ignition MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 10 of 1865

G TOWING

76GOGX-OQ2

i-^C.

y -

- r^jfftj&H

r —I

76UQGX-003

86U0GX-004

G—8

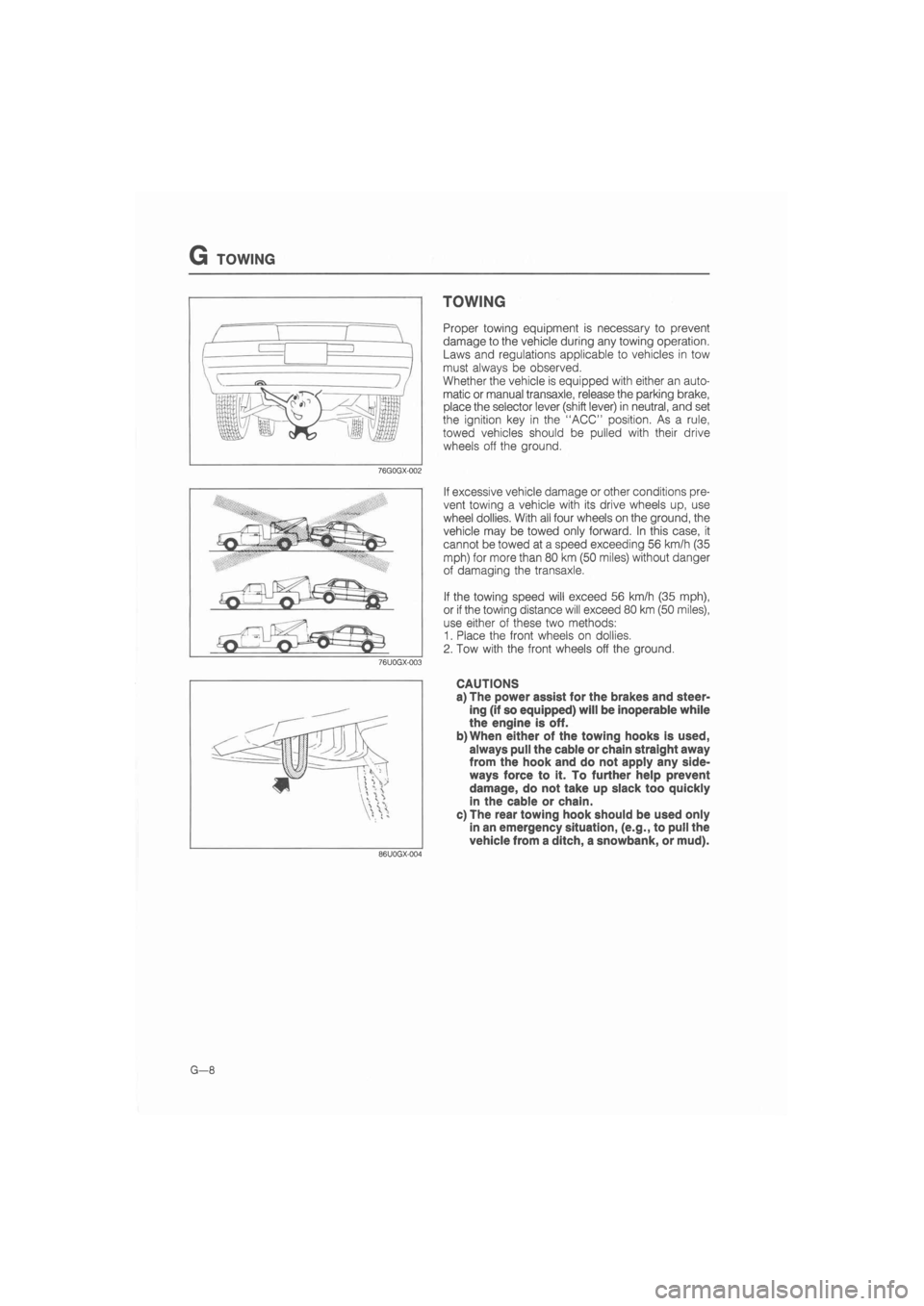

TOWING

Proper towing equipment is necessary to prevent

damage to the vehicle during any towing operation.

Laws and regulations applicable to vehicles in tow

must always be observed.

Whether the vehicle is equipped with either an auto-

matic or manual transaxle, release the parking brake,

place the selector lever (shift lever) in neutral, and set

the ignition key in the "ACC" position. As a rule,

towed vehicles should be pulled with their drive

wheels off the ground.

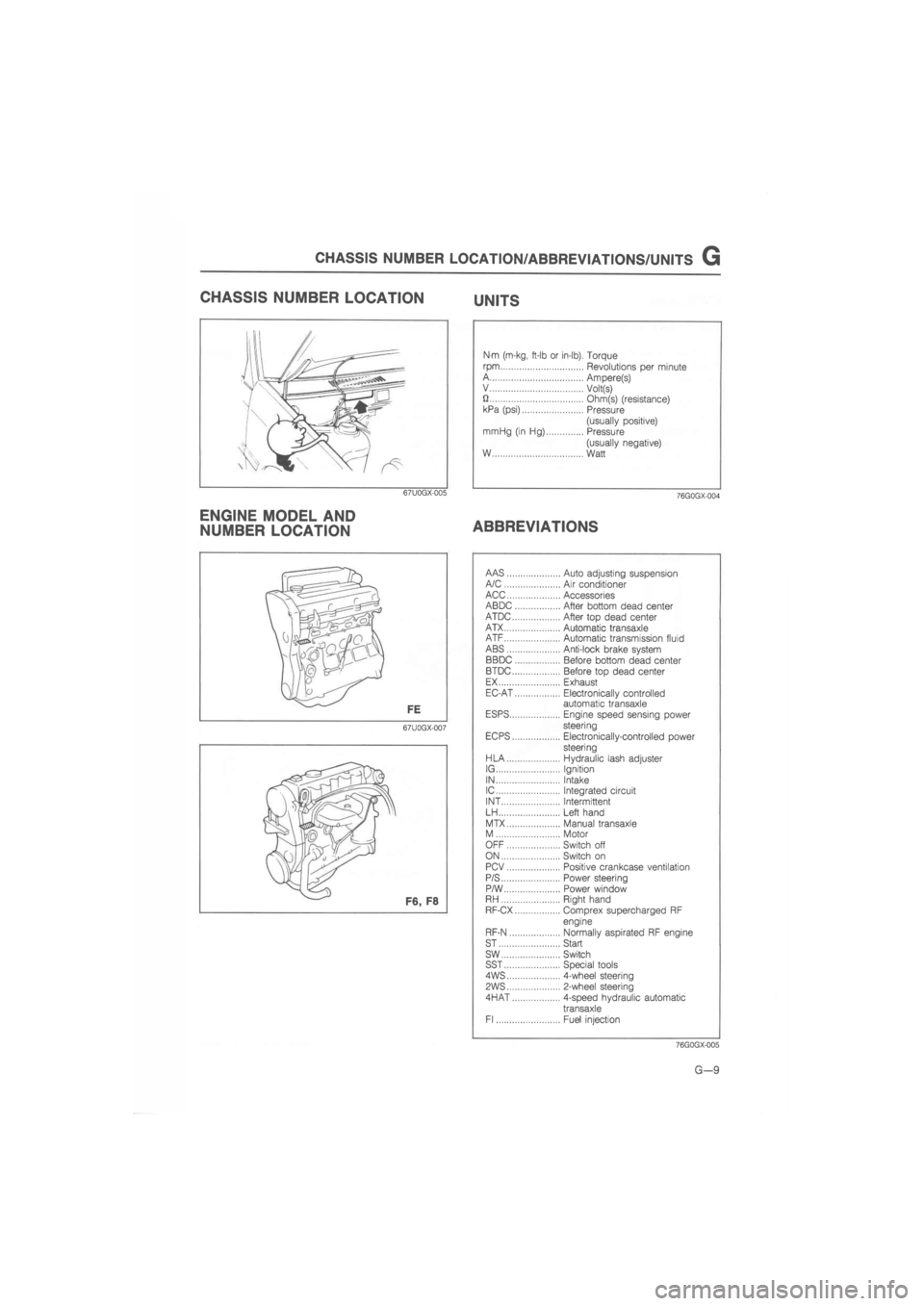

If excessive vehicle damage or other conditions pre-

vent towing a vehicle with its drive wheels up, use

wheel dollies. With all four wheels on the ground, the

vehicle may be towed only forward. In this case, it

cannot be towed at a speed exceeding 56 km/h (35

mph) for more than 80 km (50 miles) without danger

of damaging the transaxle.

If the towing speed will exceed 56 km/h (35 mph),

or if the towing distance will exceed 80 km (50 miles),

use either of these two methods:

1. Place the front wheels on dollies.

2. Tow with the front wheels off the ground.

CAUTIONS

a) The power assist for the brakes and steer-

ing (if so equipped) will be inoperable while

the engine is off.

b)When either of the towing hooks is used,

always pull the cable or chain straight away

from the hook and do not apply any side-

ways force to it. To further help prevent

damage, do not take up slack too quickly

in the cable or chain.

c) The rear towing hook should be used only

in an emergency situation, (e.g., to pull the

vehicle from a ditch, a snowbank, or mud).

Page 11 of 1865

CHASSIS NUMBER LOCATION/ABBREVIATIONS/UNITS G

CHASSIS NUMBER LOCATION UNITS

67U0GX-005

ENGINE MODEL AND

NUMBER LOCATION

Nm (m-kg, ft-lb or in-lb). Torque

rpm Revolutions per minute A Ampere(s) V Volt(s) U Ohm(s) (resistance) kPa (psi) Pressure

(usually positive) mrriHg (in Hg) Pressure

(usually negative) W Watt

76G0GX-004

ABBREVIATIONS

67U0GX-007

AAS Auto adjusting suspension A/C Air conditioner ACC Accessories ABDC After bottom dead center ATDC After top dead center ATX Automatic transaxle ATF Automatic transmission fluid ABS Anti-lock brake system BBDC Before bottom dead center BTDC Before top dead center EX Exhaust EC-AT Electronically controlled automatic transaxle ESPS Engine speed sensing power steering EC PS Electronically-controlled power steering HLA Hydraulic lash adjuster IG Ignition IN Intake IC Integrated circuit INT Intermittent LH Left hand

MTX Manual transaxle M Motor OFF Switch off ON Switch on PCV Positive crankcase ventilation P/S Power steering P/W Power window RH Right hand RF-CX Comprex supercharged RF

engine

RF-N Normally aspirated RF engine ST Start sw Switch SST Special tools 4WS 4-wheel steering

PWS 2-wheel steering

4HAT 4-speed hydraulic automatic

transaxle Fl Fuel injection

76GQGX-005

G—9

Page 14 of 1865

0 PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

EXTERIOR

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Glass, exterior bright metal and paint for damage

• Wheel lug nuts

88—118 N m (9—12 m-kg, 65—87 ft-lb)

• Tire pressures (Refer to section 12)

• All weatherstrips for damage or detachment

• Operation of bonnet release and lock

• Operation of fuel lid and trunk lid (Back door) opener

• Door operation and alignment

• Headlight aiming

INSTALL following parts:

• Wheel caps or rings (if equipped)

• Outside rear view mirror(s)

UNDER BONNET—ENGINE OFF

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

• Engine oil level

• Power steering fluid level (if equipped)

• Brake and clutch master cylinder fluid level (if equipped)

• Windshield washer reservoir fluid level

• Radiator coolant level and specific gravity

Protection °C (°F) Specific gravity at 20°C (68°F)

-4 (25) 1.028

-16(3) 1.054

-26 (-15) 1.066 -40 (-40) 1.078

• Tightness of water hose clamps (including heater hoses)

• Tightness of battery terminals

• Manual transaxle oil level

• Drive belt tensions (Refer to section 1)

• Accelerator cable and its linkage for free movement

• Headlight cleaner fluid level (if equipped)

CLEAN spark plugs

INTERIOR

INSTALL the following parts:

• Rubber stopper for inside rear view mirror

• Fuse for accessories

CHECK the operations of the following items:

• Seat controls (sliding and reclining) and head rest

• Door locks including childproof door locks (if equipped)

• Seat belts and warning system

• Ignition switch and steering lock

• Inhibitor switch (ATX only)

• All lights including warning and indicator lights

• Sound warning system

• Headlight cleaner (if equipped)

• Horn, wipers and washers (front and rear, if equipped)

• Radio and antenna (if equipped)

• Cigarette lighter and clock

• Remote control outside rear view mirrors (if equipped)

• Power windows (if equipped)

• Heater, defroster and air conditioner at various mode

selection (if equipped)

• Sunroof (if equipped)

ADJUST antenna trimmer on radio (if equipped)

CHECK the following items:

• Presence of spare fuse

• Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

• Operation and fit of windows

• Pedal height and free play of brake and clutch pedal

Pedal height mm (in) free play mm (in)

Clutch pedal 216.5-221.5 (8.52-8.72) 5-13 (0.2-0.51)

Brake pedal 222-227 (8.74-8.94) 4-7 (0.16-0.28)

• Parking brake

5-7 noches/98 N (10 kg, 22lb)

UNDER BONNET—ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

• Operation of idle-up system for air conditioner or power

steering (if equipped)

• Automatic transaxle fluid level

• Operation of dash pot

• Initial ignition timing

• Idle speed

ON HOIST

CHECK the following items:

• Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

• Tires for cuts or bruises

• Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

REMOVE protective cover from brake discs

ROAD TEST"

CHECK the following items:

• Brake operation

• Clutch operation

• Steering control

• Operation of meters and gauge

• Squeaks, rattles or unusual noise

• Engine general performance (including turbo)

• Emergency locking retractors

• Cruise control system (if equipped)

AFTER ROAD TEST

REMOVE seat and floor mat protective covers

CHECK for necessary owner information materials, tools and

spare tire in vehicle

-76G00X-002

0-2

Page 15 of 1865

For ECE Leaded gasoline

Chart symbols:

I

A

R

T

O

X

Inspect: Visual examination or functional measurement of a system's operation (performance)

Adjust : Examination resulting in adjustment or replacement

Replace or change

Tighten

Applicable

Not applicable

F8 engine with carbretor, MTX, ATX

FE engine with carbretor, MTX, ATX

FE DOHC engine with fuel injection, 4WS, MTX

RF-CX, RF-N engine with MTX

REMARKS:

Major service interval at 12 months/20,000 km (12,000 Miles), Lubrication service based on distance only 10,000 km (6,000 Miles) not time

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1 Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*2 If the vehicle is operatie under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regulary.

*3. If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4. This is a full function check of all electrical systems, i.e., all lights, washers (including condition of blades) electrical windows, sunroof, horn, etc....

*5. Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the

brake fluid should be changed annually.

>

Z H m >

o m

H >

CD r-m

o m

m O m

(D o> Q. ® a

(Q 0) <0 o

m a

o m

c/> o x m a

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation.

It is strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

m a

m z >

z o m

G)

Page 18 of 1865

0 1 C5

Interval

Procedure & item

Number of Months or km, whichever corns first

Months

x 1000 Km

Miles x 1000

Fuel lines and hoses

Spark plugs

Initial ignition timing

Idle speed

Idle mixture

Dash pot (MTX)

0.6

6

10

12

20

12

18

30

18

24

40

24

30

50

30

36

60

36

42

70

42

48

80

48

©1

O

o

o

o

o

o

©2

O

o

o

o

o

o

©3

O

O

O

O

O

©4

O

Service data and inspection point

Fittings, connections and compo-

nents for leaks

Plug gap: F8, FE (8-VALVE) 0.75—0.85 mm (0.030—0.033 in) FE (12-VALVE) FE (DOHC) 0.7—0.8 mm (0.028—0.031 in) Recommended spark plugs

F6,F8,FE 8-VALVE FE 12-VALVE DOHC

NGK BPR 5ES

BPR 6ES

BCPR 5E BCPR 6E

Nippon

Denso

W16EXR-U

W20EXR-U

Q16PR-U* Q20PR-U

Initial ignition timing 6 ±

1

° BTDC 12 ± 1° BTDC (FE DOHC)

Check the idle speed (rpm) FE DOHC 700—800 Carburetor MTX 800—850, ATX 900—950 (N range)

CO concentration FE DOHC 1.5 ±0.5 % Others 2.0 ± 0.5 % HC concentration FE DOHC Less than 1000 rpm

Operation

Page

4B—42

5-9

5-11

4A-38 4C-29

4A-38 4C—30

4A-50

4B-67

m z >

z o m

H >

00 I-m

m o m

i-CD 0) Q. (D o.

5'

0 1 m a

m D

m z >

z o m

Only FE 12-VALVE

G)

o o o>

Page 21 of 1865

r

For ECE Unleaded gasoline

Chart symbols:

I

A

R

T

O

X

Inspect: Visual examination or functional measurement of a system's operation (performance)

Adjust: Examination resulting in adjustment or replacement

Replace or change

Tighten

Applicable

Not applicable

FE engine with fuel injection, MTX, ATX

FE DOHC engine with fuel injection, 4WS, MTX

FE engine with carburetor, MTX, ATX

RF-CX, RF-N engine with MTX

REMARKS:

Major service interval at 12 months/20,000 km (12,000 Miles), Lubrication service based on distance only 10,000 km (6,000 Miles) not time

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1 Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*2 If the vehicle is operated under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended

intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regulary.

*3. If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4. This is a full function check of all electrical systems, i.e., all lights, washers (including condition of blades) electrical windows, sunroof, horn, etc....

*5. Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the brake fluid

should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It is

strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

>

Z H m z >

o m

H >

DJ r~ m

m o m

c 3

(/> O X m o c i-m

o

m z >

z o m

CD

Page 24 of 1865

o

r\3

Interval

Procedure & item

Number of Months or km, whichever corns first

Months

x

1000 Km

Miles x 1000

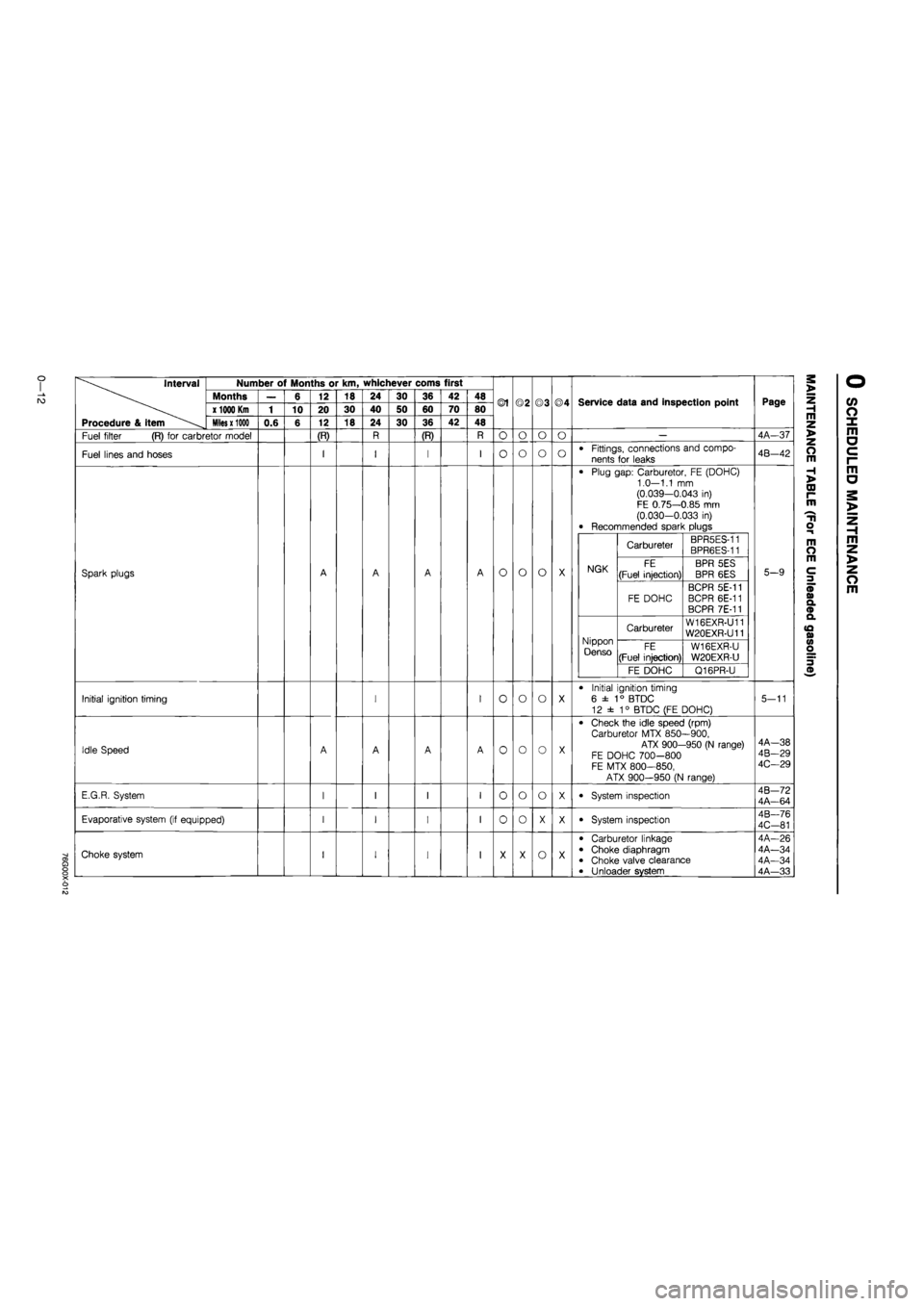

Fuel filter (R) for carbretor model

Fuel lines and hoses

Spark plugs

Initial ignition timing

Idle Speed

E.G.R. System

Evaporative system (if equipped)

O) O

X o

Choke system

0.6

6

10

12

20

12

(R)

18

30

18

24

40

24

30

50

30

36

60

36

(R)

42

70

42

48

80

48

©1

O

O

o

o

o

o

o

o

o

o

o

o

o

o

©3

o

o

o

o

o

o

o

©4

o

o

Service data and inspection point

Fittings, connections and compo-

nents for leaks

Plug gap: Carburetor, FE (DOHC) 1.0—1.1 mm (0.039—0.043 in) FE 0.75—0.85 mm (0.030-0.033 in) Recommended spark plugs

NGK

Carbureter BPR5ES-11 BPR6ES-11

NGK FE

(Fuel injection)

BPR 5ES

BPR 6ES NGK

FE DOHC

BCPR 5E-11 BCPR 6E-11 BCPR 7E-11

Nippon Denso

Carbureter W16EXR-U11 W20EXR-U11 Nippon Denso FE

(Fuel injection)

W16EXR-U

W20EXR-U

Nippon Denso

FE DOHC Q16PR-U

Initial ignition timing

6 ±

1

° BTDC

12 ± 1° BTDC (FE DOHC)

Check the idle speed (rpm) Carburetor MTX 850—900,

ATX 900-950 (N range) FE DOHC 700-800 FE MTX 800—850,

ATX 900-950 (N range)

System inspection

System inspection

Carburetor linkage Choke diaphragm Choke valve clearance Unloader system

Page

4A-37

4B-42

5-9

5-11

4A—38 4B-29 4C—29

4B—72 4A—64

4B—76

4C-81

4A-26 4A—34 4A—34 4A—33

m z >

z o m

H >

00 r-m

H o

m O m

3

CO o X m a c i-m a

m z >

z o m

Page 27 of 1865

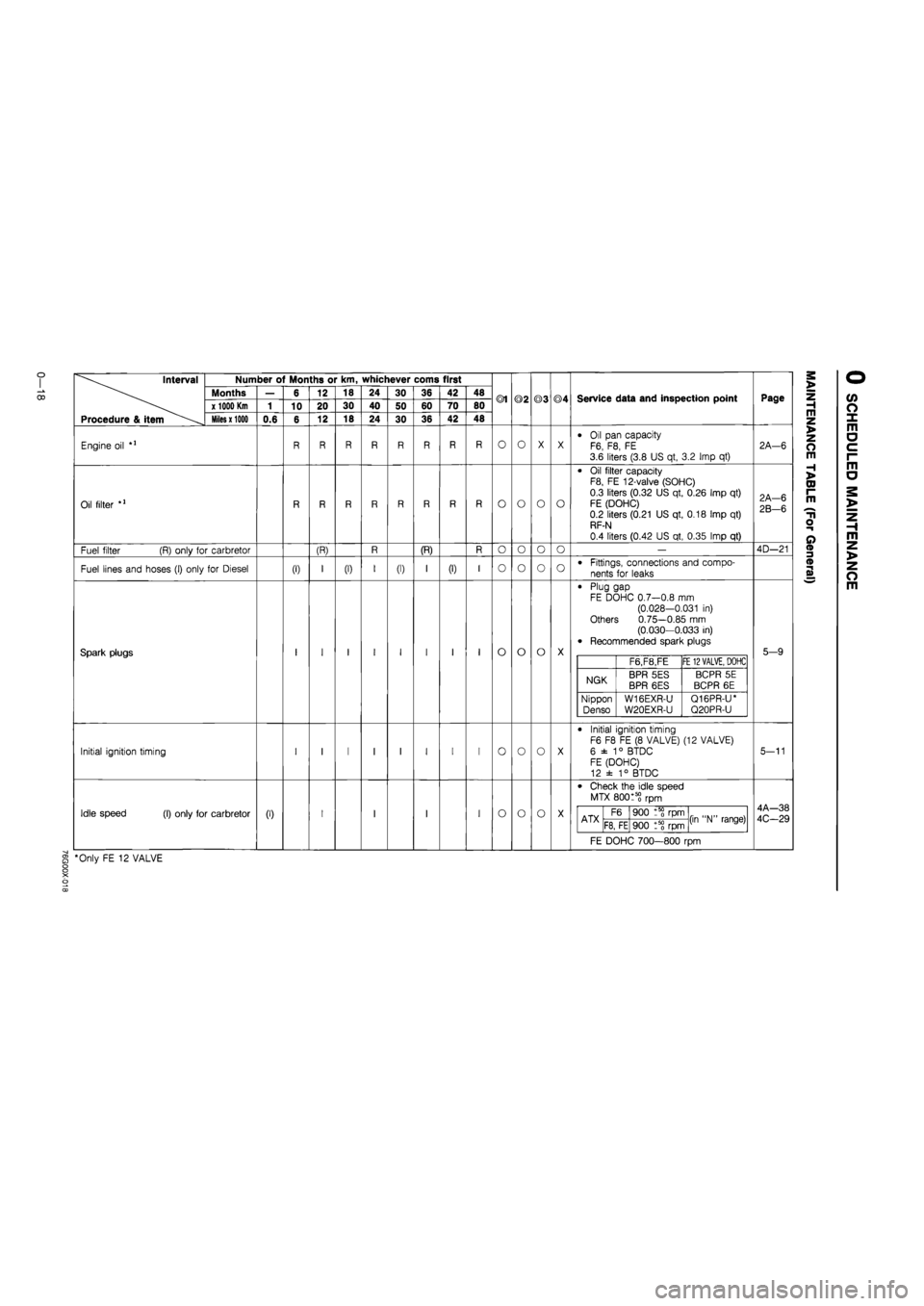

For General

Chart symbols:

I : Inspect: Visual examination and/or functional measurement of a system's operation or performance.

A : Adjust: Examination resuiting in adjustment or replacement.

R : Replace or change

T : Tighten

O : Applicable

X : Not applicable

© 1 : F6, F8 engine with carburetor, MTX, ATX

© 2 : FE engine with carbretor, MTX, ATX

©3 : FE DOHC engine with fuel injection, MTX

® 4 : RF-N engine with MTX

NOTE:

As the result of visual examination or functional measurement of a system's operation(performance), correct, clean or replace as required.

REMARKS:

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1. If the vehicle is operated under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended

intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regularly.

"2. Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*3 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt, vacuum pump belt, super charger belt if equipped.

*5 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the

brake fluid should be changed annually.

*6. Only F6 carbretor for Singapore (MTX Model)

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It i

strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

o CJ1

Page 30 of 1865

Interval

Procedure & item

Number of Months or km, whichever corns first

Months

x 1000 Km

Miles x 1000

Engine oil

Oil filter

Fuel filter (R) only for carbretor

Fuel lines and hoses (I) only for Diesel

Spark plugs

Initial ignition timing

Idle speed (I) only for carbretor

0.6

(I)

6

10

(0

12

20

12

(R)

18

30

18

(I)

24

40

24

30

50

30

(I)

36

60

36

(R)

42

70

42

(I)

48

80

48

®1

O

o

o

o

o

o

o

©2

O

o

o

o

o

o

o

©3

O

o

o

o

o

o

©4

O

o

o

Service data and inspection point

Oil pan capacity F6, F8, FE 3.6 liters (3.8 US qt, 3.2 Imp qt)

Oil filter capacity F8, FE 12-valve (SOHC)

0.3 liters (0.32 US qt, 0.26 Imp qt)

FE (DOHC) 0.2 liters (0.21 US qt, 0.18 Imp qt) RF-N

0.4 liters (0.42 US qt, 0.35 Imp qt)

Fittings, connections and compo-

nents for leaks

Plug gap FE DOHC 0.7—0.8 mm (0.028-0.031 in) Others 0.75—0.85 mm (0.030—0.033 in) Recommended spark plugs

F6,F8,FE FE

12 VALVE,

DOHC

NGK BPR 5ES BPR 6ES BCPR 5E

BCPR 6E

Nippon

Denso W16EXR-U

W20EXR-U

Q16PR-U* Q20PR-U

Initial ignition timing F6 F8 FE (8 VALVE) (12 VALVE)

6 ±

1

° BTDC FE (DOHC) 12 ± 1° BTDC

Check the idle speed

MTX 80015? rpm

ATX F6 900 rpm (in "N" range) ATX F8, FE 900 t5? rpm (in "N" range)

FE DOHC 700—800 rpm

§ *Only FE 12 VALVE

Page

2A—6

2A-6

2B-6

4D—21

5-9

5-11

4A—38

4C-29

m z >

z o m

H >

CD I-m

T1

o

o

m z >

z o m

Page 36 of 1865

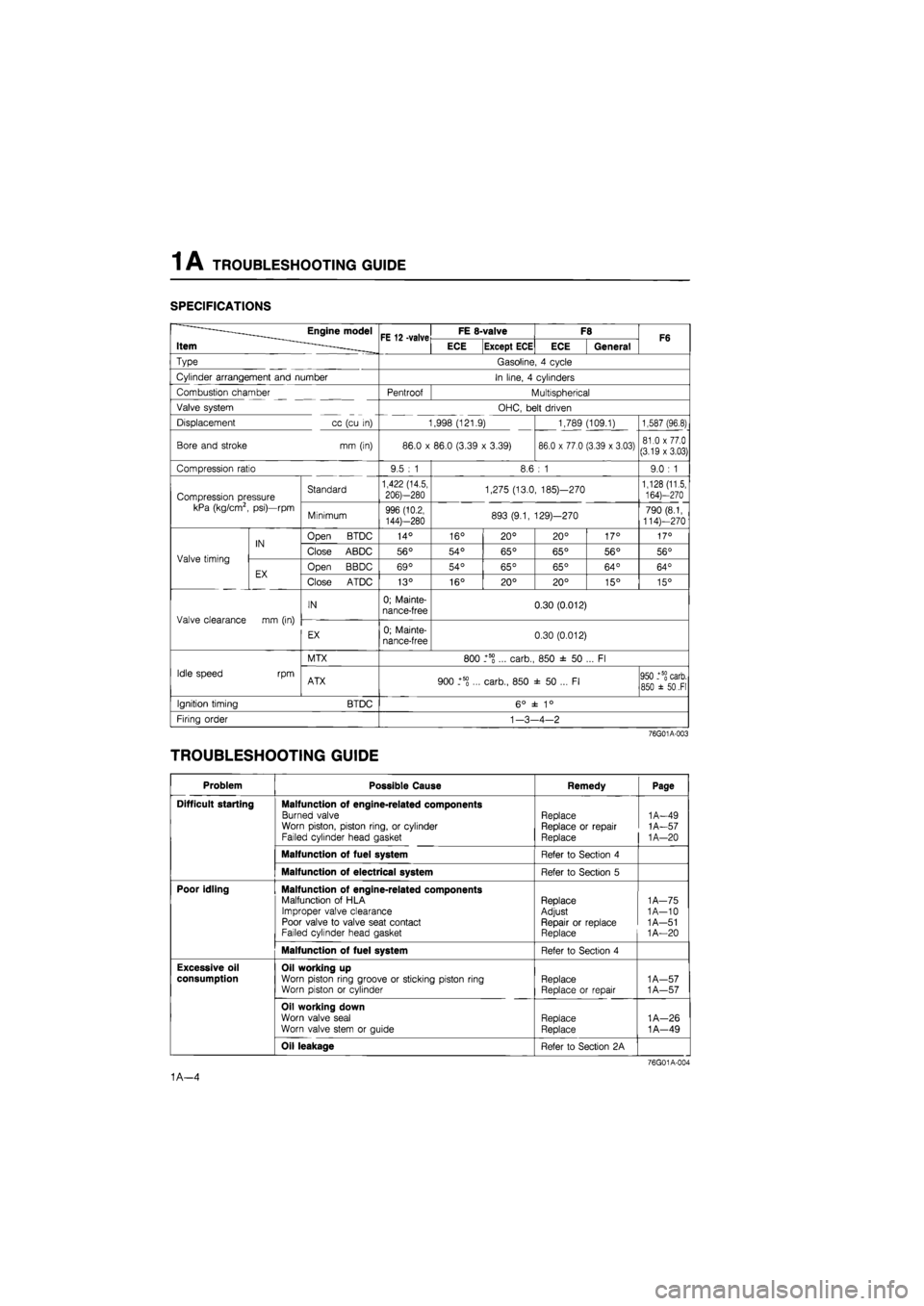

1A TROUBLESHOOTING GUIDE

SPECIFICATIONS

——Engine model

Item ^ FE 12 -valve FE 8-valve F8 F6 ——Engine model

Item ^ FE 12 -valve ECE Except ECE ECE General F6

Type Gasoline, 4 cycle

Cylinder arrangement and number In line, 4 cylinders

Combustion chamber Pentroof Multispherical

Valve system OHC, belt driven

Displacement cc (cu in) 1,998 (121.9) 1,789 (109.1) 1,587 (96.8)

Bore and stroke mm (in) 86.0 x 86.0 (3.39 x 3.39) 86.0 x 77.0 (3.39 x 3.03) 81.0 x 77.0 (3.19 x 3.03)

Compression ratio 9.5 : 1 8.6 : 1 9.0 : 1

Compression pressure kPa (kg/cm2, psi)—rpm

Standard 1,422 (14.5,

206)—280 1,275 (13.0, 185)—270 1,128 (11.5, 164)—270 Compression pressure kPa (kg/cm2, psi)—rpm Minimum 996 (10.2,

144)—280 893 (9.1, 129)—270 790 (8.1, 114)—270

Valve timing

IN Open BTDC 14° 16° 20° 20° 17° 17°

Valve timing

IN Close ABDC 56° 54° 65° 65° 56° 56° Valve timing

EX Open BBDC 69° 54° 65° 65° 64° 64° Valve timing

EX Close ATDC 13° 16° 20° 20° 15° 15°

Valve clearance mm (in)

IN 0; Mainte-nance-free 0.30 (0.012)

Valve clearance mm (in)

EX 0; Mainte-nance-free 0.30 (0.012)

Idle speed rpm

MTX 800 _+5S ... carb., 850 ± 50 ... Fl

Idle speed rpm ATX 900 _+5g ... carb., 850 ± 50 ... Fl 950 _+5§ carb. 850 ±

50

.Fl

Ignition timing BTDC 6° ± 1°

Firing order

1

-3-4-2

76G01A-003

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Difficult starting Malfunction of engine-related components

Burned valve Worn piston, piston ring, or cylinder Failed cylinder head gasket

Replace Replace or repair Replace

1A-49

1A-57

1

A—20

Malfunction of fuel system Refer to Section 4

Malfunction of electrical system Refer to Section 5

Poor idling Malfunction of engine-related components Malfunction of HLA Improper valve clearance Poor valve to valve seat contact Failed cylinder head gasket

Replace Adjust Repair or replace Replace

1

A—75 1A-10 1 A—51

1

A—20

Malfunction of fuel system Refer to Section 4

Excessive oil

consumption

Oil working up Worn piston ring groove or sticking piston ring Worn piston or cylinder Replace Replace or repair

1

A—57 1A—57

Oil working down

Worn valve seal

Worn valve stem or guide Replace

Replace

1A—26

1A—49

Oil leakage Refer to Section 2A

76G01A-004

1A—4