Air filter MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 27 of 1865

For General

Chart symbols:

I : Inspect: Visual examination and/or functional measurement of a system's operation or performance.

A : Adjust: Examination resuiting in adjustment or replacement.

R : Replace or change

T : Tighten

O : Applicable

X : Not applicable

© 1 : F6, F8 engine with carburetor, MTX, ATX

© 2 : FE engine with carbretor, MTX, ATX

©3 : FE DOHC engine with fuel injection, MTX

® 4 : RF-N engine with MTX

NOTE:

As the result of visual examination or functional measurement of a system's operation(performance), correct, clean or replace as required.

REMARKS:

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1. If the vehicle is operated under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended

intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regularly.

"2. Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*3 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt, vacuum pump belt, super charger belt if equipped.

*5 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the

brake fluid should be changed annually.

*6. Only F6 carbretor for Singapore (MTX Model)

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It i

strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

o CJ1

Page 69 of 1865

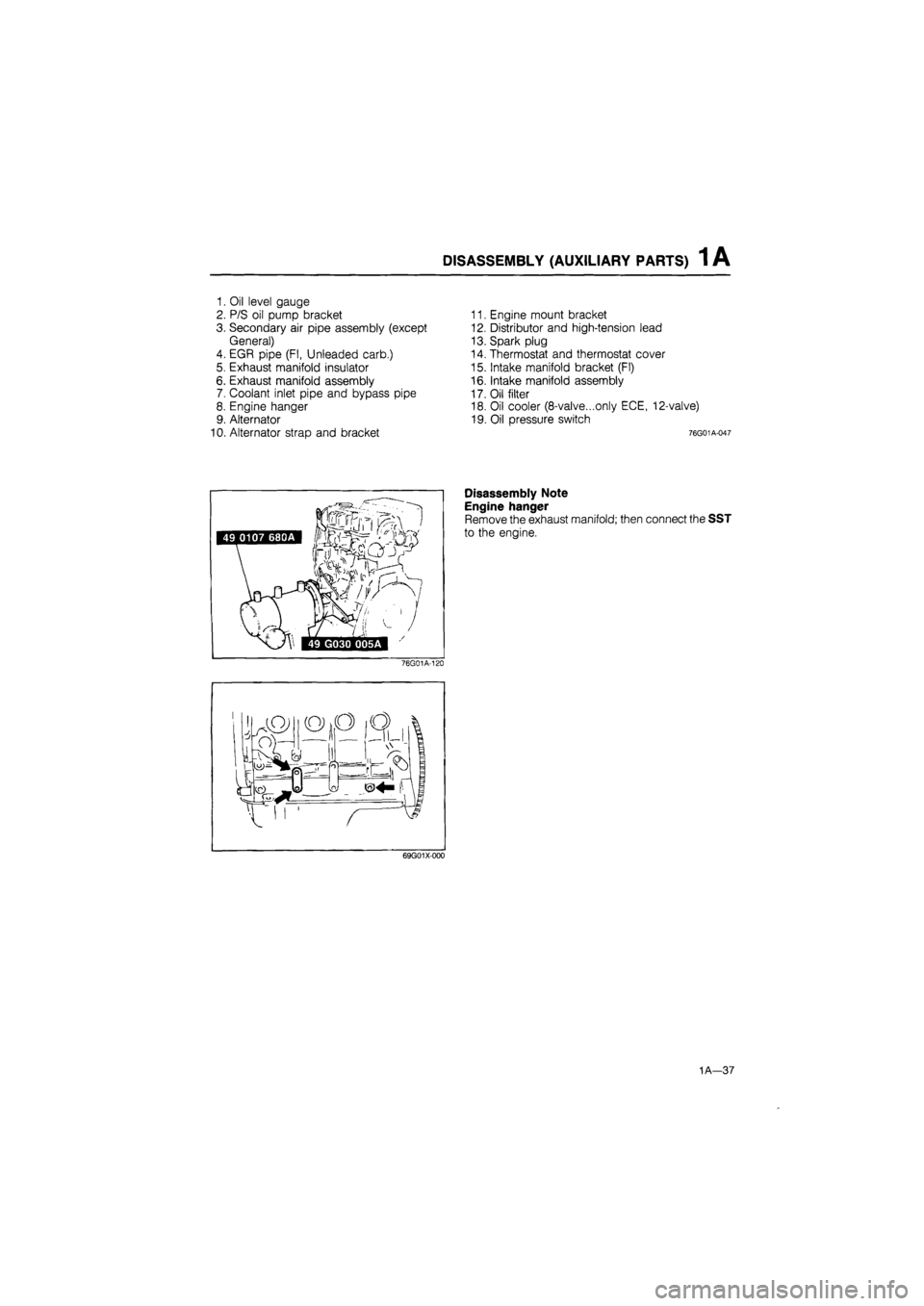

DISASSEMBLY (AUXILIARY PARTS) 1 A

1. Oil level gauge

2. P/S oil pump bracket

3. Secondary air pipe assembly (except

General)

4. EGR pipe (Fl, Unleaded carb.)

5. Exhaust manifold insulator

6. Exhaust manifold assembly

7. Coolant inlet pipe and bypass pipe

8. Engine hanger

9. Alternator

10. Alternator strap and bracket

11. Engine mount bracket

12. Distributor and high-tension lead

13. Spark plug

14. Thermostat and thermostat cover

15. Intake manifold bracket (Fl)

16. Intake manifold assembly

17. Oil filter

18. Oil cooler (8-valve...only ECE, 12-valve)

19. Oil pressure switch

76G01A-047

Disassembly Note

Engine hanger

Remove the exhaust manifold; then connect the SST

to the engine.

76G01A-120

69G01X-000

1A—37

Page 218 of 1865

1C TUNE-UP PROCEDURE

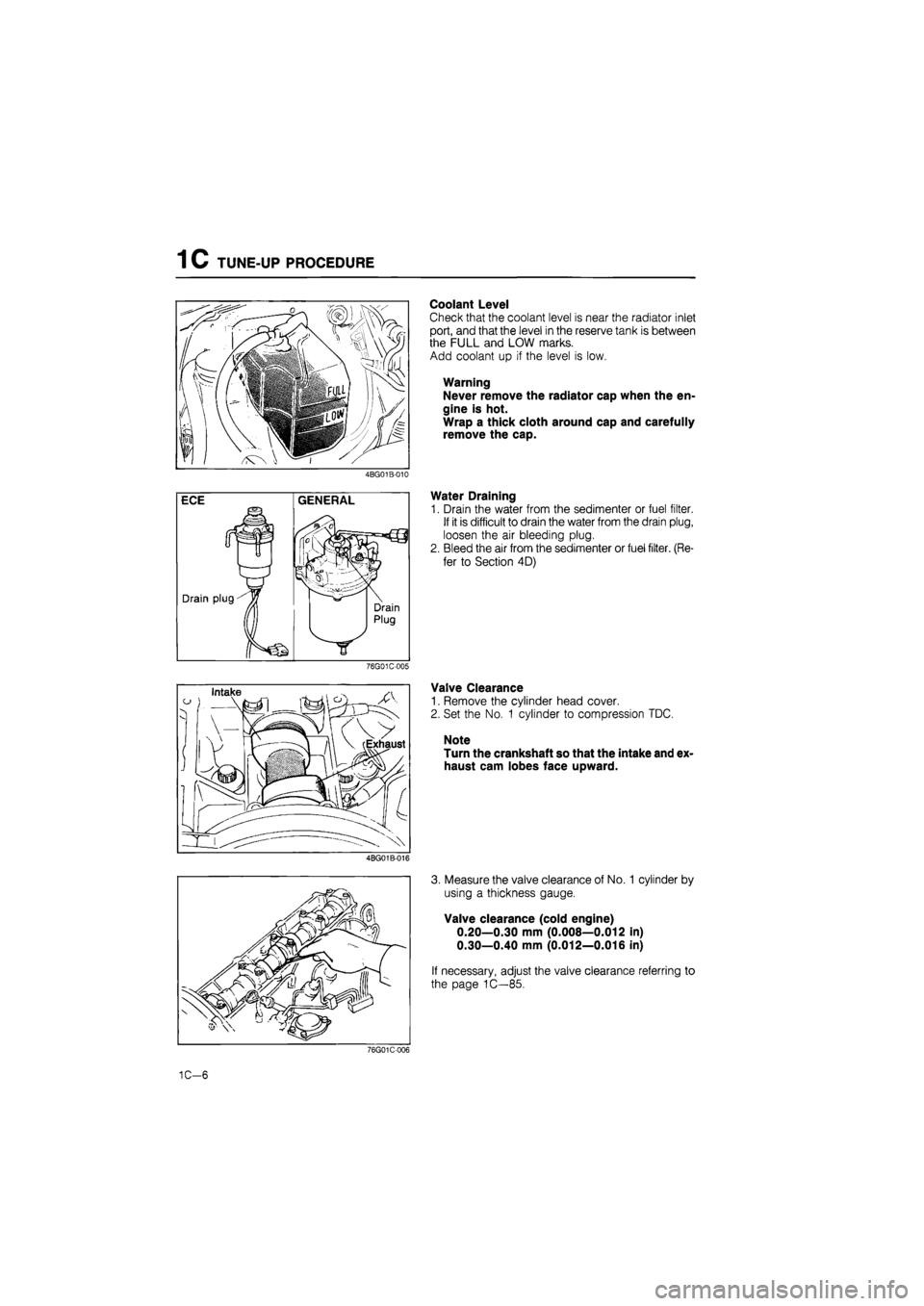

Coolant Level

Check that the coolant level is near the radiator inlet

port, and that the level in the reserve tank is between

the FULL and LOW marks.

Add coolant up if the level is low.

Warning

Never remove the radiator cap when the en-

gine is hot.

Wrap a thick cloth around cap and carefully

remove the cap.

4BG01B-010

Water Draining

1. Drain the water from the sedimenter or fuel filter.

If it is difficult to drain the water from the drain plug,

loosen the air bleeding plug.

2. Bleed the air from the sedimenter or fuel filter. (Re-

fer to Section 4D)

76G01C-005

Valve Clearance

1. Remove the cylinder head cover.

2. Set the No. 1 cylinder to compression TDC.

Note

Turn the crankshaft so that the intake and ex-

haust cam lobes face upward.

4BG01B-016

3. Measure the valve clearance of No. 1 cylinder by

using a thickness gauge.

Valve clearance (cold engine)

0.20—0.30 mm (0.008—0.012 in)

0.30—0.40 mm (0.012—0.016 in)

If necessary, adjust the valve clearance referring to

the page 1C—85.

76G01C-006

1C-6

Page 247 of 1865

DISASSEMBLY (AUXILIARY PARTS) 1 C

1. A/C compressor bracket 9. Alternator and drive belt

2. Vacuum pump and drive belt 10. Oil filter

3. Air funnel assembly 11. Oil filter cover

4. Comprex supercharger insulator 12. Oil cooler assembly

5. Comprex supercharger and drive belt 13. Exhaust pipe bracket

6. Exhaust manifold insulator 14. Alternator bracket

7. Exhaust manifold 15. Blow-by chamber

8. Intake manifold

Blow-by chamber

76G01C-074

Disassembly Note

Engine hanger

1. Remove the CSD hose.

2. Loosen the vacuum pump oil pipe bolts.

76G01C-075

3. Install the engine on the SST.

76G01C-076

1C—35

Page 315 of 1865

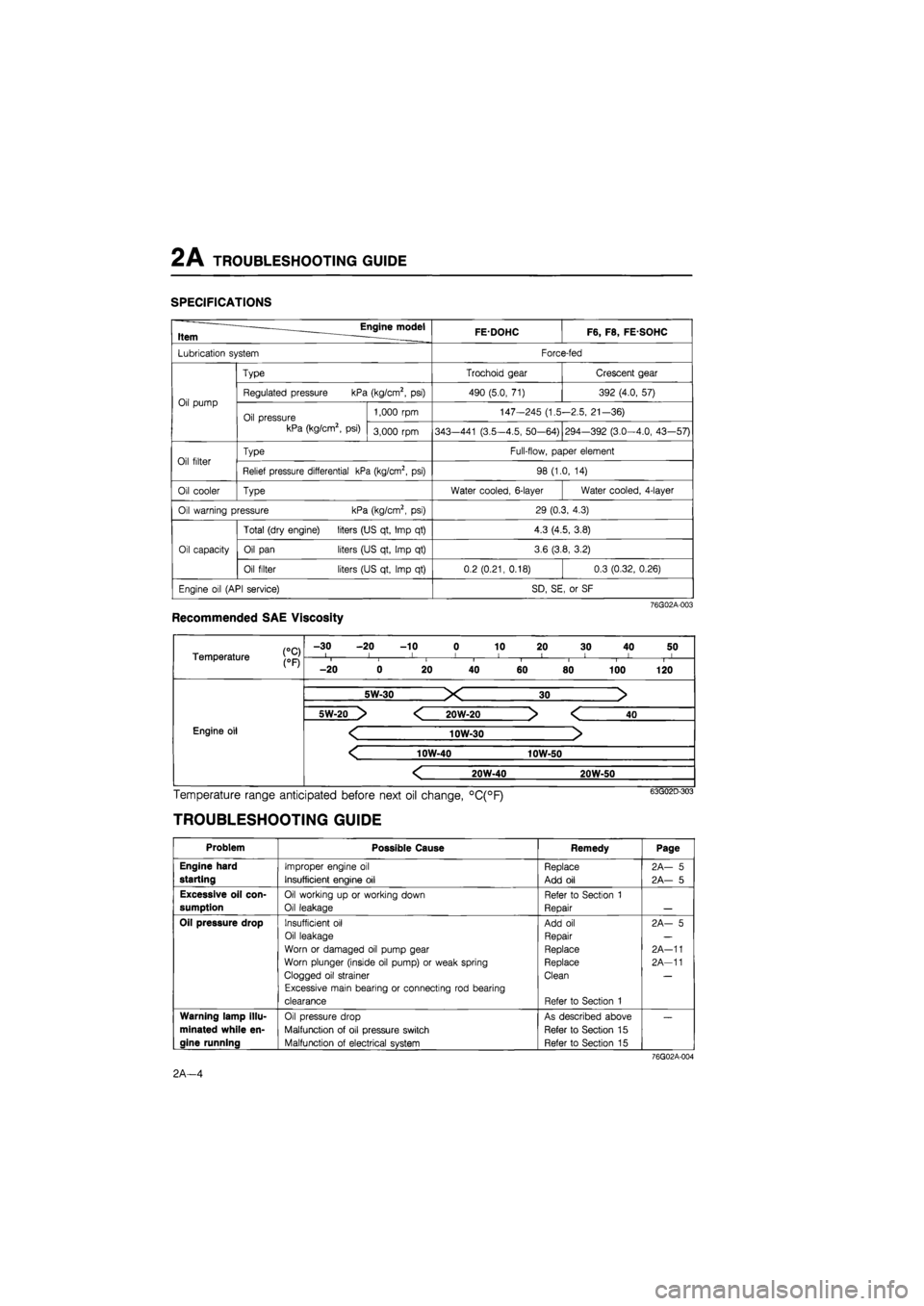

2 A TROUBLESHOOTING GUIDE

SPECIFICATIONS

Engine model Item . FEDOHC F6, F8, FE SOHC

Lubrication system Force-fed

Oil pump

Type Trochoid gear Crescent gear

Oil pump Regulated pressure kPa (kg/cm2, psi) 490 (5.0, 71) 392 (4.0, 57) Oil pump

Oil pressure kPa (kg/cm2, psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pump

Oil pressure kPa (kg/cm2, psi) 3,000 rpm 343—441 (3.5-4.5, 50-64) 294-392 (3.0-4.0, 43—57)

Oil filter Type Full-flow, paper element Oil filter Relief pressure differential kPa (kg/cm2, psi) 98 (1.0, 14)

Oil cooler Type Water cooled, 6-layer Water cooled, 4-layer

Oil warning pressure kPa (kg/cm2, psi) 29 (0.3, 4.3)

Oil capacity

Total (dry engine) liters (US qt, Imp qt) 4.3 (4.5, 3.8)

Oil capacity Oil pan liters (US qt, Imp qt) 3.6 (3.8, 3.2) Oil capacity

Oil filter liters (US qt, Imp qt) 0.2 (0.21, 0.18) 0.3 (0.32, 0.26)

Engine oil (API service) SD, SE, or SF

76G02A-003

Recommended SAE Viscosity

Temperature j0pj

-30 -20 -10 0 10 20 30 40 50 I l I I 1 < ! I I Temperature j0pj i i i i I i 1 1

-20 0 20 40 60 80 100 120

Engine oil Engine oil

5W-30 X 30 >

Engine oil Engine oil

5W-20 > < 20W-20 > < 40

Engine oil < 10W-30 > Engine oil

< 10W-40 10W-50

Engine oil Engine oil

< 20W-40 20W-50

Engine oil

Temperature range anticipated before next oil change, °C(°F)

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine oil

Insufficient engine oil

Replace

Add oil

2A— 5

2A— 5

Excessive oil con-

sumption

Oil working up or working down

Oil leakage

Refer to Section 1

Repair

Oil pressure drop Insufficient oil

Oil leakage

Worn or damaged oil pump gear

Worn plunger (inside oil pump) or weak spring

Clogged oil strainer

Excessive main bearing or connecting rod bearing

clearance

Add oil

Repair

Replace

Replace

Clean

Refer to Section 1

2A- 5

2A-11

2A-11

Warning lamp illu-

minated while en-

gine running

Oil pressure drop

Malfunction of oil pressure switch

Malfunction of electrical system

As described above

Refer to Section 15

Refer to Section 15

76G02A-004

2A—4

Page 328 of 1865

2B TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine

oil

Insufficient engine

oil

Replace

Add

oil

2B—

6

2B—

5

Excessive oil

consumption

Oil working

up or

working down

Oil leakage

Refer

to

Section

1C

As described below

Oil leakage

Loose drain plug

or

damaged washer

Faulty seal

at oil

pan and cylinder block

Damaged cylinder head cover and

its

seal

Loose

oil

pump body bolt, cylinder head cover bolt,

or

oil pan bolt

Damaged front housing gasket,

or

cylinder head gasket

Faulty

oil

seal(s)

Loose

oil

filter

Loose

or

damaged

oil

pressure switch

Tighten

or

replace

Repair

Replace

Tighten

Replace

Replace

Tighten

Tighten

or

replace

2B—10

2B—10

2B-

6

Oil pressure drop

Oil leakage

Insufficient

oil

Worn and/or damaged

oil

pump gear

Worn plunger (inside

oil

pump)

or

weak spring

Clogged

oil

strainer

Excessive

oil

clearance between main bearing

or

con-

necting

rod

bearing

As described above

Add

oil

Replace

Replace

Clean

Refer

to

Section

1C

2B-

5

2B—13

2B—14

Warning lamp il-

luminates while

engine running

Oil pressure drop

Malfunction

of oil

pressure switch

Malfunction

of

electrical system

As described above

Refer

to

Section

15

Refer

to

Section

15

76G02B-005

2B—4

Page 366 of 1865

4A

FUEL AND EMISSION

CONTROL SYSTEMS

(CARBURETOR)

OUTLINE 4A— 2

SYSTEM DIAGRAM 4A— 2

VACUUM HOSE ROUTING

DIAGRAM 4A— 5

EMISSION COMPONENTS

LOCATION 4A— 8

COMPONENT DESCRIPTIONS 4A—12

SPECIFICATIONS 4A—15

TROUBLESHOOTING GUIDE 4A—17

PARTS INSPECTION 4A—23

AIR CLEANER ELEMENT 4A—23

ACCELERATOR LINKAGE 4A—23

INTAKE MANIFOLD 4A—23

CHOKE CABLE 4A—23

FUEL SYSTEM 4A—24

TROUBLESHOOTING 4A—25

CARBURETOR 4A—26

FUEL PUMP 4A—35

FUEL TANK 4A—36

SEPARATOR 4A—37

TWO-WAY CHECK VALVE 4A—37

THREE-WAY CHECK VALVE 4A—37

FUEL FILTER 4A—37

IDLE SPEED AND IDLE MIXTURE.. 4A—38

ADJUSTMENT 4A—38

AUTO-RETURN CHOKE SYSTEM... 4A—40

TROUBLESHOOTING 4A—40

PTC HEATER SYSTEM 4A—42

TROUBLESHOOTING 4A—42

DECELERATION CONTROL SYSTEM 4A—45

TROUBLESHOOTING 4A—45

BYPASS AIR CONTROL SYSTEM.. 4A—48

DASH POT 4A—50

ANTI-AFTERBURN VALVE 4A—50

MAIN AIR BLEED CONTROL

SYSTEM 4A—51

SLOW FUEL CUT SYSTEM 4A—53

COAST ENRICHMENT SYSTEM .... 4A—54

COASTING LEANER SYSTEM 4A—56

AIR INJECTION SYSTEM 4A—58

INTAKE AIR TEMPERATURE CONTROL

SYSTEM 4A—60

TROUBLESHOOTING 4A—60

PURGE CONTROL SYSTEM 4A—63

VACUUM SWITCH VALVE 4A—63

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM 4A—64

TROUBLESHOOTING 4A—65

POSITIVE CRANKCASE VENTILATION

SYSTEM 4A—67

PCV VALVE 4A—67

IDLE-UP CONTROL SYSTEM 4A—68

TROUBLESHOOTING 4A—70

IDLE-UP SOLENOID VALVE 4A—76

EVAPORATIVE EMISSION CONTROL

SYSTEM 4A—78

TROUBLESHOOTING 4A—79

IGNITION TIMING CONTROL

SYSTEM 4A-80

TROUBLESHOOTING 4A—81

CONTROL SYSTEM 4A-83

RELATIONSHIP CHART 4A—84

ENGINE CONTROL UNIT 4A—86

INHIBITOR SWITCH 4A—93

IDLE SWITCH 4A—93

VACUUM SWITCH 4A—94

WATER THERMO SWITCH 4A—95

EXHAUST SYSTEM 4A—96

76G04A-001

Page 378 of 1865

OUTLINE

4A

Previous

626

Unlead-

ed

fuel

O O O O O O X O O O X

Previous

626

Leaded

fuel

O X X O O X X X O X

New

626

FE

8

Valve

Unlead-

ed

fuel

o O O O O O X X O O O

New

626

Sin-

gapore

o O X O O m O

O

(FE

&

F8)

O

O

(FE

&

F8)

O O

New

626

Middle

East

o X X O O X X X X X O

New

626

General

X

O

(FE

& F8)

X O O X

O

(FE

&

F8)

O

(FE

&

F8)

O

(FE

&

F8)

X o

New

626

ECE

&

Hong

Kong

o O X O O * O O O O O o

Remark

• Adjustment

speed:

2,200

±

100

rpm

(in

neutral).

• MTX • Operation:

Coolant

tempera-

ture

more

than

50°C

(122°F).

Mechanical

type

Installed

on

carburetor.

Improvement

of

product

quality.

Function

Allows

throttle

to

gradually

close

during

deceleration.

Reduces

CO

and

HC

emission.

Detects

electrical

signal

from

in-

put

devices

and

controls

output

devices. Supplies

exhaust

gas

to

intake

manifold

to

reduce

NOx

Filters

fuel

Provides

fuel

to

carburetor.

Detects

when

throttle

valve

fully

closed. Opens

fuel

passage

to

secon-

dary

stage

of

carburetor.

Controls

shutter

valve

by

intake

air

temperature. Prevents

carburetor

icing.

Supplies

fresh

air

to

exhaust

manifold

to

reduce

CO

and

HC

emissions. Prevents

fuel

from

flowing

into

two-way

or

three-way

check

valve

Component

Dashpot Engine

Contorol

Unit

EGR

Control

Valve

Fuel

Filter

Fuel

Pump

Idle

Switch

Idle-up

Solenoid

Valve

Intake

Air

Temperature

Control

Valve

PTC

Heater

Reed

Valve

Separator

•a a> a -a .2-S

3

9-a a) 5 u- O UJ

z

Ox

111 IL •a c

V (-

U.ps •o

-

X

_ X

I-

o-t-

s ®

s

*

o *

oo

x to

U. UJ

u.

T- oi CO

4 A—13

Page 380 of 1865

OUTLINE 4A

SPECIFICATIONS

F6 & F8 Engine

Engine F6 F8

Specification General Singapore General

ECE,

Hong Kong, &

Singapore

Idle speed

rpm

MTX 800

+58

Idle speed

rpm

ATX 950

t5§

(in N range)|

900 +5§ (in N

range)

CO concentration

%

2.0

± 0.5

(Without secondary

air

injection)

Carburetor

Type Down draft, two barrel

Throat diameter

mm (in)

Primary 30 (1.18) Throat diameter

mm (in)

Secondary 34 (1.34)

Venturi diameter

mm

(in) Primary 23.5 (0.93) Venturi diameter

mm

(in) Secondary 29.0 (1.14)

Main nozzle

mm (in)

Primary 2.6 (0.10) Main nozzle

mm (in)

Secondary 2.8 (0.11)

Main

jet mm (in)

Primary MTX 1.10 (0.0433) 1.09 (0.0429) 1.14 (0.045)

Main

jet mm (in)

Primary ATX 1.10 (0.0433) 1.08 (0.0425) 1.12 (0.044) Main

jet mm (in)

Secondary 1.50 (0.059)

Main

air

bleed mm (in)

Primary MTX 0.60 (0.024) 0.60 (0.024) 0.55 (0.022) Main

air

bleed mm (in)

Primary ATX 0.60 (0.024) 0.80 (0.031) 0.60 (0.024) Main

air

bleed mm (in) Secondary 0.50 (0.020)

Slow

jet mm (in)

Primary 0.48 (0.019) 0.46 (0.018) Slow

jet mm (in)

Secondary 1.00 (0.039) 1.10 (0.043)

Slow

air

bleed mm (in)

Primary No.1 0.80 (0.031)

Slow

air

bleed mm (in)

Primary No.2 1.90 (0.075) Slow

air

bleed mm (in) Secondary No.1 1.00 (0.039) 0.80 (0.031) Slow

air

bleed mm (in) Secondary No.2 0.50 (0.020)

Power

jet mm (in)

0.50 (0.0201

Fast idle adjustment

mm (in)

Clearance between

Drimarv

throttle valve and bore

1.40-1.76 (0.055—0.069) MTX: 0.48-0.64 (0.019-0.025) ATX: 0.56-0.72 (0.022-0.028)

Float level adjustment mm (in)

Max. fuel flow

"L"

Clearance between

flo

44 (17.3)

at and

air

horn without aasket Float level adjustment mm (in) Fuel stop

"H"

12.5(0.49)

Clearance between float and

air

horn without aasket; float lowered

by

own weight

Choke breaker diaphragm mmHg (inHg)

Start 180-240 (7.1—9.5) 100-160 (3.9—6.3) Choke breaker diaphragm mmHg (inHg) Stop 290-350 (11.4—13.8) 220—280 8.7—11.01

Choke opener mmHg (inHg) Start 35-65 (1.4-2.6)

...

35-65 (1.4-2.6) Choke opener mmHg (inHg) Stop

......

130-190 (5.1-7.5) 130-190 (5.1-7.5)

Fuel tank capacity

Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel Dump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8—3.8)

Feeding capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switching Manual Diaphragm type

Element tvoe Oil permeated paper

Fuel specification Leaded regular

76G04A-513

4 A—15

Page 381 of 1865

4A OUTLINE

FE Engine

Engine FE 8Valve FE 12Valve FE 8Valve

Specification General Middle East

ECE, Hong Kong, & Singapore Unleaded fuel

Idle speed

rpm

MTX 800

+5§

850

+5§

Idle speed

rpm

ATX 900

+58 (in N

range)

CO concentration

%

2.0

± 0.5

(Without secondary

air

injection)

Carburetor

Type Down draft,

two

barrel

Throat diameter

mm (in)

Primary 30 (1.18) Throat diameter

mm (in)

Secondary 34 (1.34)

Venturi diameter

mm (in)

Primary 23.5 (0.93) Venturi diameter

mm (in)

Secondary 29.0 (1.14)

Main nozzle

mm (in)

Primary 2.6 (0.10) Main nozzle

mm (in)

Secondary 2.8 (0.11)

Main

jet mm (in)

Primary MTX 1.14 (0.045) 1.09 (0.0429) 1.14 (0.045) 1.09 (0.0429) Main

jet mm (in)

Primary ATX 1.12 (0.044) 1.08 (0.0425) 1.12 (0.044) 1.09 (0.0429) Main

jet mm (in)

Secondary 1.55 (0.061) 1.50 (0.059) 1.55 (0.061) 1.50 (0.059)

Main

air

bleed

mm (in)

Primary MTX 0.50 (0.020) 0.60(0.024) 0.50 (0.020) 0.50 (0.020) Main

air

bleed

mm (in)

Primary ATX 0.55 (0.022) 0.80 (0.031) 0.55 (0.022) 0.50 (0.020) Main

air

bleed

mm (in) Secondary 0.50 (0.020)

Slow

jet mm (in)

Primary 0.46 (0.018)

Slow

jet mm (in)

Secondary MTX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 0.90 (0.035) Slow

jet mm (in)

Secondary ATX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 1.00 (0.039)

Slow

air

bleed

mm (in)

Primary No.1 0.80 (0.031)

Slow

air

bleed

mm (in)

Primary No.2 1.90 (0.075) Slow

air

bleed

mm (in) Secondary No.1 0.80 (0.031) 1.00 (0.039) 0.80 (0.031) 1.00 (0.039)

Slow

air

bleed

mm (in) Secondary No.2 0.50 (0.020)

Power

jet mm (in)

MTX 0.50 (0.020) 0.50 (0.020) Power

jet mm (in)

ATX 0.50 (0.020) 0.40 (0.016)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore

MTX 0.48—0.64

(0.019-0.025) 1.40—1.76

(0.055-0.069)

0.48—0.64

(0.019-0.025) 1.40-1.76

(0.055-0.069)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore ATX 0.56-0.72 (0.022—0.028)

1.40—1.76

(0.055-0.069) 0.56-0.72 (0.022—0.028)

1.40-1.76

(0.055-0.069)

Float level adjust-

ment

mm (in)

Max. fuel flow

"L"

Clearance between

flo

44 (17.3)

at and

air

horn without aasket Float level adjust-

ment

mm (in)

Fuel stop

"H" |

12.5(0.49)

Clearance between float and

air

horn without aasket: float lowered

bv

own weiaht

Choke breaker diaphragm mm-Hg (in-Hg)

Start 100-160 (3.9—6.3) 180—240 (7.1-9.4) 100-160

(3.9-6.3)

180-240

(7.1-9.4) Choke breaker diaphragm mm-Hg (in-Hg) Stop 220—280

(8.7-11.0)

290-350

(11.4-13.8)

220—280

(8.7-11.0)

290-350

(11.4-13.8)

Choke opener mmHg (inHg)

Start 80—120

(3.1-8.7)

30-70 (1.2-2.8) Choke opener mmHg (inHg)

Stop 220-280 (8.7—11.0) 130-190

(5.1-7.5)

Fuel tank capacity

Liters (US aal, Imp aal) 60 (15.9, 13.2)

Fuel DumD

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20—0.27, 2.8-3.8) 20-29 (0.20-0.30, 2.8-4.3)

20-26 (0.20-0.27, 2.8-3.8)

Feedina caDacitv cc/min

feu

in/mini More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switchina Diaphragm Manual Diaphragm Bimetal

Element

tvDe

Oil permeated paper

Fuel specification Leaded super

Unleaded super Leaded regular Leaded super Unleaded super Unleaded regular

76G04G-514

4A—16