stop start MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 315 of 1164

TROUBLESHOOTING GUIDE F

12 ROUGH IDLE/ENGINE STALLS JUST AFTER STARTING

DESCRIP-

*Engine starts normally but vibrates excessively or stalls just after starting (acceleration from idle) TION

*Idle conditions are normal in the other conditions [TROUBLESHOOTING HINTS]

@ Fuel injection control system or idle speed control sys-

@ Idle speed misadjustment

tern malfunction @ Ignition timing misadjustment

*Start signal not input to ECU iTEl

-s-- 3

4

5 INSPECTION

-T- ACTION

Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM,SELECT: I

r -SELECT SW: A

Check if ECU terminal voltages are OK

MTX...Especially 1 N

ATX... Especially 1T w page F-150

Connect System Selector to diagnosis connector

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up w page F-78

Ignition timing (BTDC)

l BP DOHC : 9”-11 o l BP SOHC : 4O--6O

l B8 : 60-80

Check continuity between throttle sensor termi-

nals IDL and E CT page F-159

MTX

Clearance between throttle

lever and stopper

MTX O.lmm (0.004 in)

1 .Omm (0.039 in)

ATX 0.1 mm (0.004 in)

0.6mm (0.024 in) Continuity

Yes

No

Yes

No

Try known good ECU and check if condition

mproves w page F-149 Yes

No

Yes

Go to next step No

Check for cause Yes

In same condition as Step 3 inspection

and apply parking brake

Check for correct idle speed w page F-80

Idle speed: 700-800 rpm

No

Adjust Yes

Go to next step No

Adjust Go to next step Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal IF voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

d If OK, replace ECU w page F-149

* If not OK, check wiring between

ECU and Self-Diagnosis Checker c7 page F-151

3 If OK, go to next step

3 If not OK, adjust idle speed w page F-80

w page F-79

w page F-159

F-49

Page 322 of 1164

![MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP- l Engine intermittently stops running

TION l Before stalling, engine condition OK [TROUBLESHOOTING HINTS]

@ Intermittently n MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP- l Engine intermittently stops running

TION l Before stalling, engine condition OK [TROUBLESHOOTING HINTS]

@ Intermittently n](/img/28/57077/w960_57077-321.png)

TROUBLESHOOTING GUIDE

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP- l Engine intermittently stops running

TION l Before stalling, engine condition OK [TROUBLESHOOTING HINTS]

@ Intermittently no spark or no-fuel injection caused by ve-

hicle vibration, acceleration, or deceleration

*Poor connection in wire harness

3 INSPECTION

Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON c7 page F-82

g

-%ELECT SW: A

Check for poor connection of following parts l ignition coil

l igniter l Distributor l High-tension lead l lniector

l Ci;cuit opening relay l ECU

Check if ECU terminal voltages are OK

MTX...Especially lB, 2A, 28 and 2C

ATX... Especially lB, 3A, 38 and 3C w page F-150

Note

l When checking voltages, tap, move, and

wiggle harness and connector to recreate

problem

Yes

No Service Code No. displayed

Check for cause (Refer to specified

check sequence) Note

l When checking wiring harness and

connectors, tap, move, and wiggle

suspect sensor and/or harness to

recreate problem

“88” flashes

Check ECU terminal IF voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

c3 If OK, replace ECU CT= page F-149

+ If not OK, check wiring between

ECU and Self-Diagnosis Checker

Yes

Repair or replace

No Go to next step

Yes

No

T ACTION

Go to next step w page F-83

Go to Troubleshooting No.2

‘CRANKS NORMALLY BUT WILL NOT

START (NO COMBUSTION)” CT- page F-30

Check for cause D page F-151

F-56

Page 372 of 1164

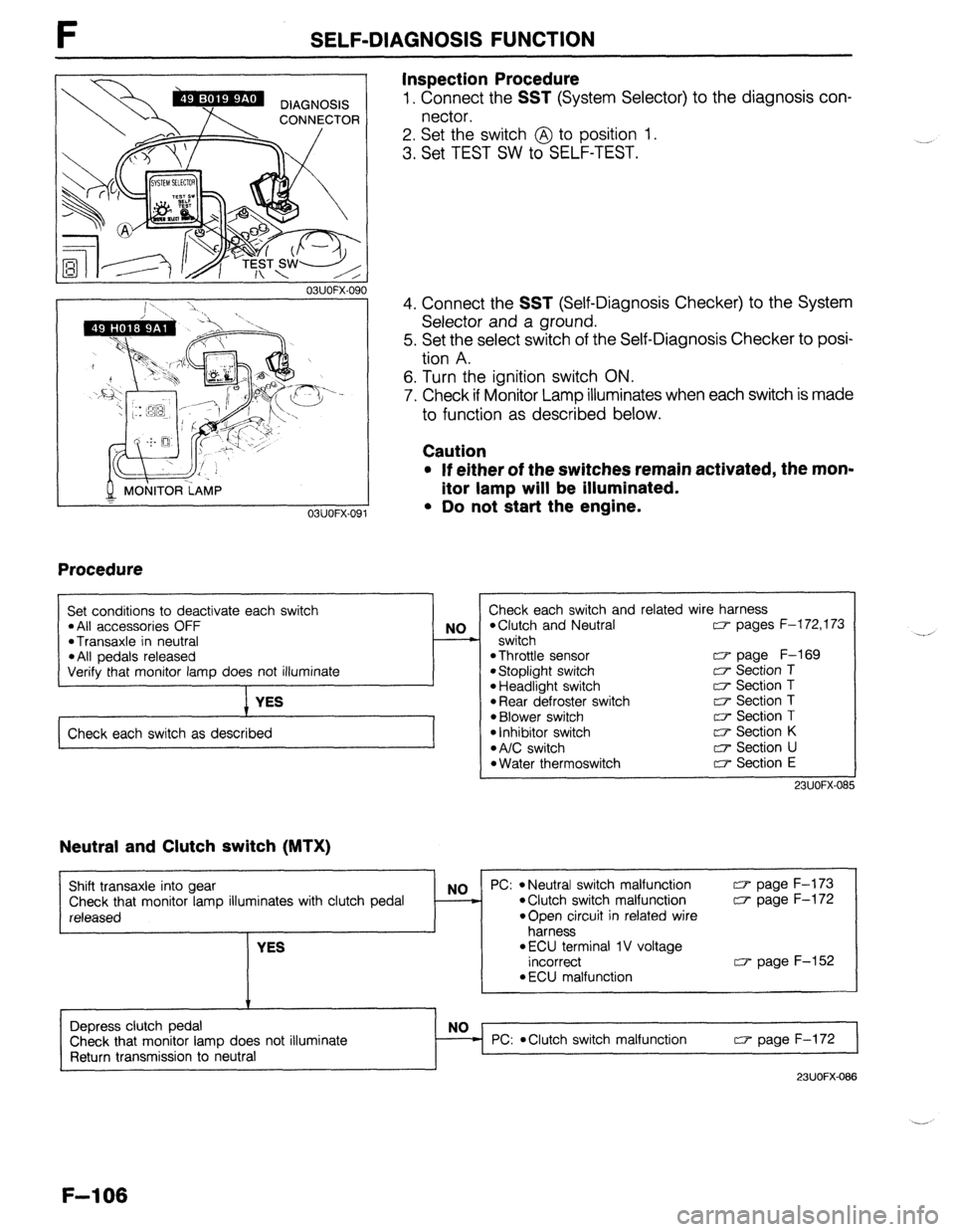

SELF-DIAGNOSIS FUNCTION

Inspection Procedure

1. Connect the SST (System Selector) to the diagnosis con-

nector.

2. Set the switch @ to position 1.

3. Set TEST SW to SELF-TEST.

03UOFX.090

MONITOR LAMP

T

03UOFX-091

Procedure

4. Connect the SST (Self-Diagnosis Checker) to the System

Selector and a ground.

5. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

6. Turn the ignition switch ON.

7. Check if Monitor Lamp illuminates when each switch is made

to function as described below.

Caution

* If either of the switches remain activated, the mon-

itor lamp will be illuminated.

l Do not start the engine.

I

I Set conditions to deactivate each switch l All accessories OFF l Transaxle in neutral l All pedals released NO

-

Verify that monitor lamp does not illuminate

YES

Check each switch as described Check each switch and related wire harness

*Clutch and Neutral CT- pages F-l 72,173

switch

*Throttle sensor w page F-169 l Stoplight switch c7 Section T l Headlight switch c7 Section T l Rear defroster switch T;P Section T l Blower switch [r+ Section T

l Inhibitor switch a Section K l A/C switch 0 Section U l Water thermoswitch c7 Section E

23UOFX-OS!

Neutral and Clutch switch (MTX)

Shift transaxle into gear

Check that monitor lamp illuminates with clutch pedal

released

YES NO PC: l Neutral switch malfunction a page F-173 l Clutch switch malfunction w page F-172

*Open circuit in related wire

harness

l ECU terminal 1 V voltage

incorrect w page F-152

l ECU malfunction

Depress clutch pedal

Check that monitor lamp does not illuminate

Return transmission to neutral PC:

*Clutch switch malfunction w page F-172

23UOFX-088

F-l 06

Page 467 of 1164

STARTING SYSTEM G

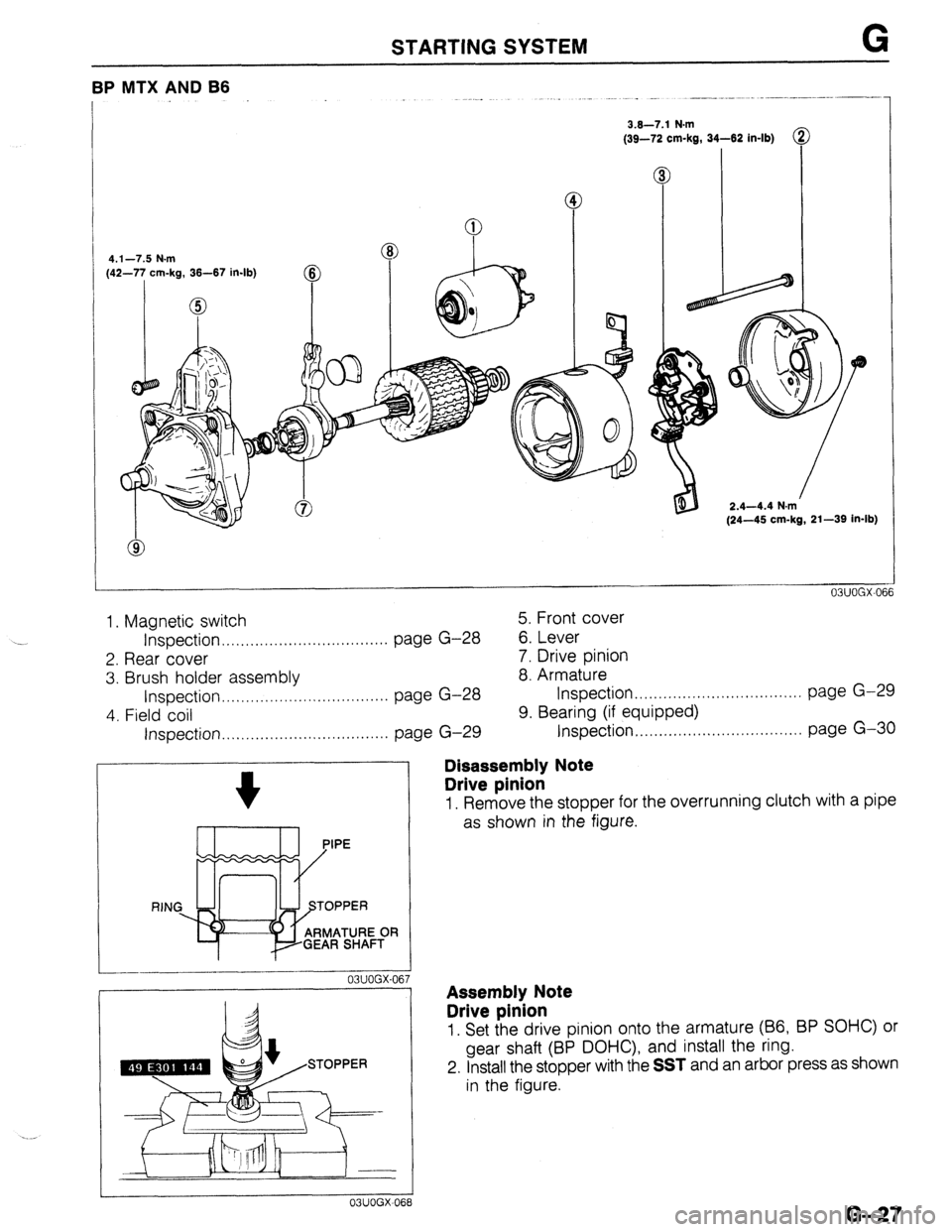

BP MTX AND B6

3.6-7.1 N.m

(39-72 cm-kg, 34-62 in-lb)

4.1-7.5 N.m

(42-77 cm-kg, 36-67 in-lb)

@

0

2.4-4.4 N.m

(24-45 cm-kg, 21-39 in-lb)

1. Magnetic switch 5. Front cover

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page G-28

6. Lever

2. Rear cover 7. Drive pinion

3. Brush holder assembly 8. Armature

Inspection.. .,..,........................... page G-28 Inspection .,,..,...............,.,........... page G-29

4. Field coil 9. Bearing (if equipped)

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page G-29 Inspection.. ,....,......................,... page G-30

--_I__-

03UOGX-06

03UOGX-06

Disassembly Note

Drive pinion

1. Remove the stopper for the overrunning clutch with a pipe

as shown in the figure.

Assembly Note

Drive pinion

1. Set the drive pinion onto the armature (66, BP SOHC) or

gear shaft (BP DOHC), and install the ring.

2. Install the stopper with the

SST and an arbor press as shown

in the figure.

G-27

Page 679 of 1164

CONVENTIONALBRAKESYSTEM P

1 SUOPX-001

03UOPX-03

0

o3uoPx-os

0

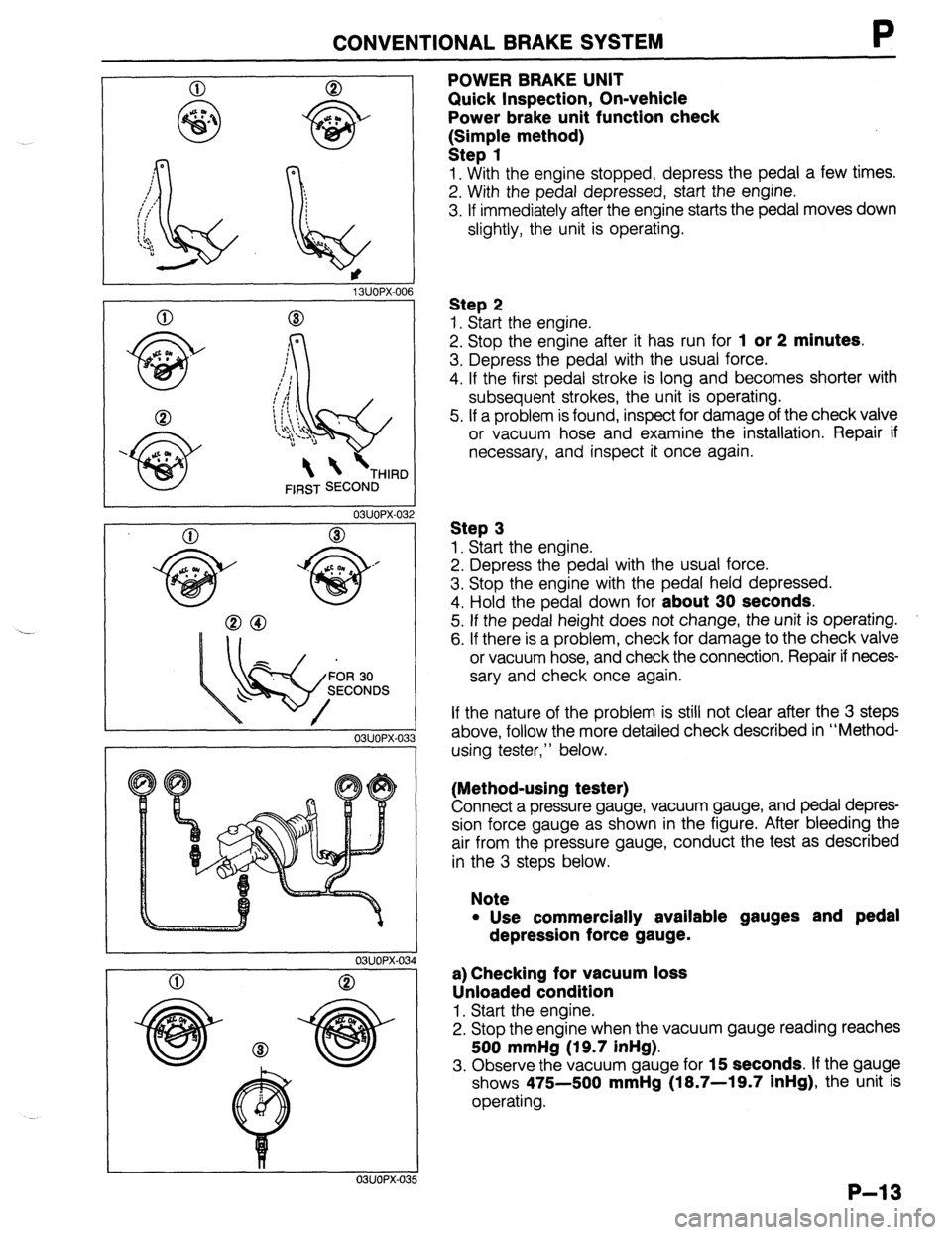

POWER BRAKE UNIT

Quick Inspection, On-vehicle

Power brake unit function check

k:;;p{e method)

1. With the engine stopped, depress the pedal a few times.

2. With the pedal depressed, start the engine.

3. If immediately after the engine starts the pedal moves down

slightly, the unit is operating.

Step 2

1. Start the engine.

2. Stop the engine after it has run for

1 or 2 minutes.

3. Depress the pedal with the usual force.

4. If the first pedal stroke is long and becomes shorter with

subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the check valve

or vacuum hose and examine the installation. Repair if

necessary, and inspect it once again.

Step 3

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal held depressed.

4. Hold the pedal down for

about 30 seconds.

5. If the pedal height does not change, the unit is operating.

6. If there is a problem, check for damage to the check valve

or vacuum hose, and check the connection. Repair if neces-

sary and check once again.

If the nature of the problem is still not clear after the 3 steps

above, follow the more detailed check described in “Method-

using tester,” below.

(Method-using tester)

Connect a pressure gauge, vacuum gauge, and pedal depres-

sion force gauge as shown in the figure. After bleeding the

air from the pressure gauge, conduct the test as described

in the 3 steps below.

Note

l Use commercially available gauges and pedal

depression force gauge.

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading reaches

500 mmHg (19.7 inHg).

3. Observe the vacuum gauge for 15 seconds. If the gauge

shows 475-500

mmHg (18.7-19.7 inHg), the unit is

operating.

P-13

Page 680 of 1164

P CONVENTIONAL BRAKE SYSTEM

0 8

500 mmHg

(19.7 inHg)

96 N (20 kg, 44 lb)

03UOPX-03

03UOPX-03

03UOPX-031

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a force of 196 N (20 kg, 44

lb).

3. With the brake pedal depressed, stop the engine when the

vacuum gauge reading reaches 500 mmHg (19.7 inHg).

4. Observe the vacuum gauge for 15 seconds. If the gauge

shows 475-500 mmHg (18.7-19.7 inHg), the unit is

operating.

b) Checking for hydraulic pressure

1. If with the engine stopped (vacuum 0 mmHg) the fluid pres-

sure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 1 1,177 kPa (12 kg/cm2, 171 psi) min

2. Start the engine. Depress the brake pedal when the vacu-

um reaches 500 mmHg (19.7 inHg). If the fluid pressure

is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 7,063 kPa (72 kg/cm’, 1,024 psi)

P-14

Page 697 of 1164

PARKING BRAKE SYSTEM

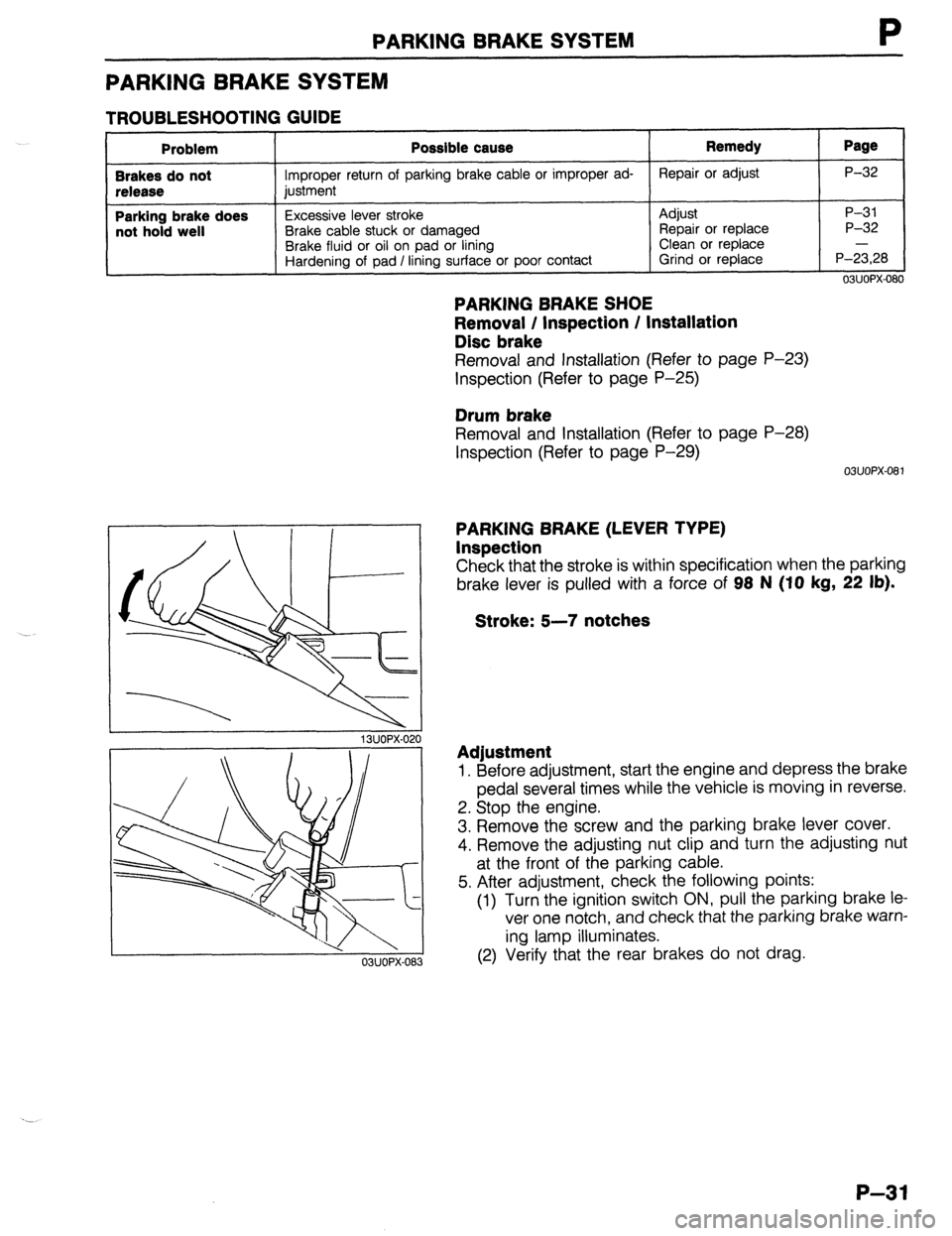

PARKING BRAKE SYSTEM

TROUBLESHOOTING GUIDE

Problem

Brakes do not

release

Parking brake does

not hold well Possible cause

Improper return of parking brake cable or improper ad-

justment

Excessive lever stroke

Brake cable stuck or damaged

Brake fluid or oil on pad or lining

Hardening of pad / lining surface or poor contact Remedy Repair or adjust

Adjust

Repair or replace

Clean or replace

Grind or replace Page P-32

P-31

P-32

P-i,28

ONOPX-080

PARKING BRAKE SHOE

Removal / Inspection / Installation

Disc brake

Removal and Installation (Refer to page P-23)

Inspection (Refer to page P-25)

Drum brake

Removal and Installation (Refer to page P-28)

Inspection (Refer to page P-29)

03u0Px-081

13UOPX-021

03UOPX-08

PARKING BRAKE (LEVER TYPE)

Inspection

Check that the stroke is within specification when the parking

brake lever is pulled with a force of 98 N (IO

kg, 22 lb).

Stroke: 5-7 notches

Adjustment

1. Before adjustment, start the engine and depress the brake

pedal several times while the vehicle is moving in reverse.

2. Stop the engine.

3. Remove the screw and the parking brake lever cover.

4. Remove the adjusting nut clip and turn the adjusting nut

at the front of the parking cable.

5. After adjustment, check the following points:

(1) Turn the ignition switch ON, pull the parking brake le

ver one notch, and check that the parking brake warn-

ing lamp illuminates.

(2) Verify that the rear brakes do not drag.

P-31

Page 989 of 1164

U

r

I

23UOUX-061

23UOUX-067

23UOUX-061 3

Caution

l Connect the charging hose to the air purge valve

via its tap pin side.

l Do not disconnect the charging hose or the serv-

ice container valve until the charging operation is

completed.

l Do not open the service container valve when not

used.

Charging from freon recovery and recycling system.

Connect the charging hose and stop valve to the manifold

gauge set air purge valve.

23UOUX-065

Caution

l Connect the charging hose to the air purge valve

via its tap pin side.

l Do not disconnect the charging hose or stop valve

until the charging operation is completed.

l Do not open the stop valve when not used.

4. Start the vacuum pump and open the high-and low-pressure

side valves of the manifold gauge set.

5. Start the pump and let it operate for 15 minutes.

6. Check high- and low-pressure side gauge readings. When

both of them are at 750 mmHg or more, close the manifold

gauge set valves.

7. Stop the vacuum pump and wait for about 5 minutes.

8. Verity that the low-pressure side gauge reading does not

change.

9. If the reading changes, retighten the piping connections and

repeat the evacuation operation.

10. If not changed, check for leaks (see below) and charge the

system.

u-33

Page 990 of 1164

ENGINE sro~i32 U

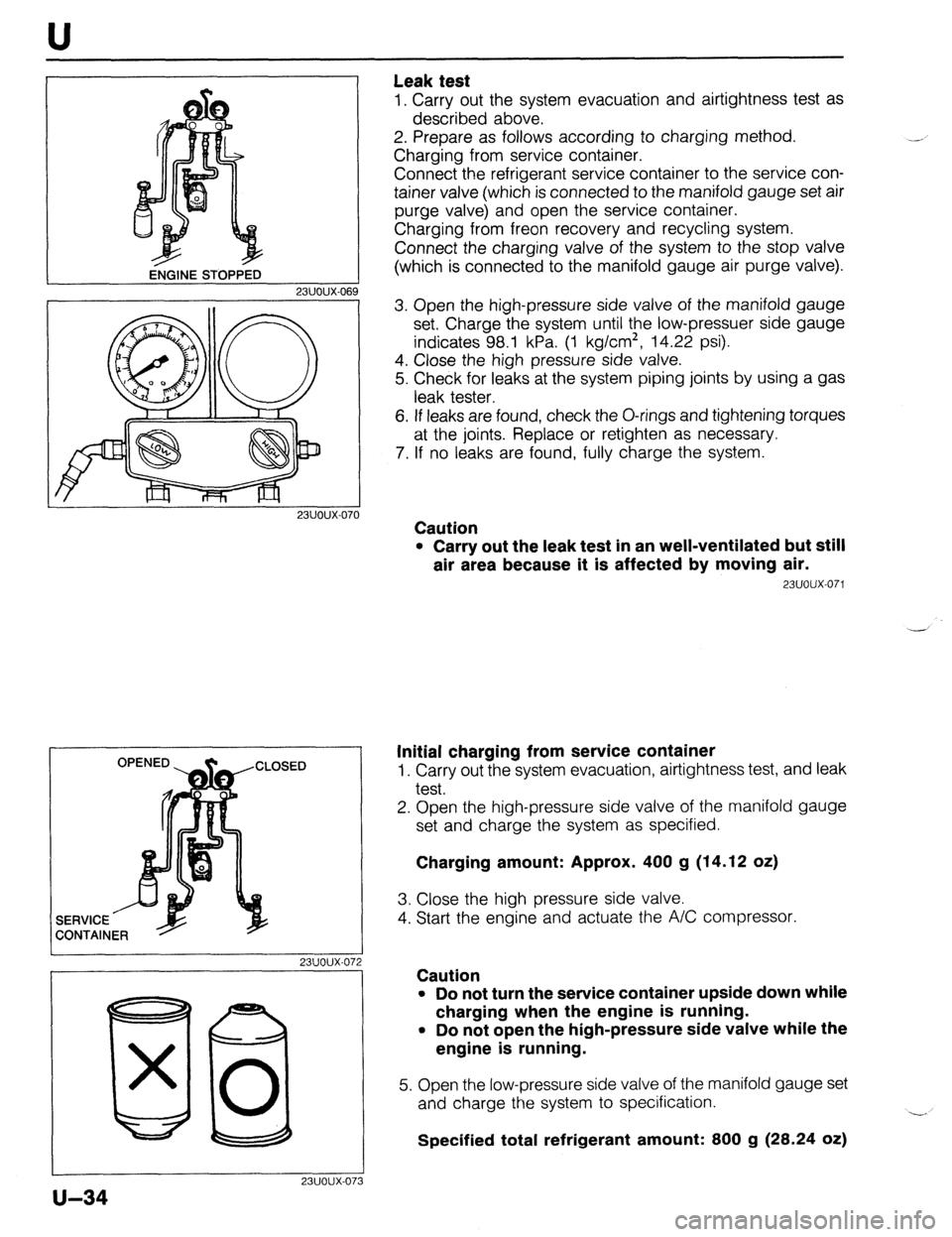

Leak test

1. Carry out the system evacuation and airtightness test as

described above.

2. Prepare as follows according to charging method.

Charging from service container.

Connect the refrigerant service container to the service con-

tainer valve (which is connected to the manifold gauge set air

purge valve) and open the service container.

Charging from freon recovery and recycling system.

Connect the charging valve of the system to the stop valve

(which is connected to the manifold gauge air purge valve).

23UOUX-06

23UOUX-070

I 23UOUX-072

I

80 x 0

23UOUX-07

u-34

3

3. Open the high-pressure side valve of the manifold gauge

set. Charge the system until the low-pressuer side gauge

indicates 98.1 kPa. (1 kg/cm*, 14.22 psi).

4. Close the high pressure side valve.

5. Check for leaks at the system piping joints by using a gas

leak tester.

6. If leaks are found, check the O-rings and tightening torques

at the joints. Replace or retighten as necessary.

7. If no leaks are found, fully charge the system.

Caution

l Carry out the leak test in an well-ventilated but still

air area because it is affected by moving air.

23UOUX-071

Initial charging from service container

1. Carry out the system evacuation, airtightness test, and leak

test.

2. Open the high-pressure side valve of the manifold gauge

set and charge the system as specified.

Charging amount: Approx. 400 g (14.12 oz)

3. Close the high pressure side valve.

4. Start the engine and actuate the A/C compressor.

Caution

l Do not turn the service container upside down while

charging when the engine is running.

l Do not open the high-pressure side valve while the

engine is running.

5. Open the low-pressure side valve of the manifold gauge set

and charge the system to specification.

Specified total refrigerant amount: 800 g (28.24 oz) -.

Page 991 of 1164

U

L

ENGINE STARTED

*-ENGINE STARTED

23UOUX.071

6. Close the low-pressure side valve.

7. Stop the engine.

8. Close the stop valves and the service container valve.

Caution

l Do not disconnect the stop valves or the service

container valve from the charging hoses when there

is refrigerant remaining in the hoses.

Refilling

Caution

l Do not overcharge the system.

l Note the sight glass during refilling the refrigerant.

Stop charging when no bubbles are observed in the

glass.

(Refer to page U-40).

l Care must be taken when the ambient temperature

is low. The bubbles may not be present even if the

refrigerant amount is insufficient.

1. Connect the manifold gauge set to the refrigerant system

charging valve.

(Refer to page U-32).

2. Start the engine.

3. Open the low-pressure side valve of the manifold gauge set

and charge the system as necessary.

4. Note the sight glass, and when no bubbles can be seen,

close the low-pressure side valve.

5. Stop the engine.

6. Close the stop valve and service container valve. Discon-

nect the stop valves quickly.

u-35