check engine light MAZDA MX-5 1997 Factory Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1997, Model line: MX-5, Model: MAZDA MX-5 1997Pages: 514, PDF Size: 17.89 MB

Page 37 of 514

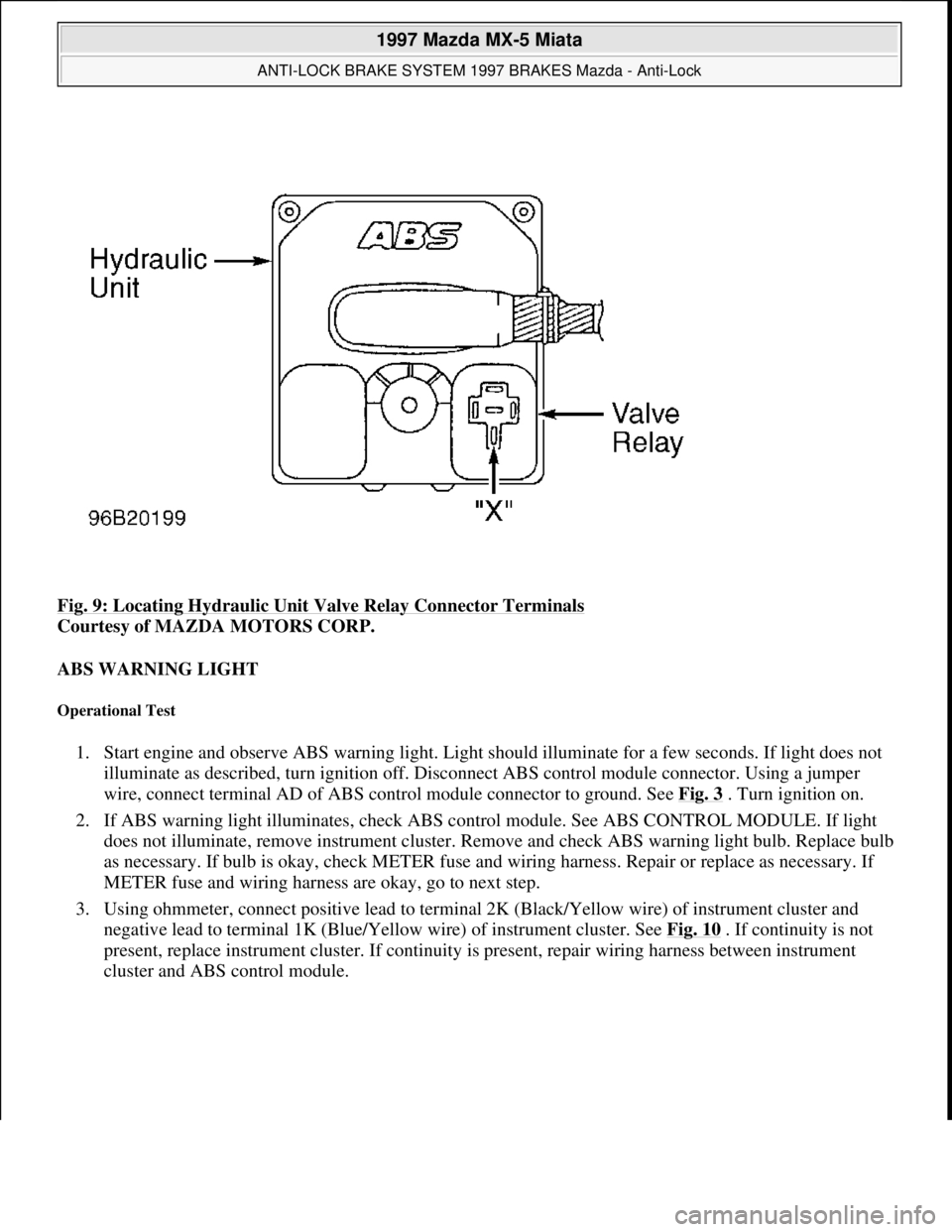

Fig. 9: Locating Hydraulic Unit Valve Relay Connector Terminals

Courtesy of MAZDA MOTORS CORP.

ABS WARNING LIGHT

Operational Test

1. Start engine and observe ABS warning light. Light should illuminate for a few seconds. If light does not

illuminate as described, turn ignition off. Disconnect ABS control module connector. Using a jumper

wire, connect terminal AD of ABS control module connector to ground. See Fig. 3

. Turn ignition on.

2. If ABS warning light illuminates, check ABS control module. See ABS CONTROL MODULE. If light

does not illuminate, remove instrument cluster. Remove and check ABS warning light bulb. Replace bulb

as necessary. If bulb is okay, check METER fuse and wiring harness. Repair or replace as necessary. If

METER fuse and wiring harness are okay, go to next step.

3. Using ohmmeter, connect positive lead to terminal 2K (Black/Yellow wire) of instrument cluster and

negative lead to terminal 1K (Blue/Yellow wire) of instrument cluster. See Fig. 10

. If continuity is not

present, replace instrument cluster. If continuity is present, repair wiring harness between instrument

cluster and ABS control module.

1997 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1997 BRAKES Mazda - Anti-Lock

Microsoft

Sunday, July 05, 2009 1:48:49 PMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 45 of 514

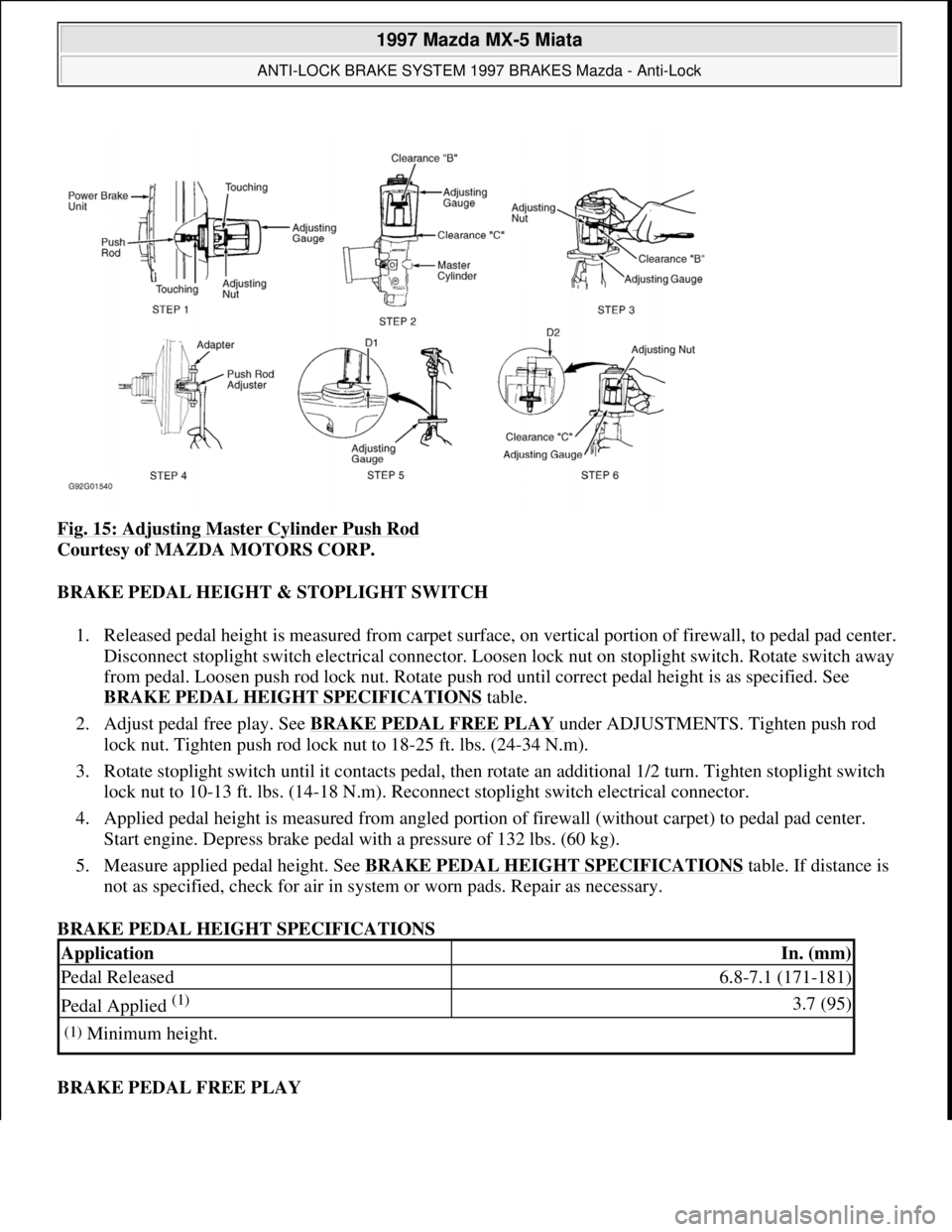

Fig. 15: Adjusting Master Cylinder Push Rod

Courtesy of MAZDA MOTORS CORP.

BRAKE PEDAL HEIGHT & STOPLIGHT SWITCH

1. Released pedal height is measured from carpet surface, on vertical portion of firewall, to pedal pad center.

Disconnect stoplight switch electrical connector. Loosen lock nut on stoplight switch. Rotate switch away

from pedal. Loosen push rod lock nut. Rotate push rod until correct pedal height is as specified. See

BRAKE PEDAL HEIGHT SPECIFICATIONS

table.

2. Adjust pedal free play. See BRAKE PEDAL FREE PLAY

under ADJUSTMENTS. Tighten push rod

lock nut. Tighten push rod lock nut to 18-25 ft. lbs. (24-34 N.m).

3. Rotate stoplight switch until it contacts pedal, then rotate an additional 1/2 turn. Tighten stoplight switch

lock nut to 10-13 ft. lbs. (14-18 N.m). Reconnect stoplight switch electrical connector.

4. Applied pedal height is measured from angled portion of firewall (without carpet) to pedal pad center.

Start engine. Depress brake pedal with a pressure of 132 lbs. (60 kg).

5. Measure applied pedal height. See BRAKE PEDAL HEIGHT SPECIFICATIONS

table. If distance is

not as specified, check for air in system or worn pads. Repair as necessary.

BRAKE PEDAL HEIGHT SPECIFICATIONS

BRAKE PEDAL FREE PLAY

ApplicationIn. (mm)

Pedal Released6.8-7.1 (171-181)

Pedal Applied (1) 3.7 (95)

(1)Minimum height.

1997 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1997 BRAKES Mazda - Anti-Lock

Microsoft

Sunday, July 05, 2009 1:48:49 PMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 46 of 514

With engine off, depress pedal a few times to eliminate vacuum. Depress brake pedal by hand and check pedal

free play. See BRAKE PEDAL FREE PLAY SPECIFICATIONS

table. Adjust play by loosening push rod

lock nut. Turn push rod until correct free play is obtained. Tighten push rod lock nut to 18-25 ft. lbs. (24-34

N.m).

BRAKE PEDAL FREE PLAY SPECIFICATIONS

PARKING/EMERGENCY BRAKE

1. Depress brake pedal several times. Pull parking brake lever with a force of 44 lbs. (20 kg). If stroke is 7-9

notches, parking brake is properly adjusted. If stroke is not 7-9 notches, raise and support rear of vehicle.

Release parking brake lever.

2. Rotate cable adjusting nut at lever end of cable, located under console cover, until stroke is within

specification. Ensure rear brakes do not drag. Ensure parking brake warning light illuminates when brake

lever is pulled one notch.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

ApplicationIn. (mm)

Miata.16-.28 (4-7)

ApplicationFt. Lbs. (N.m)

Brake Caliper Mounting Bolts37-50 (50-68)

Brakeline Nuts10-16 (14-22)

Hydraulic Unit Brakeline Union Bolts18-26 (24-35)

Hydraulic Unit Mounting Bolts/Nuts14-18 (19-24)

I-Arm-To-Rear Steering Knuckle Bolt (RX7)44-54 (59-73)

Lower Control Arm-To-Rear Steering Knuckle Nut47-54 (64-73)

Push Rod Lock Nut18-25 (24-34)

Stoplight Switch Lock Nut10-13 (14-18)

Wheel Bearing Lock Nut

Front123-159 (167-216)

Rear159-217 (216-294)

Wheel Lug Nuts66-86 (89-117)

Wheel Speed Sensor Mounting Bolt12-16 (16-22)

INCH Lbs. (N.m)

ABS Control Unit Mounting Bolts/Nuts61-87 (6.9-9.8)

1997 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1997 BRAKES Mazda - Anti-Lock

Microsoft

Sunday, July 05, 2009 1:48:49 PMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 52 of 514

Fig. 1: Locating Solenoid Valves

Courtesy of MAZDA MOTORS CORP.

SELF-DIAGNOSTIC SYSTEM

SYSTEM DIAGNOSIS

TCM monitors transmission operation and contains a self-diagnostic system which stores a Diagnostic Trouble

Code (DTC) if an electronic control system failure or component malfunction exists. If a problem exists in any

of the solenoids or speed sensors and DTC is set, TCM will deliver a signal to blink the HOLD indicator light

on instrument panel to warn the driver. DTC may be set if a failure exists and can be retrieved for transmission

diagnosis.

RETRIEVING TROUBLE CODES

NOTE: Before testing transmission, ensure fluid level is correct. Ensure engine starts

with shift lever in Park and Neutral to ensure proper adjustment of transmission

range switch. Transmission Control Module (TCM) must first be checked for

stored codes. See RETRIEVING TROUBLE CODES

.

NOTE: Before retrieving DTC, ensure proper battery voltage exists for self-diagnostic

system operation. If any DTC are present other than those listed below, see

1997 Mazda MX-5 Miata

1997 AUTOMATIC TRANSMISSIONS NC4A-EL Electronic Controls

Microsoft

Sunday, July 05, 2009 1:35:03 PMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 59 of 514

2. Measure voltage between terminal No. 1G (Green wire) and No. 2P (Black/Light Blue wire) on TCM

connector. Voltage should be about 3.3 volts at 77°F (25°C). If voltage is within specifications, go to step

6 . If voltage is not within specifications, go to next step.

3. Turn ignition off. Disconnect TCM harness connector. Measure resistance between terminals No. 1G and

No. 2P. See TFT SENSOR SPECIFICATIONS

table. If resistance is within specification, go to step 6 .

If resistance is not within specification, go to next step.

4. Inspect TFT sensor. Disconnect TFT sensor harness connector. Measure resistance between connector

terminals. See TFT SENSOR SPECIFICATIONS

table. If resistance is within specification, go to step

6 . If resistance is not within specification, replace TFT sensor.

5. Check continuity of circuits between TFT sensor and TCM. See appropriate wiring diagram in WIRING

DIAGRAMS . Repair as needed. If circuit is okay, go to next step.

6. Reconnect all harness connectors. Road test vehicle. Retrieve DTC. If code P0710 or P0711 is still

present, replace TCM. If code is no longer present, system is okay.

TFT SENSOR SPECIFICATIONS

DTC P0715: INPUT/TURBINE SPEED SENSOR

Condition

Input/Turbine speed sensor signal is not input to TCM when vehicle is moving. Possible causes for condition

are:

Input/Turbine speed sensor malfunction.

Damaged wiring or connectors between turbine speed sensor and TCM.

TCM malfunction.

Diagnosis & Repair Procedure

1. Turn ignition on. Using voltmeter, backprobe TCM harness connector. DO NOT disconnect connector.

Measure AC voltage between terminals No. 2J (positive) and No. 2L (negative). Voltage should be 0-.1

volts when idling and zero with engine stopped. If voltage is within specification, go to step 5 . If voltage

is not within specification, go to next step.

2. Turn ignition off. Disconnect TCM harness connector. Check for continuity between terminals No. 2J

(Yellow/Green wire) and No. 2L (Yellow/Blue wire). If continuity is present, go to step 5 . If continuity

is not present, go to next step.

3. Inspect sensor. See INPUT/TURBINE SPEED SENSOR

under COMPONENT TESTING. Repair as

needed. If sensor is okay, go to next step.

4. Check continuity of circuits between input/turbine speed sensor and TCM. See appropriate wiring

dia

gram in WIRING DIAGRAMS . Repair as needed. If circuits are okay, go to next step.

Fluid Temperaturek/ohms

68°F (20°C)2.5

140°F (60°C).6

176°F (80°C).35

1997 Mazda MX-5 Miata

1997 AUTOMATIC TRANSMISSIONS NC4A-EL Electronic Controls

Microsoft

Sunday, July 05, 2009 1:35:04 PMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 68 of 514

1. Ensure all connections are clean and tight. Repair as needed. Ensure that TP sensor is adjusted correctly.

See appropriate ON-VEHICLE ADJUSTMENTS article in ENGINE PERFORMANCE. Turn ignition

on. Access TCM connectors. Using voltmeter, backprobe harness connectors. DO NOT disconnect

connectors. Go to next step.

2. Measure voltage between ground and terminal No. 2T (Red/Black wire) on TCM harness connector. With

throttle closed, voltage should be .1-1.1 volts. With wide open throttle, voltage should be 3.1-4.4 volts. If

voltage is within specification, go to step 5 . If voltage is not within specification, go to next step.

3. Measure voltage between ground and terminal No. 2A (Light Green/White wire) on TCM harness

connector. With ignition on, voltage should be 4.5-5.5 volts. With ignition off, voltage should be zero

volts. If voltage is within specification, go to step 5 . If voltage is not within specification, go to next step.

4. Inspect circuits between TP sensor and TCM. See appropriate wiring diagram under WIRING

DIAGRAMS . Repair as needed. If circuits are okay between sensor and TCM, go to next step.

5. Clear codes, and road test vehicle. Retrieve DTC. If DTC P1790 is still present, replace TCM. If code is

no longer present, system is okay.

DTC P1795: IDLE SWITCH OPEN OR SHORT

Condition

Closed throttle position switch is ON and TP sensor position is closed. Possible causes are:

Damaged wiring or connectors between closed throttle position switch and TCM.

Closed throttle position switch malfunction.

TCM malfunction.

Diagnosis & Repair Procedure

1. Ensure all connections are clean and tight. Repair as needed. Turn ignition on. Access TCM connectors.

Using voltmeter, backprobe harness connectors. DO NOT disconnect connectors. Go to next step.

2. Measure voltage between ground and terminal No. 1O (Red wire) on TCM harness connector. With

throttle closed, battery voltage should be present. With wide open throttle, voltage should be zero volts. If

voltage is within specification, go to step 5 . If voltage is not within specification, go to next step.

3. Inspect circuits between closed throttle position switch and TCM. See appropriate wiring diagram under

WIRING DIAGRAMS

. Repair as needed. If circuits are okay between sensor and TCM, go to next

step.

4. Disconnect battery negative cable. Disconnect closed throttle position switch connector. Check for

continuity between closed throttle position switch terminals. If continuity exists, go to next step. If

continuity does not exist, replace or adjust throttle position sensor.

5. Clear codes, and road test vehicle. Retrieve DTC. If DTC P1795 is still present, replace TCM. If code is

no longer present, problem is intermittent. Further investigation is required.

COMPONENT TESTING

NOTE: For connector terminal identification, see COMPONENT CONNECTOR

1997 Mazda MX-5 Miata

1997 AUTOMATIC TRANSMISSIONS NC4A-EL Electronic Controls

Microsoft

Sunday, July 05, 2009 1:35:04 PMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 100 of 514

929

1. Depress brake pedal several times. Depress parking brake pedal several times with a force of 44 lbs. (20

kg). If stroke is 5-7 notches, parking brake is properly adjusted. If stroke is not 5-7 notches, rotate

adjusting nut, located under parking brake pedal, until stroke is within specification.

2. Ensure rear brakes do not drag. Ensure parking brake warning light illuminates when brake pedal is

depressed one notch.

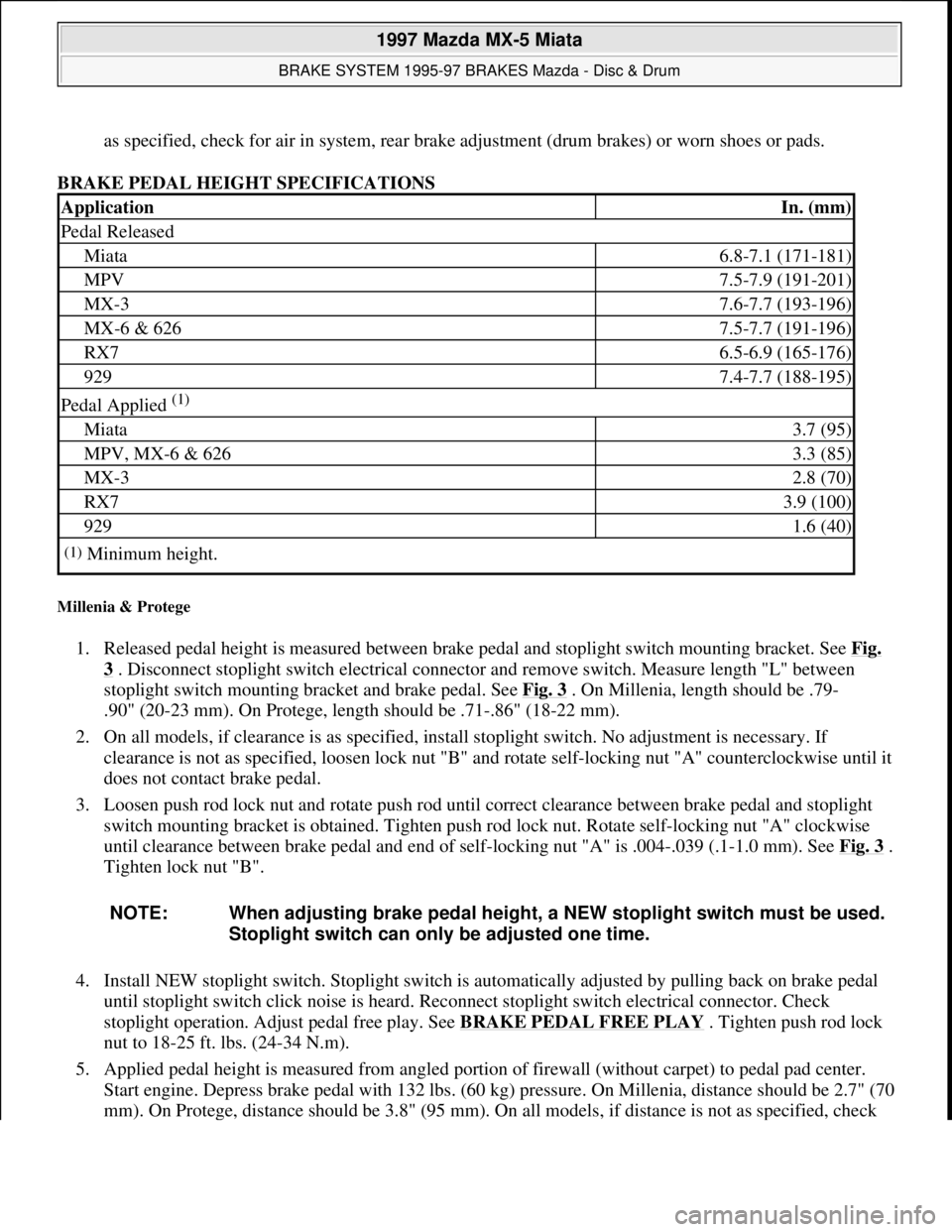

BRAKE PEDAL FREE PLAY

With engine off, depress pedal a few times to eliminate vacuum. Depress brake pedal by hand and check pedal

free play. See BRAKE PEDAL FREE PLAY SPECIFICATIONS

. Adjust play by loosening push rod lock

nut. Turn push rod until correct free play is obtained. Tighten push rod lock nut to 18-25 ft. lbs. (24-34 N.m).

BRAKE PEDAL FREE PLAY SPECIFICATIONS

BRAKE PEDAL HEIGHT & STOPLIGHT SWITCH

Miata, MPV, MX-3, MX-6, RX7, 626 & 929

1. Released pedal height is measured from carpet surface on vertical portion of firewall to pedal pad center.

Disconnect stoplight switch electrical connector. Loosen lock nut on stoplight switch. Rotate switch away

from pedal. Loosen push rod lock nut. Rotate push rod until correct pedal height is obtained. See

BRAKE PEDAL HEIGHT SPECIFICATIONS

.

2. Adjust pedal free play. See BRAKE PEDAL FREE PLAY

. Tighten push rod lock nut to 18-25 ft. lbs.

(24-34 N.m).

3. Rotate stoplight switch until it contacts pedal and then rotate an additional 1/2 turn. Tighten stoplight

switch lock nut 10-13 ft. lbs. (14-18 N.m). Reconnect stoplight switch electrical connector.

4. Applied pedal height is measured from angled portion of firewall (without carpet) to pedal pad center.

Start engine. Depress brake pedal with 132 lbs. (60 kg) pressure.

5. Measure applied pedal hei

ght. See BRAKE PEDAL HEIGHT SPECIFICATIONS . If distance is not NOTE: On B2300, B3000 & B4000, brake pedal free play is built into pedal linkage and

is not adjustable.

ApplicationIn. (mm)

Miata, MPV & MX-3.16-.28 (4-7)

Millenia, MX-6, Protege & 626.16-.47 (4-12)

RX7.12-.31 (3-8)

929.12-.47 (8-12)

NOTE: B2300, B3000 & B4000 are equipped with dual brake master cylinder and

vacuum booster. System is designed to permit full stroke of master cylinder

when brake pedal is fully depressed. Brake pedal height adjustment is not

required.

1997 Mazda MX-5 Miata

BRAKE SYSTEM 1995-97 BRAKES Mazda - Disc & Drum

Microsoft

Sunday, July 05, 2009 1:51:02 PMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 101 of 514

as specified, check for air in system, rear brake adjustment (drum brakes) or worn shoes or pads.

BRAKE PEDAL HEIGHT SPECIFICATIONS

Millenia & Protege

1. Released pedal height is measured between brake pedal and stoplight switch mounting bracket. See Fig.

3 . Disconnect stoplight switch electrical connector and remove switch. Measure length "L" between

stoplight switch mounting bracket and brake pedal. See Fig. 3

. On Millenia, length should be .79-

.90" (20-23 mm). On Protege, length should be .71-.86" (18-22 mm).

2. On all models, if clearance is as specified, install stoplight switch. No adjustment is necessary. If

clearance is not as specified, loosen lock nut "B" and rotate self-locking nut "A" counterclockwise until it

does not contact brake pedal.

3. Loosen push rod lock nut and rotate push rod until correct clearance between brake pedal and stoplight

switch mounting bracket is obtained. Tighten push rod lock nut. Rotate self-locking nut "A" clockwise

until clearance between brake pedal and end of self-locking nut "A" is .004-.039 (.1-1.0 mm). See Fig. 3

.

Tighten lock nut "B".

4. Install NEW stoplight switch. Stoplight switch is automatically adjusted by pulling back on brake pedal

until stoplight switch click noise is heard. Reconnect stoplight switch electrical connector. Check

stoplight operation. Adjust pedal free play. See BRAKE PEDAL FREE PLAY

. Tighten push rod lock

nut to 18-25 ft. lbs. (24-34 N.m).

5. Applied pedal height is measured from angled portion of firewall (without carpet) to pedal pad center.

Start engine. Depress brake pedal with 132 lbs. (60 kg) pressure. On Millenia, distance should be 2.7" (70

mm). On Protege, distance should be 3.8" (95 mm). On all models, if distance is not as specified, check

ApplicationIn. (mm)

Pedal Released

Miata6.8-7.1 (171-181)

MPV7.5-7.9 (191-201)

MX-37.6-7.7 (193-196)

MX-6 & 6267.5-7.7 (191-196)

RX76.5-6.9 (165-176)

9297.4-7.7 (188-195)

Pedal Applied (1)

Miata3.7 (95)

MPV, MX-6 & 6263.3 (85)

MX-32.8 (70)

RX73.9 (100)

9291.6 (40)

(1)Minimum height.

NOTE: When adjusting brake pedal height, a NEW stoplight switch must be used.

Stoplight switch can only be adjusted one time.

1997 Mazda MX-5 Miata

BRAKE SYSTEM 1995-97 BRAKES Mazda - Disc & Drum

Microsoft

Sunday, July 05, 2009 1:51:02 PMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 104 of 514

POWER BRAKE UNIT

1. With engine off, depress brake pedal several times. Press and hold brake pedal and start engine. If brake

pedal moves down slightly immediately after engine starts, power brake unit is operating. If brake pedal

does not move as specified, go to next step.

2. Run engine for 1-2 minutes. Stop engine. Press brake pedal several times and note if first pedal stroke is

longer than subsequent strokes. If first pedal stroke is longer than subsequent strokes, power brake unit is

operating. If length of strokes is equal, check valve and vacuum hose between vacuum source and power

brake unit. Repair as necessary, and go to next step.

3. Start engine. Press and hold brake pedal. Stop engine. Hold pedal down for about 30 seconds. If pedal

height remains at same height, power brake unit is operating. If pedal height recedes, check valve and

vacuum hose between vacuum source and power brake unit. Repair as necessary.

REMOVAL & INSTALLATION

FRONT DISC BRAKE PADS

Removal & Installation (B2300, B3000 & B4000)

1. To prevent master cylinder overflow when caliper piston is depressed, remove and discard some brake

fluid from master cylinder reservoir. Raise and support vehicle. Remove front wheel assemblies. Place a

large "C" clamp on caliper.

2. Tighten clamp to bottom piston in cylinder bore. Remove clamp. Remove 2 caliper pin bolts. Remove

caliper from rotor and wire aside. Slide brake pads off caliper anchor plate. Remove anchor plate (if

necessary). Replace pad if lining thickness is less than specified. See MINIMUM PAD LINING

SPECIFICATIONS (FRONT) .

3. To install, reverse removal procedure. Use "C" clamp and old pad to push caliper piston into piston bore

until piston bottoms out. Bleed air from brake system (if necessary).

Removal & Installation (Miata, Millenia, MPV, MX-6, 626 & 929)

1. Raise and support front of vehicle. Remove front wheel assemblies. Remove lower lock pin/guide bolt.

See Fig. 4

, Fig. 5 or Fig. 6 . Pivot caliper upward and support using rope.

2. Remove pads, shims, guide plates or pad guides and "V" springs (if equipped). Replace pad if lining

thickness is less than specified. See MINIMUM PAD LINING SPECIFICATIONS (FRONT)

.

3. To install, reverse removal procedure. Use Disc Brake Expander (49-0221-600C) and an old pad to push

piston full

y inward to install disc pads.

(38-46)

1997 Mazda MX-5 Miata

BRAKE SYSTEM 1995-97 BRAKES Mazda - Disc & Drum

Microsoft

Sunday, July 05, 2009 1:51:03 PMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 138 of 514

GENERATOR OUTPUT

1. Connect an ammeter (100-amp minimum) in-line between generator terminal "B" connector and terminal

"B" of wiring harness connector. See Fig. 1

. Turn headlights and all accessories on. Depress brake pedal.

Operate engine at 2500-3000 RPM.

2. Measure and record generator output. See GENERATOR MAXIMUM RATED OUTPUT

table. If

amperage is as specified, go to next step. If amperage is not as specified, repair or replace generator.

3. Turn off headlights and all accessories. Release brake pedal. Operate engine at 2500-3000 RPM and

measure amperage under no-load condition. No-load amperage should be 5 amps or greater. If amperage

is as specified, go to next step. If amperage is not as specified, repair or replace generator.

4. Operate engine at 2500-3000 RPM. Measure voltage between ground and terminals "S" and "L". If 14.1-

14.7 volts does not exist, repair or replace generator. If 14.1-14.7 volts exists, generator output is okay.

GENERATOR MAXIMUM RATED OUTPUT NOTE: Check generator wiring harness connections and drive belt tension. Battery

must be fully charged before testing. Wait at least 30 seconds after starting

engine before measuring system voltage.

CAUTION: Ensure generator terminal "B" does not contact ground.

ApplicationAmps

A/T70

M/T65

1997 Mazda MX-5 Miata

GENERATOR & REGULATOR 1997 STARTING & CHARGING SYSTEMS Mazda - Generators & Regulators

Microsoft

Sunday, July 05, 2009 1:53:16 PMPage 2 © 2005 Mitchell Repair Information Company, LLC.