bulb MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 910 of 1164

T INTERIOR LAMP SYSTEM

13UOTX-077 d-------BULB

LENS

T-54

13UOTX-07

23UOTX-0

CARGO COMPARTMENT LAMP

Removal / Inspection / Installation

1. Remove the lens.

2. Remove the bulb.

3. Inspect all parts and repair or replace as necessary.

4. Install in the reverse order of removal.

TRUNK COMPARTMENT LAMP

Removal / Inspection / Installation

1. Remove the lens.

2. Remove the bulb.

3. Inspect all parts and repair or replace as necessary.

4. Install in the reverse order of removal.

COURTESY LAMP

Removal / Inspection / Installation

1. Remove the lens

2. Remove the bulb.

3. Inspect all parts and repair or replace as necessary.

4. Install in the reverse order of removal.

Page 915 of 1164

WARNING SYSTEM

Light-off reminder alarm does not sound.

VB: Battery voltage

Terminal Connected to Test condition Specification To correct

C Headlight switch Headlight switch ON VB Check headlight switch and

wiring harness

(Refer to pages T-27, 28)

P Ignition switch Ignition switch ON VB Check ignition switch and

wiring harness

(Refer to page T-21)

N Door switch Any door open ov Check door switches and

All doors closed V0 wiring harness

(Refer to page T-51)

23UOTX-033

Seat belt alarm does not sound.

VB: Battery voltage

Terminal Connected to Test condition Specification To correct

P ignition switch Ignition switch ON

Vs Check ignition switch and

wiring harness

(Refer to page T-21)

D Seat belt buckle switch Seat belt buckled

00 Check seat belt buckle switch

Seat belt unbuckled

00 and wiring harness

(Refer to page S-102)

23UOTX-034

Seat belt timer does not operate.

VB: Battery voltage

Terminal Connected to Test condition Specification To correct

P Ignition switch Ignition switch ON VE Check ignition switch and

wiring harness

(Refer to page T-21)

23UOTX-035

Passive shoulder belt alarm does not sound.

VB: Battery voltage

Connected to Test condition

Ignition switch Ignition switch Specification

VB

Passive shoulder belt

control unit For 5 seconds after

ignition switch and belt

unbuckled

Other conditions 00

co

IG key illumination timer does not operate.

To correct

I

Check ignition switch and

wiring harness

(Refer to page T-21)

Check passive shoulder belt

control unit and wiring harness

(Refer to page S-104)

23UOTX-036

Ve: Battery voltage

Terminal Connected to Test condition Specification To correct

L IG key illumination Either door open

VB Check bulbs and wiring

harness

N Door switch Any door open ov Check door switches and

All doors closed

VB wiring harness

(Refer to page T-51)

23UOTX-037

T-59

Page 917 of 1164

WARNING SYSTEM T

13UOTX-07

63U15X-05

, I//

‘nF -

-

-

FUEL

13UOTX.08C

- CHARGE

13UOTX-08

13UOTX-08

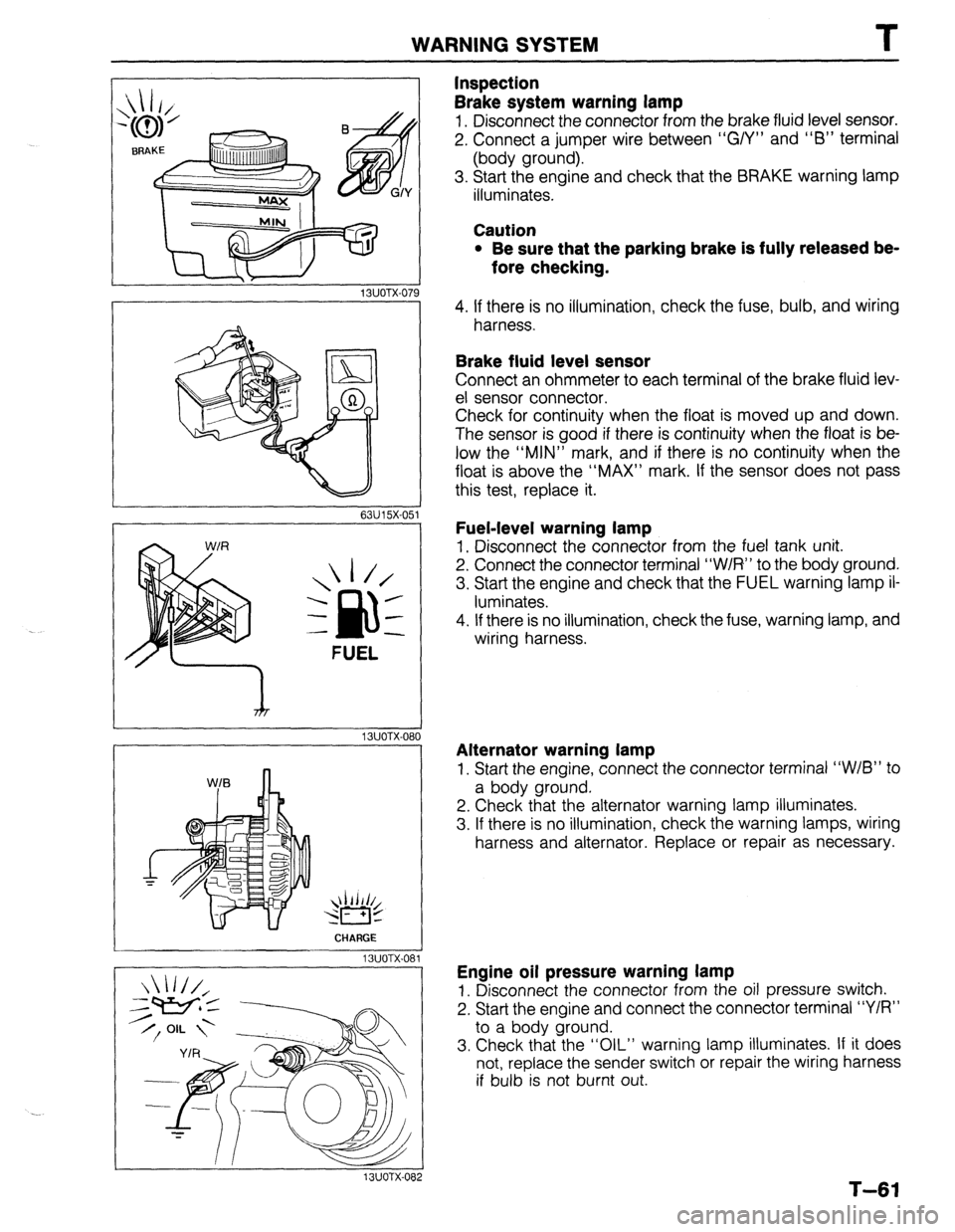

Inspection

Brake system warning lamp

1. Disconnect the connector from the brake fluid level sensor.

2. Connect a jumper wire between “G/Y” and “6” terminal

(body ground).

3. Start the engine and check that the BRAKE warning lamp

illuminates.

Caution

l Be sure that the parking brake is fully released be-

fore checking.

4. If there is no illumination, check the fuse, bulb, and wiring

harness.

Brake fluid level sensor

Connect an ohmmeter to each terminal of the brake fluid lev-

el sensor connector.

Check for continuity when the float is moved up and down.

The sensor is good if there is continuity when the float is be-

low the “MIN” mark, and if there is no continuity when the

float is above the “MAX” mark. If the sensor does not pass

this test, replace it.

Fuel-level warning lamp

1. Disconnect the connector from the fuel tank unit.

2. Connect the connector terminal “W/R” to the body ground.

3. Start the engine and check that the FUEL warning lamp il-

luminates.

4. If there is no illumination, check the fuse, warning lamp, and

wiring harness.

Alternator warning lamp

1. Start the engine, connect the connector terminal “W/B” to

a body ground.

2. Check that the alternator warning lamp illuminates.

3. If there is no illumination, check the warning lamps, wiring

harness and alternator. Replace or repair as necessary.

Engine oil pressure warning lamp

1. Disconnect the connector from the oil pressure switch.

2. Start the engine and connect the connector terminal “Y/R”

to a body ground.

3. Check that the “OIL” warning lamp illuminates. If it does

not, replace the sender switch or repair the wiring harness

if bulb is not burnt out.

T-61

Page 918 of 1164

T

I WARNING SYSTEM

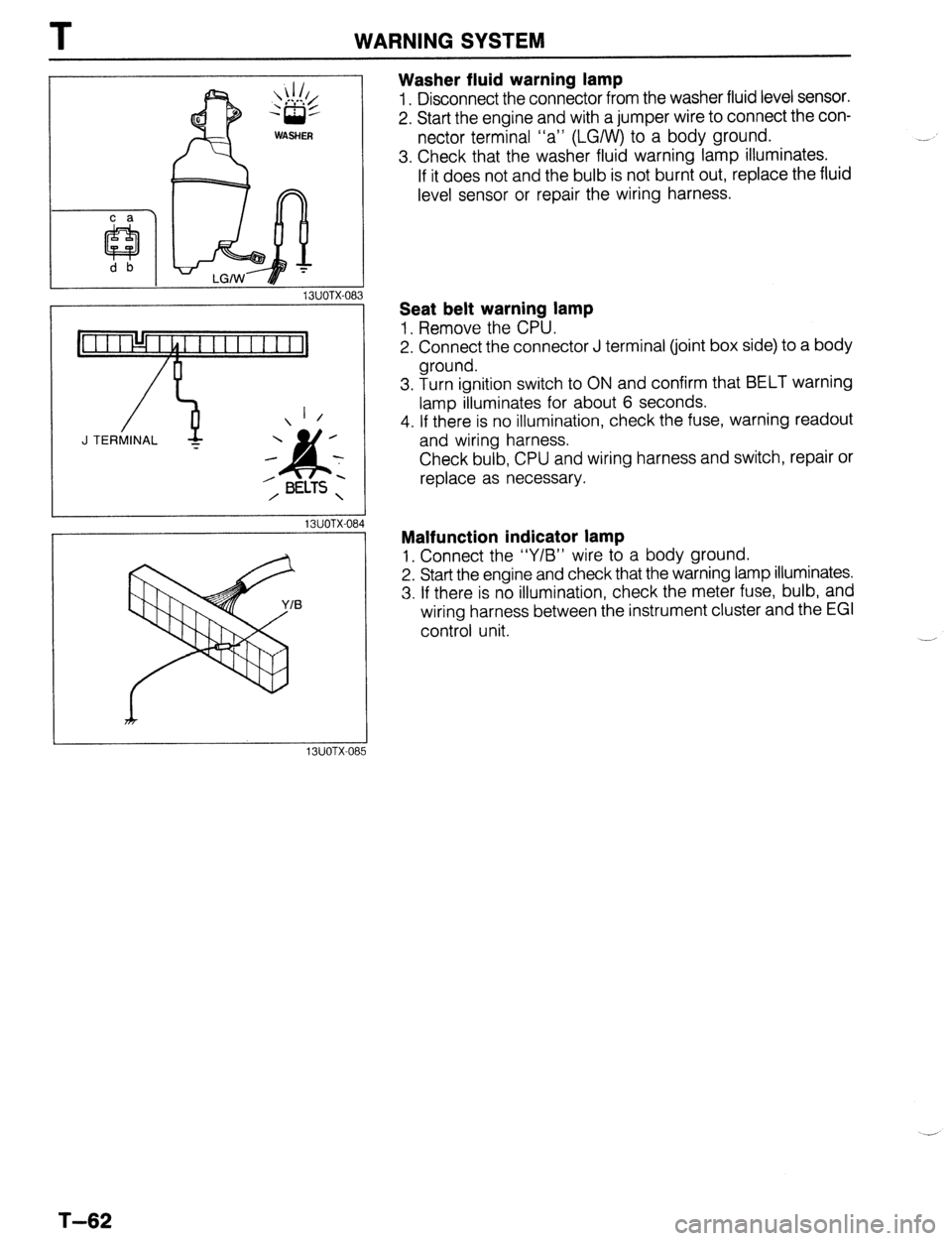

Washer fluid warning lamp

1. Disconnect the connector from the washer fluid level sensor.

2. Start the engine and with a jumper wire to connect the con-

nector terminal “a” (LGIW) to a body ground.

3. Check that the washer fluid warning lamp illuminates.

If it does not and the bulb is not burnt out, replace the fluid

level sensor or repair the wiring harness.

13UOTX-08

_-

1 /

J TERMINAL -

13UOTX-08

13UOTX-08

Seat belt warning lamp

1, Remove the CPU.

2. Connect the connector J terminal (joint box side) to a body

ground.

3. Turn ignition switch to ON and confirm that BELT warning

lamp illuminates for about 6 seconds.

4. If there is no illumination, check the fuse, warning readout

and wiring harness.

Check bulb, CPU and wiring harness and switch, repair or

replace as necessary.

Malfunction indicator lamp

1, Connect the “Y/B” wire to a body ground.

2. Start the engine and check that the warning lamp illuminates.

3. If there is no illumination, check the meter fuse, bulb, and

wiring harness between the instrument cluster and the EGI

control unit.

T-62

Page 992 of 1164

U AIR CONDITIONER

DRY AND WET THERMOMETER

13uoux-014

Performance test

After finishing repairs, conduct a performance test of the air

conditioning system as follows.

1. Connect the manifold gauge set. (Refer to page U-32.)

2. Start the engine and keep the engine speed at

1,500 rpm.

3. Operate the air conditioner at maximum cooling.

4. Open all windows and doors.

5. Place a dry-bulb thermometer in the center ventilator outlet.

6. Place a dry and wet thermometer close to the blower inlet.

7. Wait until the air conditioner outlet temperature stabilizes.

Stabilized condition

Blower inlet temperature: 25-35*C (77-95*F)

High-pressure side:

1,177-1,619 kPa (12.0-16.6 kg/cm’, 171-235 psi)

Note

l If the high-pressure side becomes too high, pour

cool water on the condenser. If It is too low, cover

the front of the condenser.

8. After the air conditioner stabilizes, read the dry and wet ther-

mometer at the air inlet.

9. Calculate the relative humidity from the chart below by com-

paring the wet- and dry-bulb readings.

05uoux-051

‘C ‘F

26

24

22

20

18

16

14

12

10

U

--k----

RELATIVE HUMIDITY ‘%’

I 96U16X.103

IO. Read the dry thermometer at the air outlet, and calculate

the difference between the inlet dry-bulb and outlet dry-bulb

temperatures.

11. Verify that the intersection of the relative humidity and tem-

perature difference is in the shaded zone.

U-36

Page 996 of 1164

U AIR CONDITIONER

OFF

03UOUX-06

03UOUX-06,

03UOUX-06

On-vehicle Inspection

Thermoswitch

1. Remove the glove box.

2. Run the engine at idle.

3. Turn OFF the A/C switch and set the blower switch to the

highest position to operate the blower fan for a few minutes.

4. After a few minutes, turn OFF the blower switch and stop

the engine.

5. Disconnect the thermoswitch connector and check for con-

tinuity between terminals of the switch.

Terminals Continuity

a-b Yes

6. If not as specified, replace the thermoswitch.

Note

l The thermoswitch contacts will be open if the

evaporator temperature is below 0.4 f 0.7OC (32.7

z!z 1.3OF).

Inspection

Thermoswitch

1. Immerse the sensing bulb in a container of ice water.

2. Check continuity between terminals of the switch as

specified.

Terminals

a-b Temperature Continuity

Above 5°C Yes

Below 0% No

3. If not as specified, replace the thermoswitch

Evaporator

1. Check the evaporator fins for blockage. If the fins are

clogged, clean them with compressed air.

Caution

l Never use water to clean the evaporator.

2. Check the fittings for cracks and other damage.

Replace the evaporator if necessary.

u-40

Page 1034 of 1164

TD TECHNICAL DATA

Coil Spring Specifications (See page R-5 for coil spring applications)

*’ Main identification mark color: Indicated on second coil from bottom. l * Auxiliary identification mark color: Indicated on third coil from bottom.

T. BODY ELECTRICAL SYSTEM

Item

Headlight

Frnnt tl wn sinnnl/Pnrkinn linht

Specification (W) (Bulb Trade number)

65145 (9004)

2718 II I 571

I

“‘VW, I u”“y’ 1. I” \’ ‘V’,

uinh mount stoplight 18.4 (1141)

turn single light 27 (1156)

Y-,-~p light 27 (1156)

Rear side marker light (Sedan) 3.8 (194)

License plate light 7.5 (89) [PROTEGE], 5 (168) [3HBl

Interior 10

Interior and spot lamp

spot 6

Interior lamp 10

‘i--” Spot lamp (in overhead console)

8 (67)

Cargo room lamp 5 (168)

Trunk room lamp 5 (168)

I I

ntminr Iamnc

I

Curtesy lamp

High beam

Turn light

Brake

Hold

) Charge 5 (168)

3.4

3.4

3

3 (158)

i

Oil pressure

Washer

Seat belt

Malfunction

Fuel

illumination 3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3.4 Indicator and

warning lamps

Check 3 (158)

Dif. lock

I 3 (158) .-

,

-.-’

I

I

TD-20

Page 1065 of 1164

Reading Wiring Diagrams Z-GI-9

Symbol ‘ Meaning Symbol Meaning

Horn l Generates sound when current flows. Switch (1) l Allows or breaks current flow by

opening and closing circuits.

Speaker

w

Heater l Generates heat when current flows. Normally open (NO)

Switch (2)

Normally closed (NC)

Harness l Unconnected intersecting harness.

Speed sensor l Movement of magnet in speedometer

set turns contact within sensor on and

Off. (Not connected)

l Connected intersecting harness.

Ignition switch @Turning ignition key operates switch

contacts to complete various circuits.

(Connected)

rlormally open (NO)

Relay (1) l Current flowing through coil produces electromagnetic force causing contact to open or close.

____- .~.~~

Open Closed

--.--.-m.---------,

Relay (2) Normally open relay (NO)

- Ri i No flow ’ ni 1 Closed

Normally closed relay (NC) Flow

ormally closed (NC)

Sensor (variable) l Resistor whose resistance changes Diode

l Known as a semiconductor rectifier.

--3p6G- with operation of other components. diode allows current flow in one

direction only

--T- IA

IY Calhode(K)+- Anode(A)

* Flow of electric current

K-1 KD, he>:

-

ensor (thermistor)

l Resistor whose resistance changes Light emitting diode 0 Diode that lights when current flows

with temperature.

(LED)

l Unlike ordinary light bulbs, diode does

not generate heat when lit

Capacitor

l Component that temporarily stores “2, Cathode(K) --&---Anode(A)

I7

Cathode(K)

electrical charge.

c Anode(A)

----il---- .

Flow of electric current

Solenoid

l Current flowing through co11 generates Reference(zener) l Allows current to flow In one dlrectlon

electromagnetic force to operate diode up to a certain voltage. allows current

plungers, etc. cd to flow In other dIrectron once that

J-

voltage IS exceeded.

z-9

Page 1069 of 1164

Troubleshooting Z-Gl-13

el

-

Ill

31

-

I1

Jl

:n

r.

7a

ver

le

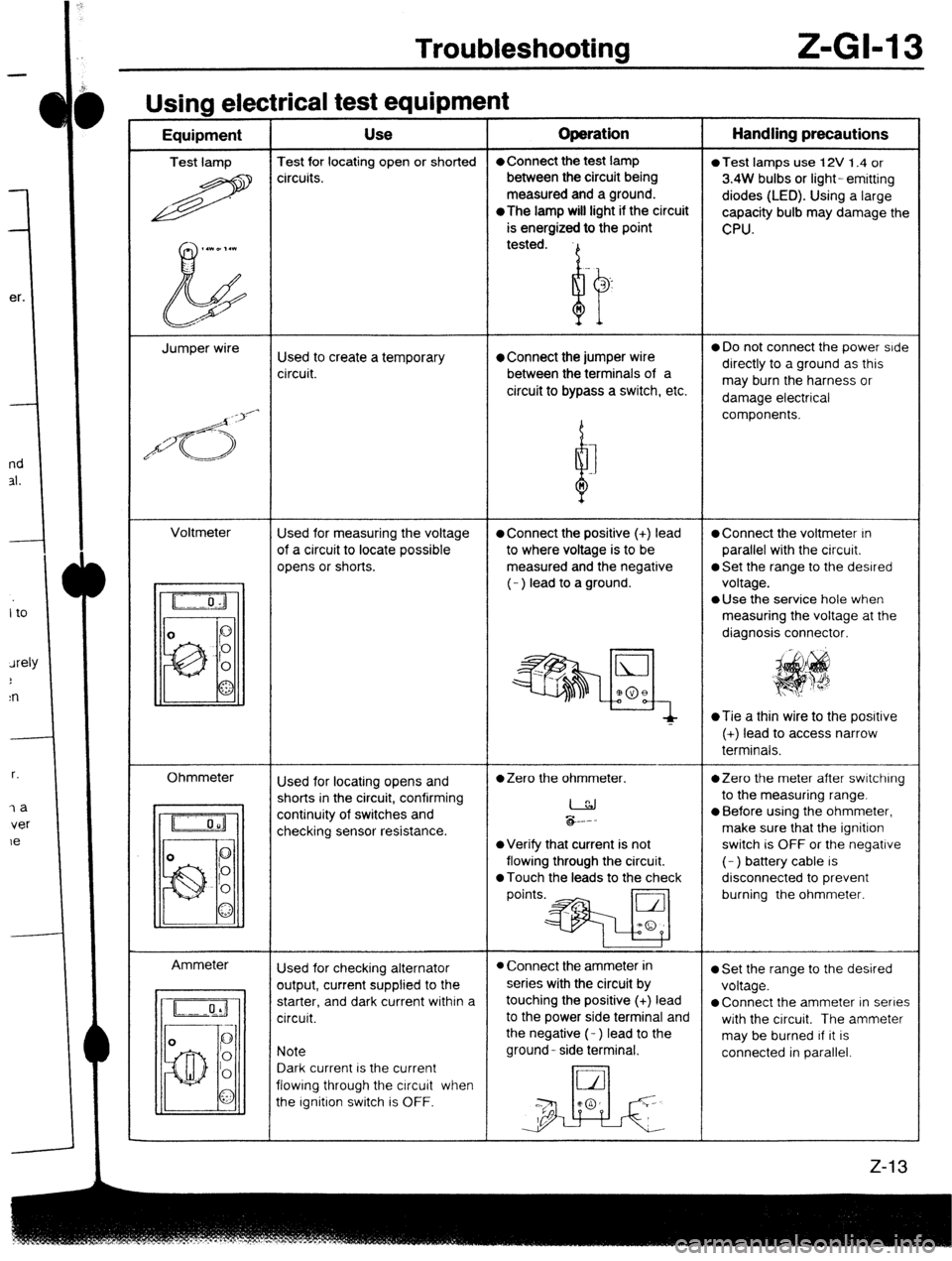

Usina electrical test eaubment -----w - I - Equipment Use Operation Handling precautions

Test lamp Test for locating open or shorted l Connect the test lamp

0 Test lamps use 12V 1.4 or

R circuits. between the circuit being

3.4W bulbs or light- emitting

measured and a ground.

diodes (LED). Using a large

*The

lamp will light if the circuit

capacity bulb may damage the

is energized to the point

CPU.

,.WD,.l

b tested.

Jumper wire

Used to create a temporary l Connect the jumper wire 0 Do not connect the power side

circuit. between the terminals of a directly to a ground as this

circuit to bypass a switch, etc. may burn the harness or

damage electrical

/d<;>‘-

d components.

I

n

Voltmeter

Used for measuring the voltage

l Connect the positive (+) lead l Connect the voltmeter In

of a circuit to locate possible to where voltage is to be parallel with the circuit.

opens or shorts. measured and the negative

0 Set the range to the desired

(- ) lead to a ground. voltage.

l Use the service hole when

measuring the voltage at the

diagnosis connector.

~Tie a thin wire to the posrtive

(+) lead to access narrow

terminals.

Ohmmeter

Ammeter Used for locating opens and

l Zero the ohmmeter. *Zero the meter after switching

shorts in the circuit, confirming

I to the measuring range.

continuity of switches and

checking sensor resistance. &.--

l Before using the ohmmeter,

make sure that the ignition

l Verify that current is not switch is OFF or the negative

flowing through the circuit. (- ) battery cable is

0 Touch the leads to the check disconnected to prevent

points.* burning the ohmmeter.

Used for checking alternator

l Connect the ammeter in l Set the range to the desired

output, current supplied to the series with the circuit by

voltage.

starter, and dark current within a touching the positive (+) lead

l Connect the ammeter in series

circuit. to the power side terminal and

with the circuit. The ammeter

the negative (- ) lead to the

may be burned If it is

Note ground- side terminal.

connected in parallel.

Dark current is the current

flowing through the circuit when

the Ignition switch is OFF.

Page 1110 of 1164

WlRlNQ DIMRAM

IITHOUT

:RUISE CONTROL’ HEADL1GHTS E-l

ILLUMINATION

BULB TRADE NUMBER

HEADLIGHT: 9004 (65/45W)

-01 COMBINATION E-02 COMBINATION E-03 HEADLIGHT LH (F) E-04 HEADLIGHT RH (F: