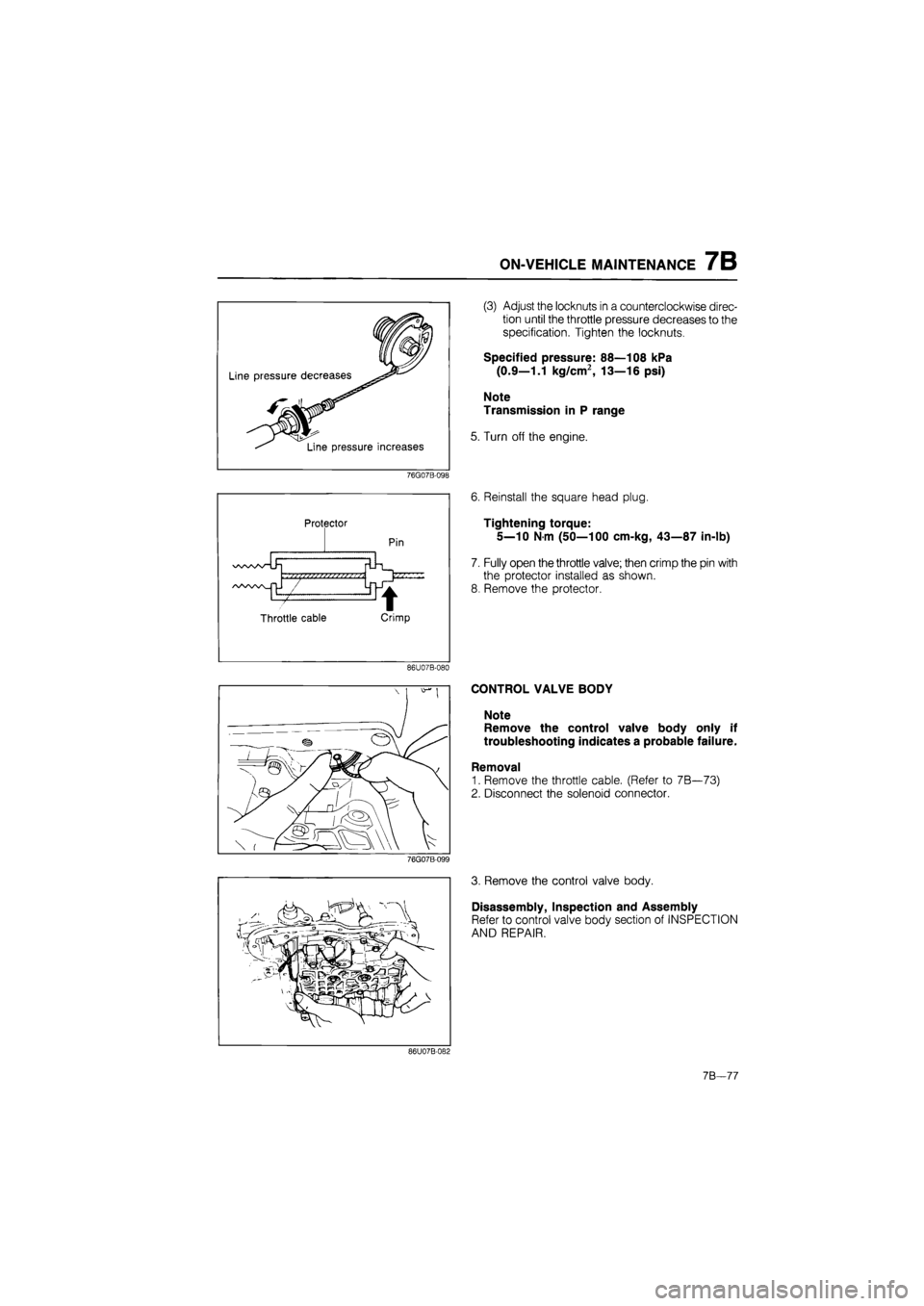

(3) Adjust the locknuts in a counterclockwise direc-

tion until the throttle pressure decreases to the

specification. Tighten the locknuts.

Specified pressure: 88—108 kPa

(0.9—1.1 kg/cm2, 13—16 psi)

Note

Transmission in P range

5. Turn off the engine.

6. Reinstall the square head plug.

Tightening torque:

5—10 N m (50—100 cm-kg, 43—87 in-lb)

7. Fully open the throttle valve; then crimp the pin with

the protector installed as shown.

8. Remove the protector.

CONTROL VALVE BODY

Note

Remove the control valve body only if

troubleshooting indicates a probable failure.

Removal

1. Remove the throttle cable. (Refer to 7B—73)

2. Disconnect the solenoid connector.

76G07B-099

3. Remove the control valve body.

Disassembly, Inspection and Assembly

Refer to control valve body section of INSPECTION

AND REPAIR.

86U07B-082

7B—77

Page 944 of 1865

7B ON-VEHICLE MAINTENANCE

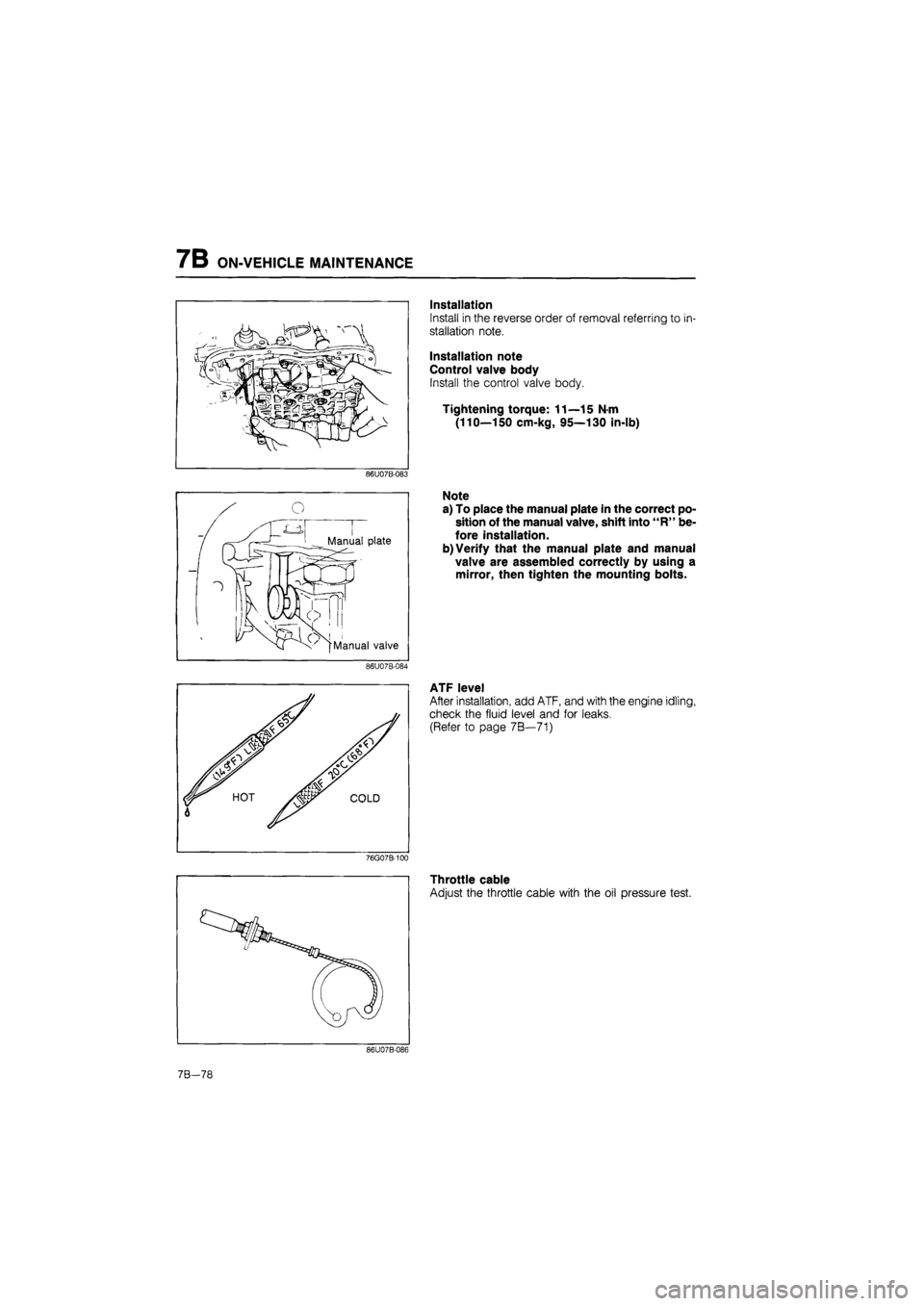

Installation

Install in the reverse order of removal referring to in-

stallation note.

Installation note

Control valve body

Install the control valve body.

Tightening torque: 11—15 N-m

(110—150 cm-kg, 95—130 in-lb)

86U07B-083

Note

a) To place the manual plate in the correct po-

sition of the manual valve, shift into "R" be-

fore installation.

b) Verify that the manual plate and manual

valve are assembled correctly by using a

mirror, then tighten the mounting bolts.

86U07B-084

w v

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks.

(Refer to page 7B—71)

76G07B-100

Throttle cable

Adjust the throttle cable with the oil pressure test.

86U07B-086

7B-78

Page 945 of 1865

ON-VEHICLE MAINTENANCE 7B

OIL STRAINER

Removal

1. Jack up the vehicle and support it with safety

stands.

2. Drain the ATF.

3. Remove the left side splash shield.

86U07B-087

86U07B-088

Inspection

Check the following and repair or replace any faulty

parts.

1. Deformed or cracked oil pan

2. Deformed or clogged oil strainer

86U07B-089

Installation

1. Apply ATF to the O-ring and install it onto the oil

strainer.

2. Install the oil strainer.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

86U07B-090

7B-79

Page 946 of 1865

7B ON-VEHICLE MAINTENANCE

86U07B-091

76G07B-101

76G07B-102

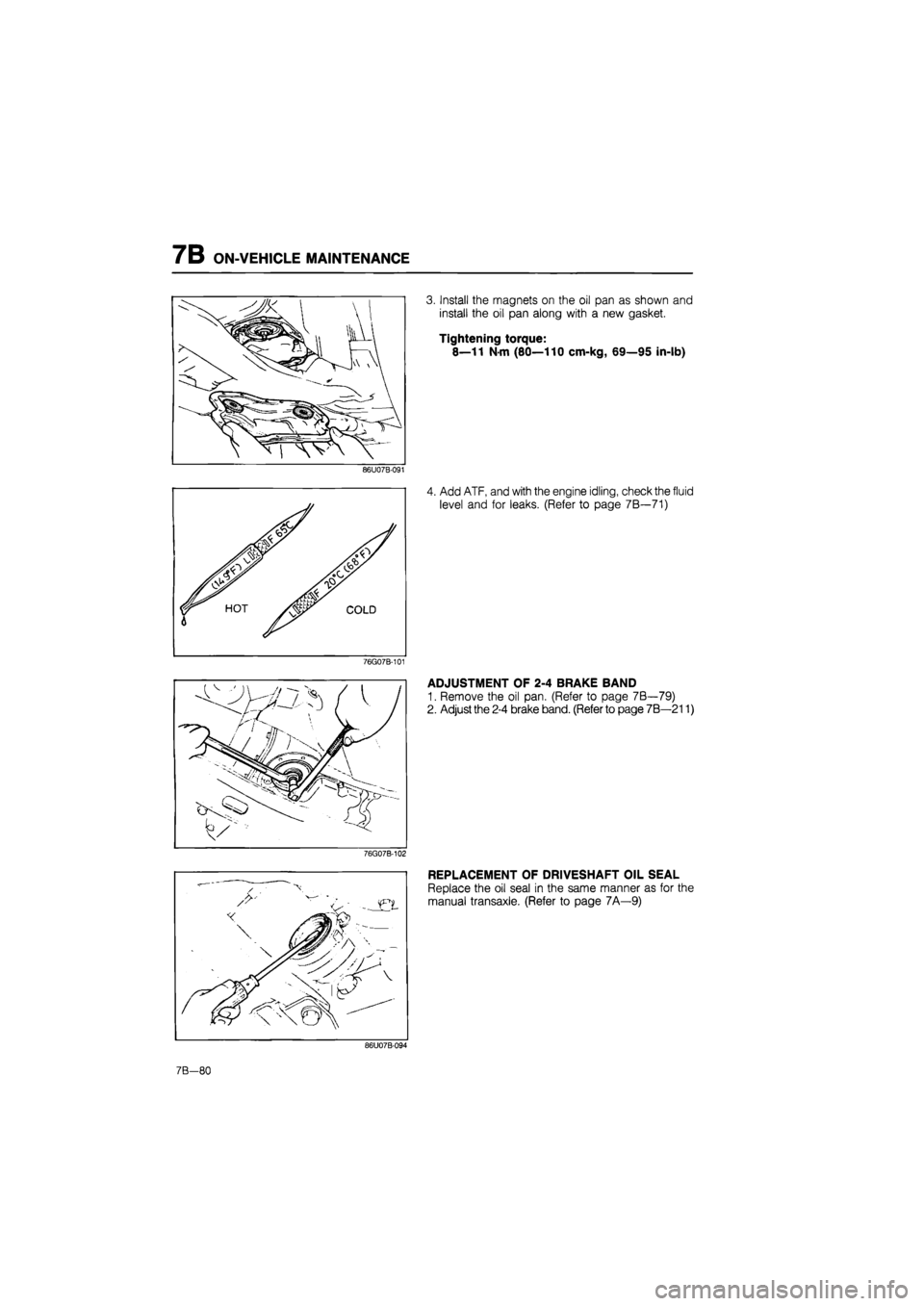

3. Install the magnets on the oil pan as shown and

install the oil pan along with a new gasket.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

4. Add ATF, and with the engine idling, check the fluid

level and for leaks. (Refer to page 7B—71)

ADJUSTMENT OF 2-4 BRAKE BAND

1. Remove the oil pan. (Refer to page 7B—79)

2. Adjust the 2-4 brake band. (Refer to page 7B—211)

REPLACEMENT OF DRIVESHAFT OIL SEAL

Replace the oil seal in the same manner as for the

manual transaxle. (Refer to page 7A—9)

86U07B-094

7B-80

Page 947 of 1865

OH -VEHICLE MAmTENANSl

3. Remove

OIL COOLER

the oil cooler.

cSckmetollowing and repair or replace

2 Bent fins (repair w

any faulty

Installation Install the oi! cooler referring to installation note.

Installation note

OH cooler Install the oil cooler.

Tightening torque: 8—11 N-m (SO—1W cm-kg, 69—95 in-lb)

i5U07B-098 76-81

Page 948 of 1865

7B ON-VEHICLE MAINTENANCE

GOVERNOR (G4A-HL)

Removal

1. Remove the clip from the governor cover.

2. Remove the stopper bolt; then remove the gover-

nor assembly.

76G07B-103

Disassembly, Inspection and Assembly

Refer to Governor section of INSPECTION AND

REPAIR.

76G07B-104

Installation

Install in the reverse order of removal referring to in-

stallation note.

Installation note

Stopper bolt

Tighten the stopper bolt.

Tightening torque:

6—9 Nm (60—90 cm-kg, 52—78 in-lb)

76G07B-105

7B-82

Page 949 of 1865

REMOVAL 7B

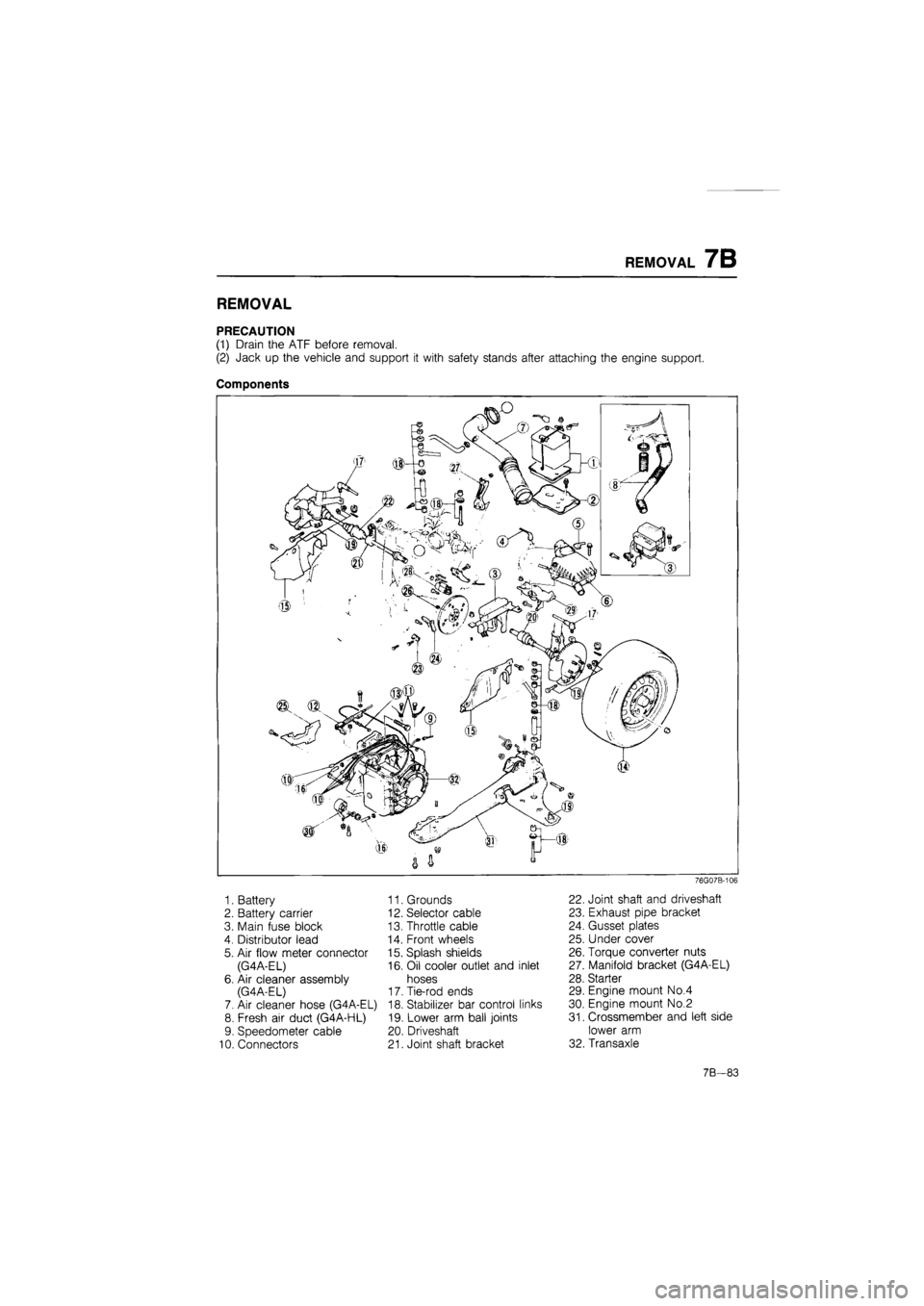

REMOVAL

PRECAUTION

(1) Drain the ATF before removal.

(2) Jack up the vehicle and support it with safety stands after attaching the engine support.

Components

1. Battery

2. Battery carrier

3. Main fuse block

4. Distributor lead

5. Air flow meter connector

(G4A-EL)

6. Air cleaner assembly

(G4A-EL)

7. Air cleaner hose (G4A-EL)

8. Fresh air duct (G4A-HL)

9. Speedometer cable

10. Connectors

11. Grounds

12. Selector cable

13. Throttle cable

14. Front wheels

15. Splash shields

16. Oil cooler outlet and inlet

hoses

17. Tie-rod ends

18. Stabilizer bar control links

19. Lower arm ball joints

20. Driveshaft

21. Joint shaft bracket

76G07B-106

22. Joint shaft and driveshaft

23. Exhaust pipe bracket

24. Gusset plates

25. Under cover

26. Torque converter nuts

27. Manifold bracket (G4A-EL)

28. Starter

29. Engine mount No.4

30. Engine mount No.2

31. Crossmember and left side

lower arm

32. Transaxle

7B—83

Page 950 of 1865

7B REMOVAL

76G07B-107

G4A-EL

76G07B-108

76G07B-109

1. Remove the battery and battery carrier.

2. Disconnect the main fuse block.

3. Disconnect the distributor lead.

4. Disconnect the air flow meter connector and re-

move the air cleaner assembly. (G4A-EL)

5. Remove the air cleaner hose. (G4A-EL)

6. Remove the fresh air duct. (G4A-HL)

7. Disconnect the speedometer cable.

8. Disconnect the connectors.

(1) Inhibitor switch

(2) Solenoid valve

(3) Pulse generator (G4A-EL)

(4) Fluid temperature switch (G4A-EL)

9. Disconnect the grounds from the transaxle case.

10. Disconnect the selector cable.

11. Disconnect the throttle cable.

76G07B-110

7B—84