MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 971 of 1865

DISASSEMBLY 7B

Outlet pipe

83U07B-168

83U07B-169

83U07B-170

3. Remove the governor outlet pipe, governor inlet

pipe, and O-rings.

4. Remove the 2-3 accumulator piston assembly and

O-rings.

5. Remove the bearing housing.

(1) Remove the bolt indicated in the figure.

(2) Remove the roll pin with a pin punch.

(3) Remove the bearing housing by tapping light-

ly with a plastic hammer.

6. Remove the idle gear assembly and output gear

assembly by tapping out from the torque convert-

er side.

83U07B-171

7B-105

Page 972 of 1865

7B DISASSEMBLY

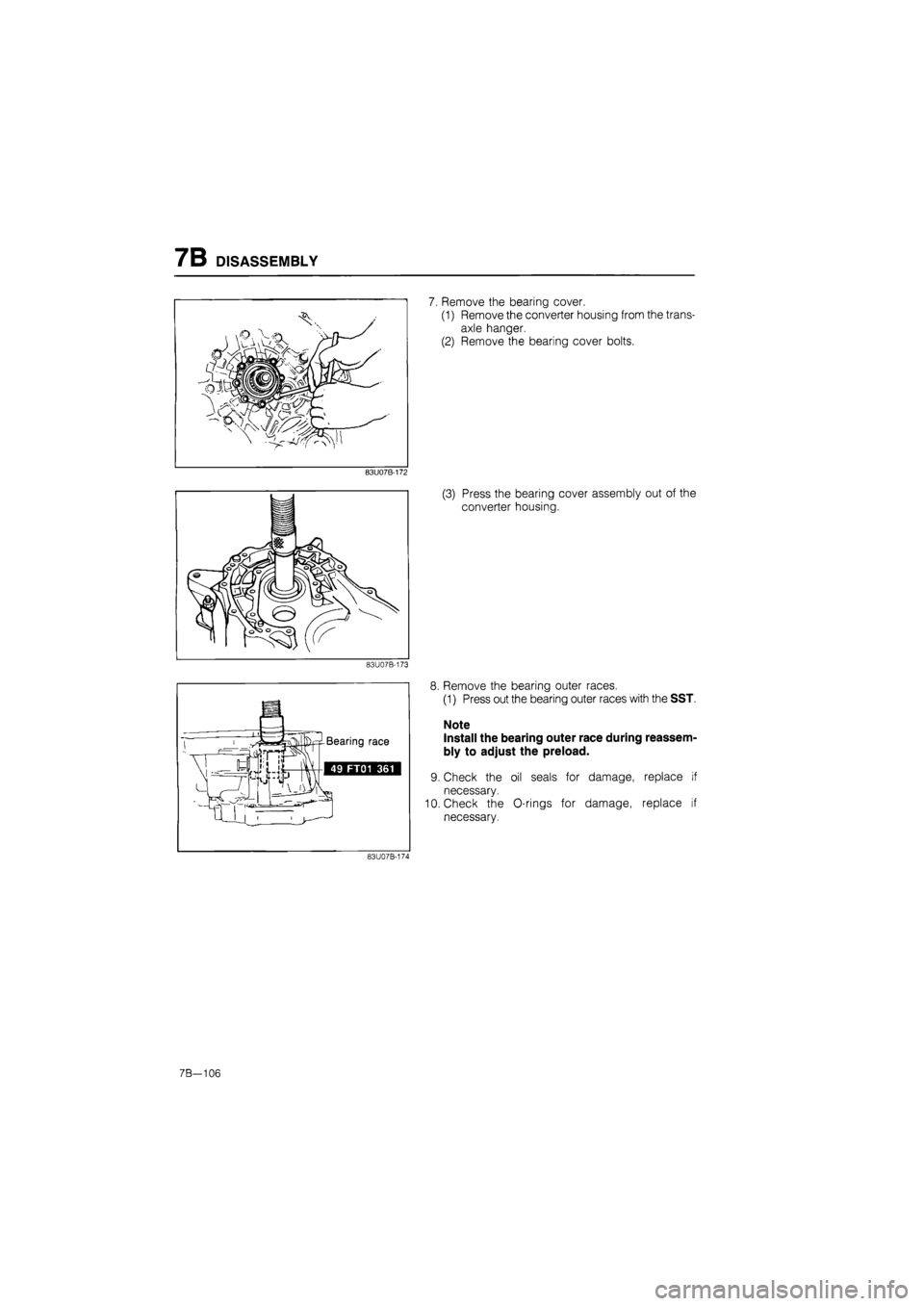

7. Remove the bearing cover.

(1) Remove the converter housing from the trans-

axle hanger.

(2) Remove the bearing cover bolts.

83U07B-173

8. Remove the bearing outer races.

(1) Press out the bearing outer races with the SST.

Note

Install the bearing outer race during reassem-

bly to adjust the preload.

9. Check the oil seals for damage, replace if

necessary.

10. Check the O-rings for damage, replace if

necessary.

83U07B-174

7B—106

Page 973 of 1865

INSPECTION AND REPAIR 7B

INSPECTION AND REPAIR

PRECAUTION

(1) Several of the parts resemble each other; organize them so that they do not get mixed up.

(2) Clean each part with cleaning oil, clean out the oil holes and oil passages with compressed air,

and check that there are no obstructions.

(3) When using cleaning oil and compressed air, wear protective eyewear.

(4) If a clutch plate or brake band is replaced with a new one, soak it in ATF for 2 hours or more

before installing.

(5) Before assembly, apply ATF to all seal rings, rotating parts, and sliding parts.

(6) All seals, gaskets and roll pins must be replaced with new ones during assembly.

(7) Use petroleum jelly, not grease where required.

(8) When it is necessary to replace a bushing, replace the assembly which includes that bushing.

76G07B-217

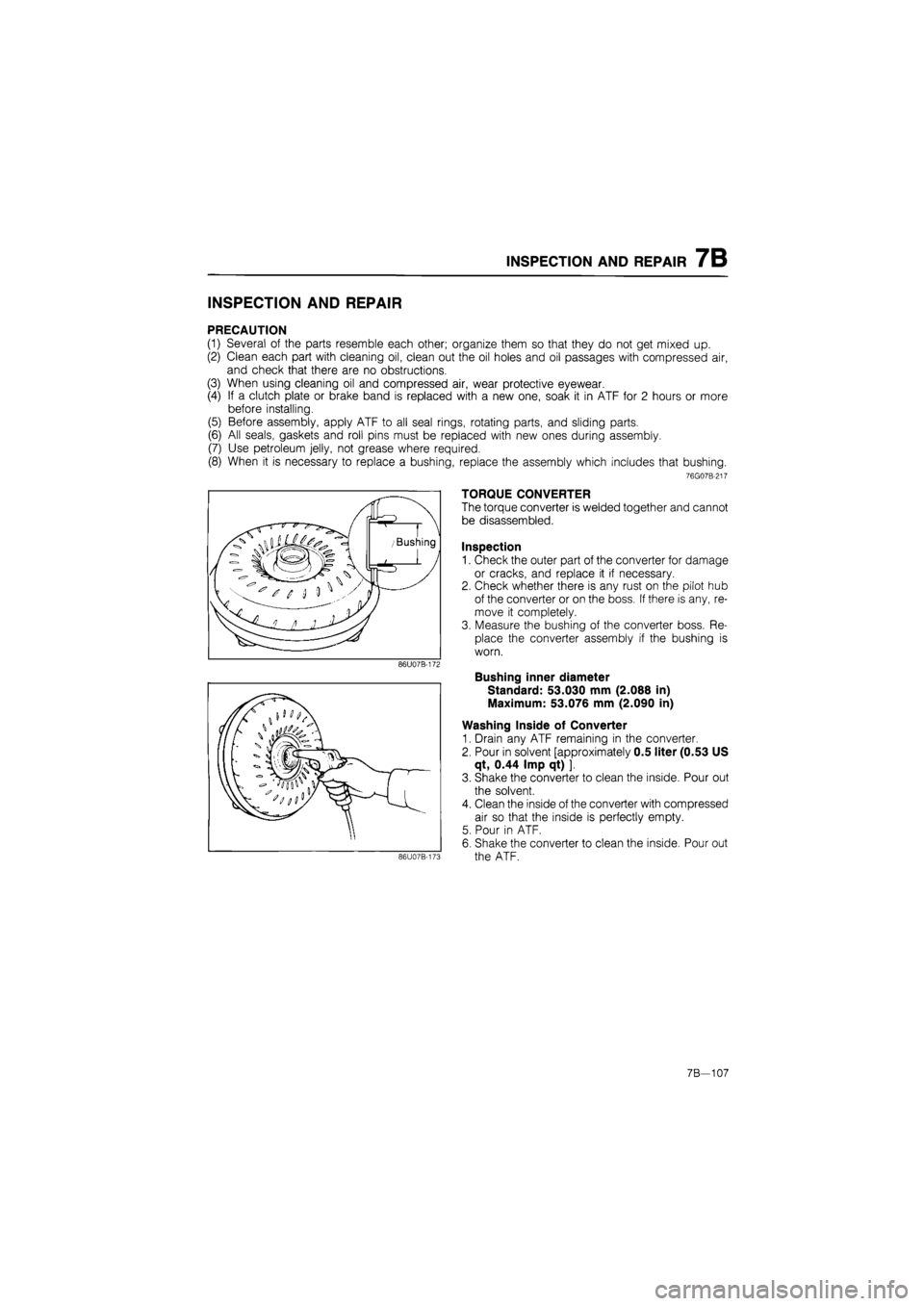

TORQUE CONVERTER

The torque converter is welded together and cannot

be disassembled.

Inspection

1. Check the outer part of the converter for damage

or cracks, and replace it if necessary.

2. Check whether there is any rust on the pilot hub

of the converter or on the boss. If there is any, re-

move it completely.

3. Measure the bushing of the converter boss. Re-

place the converter assembly if the bushing is

worn.

Bushing inner diameter

Standard: 53.030 mm (2.088 in)

Maximum: 53.076 mm (2.090 in)

Washing Inside of Converter

1. Drain any ATF remaining in the converter.

2. Pour in solvent [approximately 0.5 liter (0.53 US

qt, 0.44 Imp qt) ].

3. Shake the converter to clean the inside. Pour out

the solvent.

4. Clean the inside of the converter with compressed

air so that the inside is perfectly empty.

5. Pour in ATF.

6. Shake the converter to clean the inside. Pour out

the ATF.

7B—107

Page 974 of 1865

7B INSPECTION AND REPAIR

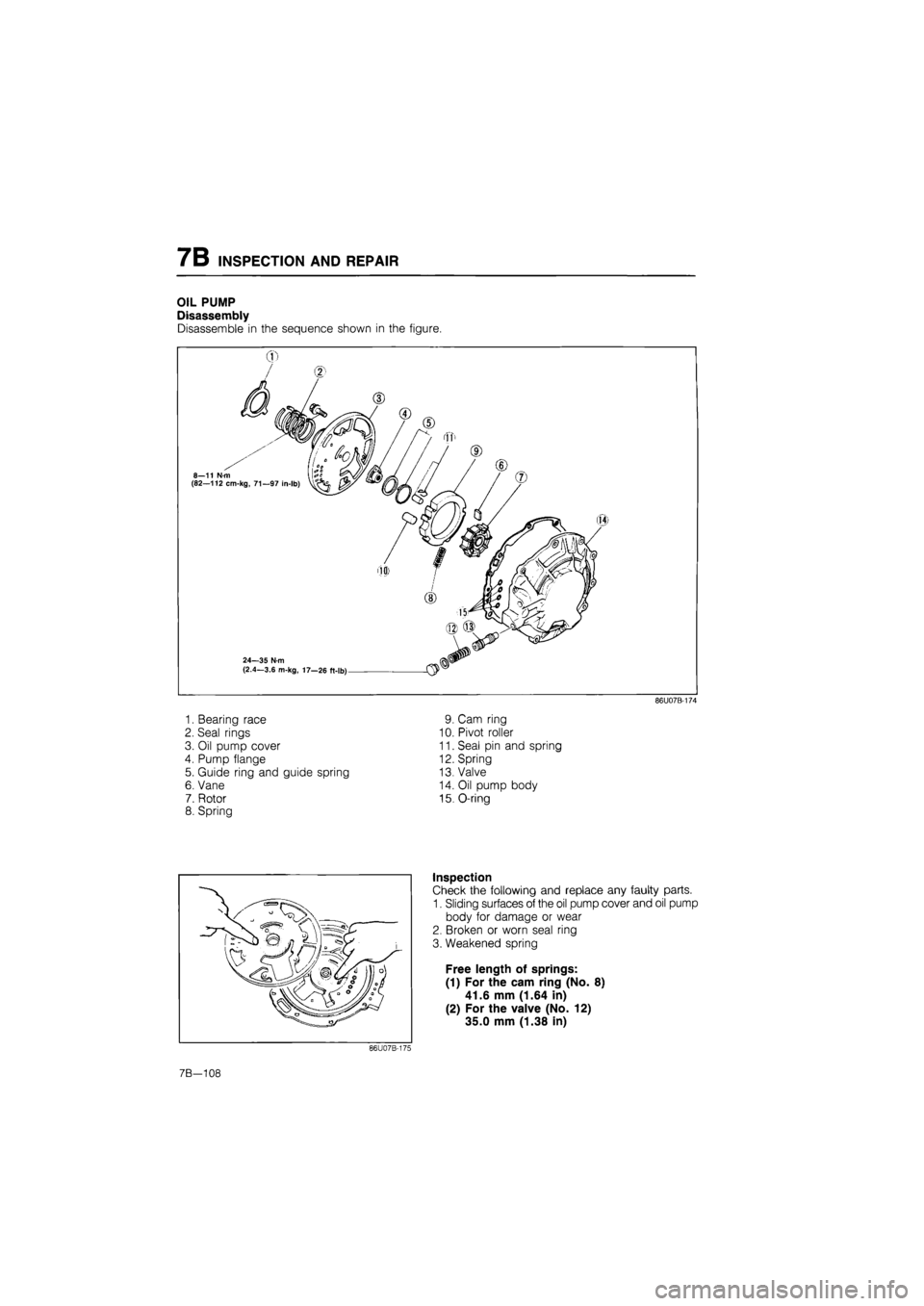

OIL PUMP

Disassembly

Disassemble in the sequence shown in the figure.

8—11 Nm (82—112 cm-kg, 71—97 in-lb)

24—35 N-m (2.4-3.6 m-kg, 17-26 ft-lb)

1. Bearing race

2. Seal rings

3. Oil pump cover

4. Pump flange

5. Guide ring and guide spring

6. Vane

7. Rotor

8. Spring

86U07B-174

9. Cam ring

10. Pivot roller

11. Seal pin and spring

12. Spring

13. Valve

14. Oil pump body

15. O-ring

Inspection

Check the following and replace any faulty parts.

1. Sliding surfaces of the oil pump cover and oil pump

body for damage or wear

2. Broken or worn seal ring

3. Weakened spring

Free length of springs:

(1) For the cam ring (No. 8)

41.6 mm (1.64 in)

(2) For the valve (No. 12)

35.0 mm (1.38 in)

86U07B-175

7B—108

Page 975 of 1865

INSPECTION AND REPAIR 7B

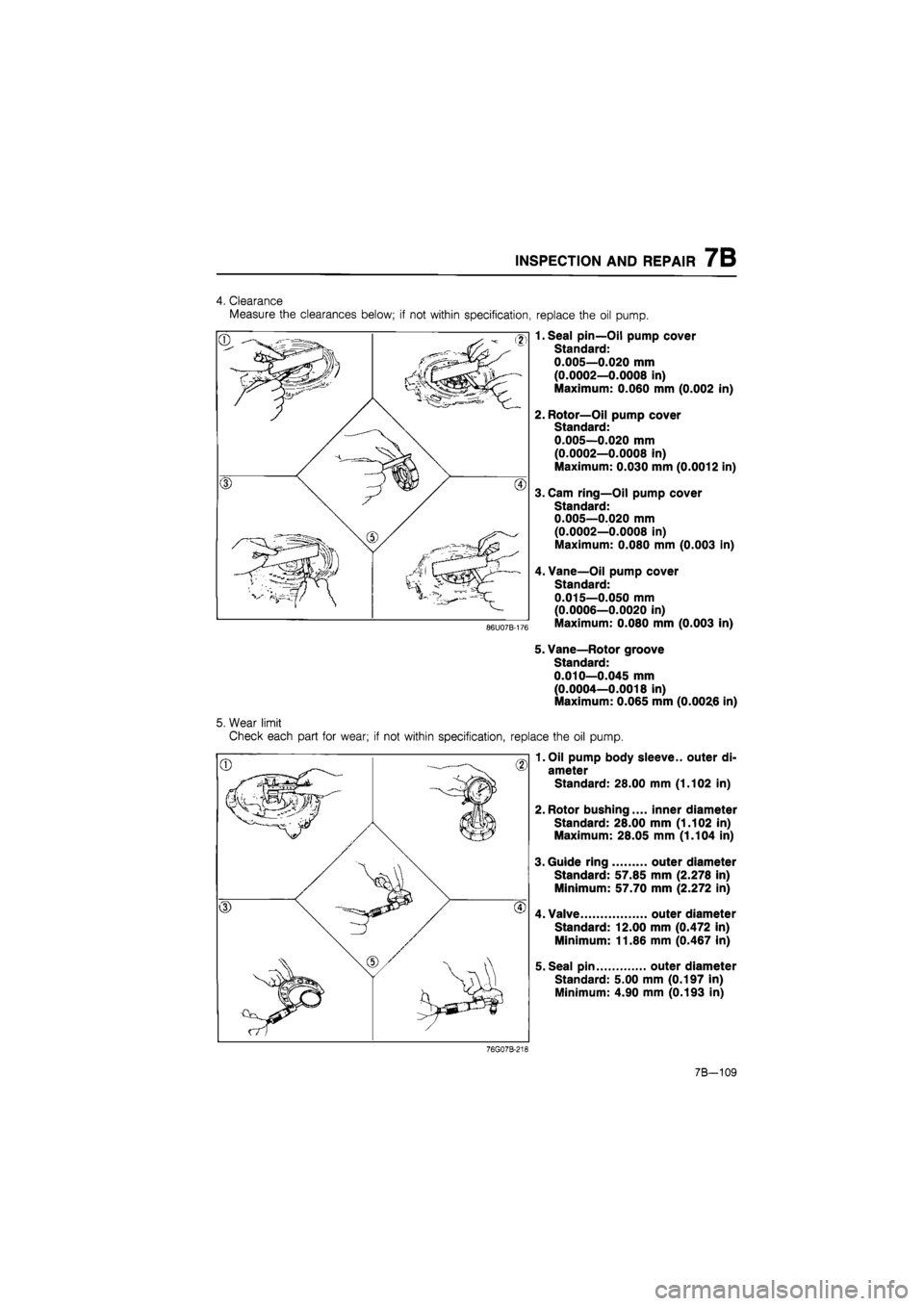

replace the oil pump.

1. Seal pin—Oil pump cover

Standard:

0.005—0.020 mm

(0.0002—0.0008 in)

Maximum: 0.060 mm (0.002 in)

2. Rotor—Oil pump cover

Standard:

0.005—0.020 mm

(0.0002—0.0008 in)

Maximum: 0.030 mm (0.0012 in)

3. Cam ring—Oil pump cover

Standard:

0.005—0.020 mm

(0.0002—0.0008 in)

Maximum: 0.080 mm (0.003 in)

4. Vane—Oil pump cover

Standard:

0.015—0.050 mm

(0.0006—0.0020 in)

Maximum: 0.080 mm (0.003 in)

5. Vane—Rotor groove

Standard:

0.010—0.045 mm

(0.0004—0.0018 in)

Maximum: 0.065 mm (0.0026 in)

5. Wear limit

Check each part for wear; if not within specification, replace the oil pump.

1. Oil pump body sleeve., outer di-

ameter

Standard: 28.00 mm (1.102 in)

2. Rotor bushing.... inner diameter

Standard: 28.00 mm (1.102 in)

Maximum: 28.05 mm (1.104 in)

3. Guide ring outer diameter

Standard: 57.85 mm (2.278 in)

Minimum: 57.70 mm (2.272 in)

4. Valve outer diameter

Standard: 12.00 mm (0.472 in)

Minimum: 11.86 mm (0.467 in)

5. Seal pin outer diameter

Standard: 5.00 mm (0.197 in)

Minimum: 4.90 mm (0.193 in)

4. Clearance

Measure the clearances below; if not within specification,

7B-109

Page 976 of 1865

7B INSPECTION AND REPAIR

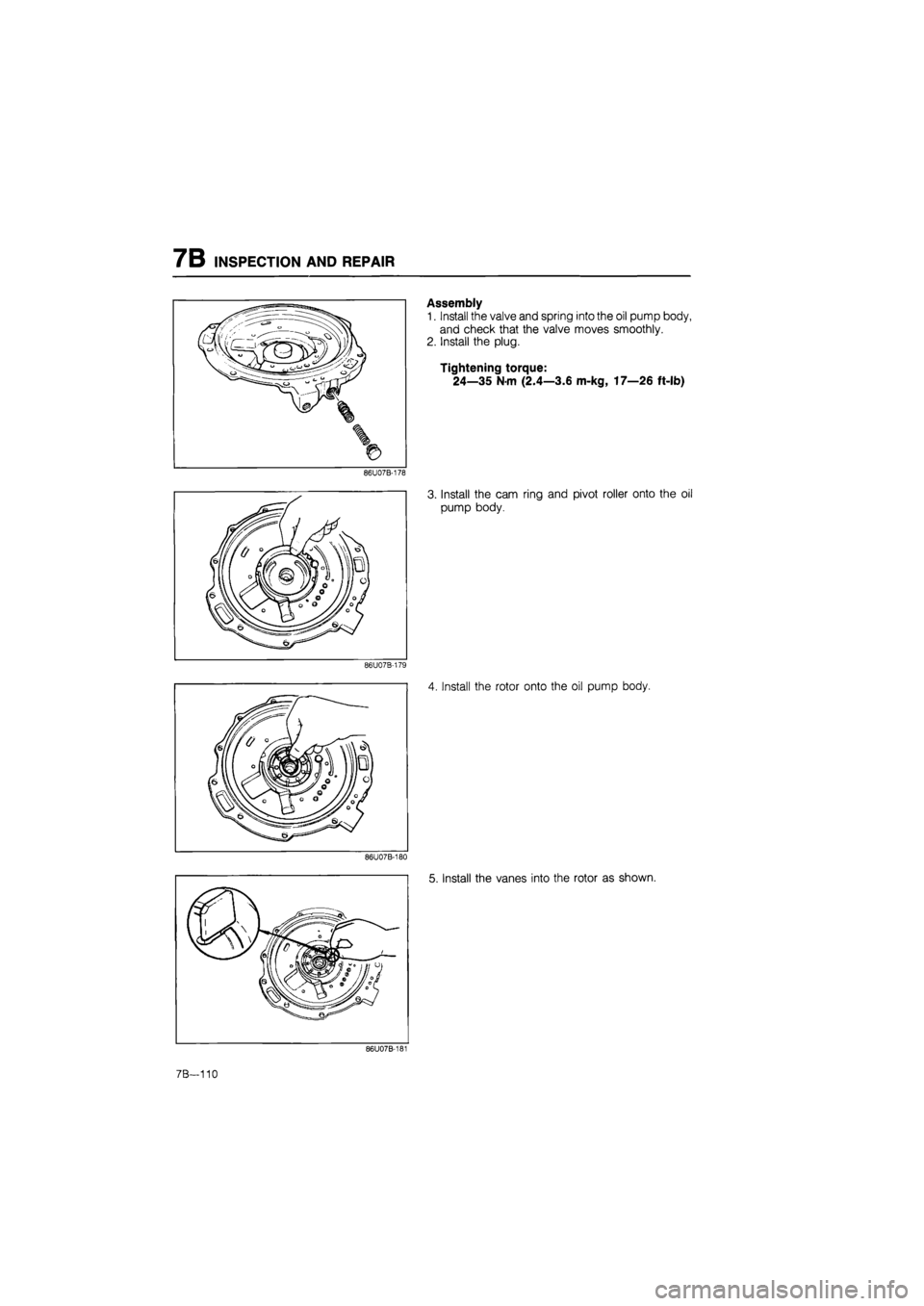

Assembly

1. Install the valve and spring into the oil pump body,

and check that the valve moves smoothly.

2. Install the plug.

Tightening torque:

24—35 Nm (2.4—3.6 m-kg, 17—26 ft-lb)

86U07B-178

86U07B-179

/iiiMd ill

I

o (II m IP

f©

vA /J o " /1 °

Q® //joj / // ° r o t

3. Install the cam ring and pivot roller onto the oil

pump body.

4. Install the rotor onto the oil pump body.

86U07B-180

5. Install the vanes into the rotor as shown.

86U07B-181

7B—110

Page 977 of 1865

INSPECTION AND REPAIR 7B

Guid spring

86U07B-182

86U07B-183

86U07B-184

6. Install the guide spring and guide ring while ex-

panding the vanes toward the cam ring.

7. Install the pump flange onto the rotor.

8. Install the spring between the cam ring and oil

pump body.

9. Install the seal pins and springs with the pins fac-

ing toward the oil pump body.

Note

Install the seal pins round end first.

10. Install the O-rings.

86U07B-185

7R

1 11

Page 978 of 1865

7B INSPECTION AND REPAIR

86U07B-186

86U07B-187

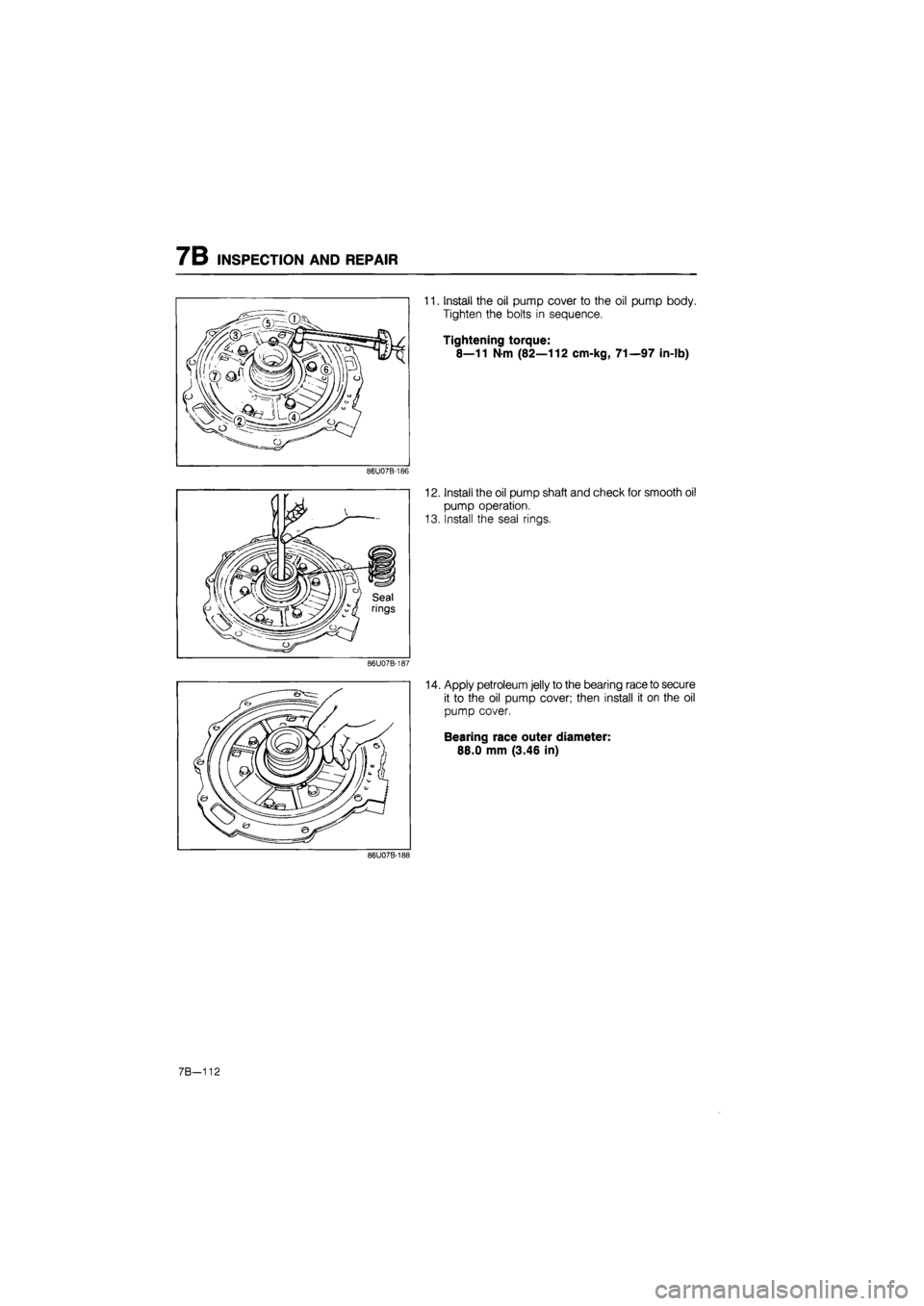

11. Install the oil pump cover to the oil pump body.

Tighten the bolts in sequence.

Tightening torque:

8—11 Nm (82—112 cm-kg, 71—97 in-lb)

12. Install the oil pump shaft and check for smooth oil

pump operation.

13. Install the seal rings.

14. Apply petroleum jelly to the bearing race

to

secure

it to the oil pump cover; then install it on the oil

pump cover.

Bearing race outer diameter:

88.0 mm (3.46 in)

86U07B-188

7B—112

Page 979 of 1865

INSPECTION AND REPAIR 7B

CLUTCH ASSEMBLY

Disassembly

Disassemble in the sequence shown in the figure referring to the disassembly note for the specially

marked parts.

—Forward clutch—

1. Thrust bearings

2. Snap ring

3. Retaining plate

4. Drive and driven plates

5. Dished plate

—Coasting clutch—

6. Snap ring

7. Retaining plate

8. Drive and driven plates

9. Dished plate

10. Snap ring

11. Spring and retainer as-

sembly

12. Coasting clutch drum

13. Coasting piston

14. Outer seal

15. Inner seal

16. Outer seal

17. Seal rings

—Reverse clutch—

18. Snap ring

86U07B-189

19. Retaining plate

20. Drive and driven plates

21. Dished plate

22. Snap ring

23. Return spring stopper

24. Piston return spring

25. Reverse piston

26. Seal rings (inner and outer)

27. Reverse and forward drum

7B—113

Page 980 of 1865

7B INSPECTION AND REPAIR

86U07B-190

86U07B-191

76G07B-130

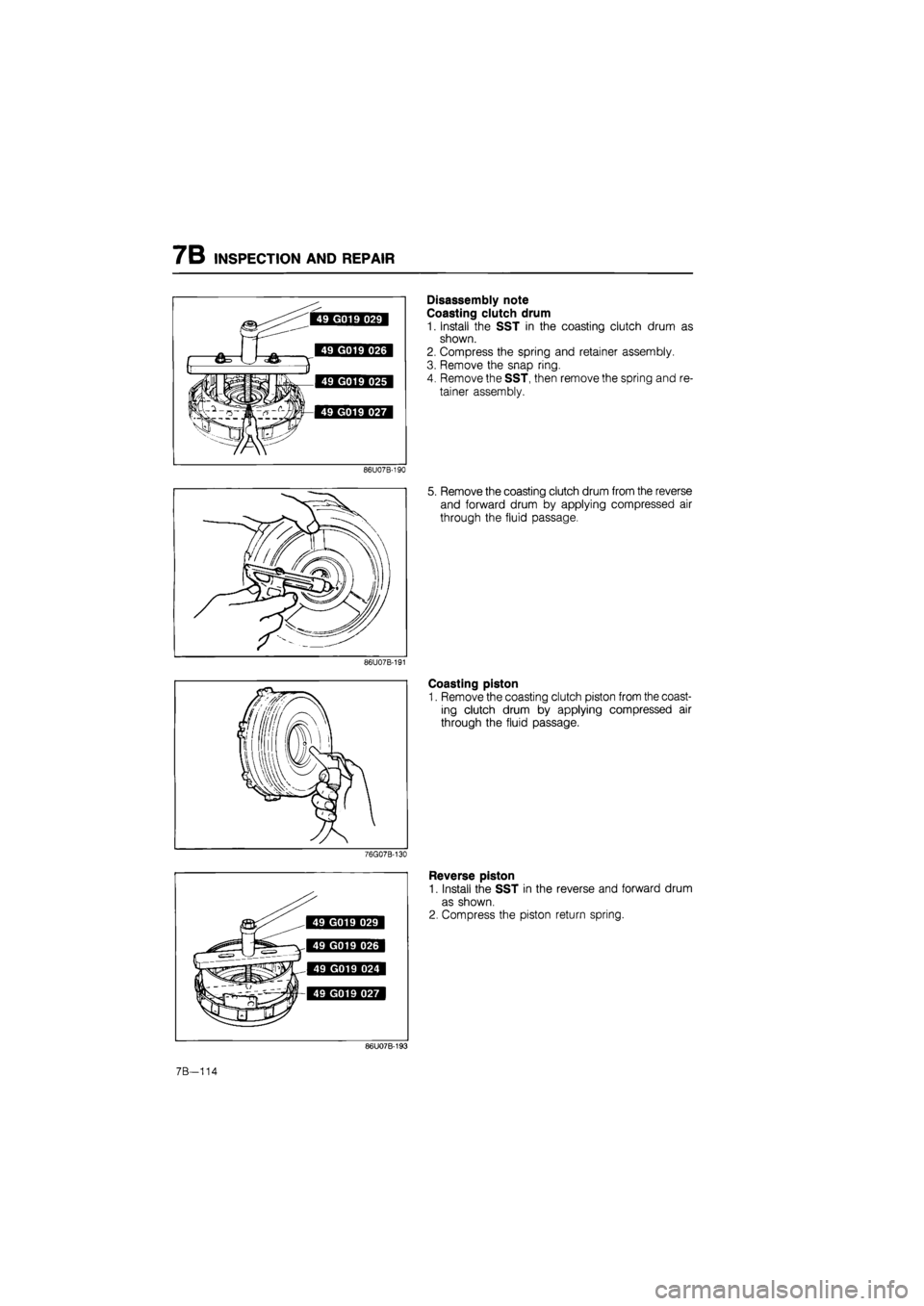

Disassembly note

Coasting clutch drum

1. Install the SST in the coasting clutch drum as

shown.

2. Compress the spring and retainer assembly.

3. Remove the snap ring.

4. Remove the SST, then remove the spring and re-

tainer assembly.

5. Remove the coasting clutch drum from the reverse

and forward drum by applying compressed air

through the fluid passage.

Coasting piston

1. Remove the coasting clutch piston from the coast-

ing clutch drum by applying compressed air

through the fluid passage.

Reverse piston

1. Install the SST in the reverse and forward drum

as shown.

2. Compress the piston return spring.

86U07B-193

7B—114