MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 931 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

76G07B-069

76G07B-070

76G07B-071

INHIBITOR SWITCH

Inspection

1. Check that the starter turns with the ignition switch

at START position and the selector in the P and

N ranges, and dose not operate in other positions.

2. Check that the back-up (reverse) light illuminates

when shifted to the R range with the ignition switch

in the ON position.

3. Check the inhibitor switch if it is not working

properly.

Inspection of continuity

1. Disconnect the inhibitor switch connector.

2. Check continuity of the terminals.

G4A-EL

Position Connector terminal Position A B c D E F G H 1

P O-—O 0--O

R o--O

N o--o Pi N o--o

D o D U

S pi o S

L r o L

O—O: Indicates continuity

G4A-HL

Position Connector terminal Position a b c d

P 1 O— —O

O--o

N

D, 1, 2

O--O

O—O: indicates continuity

3. If not correct, replace switch and perform adjust-

ment of inhibitor switch.

Adjustment

1. Shift the selector lever to N range.

2. Loosen the inhibitor switch mounting bolts.

76G07B-072

7B—65

Page 932 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

76G07B-073

7B-66

3. Remove the screw and move the inhibitor switch

so that the small hole is aligned with the screw hole.

4. Set the alignment by inserting a 2.0 mm (0.079

in) diameter pin through the holes.

5. Loosely tighten the switch mounting bolts, remove

the pin, and reinstall the screw.

6. Tighten the switch mounting bolts to specification.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

7. Recheck the continuity of the individual terminals.

WATER TEMPERATURE SWITCH

Inspection

1. Remove the water temperature switch.

2. Place the switch in water with a thermometer and

heat up the water gradually.

3. Check the continuity of the terminals. If necessary

replace the switch.

Connection guide

Water temperature Continuity

Below 65°C (149°F) Yes

Above 72°C (162°F) \ No

FLUID TEMPERATURE SWITCH (G4A-EL)

Inspection

1. Remove the fluid temperature switch.

2. Place the switch in oil with a thermometer as shown

and heat it up gradually.

3. Check the continuity of the terminals. If necessary

replace the switch.

Connection guide

Fluid temperature Continuity

Above 150°C (302°F) Yes

Below 143°C (289°F) No

BRAKE LIGHT SWITCH (G4A-EL)

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage between terminal (WG) and

ground while depressing the brake pedal.

Terminal voltage I Brake pedal

Approx. 12V Depressed

Below 1,5V Released

3. If not correct, check continuity of the switch.

Page 933 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

Inspection of Continuity

1. Disconnect the brake light switch connector.

2. Check for continuity between the terminals while

depressing the brake pedal.

79G07C-114

76G07B-076

KICK-DOWN SWITCH (G4A-HL)

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage at terminal (V) with a voltmeter.

Depressing stroke Terminal voltage

7/8-8/8 (Full) Approx. 12V

0-7/8 Below 1,5V

3. If not correct, check the wiring harness, switch, or

adjust the switch position.

Inspection of Continuty

1. Disconnect the kick-down switch connector.

2. Check for continuity of the switch with an

ohmmeter.

Switch Continuity

Pushed Yes

Released No

3. If not correct, replace the kick-down switch.

76G07B-077

Adjustment

1. Loosen the kick-down switch locknuts.

2. Depress the accelerator pedal fully.

3. Turn the switch until the threaded case touches the

stopper.

4. Turn the switch counterclockwise by one half revo-

lution.

5. Secure the switch with the locknut.

76G07B-078

7B—67

Page 934 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

76G07B-079

76G07B-080

76G07B-081

PULSE GENERATOR (G4A-EL)

Inspection

1. Disconnect the pulse generator connector.

2. Check for continuity between the terminals, if

necessary replace the pulse generator.

Resistance: 200—400fl

VEHICLE SPEED SENSOR (G4A-EL)

Inspection of voltage

1. Connect a voltmeter between the 1Q terminal of

the EC-AT control unit and ground as shown.

2. Turn the ignition switch ON.

3. Remove the speedometer cable from the transaxle.

4. Slowly turn the speedometer cable one turn.

5. Check that approx. 4.5V is shown 4 times.

6. If not correct, check the combination meter.

CRUISE CONTROL SWITCH (CRUISE CONTROL

UNIT)

Refer to Section 15.

IDLE SWITCH AND THROTTLE SENSOR

(G4A-EL)

Refer to Section 4A.

OD RELEASE SOLENOID VALVE (G4A-HL)

Inspection of Resistance

1. Disconnect the solenoid valve connector.

2. Check resistance between the terminals.

Resistance: 13—27 ft

3. If not correct, replace the solenoid valve.

76G07B-082

7B-68

Page 935 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

76G07B-083

EC-AT CONTROL UNIT (G4A-EL)

SOLENOID VALVES (G4A-EL)

Inspection of Resistance

1. Disconnect the negative battery cable.

2. Disconnect the solenoid valve connector.

3. Measure the resistance of the terminals except (A)

terminal, if necessary replace the solenoid valve.

Resistance: 13—271]

Note

1-2 solenoid valve : F

2-3 solenoid valve : C,E

3-4 solenoid valve : B

Lock-up solenoid valve : D

NO LOAD SIGNAL (G4A-EL)

Refer to STEP 3 in Troubleshooting.

MODE, AND HOLD INDICATOR LIGHT (G4A-EL)

Refer to Section 15.

OD OFF INDICATOR LIGHT (G4A-HL)

Refer to Section 15.

/ 1S 10 10 1M X 1G 1E 1C

1A

1T 1R 1P 1N 1L 1J 1H 1F 1D 1B

/—

20 2M 2K X 2E 2C 2A

2P 2N 2L 2J 2H 2F 2D 2B

Terminal Voltage Chart

Terminal Connected to Voltage Condition

1A (Input) Hold switch Approx. 12V Switch depressed 1A (Input) Hold switch Below 1.5 V Switch released

1B (Input) Mode switch (Power side) Below 1.5V POWER mode 1B (Input) Mode switch (Power side) Approx. 12V ECONOMY mode

1C (Input)

Inhibitor

switch

L range Approx. 12V L range 1C (Input)

Inhibitor

switch

L range Below 1.5V Other ranges

1D (Input) Inhibitor

switch

S range Approx. 12 V S range 1D (Input) Inhibitor

switch

S range Below 1,5V Other ranges

1E (Input)

Inhibitor

switch D range Approx. 12V D range 1E (Input)

Inhibitor

switch D range Below 1.5 V Other ranges

1F (Input)

Inhibitor

switch

N and P range

Below 1,5V N or P range 1F (Input)

Inhibitor

switch

N and P range Approx. 12V Other ranges

1G (Input) Water temperature switch Approx. 12V Above 72°C (162°F) 1G (Input) Water temperature switch Below 1,5V Below 65°C (149°F)

1H — —

11 — —

7B-69

Page 936 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

Terminal Connected to Voltage Condition

1J — — —

1K — — —

1L (Input) Idle switch Below 1.5V At idle 1L (Input) Idle switch Approx. 12V Other speeds

1M — — —

1N (Input) Brake light switch Approx. 12V Brake pedal depressed 1N (Input) Brake light switch Below 1.5V Brake pedal released

10 (Input) Throttle sensor

Approx. 5V Ignition switch ON 10 (Input) Throttle sensor Below 1,5V Ignition switch OFF

1P (Input)

Throttle sensor

Approx. 0.5—4.3V Throttle valve fully closed to fully open

1Q (Input) Vehicle speed sensor

Approx. 4.5V During driving

1Q (Input) Vehicle speed sensor Approx. 4.5V or below 1.5V Vehicle stopped

1R (Ground) Throttle sensor Below 1,5V —

1S (Input) Pulse generator Approx. 12V Engine running 1S (Input) Pulse generator Below 1,5V Engine stopped

1S (Ground) Pluse generator Below 1.5V —

2A (Battery power) Battery Approx. 12V Ignition switch ON 2A (Battery power) Battery Below 1,5V Ignition switch OFF

2B (Ground) Body ground Below 1,5V —

2C (Memory power) Battery Approx. 12V —

2D (Ground) Body ground Below 1,5V —

2E (Output) 1-2 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2E (Output) 1-2 shift solenoid valve Below 1.5V Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Below 1,5V

Refer to page 7B—26 of solenoid valve

operation table

2G — — —

2H (Output) 3-4 shift solenoid valve Approx. 12V Refer to page 7B—26 of solenoid valve operation table 2H (Output) 3-4 shift solenoid valve Below 1.5V

Refer to page 7B—26 of solenoid valve operation table

21 — — —

2J (Output) Lock-up solenoid valve Approx. 12V Lock-up 2J (Output) Lock-up solenoid valve Below 1,5V Other

2K (Output) Hold indicator Below 1,5V Hold mode 2K (Output) Hold indicator Approx. 12V Other modes

2L (Output) Mode indicator Approx. 12V Hold mode 2L (Output) Mode indicator Below 1,5V Power or economy mode

2M (Output) EC-AT Tester

(malfunction code)

Approx. 12V Normal

2M (Output) EC-AT Tester

(malfunction code) Below 1,5V If malfunction present 2M (Output) EC-AT Tester

(malfunction code) Code signal Self-diagnosis check connector grounded

2N — — —

20 (Input) Fluid temperature switch Below 1,5V Above 150°C (302°F) 20 (Input) Fluid temperature switch Approx. 10—12V Below 143°C (289°F)

2P (Input) EC-AT check connect Approx. 12V —

76G07B-084

7B-70

Page 937 of 1865

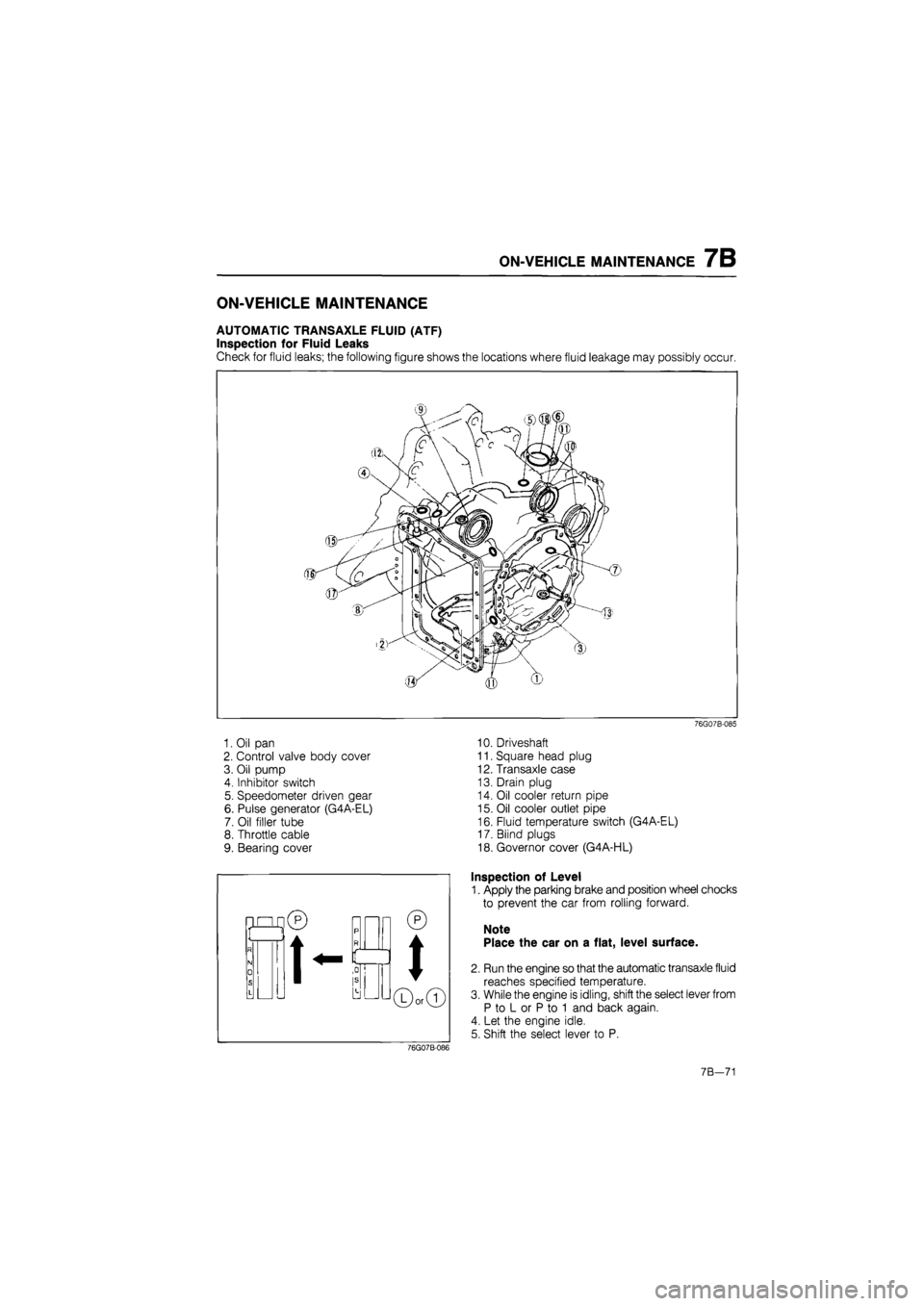

ON-VEHICLE MAINTENANCE 7B

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator (G4A-EL)

7. Oil filler tube

8. Throttle cable

9. Bearing cover

76G07B-085

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch (G4A-EL)

17. Blind plugs

18. Governor cover (G4A-HL)

Inspection of Level

1. Apply the parking brake and position wheel chocks

to prevent the car from rolling forward.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches specified temperature.

3. While the engine is idling, shift the select lever from

P to L or P to 1 and back again.

4. Let the engine idle.

5. Shift the select lever to P.

76G07B-086

7B—71

Page 938 of 1865

![MAZDA 626 1987 Workshop Manual

7B ON-VEHICLE MAINTENANCE

86U07B-064

86U07B-065

t «

•A

0 0

0 »

LX] O 9

m

(2)

(1)

Button need not

be depressed

Button must be pressed

76F07B-022

6. Ensure that the ATF level is be MAZDA 626 1987 Workshop Manual

7B ON-VEHICLE MAINTENANCE

86U07B-064

86U07B-065

t «

•A

0 0

0 »

LX] O 9

m

(2)

(1)

Button need not

be depressed

Button must be pressed

76F07B-022

6. Ensure that the ATF level is be](/img/28/57059/w960_57059-937.png)

7B ON-VEHICLE MAINTENANCE

86U07B-064

86U07B-065

t «

•A

0 0

0 »

LX] O 9

m

(2)

(1)

Button need not

be depressed

Button must be pressed

76F07B-022

6. Ensure that the ATF level is between the F and L

marks. Add ATF to specification, if necessary.

Low temperature scale:

20°C (68°F)

High temperature scale:

65°C (149°F)

ATF type:

Dexron II or M HI

Inspection of Condition

1. Check the ATF for discoloration.

2. Check the ATF for any unusual smell.

Note

Determine whether or not the automatic trans-

mission should be disassembled by observ-

ing the condition of fluid carefully.

If the fluid is muddy and varnished, it indicates

burned drive plates.

SELECTOR LEVER

Inspection

1. Check that the selector lever can only be shifted

as shown in the figure.

2. Make sure there is a click at each range when shift-

ed from P <-> L or P <-» 1 range.

3. Check that the position of the selector lever and

the indicator are exact.

4. Check that the button returns smoothly when used

to shift the selector.

Adjustment

1. Loosen locknuts A, B, and lockbolt C.

2. Shift the selector lever to P range.

3. Shift the transaxle to P range by moving the man-

ual shaft of the transaxle.

4. While holding the selector lever forward in P range,

tighten lockbolt C to the specified torque.

Tightening torque:

8—11 N-m (80—110 cm-kg, 67—95 in-lb)

76F07B-023

7B—72

Page 939 of 1865

ON-VEHICLE MAINTENANCE 7B

76F07B-024

5. Turn locknut A by hand until it just touches the

spacer.

6. Tighten locknut B to the specified torque.

Tightening torque:

8—11 N m (80—110 cm-kg, 67—96 in-lb)

7. Shift the selector lever to N range.

8. With the button on the selector lever knob pressed,

push the selector toward R range with a force of

20 N (2 kg, 4.4 lb) and check the amount of move-

ment (a) at the selector lever knob.

9. Pull the selector lever toward D range in the same

manner and check the amount of movement (b).

10. Verify the stroke difference of (a) and (b) is as

specified.

Stroke difference: 8 mm (0.315 in) max.

Note

If not with in specification, readjust locknuts

A and B.

11. Check the selector lever operation.

(Refer to Inspection section.)

76F07B-025

THROTTLE CABLE

Inspection

1. Check the inner and outer cable for damage.

2. Make sure that the accelerator operates smoothly.

86U07B-066

Removal

1. Remove the battery and battery carrier.

2. Disconnect the main fuse block. (G4A-EL)

76G07B-090

7B—73

Page 940 of 1865

7B ON-VEHICLE MAINTENANCE

3. Separate the harness from the clip.

4. Jack up the vehicle and support it with safety

stands, then drain the ATF.

76G07B-091

5. Remove the throttle cable from the throttle cam

(throttle chamber).

6. Remove the control valve body cover and gasket.

7. Remove the throttle cable from the throttle cam

(control valve body).

8. Remove the mounting bolt and throttle cable from

the transaxle.

9. Remove the O-ring.

76G07B-092

86U07B-075

Installation

Install in the reverse order of removal referring to in-

stallation note.

Installation note

Throttle cable

Install the throttle cable and a new O-ring into the

transaxle case.

Tightening torque:

(A)

8—11 Nm

(80—110 cm-kg, 69—95 in-lb)

(1)19—26

N

m

(1.9—2.6 m-kg, 14—19 ft-lb)

Control valve body cover

Install the control valve body cover and a new gasket.

Tightening torque:

8—11 Nm (85—110 cm-kg, 74—95 in-lb)

86U07B-076

7B—74