length MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 443 of 1164

OUTLINE G

OUTLINE

SPECIFICATIONS

Item EnginelTransaxle

‘-2, B6 SOHC BP SOHC BP DOHC

MTX 1 ATX MTX ( ATX

Voltage v 1 12

I

3attery

Dark current*’ Type and capacity

(20-hour rate)

mA 55D23L (60AH) 55D23L (60AH)

Max. 20.0

L\lternator

Starter

Type AC

output V-A 12-65

Regulator type Transistorized (built-in IC regulator)

Regulated voltage V 14.1-14.7

Brush length Standard 21.5 (0.846)

mm (in) Minimum 8.0 (0.315)

Drive belt deflection

New

98 N (10 kg, 22 lb)

mm (in) Used 8-Q (0.31-0.35)

Q-10 (0.35-0.39)

Type

I Direct Direct

I Coaxial

Direct Coaxial

reduction reduction I

output V-kW 12-0.95 12-0.95 12-1.4

12-0.95 12-1.4

Brush length Standard 17 (0.67) 17 (0.67) 17.5 (0.69) 17 (0.67)

17.5 (0.69)

mm (in) Minimum 11.5 (0.453) 11.5 (0.453) 10.0 (0.39) 11.5 (0.453) 10.0 (0.39)

Distributor

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded) Electronic spark advance (photo diode)

6O--8O 4O-6O Q”-1 1 o

Ignition coil

Spark plug Resistance

(at 20% [68OF]) Primary

coil winding 0.81-O.QQg

Secondary

coil winding IO-16 kg

BKR5E-11 BKR5Ell BKR5Ell

NGK

BKR6E-11 BKRGEl 1 BKRGEli

BKR7Ell

Type NIPPON-

DENSON Kl GPR-Ul l

K20PRU 11 KIGPR-Ull

K20PR-Ul l KIGPR-Ull

K20PRUll

K22PR-Ul l

I Plua aao mm (in) I 1.0-l .l (0.039-0.043)

Firing order

’ Dark current is the constant flow of current while the ignition switch is OFF.

(i.e. engine control unit, audio, etc.) l-3-4-2

23lJOGX-00

G-3

Page 599 of 1164

OUTLINE, TROUBLESHOOTING GUIDE M

OUTLINE

SPECIFICATIONS

Engine/Transaxle

86 SOHC

I BP SOHC BP DOHC

MTX 1 ATX 1 MTX 1 ATX

Front axle

Bearing play axial direction Rear axle

Bearina olav axial direction I

mm (in) 0.05 (0.002)

mm (in) I 0.05 (0.002) Drive shaft

j Inside Tripod ioint

I Joint type I -

Outside I Ball ioint 1

Right side 919.3 (36.19)

918.7 (36.17) 630.7 (24.83)

Length of shaft

mm (in)

Left side 637.8 (25.11)

640.2 (25.20) 621.2 637.1

(24.46) (25.08)

Shaft diameter mm (in) Right side 21.5 (0.85) 23.0 (0.91)

Left side

21.5 (0.85)

23.0 (0.91)

23UOMX-003

TROUBLESHOOTING GUIDE

FRONT AXLE Problem

Steering wheel

vibration

Steering wheel pulls

or one-sided braking

Excessive steering

wheel play

Abnormal noise

Grease leakage from

boot Possible Cause Action

Worn or damaged wheel bearing

Excessive wheel bearing play

Worn or damaged wheel bearing

Excessive wheel bearing play

Excessive wheel bearing play Replace

Tighten or replace

Replace

Tighten or replace

Tighten or replace

Bent drive shaft or joint shaft

Worn or damaged wheel bearing

Worn drive shaft or joint shaft splines

Insufficient grease in joint or on splines of drive shaft

insufficient grease in joint or splines of joint shaft

Nom drive shaft tripod joint Replace

Replace

Replace

Replenish or replace

Add or replace

Replace

Damaged or broken boot

Faulty boot band

Excessive grease Replace

Replace

Reoair Page M- 7

M- 5,7

M- 7

M- 5,7

M- 57

M-18, 22

M- 7

M-18, 22

M-22, 25

M-18

M-25

M-25

M-25

M-25

23UOMX-004

REAR AXLE Problem Possible Cause Action Page

Steering wheel

Worn or damaged wheel bearing

Replace M-11, 14 vibration

Excessive wheel bearing play Tighten or replace M-11, 14 Steering wheel pulls

Worn or damaged wheel bearing Replace M-11, 14 or one-sided braking Excessive wheel bearing play Tighten or replace M-11, 14 Excessive steering

Excessive wheel bearing play Tighten or replace M-11, 14 wheel olav

Abnormal noise

Worn or damaged wheel bearing Replace M-11, 14

23UOMX-005

M-3

Page 624 of 1164

DRIVE SHAFT

8. Apply the specified grease included in the kit to the tripod

joint, outer ring, and boot. Install the outer ring.

9. If the wheel-side boot was removed, fill with the specified

grease included in the kit.

Specified grease

!J@z)

B6 SOHC BP SOHC BP DOHC

Right Left Right

Left Right Left

side side side side side side

DIFFEREN- 2;&y’ 140 (4.94) 145 (5.12)

TIAL SIDE y;L44;)

YELLOW YELLOW YELLOW

WHEEL SIDE 70 (2.47) 140 (4.94) 90 (3.18)

BLACK BLACK BLACK

23UOMX-03

I I

I

23UOMX-0:

M-28

Caution

l Be sure the boots are not dented or twisted.

. Carefully lift up the small end of the boots to release

any trapped air.

10. Install the boots.

11. Measure the length of the drive shaft.

Standard length: mm (in)

B6 SOHC BP SOHC BP DOHC

MTX 1 ATX MTX 1 ATX MTX 1 ATX

light side 919.3 918.7

630.7

(36.19) (36.17) (24.83)

640.2 621.2 637.1

(25.20) (24.46) (25.08)

I Left side

I 637.8

(25.11)

12. Fold the new bands back by pulling on the ends with pliers.

13. Lock the ends of the bands by bending the locking clips.

Page 635 of 1164

MANUAL STEERING N

13UONX-01

23UONX-05

POSITION

1 SGONX-Oi

23UONX.01 I1

Disassembly note

Steering lock assembly

Use a chisel to make a groove in the head of the steering lock

mounting bolts. Remove the bolts with a screwdriver; then re-

move the steering lock assembly.

Caution

l Secure the shaft in a vise protected with brass pads

or cloth.

Inspection

Check for the following and replace the assembly if necessary.

Steering shaft assembly

1. Column bushing wear.

2. Steering shaft length.

Specified length: 558.3~560.3mm (21.98-22.06 in)

3. Tilt operation.

(1) Verify that the adjusting lever moves smoothly from un-

lock position to lock position.

(2) Verify that the steering shaft is fixed firmly when the ad-

justing lever is locked.

Intermediate shaft, Universal joint

Universal joint looseness, abnormal noise, or sticking.

N-l 1

Page 669 of 1164

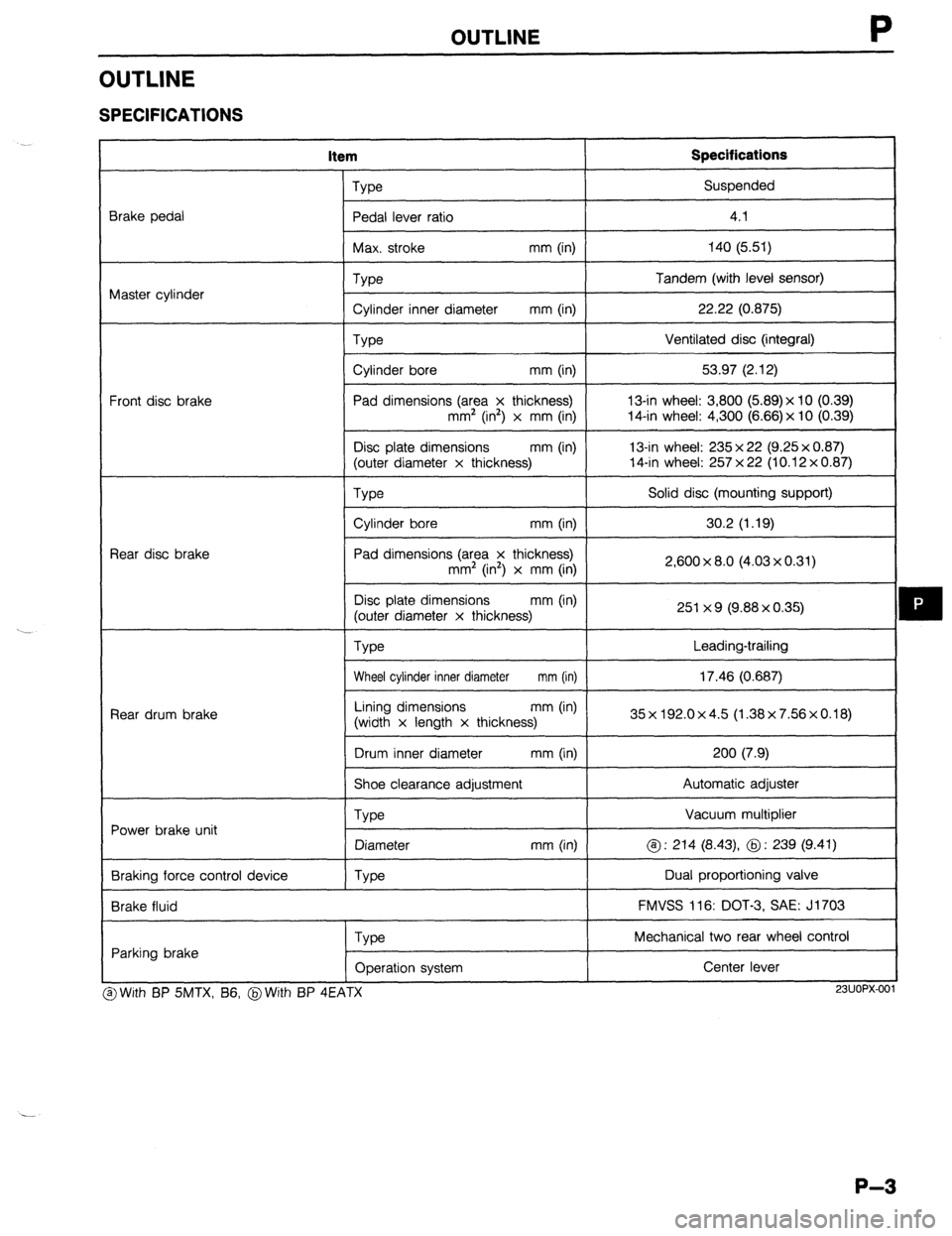

OUTLINE

OUTLINE

SPECIFICATIONS

item Specifications

Brake pedal

Master cylinder

Front disc brake

Rear disc brake

Rear drum brake

Power brake unit

Braking force control device

Brake fluid Type Suspended

Pedal lever ratio

I 4.1

I

Max. stroke mm (in) 140 (5.51)

I

Type

Cylinder inner diameter mm (in)

Type

Cylinder bore mm (in)

Pad dimensions (area x thickness)

mm’ (in2) x mm (in)

Disc plate dimensions mm (in)

(outer diameter x thickness) Tandem (with level sensor)

22.22 (0.875)

Ventilated disc (integral)

53.97 (2.12)

13-in wheel: 3,800 (5.89)x 10 (0.39)

14-in wheel: 4,300 (6.66) x 10 (0.39)

13-in wheel: 235 x 22 (9.25 x 0.87)

14-in wheel: 257 x 22 (10.12 x 0.87)

We

I Solid disc (mounting support)

I

Cylinder bore mm (in)

I 30.2 (1.19)

I

Pad dimensions (area x thickness)

mm2 (in’) x mm (in)

Disc plate dimensions mm (in)

(outer diameter x thickness)

Type 2,600 x 8.0 (4.03 x 0.31)

251 x 9 (9.88 x 0.35)

Leading-trailing

Wheel cylinder inner diameter mm (in) 17.46 (0.687)

I

Lining dimensions mm (in)

(width x length x thickness) 35x192.0x4.5 (1.38x7.56x0.18)

I

Drum inner diameter mm (in) 200 (7.9)

I

Shoe clearance adjustment Automatic adjuster

Vacuum multiplier

@ : 214 (8.43) @ : 239 (9.41)

Dual proportioning valve

FMVSS 116: DOT-3, SAE: J1703

Type

Diameter

Type mm (in)

Parking brake

Type

Operation system Mechanical two rear wheel control

Center lever I

3 With BP SMTX, B6, @With BP 4EATX

I I

23UOPX-001

P-3

Page 795 of 1164

WINDSHIELD S

1. Sun visor and adaptor 7. Glass stopper

2. Inside rearview mirror, overhead console 8. A-pillar garnish (Hatchback)

(With sliding sunroof) Removal / Installation . . . . . . . . . . . . . . . . . . page S-42

3. A-pillar trim 9. Upper windshield molding

Removal / Installation ..,.,..... pages S-97, 98 Removal / Installation . . . . . . . . . . . . . . . . . . page S-42

4. Upper garnish 10. Windshield

5. Wiper arm and blade Removal Note .,.....*.........*........... page S-59

Removal / Installation . . . . . . . . . . . . page S-72 Installation Note ..,......*................ page S-60

6. Cowl arille 11. Spacer

Removal I Installation . . . . . . . . . . . . page S-53 12. Protector

1 HEADLINER

Gsi?i==

SiX.A-A

03uosx-08

PROTECTIVE TAPE -I

9 03UOSX-088

Removal Note

Windshield

1, Use protective tape or cloth along the front edge of the head-

liner to protect it from damage.

2. Apply protective tape along the edge of the body.

3. Using an awl, make a hole through the sealant from the in-

side of the vehicle.

4. Pass piano wire through the hole.

5. Wind each end of the wire around a bar.

6. Working with another person, saw through the sealant

around the edge of the glass. Then remove the glass.

Caution

l Use a long sawing action to spread the work over

the whole length of wire to prevent if from breaking.

l Be careful that the wire does not rub on the body

or dash panel.

Note

l If the glass is not to be reused, a tool like that shown

in the figure may be used.

Insert the blade in the sealant, and pull on the bars.

s-59

Page 800 of 1164

S REAR WINDOW GLASS

HATCHBACK

1

J

03UOSX-106

1. Rear wiper arm and blade

Removal / Installation . . . . . . . . . . . . . . . . . . page S-78

2. Rear window molding

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page S-44

Installation . . . . .,...,........................ page S-45

3. Rear hatch lower trim 4. Seaming welt

5. Rear window glass

Removal Note ..,.,,,.......,.............. page S-64

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page S-65

6. Spacer ‘.-

Removal / Installation . . . . . . . . . . . . . . . . page S-98

Removal Note

PROTECTIVE TAPE Rear window glass

1. Apply protective tape along the edge of the body to pro-

tect it from damage.

2. Using an awl, make a hole through the sealant from the in-

side of the vehicle.

3. Pass piano wire through the hole.

4. Wind each end of the wire around a bar.

5. Working with another person, saw through the sealant

around the edge of the glass. Then remove the glass.

Caution

l Use a long sawing action to spread the work over

the whole length of wire to prevent it from breaking.

l Be careful that the wire does not rub on the body.

I SMUOSX-139

Page 822 of 1164

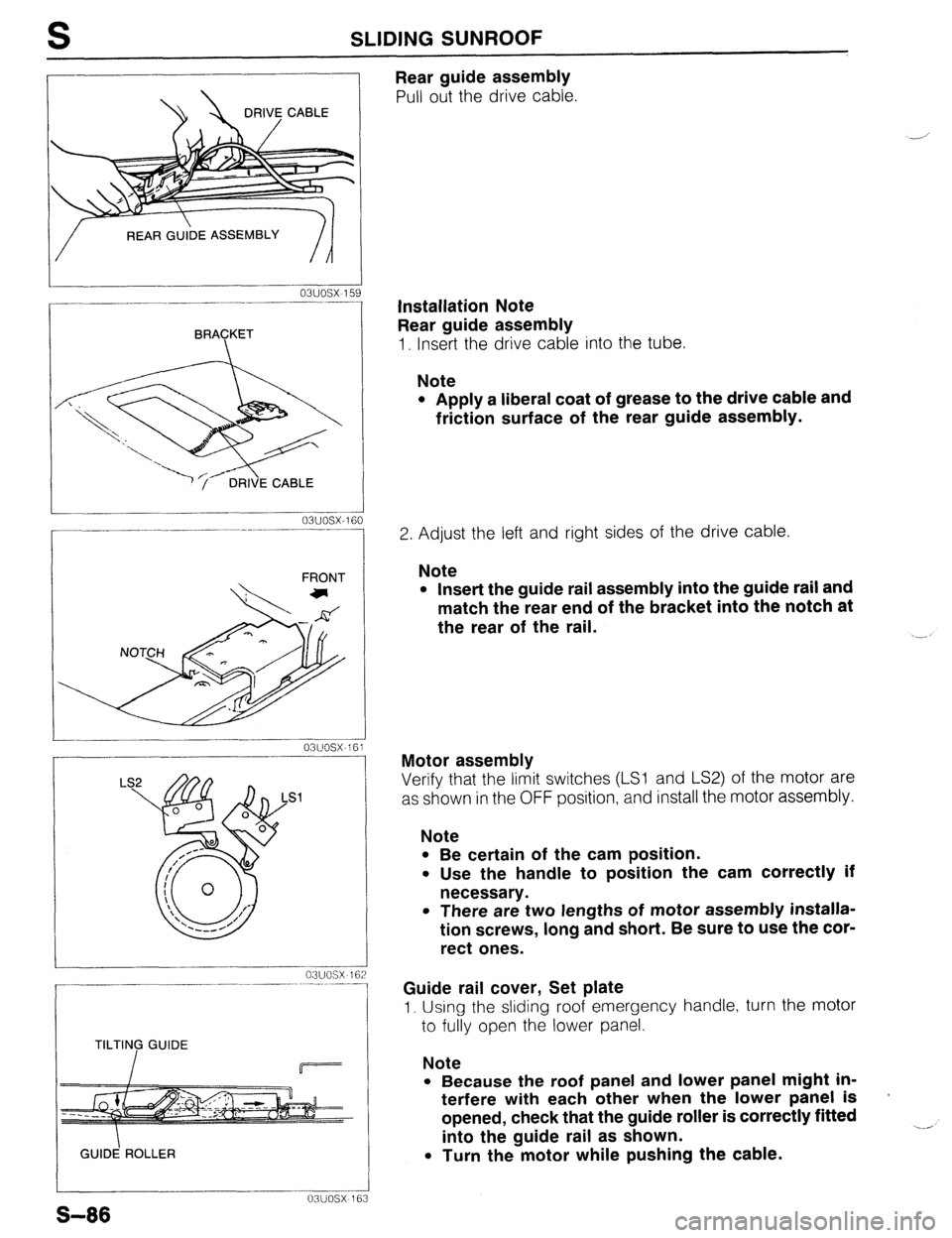

S SLIDING SUNROOF

DRIVE CABLE

o3uosx15

I-- _-_- ~_..___ -~--

BRACKET

- 031JOSX-1E 1 i0

FRONT

03uoti ----1

03uosx 163

S-86

TILTING GUIDE

GUID! ROLLER

Rear guide assembly

Pull out the drive cable.

installation Note

Rear guide assembly

1, Insert the drive cable into the tube.

Note

l Apply a liberal coat of grease to the drive cable and

friction surface of the rear guide assembly.

2. Adjust the left and right sides of the drive cable.

Note

l Insert the guide rail assembly into the guide rail and

match the rear end of the bracket into the notch at

the rear of the rail.

Motor assembly

Verify that the limit switches (LSI and LS2) of the motor are

as shown in the OFF position, and install the motor assembly.

Note

l Be certain of the cam position.

l Use the handle to position the cam correctly if

necessary.

l There are two lengths of motor assembly installa-

tion screws, long and short. Be sure to use the cor-

rect ones.

Guide rail cover, Set plate

1. Using the sliding roof emergency handle, turn the motor

to fully open the lower panel.

Note

l Because the roof panel and lower panel might in-

terfere with each other when the lower panel is ’

opened, check that the guide roller is correctly fitted

into the guide rail as shown. ..J

l Turn the motor while pushing the cable.

Page 1016 of 1164

TD TECHNICAL DATA

MEASUREMENTS

I ._.____2_ nem

Overall length

Overall width

Overall height

Wheel base

Front tread

Rear tread Body ) mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in) PRfWFr.f! . . ..s .-VW Hatchback 4,355 (171.5) 4,155 (163.6)

1,675 (65.9) 1,670 (65.7)

1,375 (54.1) 1,380 (54.3)

2,500 (98.4) 2,450 (96.5)

1,430 (56.3)

1,435 (56.5)

Bl. ENGINE (B6 AND BP SOHC)

1 Type

1 Cylinder arrangement and number Engine

86 SOHC BP SOHC

^ . . _

,?

I

uasollne, 4-cyw

. . *. 4

in-line 4-cyrinaer

Pentroof

1

I Combustion chamber I Multispherical

J Valve system OHC, belt-driven OHC, belt-driven 16 valves

. , I (3.07 x 3.29) 83.0 x 85.0 (3.27 x 3.35)

Total piston displacement cc (cu in) 1,597 (97.4) 1,839 (112.2)

Compression ratio 9.3 8.9

) Standard 1,236 (12.6, 179)-300 1,197 (12.2, 173)300

I

863 (8.8, 125)-300 834 (8.5, 121)300 1 Bore x Stroke

mm (in) I 78.0 x 83.6

Compression pressure

kPa (kg/cm’, psi)-rpm

E cvlinders 1 Maximum difference

196 (2.0, 28)

I

, ------- ---- -J - IN Open BTDC 14O 2O

Close ABDC 50°

Valve timing

Open BBDC 52O 55O

EX

Close ATDC 12O 8O

IN 0 Maintenance-free I \/AIo &-in --

Valve clearance EX 0 Maintenance-free

(Warm engine) mm (in) / ,,syi: 1

IN 0 Maintenance-free

I , EX 0 Maintenance-free

I Cylinder head

Height

Distortion

Grinding Valve and T _

Valve head diameter

Valve head margin thickness

Valve face angle IN mm (in) EX

IN

mm b-4 Fx mm (in) 107.4-107.6 (4.228-4.236)

mm (in) 0.15 (0.006) max. 0.10 (0.004) max.

mm (in) 0.20 (0.008) max. 0.10 (0.004) max.

37.9-38.1 (1.492-l ,500) 29.9-30.1 (1.177-1.185)

31 .Q-32.1 (1.256-l ,264) 24.85-25.15 (0.978-0.990)

0.8 (0.031) 0.9 (0.035)

1.1 10.043) 1 .o (0.039)

-, ,

\- I

IN 45O

EX 45O

I I Standard

IN

Minimum

Valve length mm (in)

EX Standard

Minimum I”L. I, \*.“cL

Valve stem diameter IN

mm On) EX 6.970-6.985 (0.2744-

6.965-6.980 (0.2742-

Guide inner diameter

I Valve stem-to-guide clearance mm (in) lTj7---- ,

Maximum 103.77 (4,085) 101.77 (4.007)

103.27 (4.066) 101.27 (3.987)

102.67 (4.042) 102.97 (4.054)

,n+ 47 IA noo

1 102.47 (4.034)

-0.2750) 5.970-5.985 (0.2350-0.2356)

-0.2748) 5.965-5.980 (0.2348-0.2354)

3.2760-0.2768) 6.01-6.03 (0.2366-0.2374)

0.025-0.060 (0.001 O-0.0024)

0.030-0.065 (0.001 l-0.0026)

-.

I

mm (in) 1 7.01-7.03 (r ‘

1 IN

Guide projection (Height “A”) IN

mm (in) Ex 13.2-l 3.8 (0.520-

13.2-13.8 (0.520-

TD-2

Page 1017 of 1164

TECHNICAL DATA TD

Item Engine

B6 SOHC BP SOHC

Valve seat

IN

45O

Seat angle

EX 45O

Seat contact width IN

mm 04 EX 1.1-l .7 (0.043-0.067) 0.8-l .4 (0.031-0.055)

1.1-l .7 (0.043-0.067) 0.8-l .4 (0.031-0.055)

IN Standard 39 (1.5354) 42.5 (1.673)

Seat sinking mm (in) Maximum 40.5 (1.594) 44.0 (1.732)

EX Standard 39 (1.5354) 41.0 (1.614)

Maximum 40.5 (1.594) 42.5 (1.673) Valve spring

Standard mm (in) 43.66 (1.7188) 46.12 (1.8157)

IN

Minimum N (kg, Ib)/mm (in) 224-253 (22.8-25.8, 205-231 (20.9-4X3.5,

Free length 50--57)/35.5 (1.398) 46-52)/39 (1.535)

Standard mm (in) 43.66 (1.7188) 43.61 (1.7169)

EX

Minimum N (kg, Ib)/mm (in) 224-253 (22.8-25.8, 129-147 (13.1-15.0,

50-57)/35.5 (1.398) 29-33)/37.5 (1.476)

Out-of-square mm (in) 1 Maximum 1.52 (0.060) IN...l.61 (0.063) EX...1.52 (0.060)

Lobe height mm (in) IN

EX Standard 36.451 (1.4351) 35.993 (1.4170)

Wear limit 36.251 (1.4272) 35.793 (1.4092)

Standard 36.451 (1.4351) 36.273 (1.4281)

Wear limit 36.251 (1.4272) 36.073 (1.4202)

Front 43.440-43 ,460 No.1 & 43.440-43.460

(1.7102-l .7 ‘110) No.5 (1.7102-1.7110)

43.430-43 ,445 No.2 & 43.425-43.450

mm (in) Center

(1.7098-l .7 ‘108) No.4 (1.7096-l .7106)

. , L

Rear 43.440-43.460 No’3 43.41 o-43.435

(1.7102-l .7110) (1.7091-1.7100)

1 Out-of-round 0.05 (0.002) max.

Front 0.055-0.095 No.1 & 0.040-0.075

(0.0021-0.0037) No.5 (0.0016-0.0030)

e--I-.. 0.060-O. 105 No.2 84 0.035-0.080

1041) No.4

“.“-.-..“” (O.OOi 4-0.0031)

Rear 0.055-0.095 0.050-0.095

(0.0021-0.0037) No.3

(0.0020-0.0037)

1 Maximum

0.15 (0.006)

0.01 (0.0004)

0.03 (0.0012)

0.05-0.18 (0.0020-0.0071) 0.06-0.19 (0.0024-0.0075)

n ‘1 m *no Journal diameter

Camshaft hearinn nil cIewanr.F? mm tin I b,er’Ler I (0.0023--0.c

Camshaft runout mm (in) Maximum

Camshaft end play mm (in) Standard

Maximum

I Rocker arm and rocker arm shaft

Rocker arm inner diameter mm (in) 18.000-18.027 (

Rocker arm shaft diameter mm (in)

17 9.59-17 981) I “.L ~“.““O,

lN...19.000--19.027 (0.7480-0.7491)

o.7087-o’70g7) EX...19.000-19.033 (0.7480-0.7493)

I .““” -- -

0 7070-0.7079) 18.959-18.980 (0.7464-0.7472)

lN...0.020-0.068 (0.0008-0.0027)

Rnrkx arm tn shaft clearance

mm (in Standard

I .Y”,.VG 11.,, .” -,,-.. “,“-.“, .I”

““” ,“‘I o.020-o.068 (“~ooo8-o~oo27) EX...O.020-0.074 (0.0008-0.0029)

Maximum 0.10 (0.004) Cylinder block

Height mm (in) 221.5 (8.720)

Distortion mm (in) 0.15 (0.006) max.

Grinding mm (in) 0.20 (0.008) max.

^. , ,

78.006-78.013 (3.0711-3.0714) 183.006-83.013 (3.2679-3.2682)

-.n nr,. -,n fin,% ,n nnnr

” nn’n’ ’ “- T)cc 83.263 (3.2778-3.2781) Cylinder bore diameter stanaara size

mm (in) 0.25 (0.010) oversize IU.L3cl-/U.dDJ (J.uouu-J.uo IL) 1 OJ.LJU--

0.50 (0.020) oversize 78.506-78.513 (3.0908-3.0911) ) 83.506-

Cylinder bore taper and out-of-round mm (in) 0.019 (0.0007) ma: 83.513 i3.2876-3.2879)

I(.

TD-3