ignition MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 42 of 1865

1A TUNE-UP PROCEDURE

No.1 IN No.2 IN

No.1 EX No.3 EX

76G01A-015

Adjust bolt

^N^^^^^Lock nut

SsKs&b ' Valve

Camshaft >Nw clearance

76G01A-016

76G01A-017

Valve Clearance (8-valve)

1. Warm up the engine to the normal operating tem-

perature.

2. With the piston of the No.1 cylinder at TDC of com-

pression stroke.

Adjust the valve clearance as shown in the figure.

Valve clearance (valve side)

IN : 0.30 mm (0.012 in)

EX: 0.30 mm (0.012 in)

3. Turn the crankshaft one full turn so that the piston

of the No.4 cylinder is at TDC of compression

stroke.

Adjust the clearances of the remaining valves.

Ignition Timing

1. Warm up the engine and run it at idle.

2. Turn all electric loads OFF.

3. Connect a timing light tester.

4. Disconnect the vacuum hose from the vacuum

control, and plug the hose.

5. Check that the ignition timing mark (yellow) on the

crankshaft pulley and the timing mark on the tim-

ing belt cover are aligned.

Ignition timing: 6° ±

1

° BTDC (at idle speed)

6. If necessary adjust the ignition timing by turning

the distributor.

69G01B-518

1A—10

Page 45 of 1865

ON-VEHICLE INSPECTION 1 A

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following points.

1. Ignition system (Refer to Section 5)

2. Compression

3. Fuel system (Refer to Section 4)

COMPRESSION

1. Check that the battery is fully charged. Recharge

if necessary.

76G01A-107

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all spark plugs.

5. Disconnect the primary wire connector from the

ignition coil.

86U01X-020

6. Connect a compression gauge to No.

1

spark plug

hole.

7. Fully depress the accelerator pedal and crank the

engine.

8. Note the maximum gauge reading.

9. Check each cylinder.

Compression pressure kPa (kg/cm2, psi)-rpm

Standard Minimum

F6 1,128 (11.5, 164)—270 790 (8.1, 114)—270

F8-FE 1,275 (13.0, 185)—270 893 (9.1, 129)—270

FE 12-valve 1,422 (14.5, 206)—280 996 (10.2, 144)—280

76G01A-023

Possible Cause

86U01X-022

1A—13

Page 130 of 1865

1A INSTALLATION

76G01A-147

86U01X-199

86U01X-200

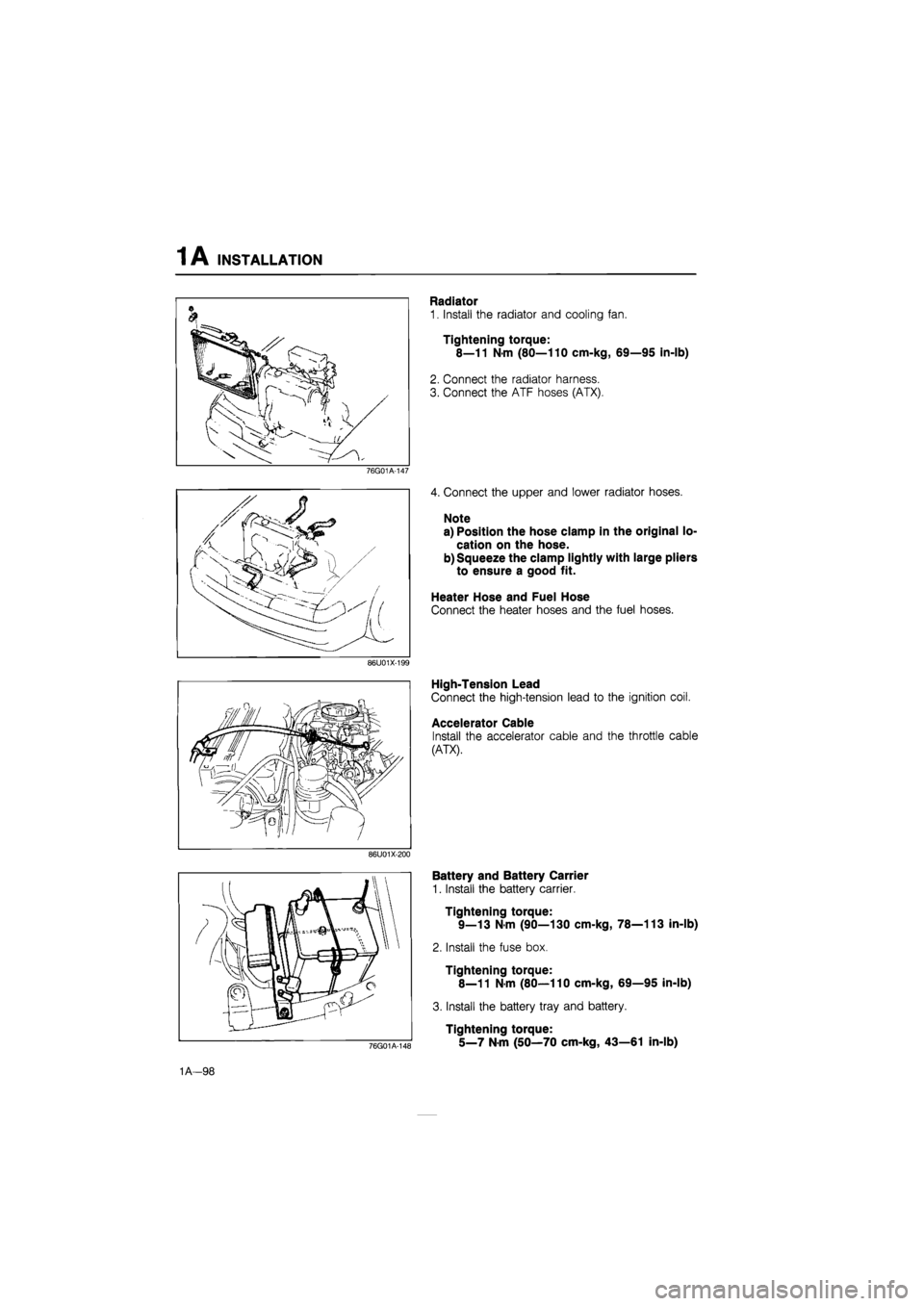

Radiator

1. Install the radiator and cooling fan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Connect the radiator harness.

3. Connect the ATF hoses (ATX).

4. Connect the upper and lower radiator hoses.

Note

a) Position the hose clamp in the original lo-

cation on the hose.

b) Squeeze the clamp lightly with large pliers

to ensure a good fit.

Heater Hose and Fuel Hose

Connect the heater hoses and the fuel hoses.

High-Tension Lead

Connect the high-tension lead to the ignition coil.

Accelerator Cable

Install the accelerator cable and the throttle cable

(ATX).

76G01A-148

Battery and Battery Carrier

1. Install the battery carrier.

Tightening torque:

9—13 N-m (90—130 cm-kg, 78—113 in-lb)

2. Install the fuse box.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

3. Install the battery tray and battery.

Tightening torque:

5_7 Nm (50—70 cm-kg, 43—61 in-lb)

1A—98

Page 134 of 1865

TROUBLESHOOTING GUIDE 1 B

SPECIFICATIONS

Engine model FE DOHC

Item Leaded fuel Unleaded fuel

Type Gasoline, 4 cycle

Cylinder arrangement and number In line, 4 cylinders

Combustion chamber Pentroof

Valve system OHC, belt driven

Displacement cc (cu in) 1,998 (121.9)

Bore and stroke mm (in) 86.0 x 86.0 (3.39 x 3.39)

Compression ratio 10.0 : 1 9.2 : 1

Compression pressure Standard 1,422 (14.5, 206)—290 1,373 (14.0, 199)—310

kPa (kg/cm2, psi)-rpm Minimum 996 (10.2, 144)—290 961 (9.8, 139)—310

IN Open BTDC 10° 10°

Valve timing

IN Close ABDC 60° 55° Valve timing

EX Open BBDC 60° 55° EX Close ATDC 10° 10°

Valve clearance mm (in) IN 0; Maintenance-free Valve clearance mm (in) EX 0; Maintenance-free

Idle speed rpm 750 ± 50

Ignition timing BTDC 12° ± 1°

Firing order 1—3--4-2

76G01B-002

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Difficult starting Malfunction of engine-related components

Burned valve

Worn piston, piston ring, or cylinder

Failed cylinder head gasket

Replace

Replace or repair Replace

1B—35 1B—43 1B—16

Malfunction of fuel system Refer to Section 4C

Malfunction of electrical system Refer to Section 5

Poor Idling Malfunction of engine-related components Malfunction of HLA

Poor valve to valve seat contact

Failed cylinder head gasket

Replace

Repair or replace

Replace

1B—60 1B—37 1B—16

Malfunction of fuel system Refer to Section 4C

Excessive oil

consumption Oil working up Worn piston ring groove or sticking piston ring Worn piston or cylinder

Replace

Replace or repair

1B-43 1B-43

Oil working down

Worn valve seal

Worn valve stem or guide

Replace

Replace 1B-35

Oil leakage Refer to Section 2A

76G01B-003

1B—3

Page 139 of 1865

TUNE-UP PROCEDURE 1 B

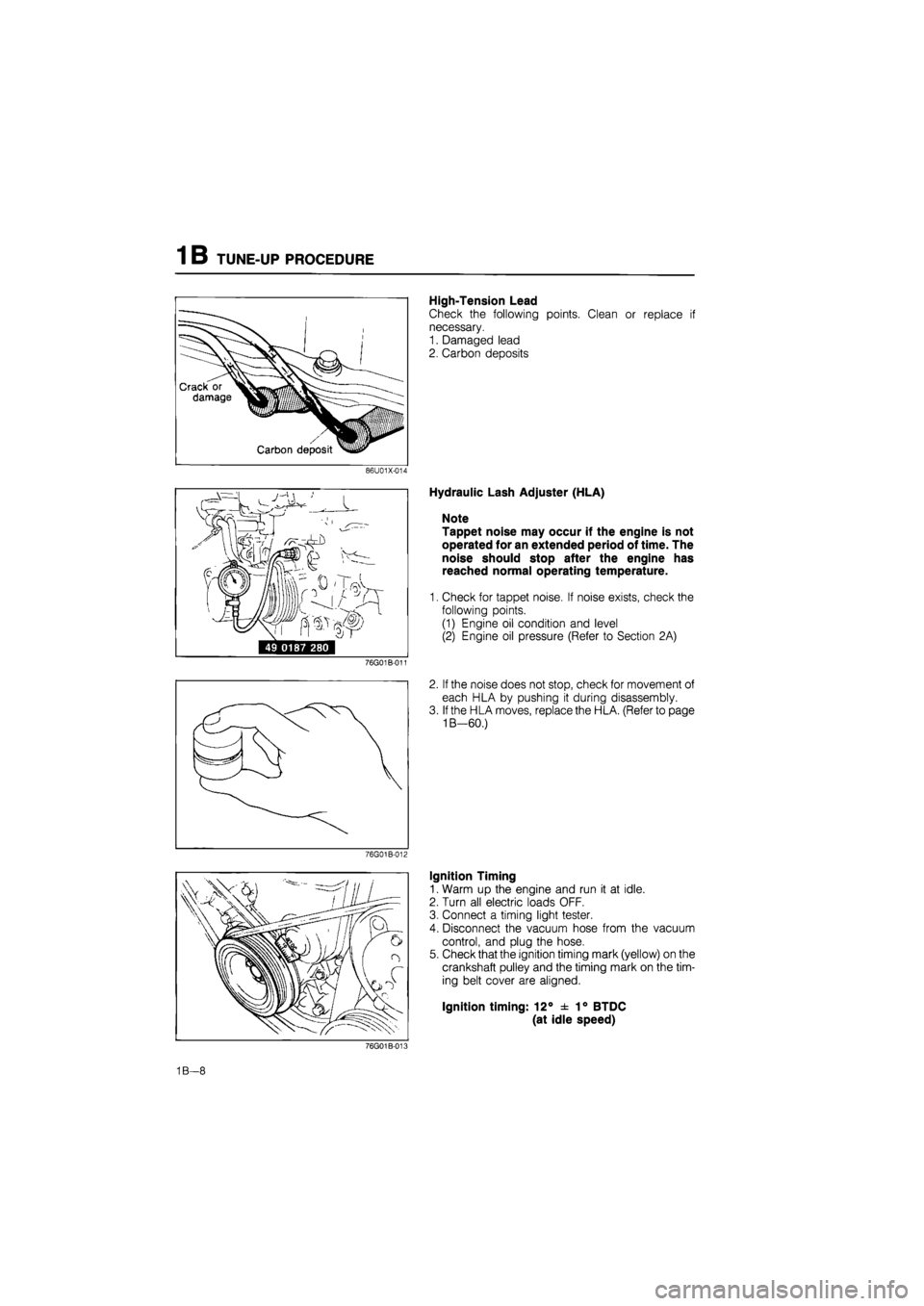

High-Tension Lead

Check the following points. Clean or replace if

necessary.

1. Damaged lead

2. Carbon deposits

86U01X-014

i^rrr ' /

49 0187 280

76G01B-011

76G01B-012

Hydraulic Lash Adjuster (HLA)

Note

Tappet noise may occur if the engine is not

operated for an extended period of time. The

noise should stop after the engine has

reached normal operating temperature.

1. Check for tappet noise. If noise exists, check the

following points.

(1) Engine oil condition and level

(2) Engine oil pressure (Refer to Section 2A)

2. If the noise does not stop, check for movement of

each HLA by pushing it during disassembly.

3. If the HLA moves, replace the HLA. (Refer to page

1B—60.)

Ignition Timing

1. Warm up the engine and run it at idle.

2. Turn all electric loads OFF.

3. Connect a timing light tester.

4. Disconnect the vacuum hose from the vacuum

control, and plug the hose.

5. Check that the ignition timing mark (yellow) on the

crankshaft pulley and the timing mark on the tim-

ing belt cover are aligned.

Ignition timing: 12° ± 1° BTDC

(at idle speed)

76G01B-008

1B—8

Page 140 of 1865

TUNE-UP PROCEDURE 1 B

76G01B-015

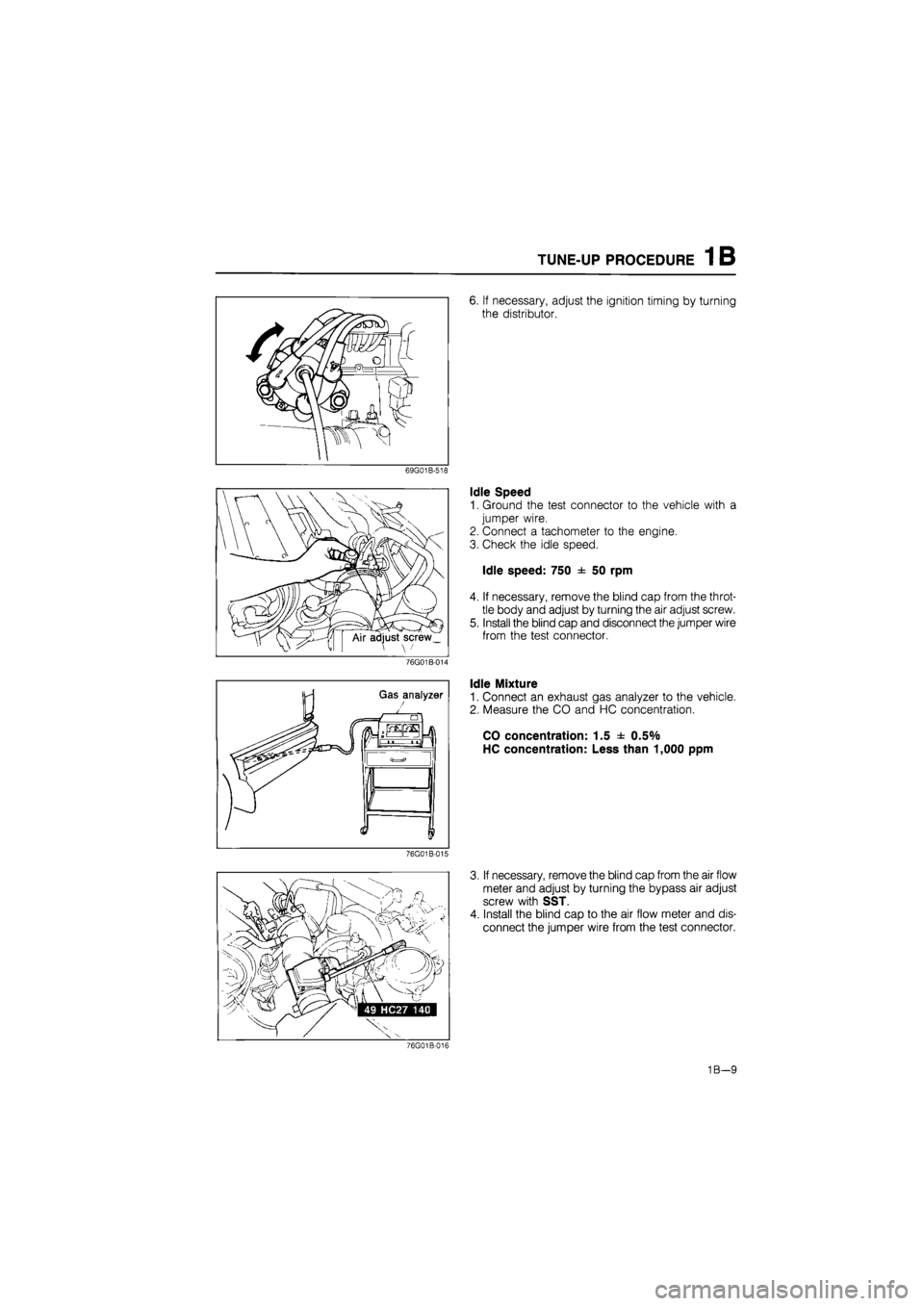

6. If necessary, adjust the ignition timing by turning

the distributor.

Idle Speed

1. Ground the test connector to the vehicle with a

jumper wire.

2. Connect a tachometer to the engine.

3. Check the idle speed.

Idle speed: 750 ± 50 rpm

4. If necessary, remove the blind cap from the throt-

tle body and adjust by turning the air adjust screw.

5. Install the blind cap and disconnect the jumper wire

from the test connector.

Idle Mixture

1. Connect an exhaust gas analyzer to the vehicle.

2. Measure the CO and HC concentration.

CO concentration: 1.5 ± 0.5%

HC concentration: Less than 1,000 ppm

3. If necessary, remove the blind cap from the air flow

meter and adjust by turning the bypass air adjust

screw with SST.

4. Install the blind cap to the air flow meter and dis-

connect the jumper wire from the test connector.

76G01B-016

1B—9

Page 141 of 1865

1 B ON-VEHICLE INSPECTION

76G01B-017

86U01X-020

76G01B-018

Possible Cause

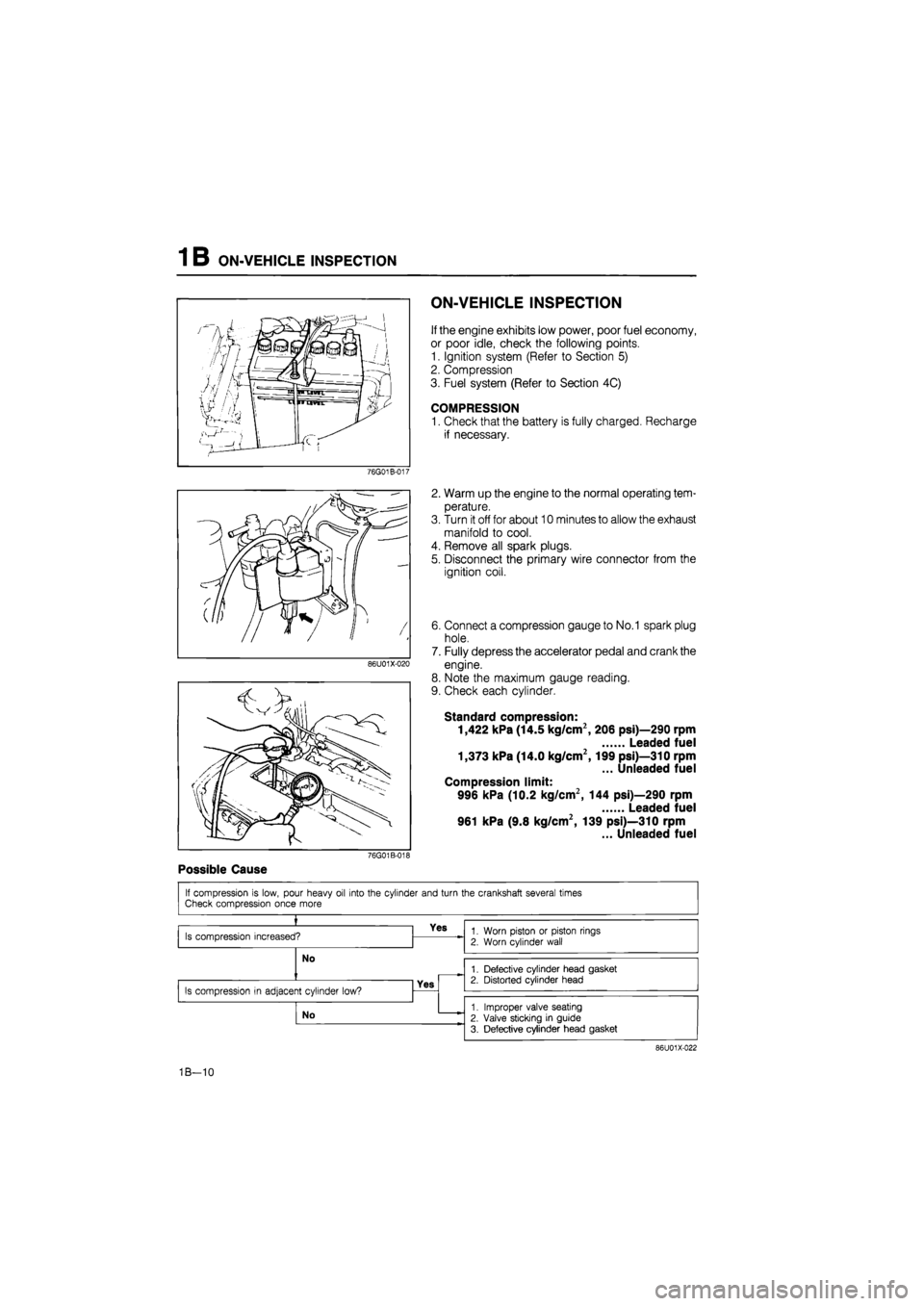

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following points.

1. Ignition system (Refer to Section 5)

2. Compression

3. Fuel system (Refer to Section 4C)

COMPRESSION

1. Check that the battery is fully charged. Recharge

if necessary.

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all spark plugs.

5. Disconnect the primary wire connector from the

ignition coil.

6. Connect a compression gauge to No.1 spark plug

hole.

7. Fully depress the accelerator pedal and crank the

engine.

8. Note the maximum gauge reading.

9. Check each cylinder.

Standard compression:

1,422 kPa (14.5 kg/cm2, 206 psi)—290 rpm

Leaded fuel

1,373 kPa (14.0 kg/cm2,199 psi)—310 rpm

... Unleaded fuel

Compression limit:

996 kPa (10.2 kg/cm2, 144 psi)—290 rpm

Leaded fuel

961 kPa (9.8 kg/cm2, 139 psi)—310 rpm

... Unleaded fuel

If compression is low, pour heavy oil into the cylinder and turn the crankshaft several times Check compression once more

»

Is compression increased? Yes 1. Worn piston or piston rings

2. Worn cylinder wall

No

1. Worn piston or piston rings

2. Worn cylinder wall

No 1. Defective cylinder head gasket 2. Distorted cylinder head

Is compression in adjacent cylinder low? Yes

1. Defective cylinder head gasket 2. Distorted cylinder head

Is compression in adjacent cylinder low?

No 1. Improper valve seating

2. Valve sticking in guide

3. Defective cylinder head gasket

86U01X-022

1B—10

Page 211 of 1865

1B INSTALLATION

76G01B-113

76G01B-114

76G01B-115

Radiator

1. Install the radiator and cooling fan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Connect the radiator harness.

3. Connect the upper and lower radiator hoses.

Note

a) Position the hose clamp in the original lo-

cation on the hose.

b) Squeeze the clamp lightly with large pliers

to ensure a good fit.

Heater Hose and Fuel Hose

Connect the heater hoses and the fuel hoses.

High-Tension Lead

Connect the high-tension lead to the ignition coil.

Accelerator Cable

Install the accelerator cable.

76G01A-148

Battery and Battery Carrier

1. Install the battery carrier.

Tightening torque:

9—13 N-m (90—130 cm-kg, 78—113 in-lb)

2. Install the fuse box.

Tightening torque:

8—11

N

m (80—110 cm-kg, 69—95 in-lb)

3. Install the battery tray and battery.

Tightening torque:

5_7

N m

(50—70 cm-kg, 43—61 in-lb)

1B—80

Page 351 of 1865

3A COOLING FAN

COOLING FAN

SYSTEM CIRCUIT

IG1 IG Relay

*

No.1

relay

Water thermo switch

I With A/C

CM)

Main fan

1

L..±

No.2

relay

IG2

Add.

relay ol

(M)

A/C sw.

Add fan

86U03X-019

CIRCUIT INSPECTION

1. Turn the ignition switch ON.

2. Disconnect the water thermo switch connector, and

check that the fan operates.

3. If the fan doesn't operate, check the fuse, fan re-

lay, fan motor, thermo switch and wiring harness.

76G03A-010

3 A—12

Page 353 of 1865

3A COOLING FAN

WATER THERMO SWITCH

1. Remove the cooling fan water thermo switch.

Note

Make sure that the ignition switch is OFF. If

not, the fan will operate when the connector

is removed.

76G03A-013

76G03A-014

Place the water thermo switch in water.

Heat the water gradually, and check for continui-

ty of the switch with an ohmmeter. Replace if

necessary.

Water thermo switch (ON OFF):

97°C (207°F)....ECE, Hong Kong, Singapore

91

°C (196°F)....General, Middle East

Install the water thermo switch and a new O-ring.

Caution

Do not use sealing tape.

3 A—14