torque MAZDA MX-5 1994 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 441 of 1708

ELECTRICAL SYSTEM COMPONENTS Continuity 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Disconnect the select lever from the manual shaft. 3. Disconnect the parwneutral switch connector. 4. Check continuity of the terminals. 0---0: Indicates continuity 5. If not correct, adjust the parwneutral switch. 6. If correct, check or adjust the selector lever. (Refer to page K-163.) Adjustment 1. Move the manual shaft to N position. 2. Loosen the parwneutral switch mounting Nuts. 3. Remove the screw on the switch body and move the parkheutral switch so that the screw hole is aligned with the small hole inside the switch. Check their alignment -i by inserting a 2.0mm (0.079 in) diameter pin through the holes. 4. Tighten the mounting nuts and remove the pin. Tightening torque: 5.0--6.8 N-m (50-70 kgfacm, 44--60 in-lbf) 5. Install and tighten the screw in the switch body. 6. Check the continuity of the parwneutral switch. 7. If not correct, replace the parklneutral switch. 8. Connect the selector lever. Tightening torque: 45-63 N.m (4.5-6.5 kgf-m, 33--47 ft-lbf) Gartner Banana

Page 442 of 1708

ELECTRICAL SYSTEM COMPONENTS K ATF THERMOSENSOR Inspection 1. Refer to "Replacement" below for removal of the ATF thermosensor. 2. Place the ATF thermosensor in ATF with a thermometer as shown, and heat the ATF gradually. 3. Measure resistance between the terminals of the ATF thermosensor. ATF temperature- {OF) 1 Resistance (kR) 20 (68) 2.5 4. If not correct, replace the ATF thermosensor. 5. Refer to "Replacement" for installation of the ATF ther- mosensor. Replacement 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 3. Disconnect the ATF thermosensor connector. 4. Remove the ATF thermosensor. 5. Install the new ATF thermosensor. Tightening torque: 7.9-1 0.7 N-m (80-11 0 kgf-cm, 70-95.4 in-lbf) 6. Connect the ATF thermosensor connector. 7. Connect the negative battery cable. VEHICLE SPEED PULSE GENERATOR Inspection 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 3. Disconnect the vehicle speed pulse generator connec- tor. 4. Measure resistance between the terminals of the vehicle speed pulse generator. Resistance: 24552 5. If not correct, replace the vehicle speed pulse generator. 6. Connect the vehicle speed pulse generator connector. 7. Connect the negative battery cable. Gartner Banana

Page 443 of 1708

K ELECTRICAL SYSTEM COMPONENTS Replacement 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 4 3. Disconnect the vehicle speed pulse generator connec- tor. 4. Remove the vehicle speed pulse generator. 5. Install the new vehicle speed pulse generator. Tightening torque: 7.9--10.7 N-m (80-110 kgfecm, 70-95.4 in-lbf) 6. Connect the vehicle speed pulse generator connector. 7. Connect the negative battery cable. 1-2 SHIFT, 2-3 SHIFT, 3-4 SHIFT, 3-2 CONTROL SOLENOID VALVE Inspection 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Disconnect the solenoid valve connector. d 3. Measure resistance between each terminal and ground. Resistance: l3-27a 4. If not correct, check the wiring harness for an open or short circuit. Replace the solenoid valve. Solenoid valve 1-2 shift 2-3 shift 3-4 shift 3-2 control LOCKUP CONTROL SOLENOID VALVE lnspection 1. Disconnect the solenoid valve connector. 2. Measure the resistance between the terminals. Terminal C D - A B Resistance: l3-2Sil 3. If not correct, replace the solenoid valve. Gartner Banana

Page 446 of 1708

ELECTRICAL SYSTEM COMPONENTS K Terminal 2D (Input) 2E (Output) 2F (Input) 2G (Output) 2H (Input) - !I (Output) !J (Input)' - !K (Output) - !L (Ground)' 'M (Output) 1-2 shift solenoid valve 1 2E (S range) 2-3 shift solenoid valve Connected to Voltmeter I I +terminal . ParWneutral switch (D range) 2D - - (L range) 3-4 shift solenoid lalve Jehicle speed pulse 2J lenerator .ockup control ;olenoid valve 2K lehicle speed pulse 2L lenerator - 1 - I I - , - Z - 1 d - _4 3 V - - ower) E P (Ground) - 2P Ground ov - Q (Battery sattery 2Q B+ lgnition switch ON ower) OV Ignition switch OFF R - - - - - s (Battery Battery 2s B+ lgnition switch ON ~wer) Ground OV lgnition switch OFF Throttle position sen- 2T 'I- (Input) sor Approx. Throttle valve closed throttle position to wide 0.44.1 V open throttle Checked with AC range 1-2 control solenoid 'alve I 2M 1 ( Blow l.5V I 1 B+ 3-2 or 4-2 downshift OV Other conditions - - - I I I I lattery 20 B+ Constant Replacement Disconnect the negative battery cable. Disconnect the powertrain control module (Transmis- sion) connector. Remove the bolt and nut shown in the figure, and re- move the powertrain control module (Transmission). Install the new powertrain control module (Transmis- sion). Tightening torque: 19-25 N-m (1 .S2.6 kgf-m, 14--18 ftslbf) Connect the powertrain control module (Transmission). Connect the negative battery cable. Gartner Banana

Page 448 of 1708

TRANSMISSION K 1. Shift rod 12. Lockup solenoid connector 2. Undercover 13. Oil pipe 3. Performance rod 14. Harness 4. Exhaust pipe 15. Power plant frame (PPF) 5. Propeller shaft Removal Note ............. page K-48 Removal .................... section L 1 6. Undercover 6. Speedometer cable 17. Torque converter Nut - 7. Vacuum hose 18. Starter u 8. Parklneutral switch connector 19. Transmission mount bolt 9. Vehicle speed pulse generator connector 20. Transmission 10. Solenoid connector Removal Note ............. page K-49 11. ATF thermosensor connector Gartner Banana

Page 452 of 1708

TRANSMISSION K Components / @ O-RING. O-RING, REPLACE O-RING, REPLACE 1. Vacuum diaphragm 6. Oil pan On-vehicle Removal ....... page K-130 7. Magnet Inspection ................ page K-130 8. Control valve body On-vehicle Installation ..... page K-131 Disassembly I Inspection ... page K-112 On-vehicle Adjustment ..... page K-131 Assembly ................ page K-125 2. Lockup control solenoid valve On-vehicle Removal ....... page K-128 Inspection ................ page K- 42 On-vehicle Installation ..... page K-129 3. Vehicle speed pulse generator 9. Solenoid valve connector Inspection ................ page K- 41 10. Converter housing 4. ParWneutral switch 11. 2nd band servo w Inspection ................ page K- 39 Disassembly I Inspection I Adjustment ............... page K- 40 Assembly ............... page K- 83 5. Torque converter On-vehicle Adjustment ..... page K- 85 Inspection ................ page K- 61 Gartner Banana

Page 456 of 1708

TRANSMISSION K Procedure 1. Place wooden blocks under the transmission at the con- verter housing and the extension housing positions. 2. Remove the oil pan and gasket. Examine any material found in the pan or on the magnet to determine the condition of the transmission. Clutch facing material . . . . . Drive plate and brake band wear Steel (magnetic) . . . . . . . . . . Bearing, gear, and driven plate wear Aluminum (nonmagnetic) . . Bushings or cast alumi- num parts wear If large amounts of material are found, replace the torque converter and carefully check the transmission for the cause. 3. Install the oil pan and gasket with a few bolts to protect the valve body. 4. Remove the vacuum diaphragm, lockup control solenoid valve, vehicle speed pulse generator, and O-rings. 5. Remove the parwneutral switch. 6. Remove the speedometer driven gear from the exten- sion housing. 7. Remove the O-ring from the speedometer driven gear. Gartner Banana

Page 457 of 1708

K TRANSMISSION 8. Remove the torque converter, and immediately turn it so that the hole faces upward. This will help to keep any re- maining fluid from spilling. 9. Assemble the SST as shown. 10. Mount the transmission onto the SST. 11. Remove the oil pan and gasket. 12. Remove the magnets. 13. Disconnect the solenoid valve connectors. 14. Remove the harnesses from the bracket. Gartner Banana

Page 462 of 1708

TRANSMISSION K 41. Remove the oil distributor. 42. Remove the bearing. TORQUE CONVERTER Inspection 1. Check the outside of the converter for damage and cracks, and replace the torque converter if there is any problem. 2. Check for rust on the pilot hub or on the boss, and re- move the rust completely if there is any. Washing inside the converter 1. Drain any ATF remaining in the converter. 2. Pour in solvent (0.5 L, 0.5 US qt, 0.4 Imp qt). 3. Shake the converter to clean the inside. Pour out the sol- vent. 4. Clean the inside of the converter with compressed air so that the inside is completely empty. 5. Pour in ATF. 6. Shake the converter to clean the inside. Pour out the ATF. Gartner Banana

Page 467 of 1708

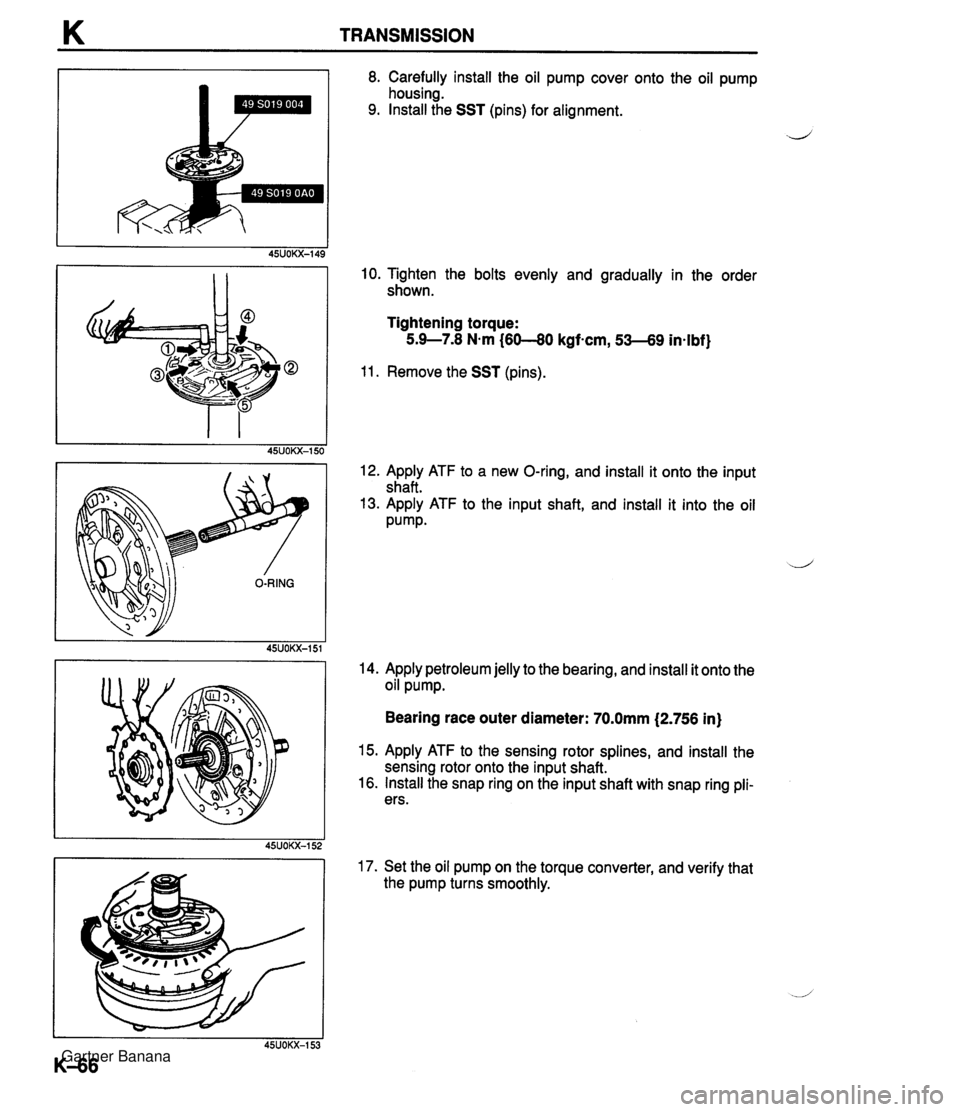

K TRANSMISSION 8. Carefully install the oil pump cover onto the oil pump housing. 9. Install the SST (pins) for alignment. J 10. Tighten the bolts evenly and gradually in the order shown. Tightening torque: 5.9-7.8 N-m (6040 kgf-cm, 53-69 in-lbf) 11. Remove the SST (pins). 12. Apply ATF to a new O-ring, and install it onto the input shaft. 13. Apply ATF to the input shaft, and install it into the oil Pump. 14. Apply petroleum jelly to the bearing, and install it onto the oil pump. Bearing race outer diameter: 70.0mm (2.756 in) 15. Apply ATF to the sensing rotor splines, and install the sensing rotor onto the input shaft. 16. Install the snap ring on the input shaft with snap ring pli- ers. 17. Set the oil pump on the torque converter, and verify that the pump turns smoothly. Gartner Banana