tire pressure MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 20 of 1164

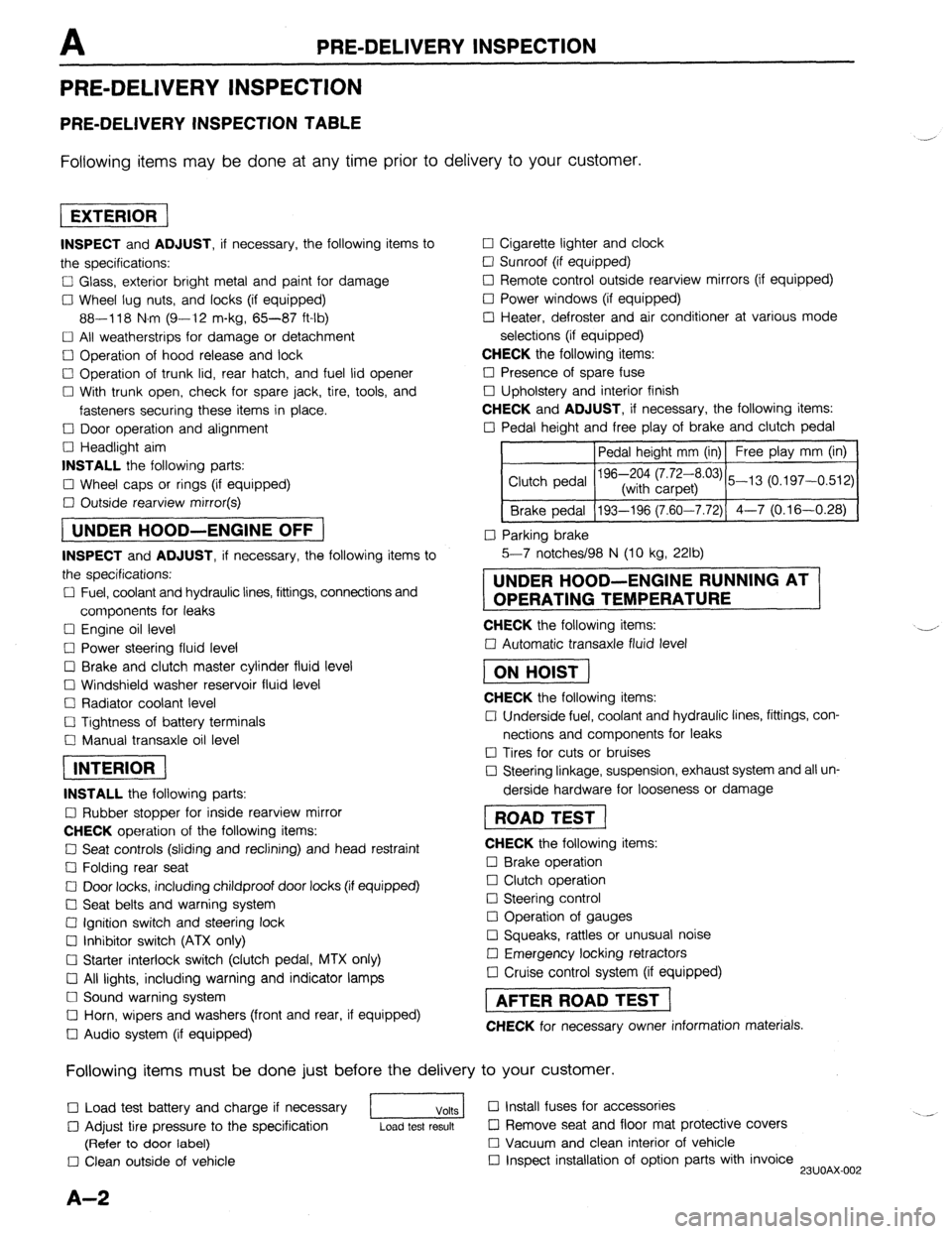

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 28 of 1164

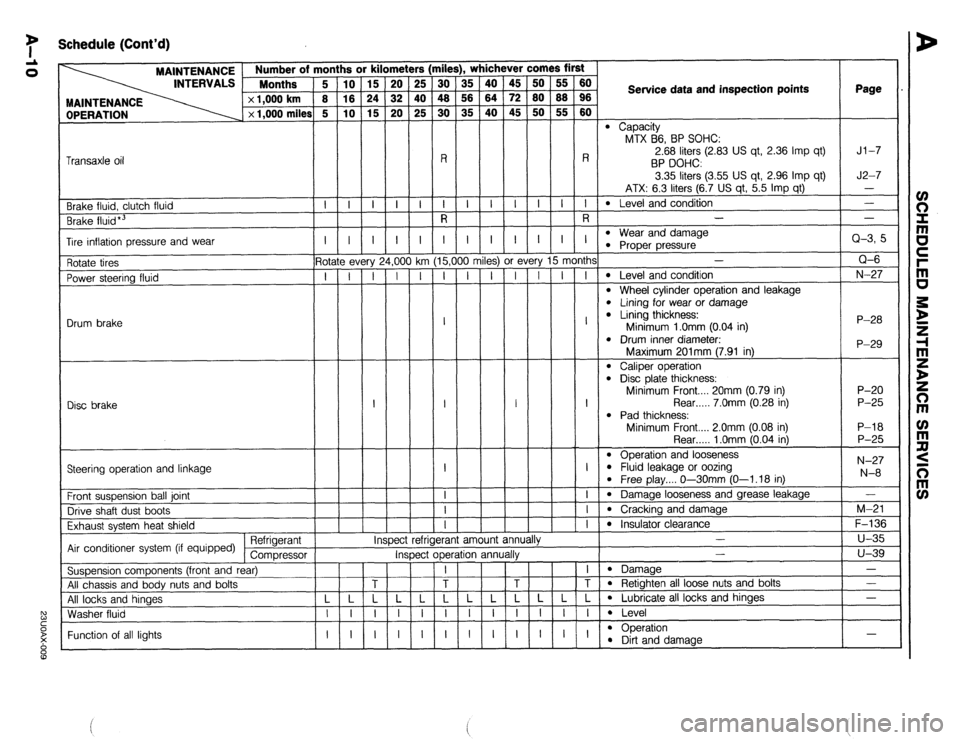

7 Schedule (Cont’d)

rile

iii

48

30

-

R

I

R !rs

25

40

25

-

-i- , whichever comes first

OPERATION MAINTENANCE Number of m

INTERVALS Months

x 1,000 km

x 1,000 miles

ii

is

G

-

i-

-

-

I

5-

T

-

-

-

-

-

-

- ii

z

ro

-

I-

-

-

I

- 45

72

45

-

-i-

-

-

I

-

ry 15 month:

I I I

A

t

A

j

milt Service data and inspection points Page

l Capacity

MTX B6, BP SOHC:

2.68 liters (2.83 US qt, 2.36 Imp qt)

BP DOHC

3.35 liters (3.55 US qt, 2.96 Imp qt)

ATX: 6.3 liters (6.7 US qt, 5.5 Imp qt)

l Level and condition

- Jl-7

J2-7

- Transaxle oil

l Wear and damaae -i- -i- -i- -

Brake fluid, clutch fluid

Brake fluid*3 -

Q-3, 5

Q-6

N-27

P-28

P-29 I I

- I

1,oo

-i

-

-

-

-

-

-

- I

G

T

-

-

-

-

-

-

- I

15,(

I Tire inflation pressure and wear l Proper pressure-

-

l Level and condition

l Wheel cylinder operation and leakage l Lining for wear or damage l Lining thickness:

Minimum 1 .Omm (0.04 in)

l Drum inner diameter. 3s) or f

I I

I

:t r

- Rotate tires

Power steering fluid

Drum brake ? every

I I

Disc brake I I

Maximum 201mm (7.91 in)

l Caliper operation l Disd plate thickness:

Minimum Front.... 20mm (0.79 in)

Rear . . . . . 7.0mm (0.28 in)

l Pad thickness:

Minimum Front.... 2.0mm (0.08 in) P-20

P-25

P-l 8

P-25

N-27

N-8 Rear . . . . . 1 .Omm (0.04 in)

l Operation and looseness l Fluid leakage or oozina

l Free play.... O--3OmmjO-1.18 in)

l Damage looseness and grease leakage

l Cracking and damage

l Insulator clearawp .-v

-

Steering operation and linkage

I

-i-

-I-

-i- Front suspension ball joint

Drive shaft dust boots

Exhaust system heat shield

Air conditioner system (if equipped) Refrigerant

Compressor

Suspension components (front and rear)

All chassis and body nuts and bolts

All locks and hinaes

Washer fluid -

M-21

F-136

u-35

u-39

-

- IY efrigerant amount ann

*. I# mspec

Inspect operation annualry -

l Damaae

l Retighten all loose nuts and bolts

l Lubricate all locks and hinges

l Level

l ODeration - Function of all lights l !%t and damage -

Page 327 of 1164

![MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

9 LACK OF POWER

_-- --

L L -

ESCRIP- *Performance poor under load when throttle valve wide open

ION *Reduced maximum speed

* Idle condition normal

VtOUBLESHOOTlNG HINTS] MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

9 LACK OF POWER

_-- --

L L -

ESCRIP- *Performance poor under load when throttle valve wide open

ION *Reduced maximum speed

* Idle condition normal

VtOUBLESHOOTlNG HINTS]](/img/28/57077/w960_57077-326.png)

TROUBLESHOOTING GUIDE F

9 LACK OF POWER

_-- --

L L -

ESCRIP- *Performance poor under load when throttle valve wide open

ION *Reduced maximum speed

* Idle condition normal

VtOUBLESHOOTlNG HINTS]

) Factors other than engine malfunction

*Clutch slipping

* ATX slipping

l Brake dragging l Low tire pressure

l Incorrect We size l Overloaded

‘, Low intake air amount @ Air/Fuel mixture too lean

l Fuel line pressure decreases l Fuel injection malfunction

@ Poor ignition

@ Low engine compression

@ Alcohol blended fuel used

l Throttle valve not open fully

*Clogged intake air system

l Low tire pressure CY Section H

CY Section K

cz7 Section P

c7 Section Q

w page F-l 14

CT= page F-l 12

Checker with ignition switch ON

w page F-83

rminal 1F voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU w page F-149

c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

Ignition timing (BTDC)

l BP DOHC : 9*-l lo l BP SOHC

: 4O-8O 4 If advances, go to next step

* If not advance, check ECU terminal

w page F-150

F-61

Page 331 of 1164

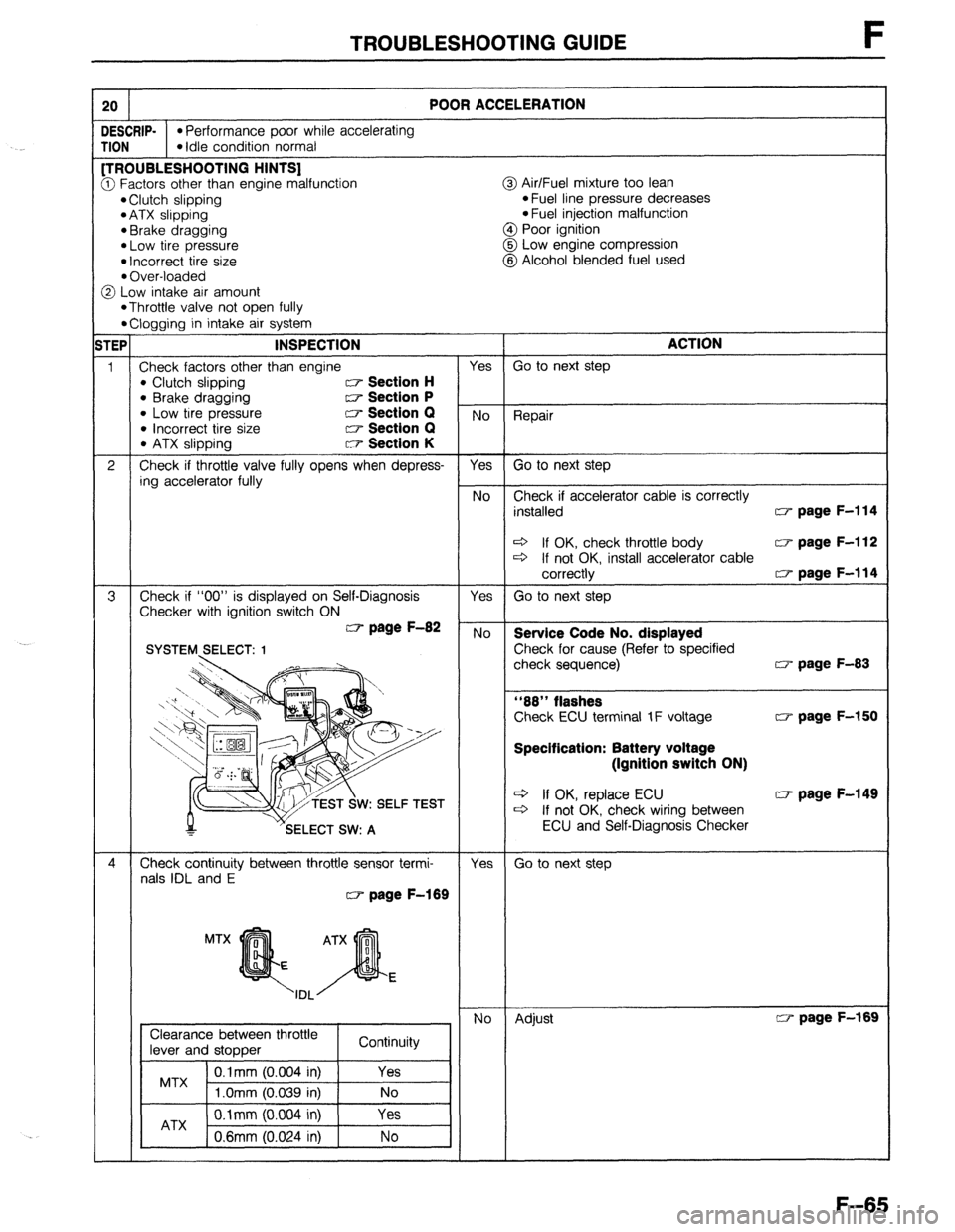

TROUBLESHOOTING GUIDE F

20 POOR ACCELERATION

DESCRIP- l Performance poor while accelerating

TION l idle condition normal [TROUBLESHOOTING HINTS)

3 Factors other than engine malfunction @ Air/Fuel mixture too lean

*Clutch slipping l Fuel line pressure decreases l ATX slipping l Fuel injection malfunction

l Brake dragging @ Poor ignition l Low tire pressure

@ Low engine compression

l Incorrect tire size @ Alcohol blended fuel used l Over-loaded

3 Low intake arr amount

*Throttle valve not open fully

*Clogging in intake air system

Check factors other than engine CT Section H

c7 Section

P

ing accelerator fully w page F-l 14

w page F-l 12

Checker with ignition switch ON w page F-83

rminal 1 F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST c3 If OK, replace ECU w page F-149 r;3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

Clearance between throttle

lever and stopper

0.1 mm (0.004 in)

l.Omm (0.039 in)

O.lmm (0.004 in)

0.6mm (0.024 in)

Page 341 of 1164

![MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati](/img/28/57077/w960_57077-340.png)

TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operation, stop and go driving, extended winter

warm-up periods, etc., as opposed to “trip” mileage, an attempt should be made to determine these factors when con-

fronted with “poor mileage” conditions. However, since the operator is not always at fault, the following is offered.

@II Operator depressing accelerator more than usual due to

@ Air/Fuel mixture too rich

low engine power

l Poor ignition *High fuel line pressure

@ Alcohol blended fuel used

*Low intake air amount

l Electronic spark advance control system malfunction @ High vehicle load l Low tire pressure

*Clutch slipping/ATX slipping l Incorrect tire size l Exhaust component restricted l Brake dragging ;TEP

INSPECTION ACTION

1

Check factors other than engine Yes

Go to next step

l Low tire pressure = Section Q 9 Unrecommended tire srze v Section Q l Clutch slipping w Section H l Brake dragging No

0 Section P Repair

l Exhaust component restricted cz= page F-136

2

Check if air hoses are connected correctly - Yes

Go to next step CI page F-109

No

Repair 3

Check if “00” IS displayed on Self-Diagnosis

Yes

Checker with ignition switch ON Go to next step W page F-82 No

SYSTEM SELECT: 1 Service Code No. displayed Check for cause (Refer to specified

check sequence) w page F-63

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU CT= page F-149 e If not OK, check wiring between

ECU and Self-Diagnosis Checker 4

Check for correct intake manifold vacuum at idle

Yes Go to next step Vacuum: More than 450 mmHg (17.7 inHg) No

Check for air leakage at intake air sys-

tem components 5

Check if air cleaner element is clean Yes

Go to next step CT= page F-79

No

Replace air cleaner element

F-75

Page 650 of 1164

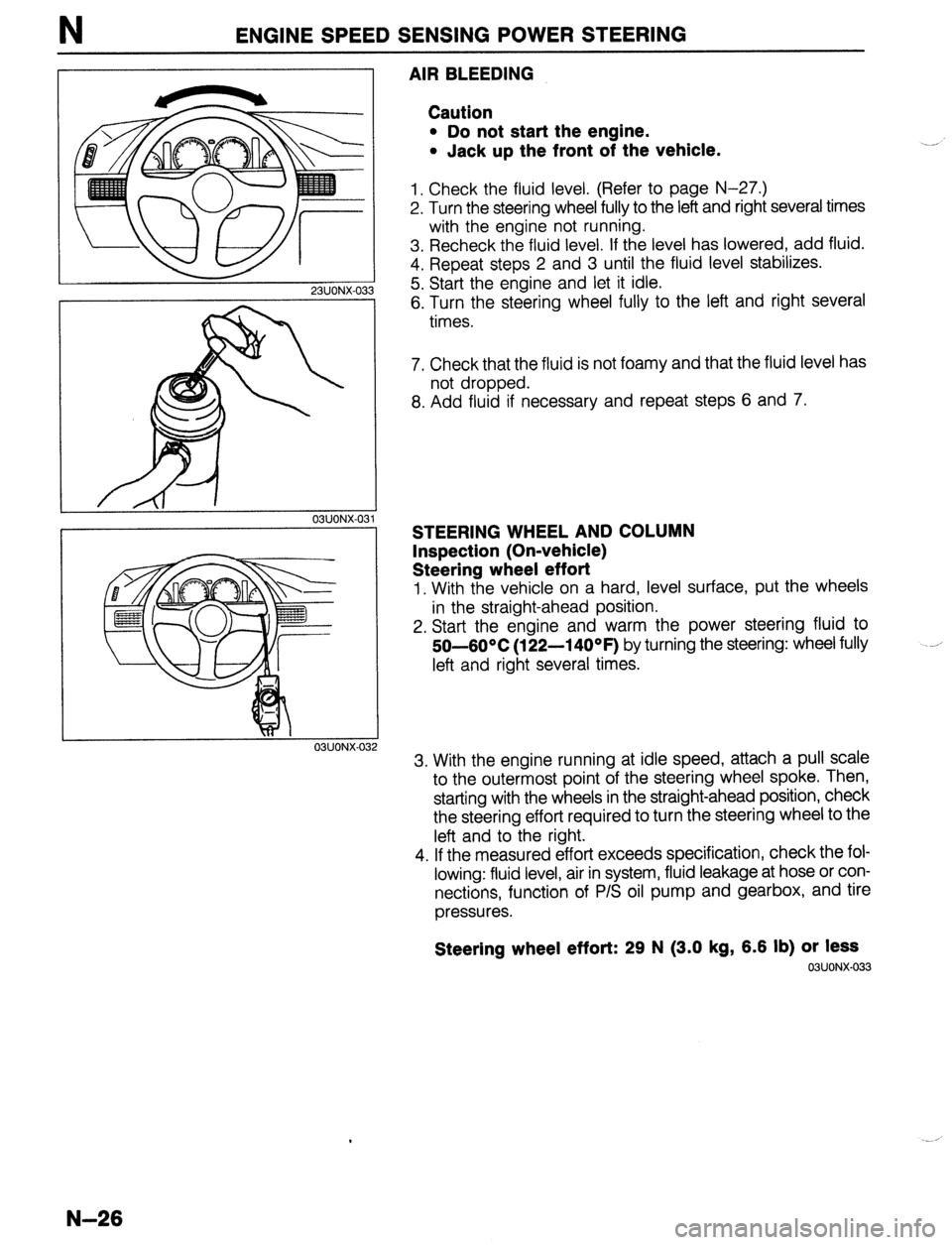

ENGINE SPEED SENSING POWER STEERING

23UONX-03

03UONX-032

AIR BLEEDING

Caution

l Do not start the engine.

l Jack up the front of the vehicle.

1. Check the fluid level. (Refer to page N-27.)

2. Turn the steering wheel fully to the left and right several times

with the engine not running.

3. Recheck the fluid level. If the level has lowered, add fluid.

4. Repeat steps 2 and 3 until the fluid level stabilizes.

5. Start the engine and let it idle.

6. Turn the steering wheel fully to the left and right several

times.

7. Check that the fluid is not foamy and that the fluid level has

not dropped.

8. Add fluid if necessary and repeat steps 6 and 7.

STEERING WHEEL AND COLUMN

Inspection (On-vehicle)

Steering wheel effort

1. With the vehicle on a hard, level surface, put the wheels

in the straight-ahead position.

2. Start the engine and warm the power steering fluid to

50-60°C

(122-14OOF) by turning the steering: wheel fully

left and right several times.

3. With the engine running at idle speed, attach a pull scale

to the outermost point of the steering wheel spoke. Then,

starting with the wheels in the straight-ahead position, check

the steering effort required to turn the steering wheel to the

left and to the right.

4. If the measured effort exceeds specification, check the fol-

lowing: fluid level, air in system, fluid leakage at hose or con-

nections, function of P/S oil pump and gearbox, and tire

pressures.

Steering wheel effort: 29 N (3.0 kg, 6.6 lb) or less 03UONX-033

N-26

Page 671 of 1164

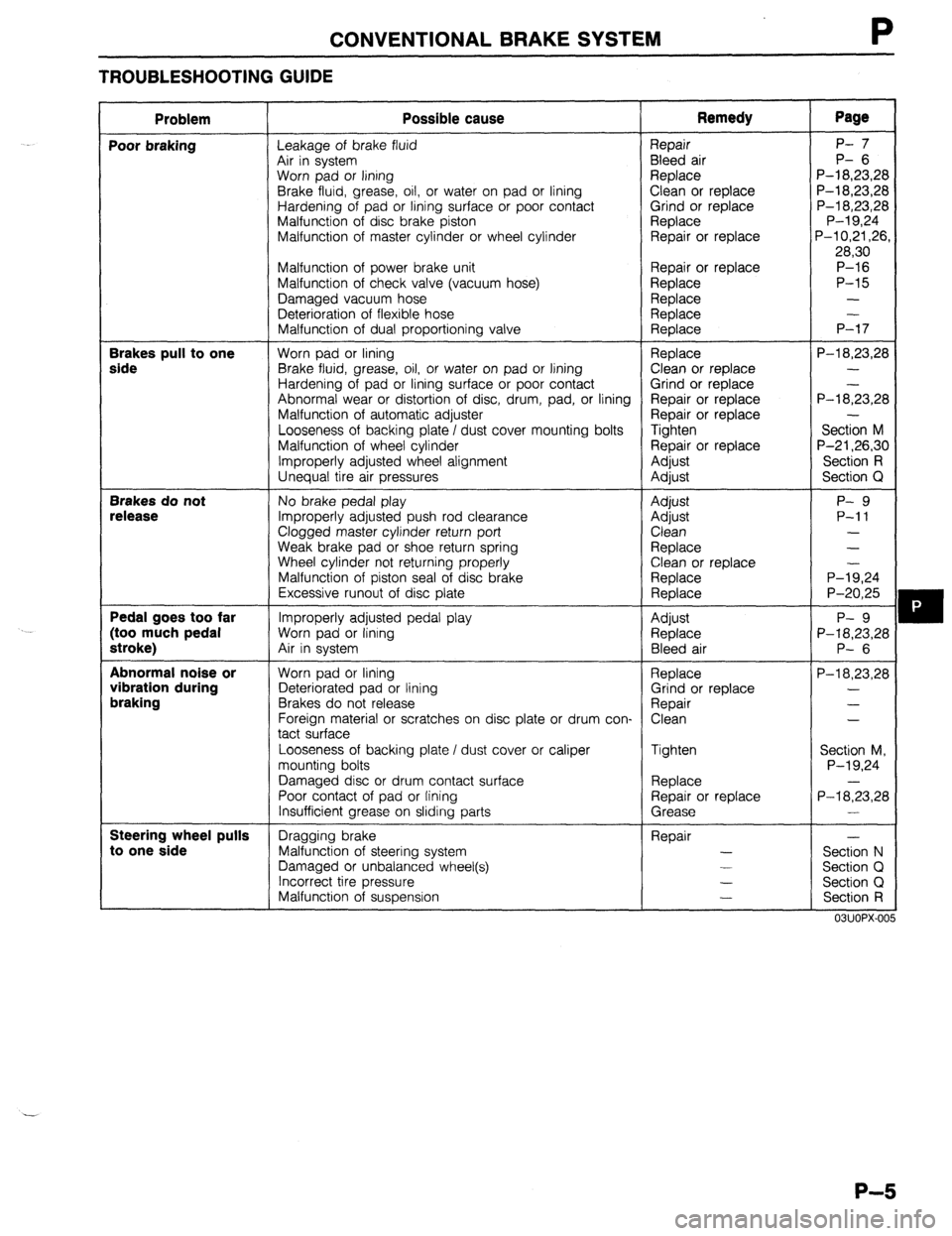

CONVENTIONAL BRAKE SYSTEM

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Poor braking

Leakage of brake fluid Repair P- 7

Air in system Bleed air P- 6

Worn pad or lining Replace P-l 8,23,28

Brake fluid, grease, oil, or water on pad or lining Clean or replace P-18,23,28

Hardening of pad or lining surface or poor contact Grind or replace P-l 8,23,28

Malfunction of disc brake piston Replace P-l 9,24

Malfunction of master cylinder or wheel cylinder Repair or replace P-l 0,21,26,

28,30

Malfunction of power brake unit Repair or replace P-16

Malfunction of check valve (vacuum hose) Replace P-15

Damaged vacuum hose Replace -

Deterioration of flexible hose Replace -

Malfunction of dual proportioning valve Replace P-17 Brakes pull to one

Worn pad or lining Replace P-l 8,23,28 side Brake fluid, grease, oil, or water on pad or lining Clean or replace -

Hardening of pad or lining surface or poor contact Grind or replace

Abnormal wear or distortion of disc, drum, pad, or lining Repair or replace P-l 8;3,28

Malfunction of automatic adjuster Repair or replace -

Looseness of backing plate I dust cover mounting bolts Tighten Section M

Malfunction of wheel cylinder Repair or replace P-21,26,30

Improperly adjusted wheel alignment Adjust Section R

Unequal tire air pressures

Adjust Section Q Brakes do not

No brake pedal play Adjust P- 9 release Improperly adjusted push rod clearance Adjust P-11

Clogged master cylinder return port Clean -

Weak brake pad or shoe return spring Replace -

Wheel cylinder not returning properly

Clean or replace

Malfunction of piston seal of disc brake Replace P-l;,24

Excessive runout of disc plate

Replace P-20,25 Pedal goes too far

Improperly adjusted pedal play Adjust P- 9 (too much pedal Worn pad or lining

Replace P-18,23,28 stroke) Air in system

Bleed air P- 6 Abnormal noise or

Worn pad or lining

Replace P-18,23,28 vibration during Deteriorated pad or lining Grind or replace - braking Brakes do not release Repair -

Foreign material or scratches on disc plate or drum con- Clean -

tact surface

Looseness of backing plate / dust cover or caliper Tighten

Section M,

mounting bolts P-l 9,24

Damaged disc or drum contact surface Replace -

Poor contact of pad or fining Repair or replace

P-18,23,28

Insufficient grease on sliding parts Grease - Steering wheel pulls

Dragging brake Repair - to one side Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Cl

Incorrect tire pressure -

Section Q

Malfunction of suspension -

Section R

mm> IAn\, ,.e

P-5

Page 702 of 1164

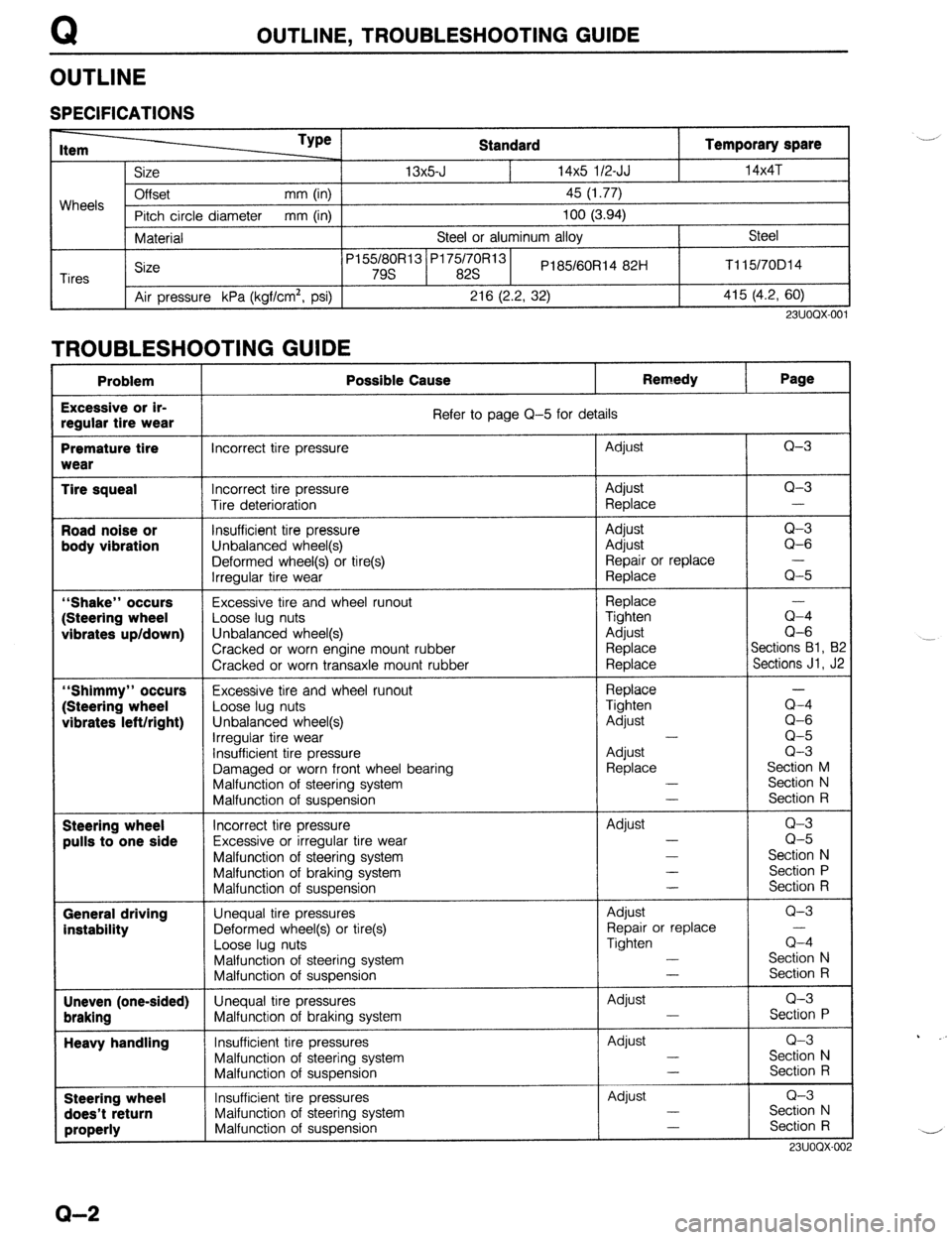

Q OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

Wheels

Tires Standard Temporary spare __/

Size 13x5-J 14x5 l/2-JJ l4x4T

Offset mm (in)

45 (1.77)

Pitch circle diameter mm (in)

100 (3.94)

Material Steel or aluminum alloy Steel

Size P155/80R13’P175/70R131

PI 85/60Rl4 82H Tll5/70D14

79s 82s

Air pressure kPa (kgflcm’, psi)

216 (2.2, 32) 415 (4.2, 60)

23UOQX-001

TROUBLESHOOTING GUIDE _____ -_- ____ _ __.- -. -.-.--

Problem Possible Cause Remedy Page

Excessive or ir-

regular tire wear Refer to page Q-5 for details

Premature tire incorrect tire pressure Adjust Q-3

wear

Tire squeal Incorrect tire pressure Adjust Q-3

Tire deterioration Replace -

Road noise or Insufficient tire pressure Adjust Q-3

body vibration

Unbalanced wheel(s) Adjust Q-6

Deformed wheel(s) or tire(s) Repair or replace

Irregular tire wear Replace Q-5

“Shake” occurs Excessive tire and wheel runout

Replace

(Steering wheel Loose lug nuts

Tighten a-4

vibrates up/down) Unbalanced wheel(s)

Adjust Q-6

Cracked or worn engine mount rubber

Replace Sections Bl, B:

Cracked or worn transaxle mount rubber

Replace Sections Jl, J2

“Shimmy” occurs Excessive tire and wheel runout

Replace

(Steering wheel

Loose lug nuts Tighten a-4

vibrates left/right) Unbalanced wheel(s)

Adjust Q-6

irregular tire wear -

Q-5

insufficient tire pressure

Adjust Q-3

Damaged or worn front wheel bearing

Replace Section M

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Steering wheel Incorrect tire pressure Adjust Q-3

pulls to one side Excessive or irregular tire wear -

Q-5

Malfunction of steering system -

Section N

Malfunction of braking system -

Section P

Malfunction of suspension -

Section R

General driving Unequal tire pressures Adjust Q-3

instability Deformed wheel(s) or tire(s) Repair or replace

Loose lug nuts Tighten Q-4

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Uneven (one-sided) Unequal tire pressures

Adjust Q-3

braking Malfunction of braking system -

Section P

Heavy handling Insufficient tire pressures Adjust Q-3

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Steering wheel Insufficient tire pressures Adjust Q-3

does’t return Malfunction of steering system -

Section N

properly Malfunction of suspension -

Section R

731100x-or . _. -,

Q-2

Page 703 of 1164

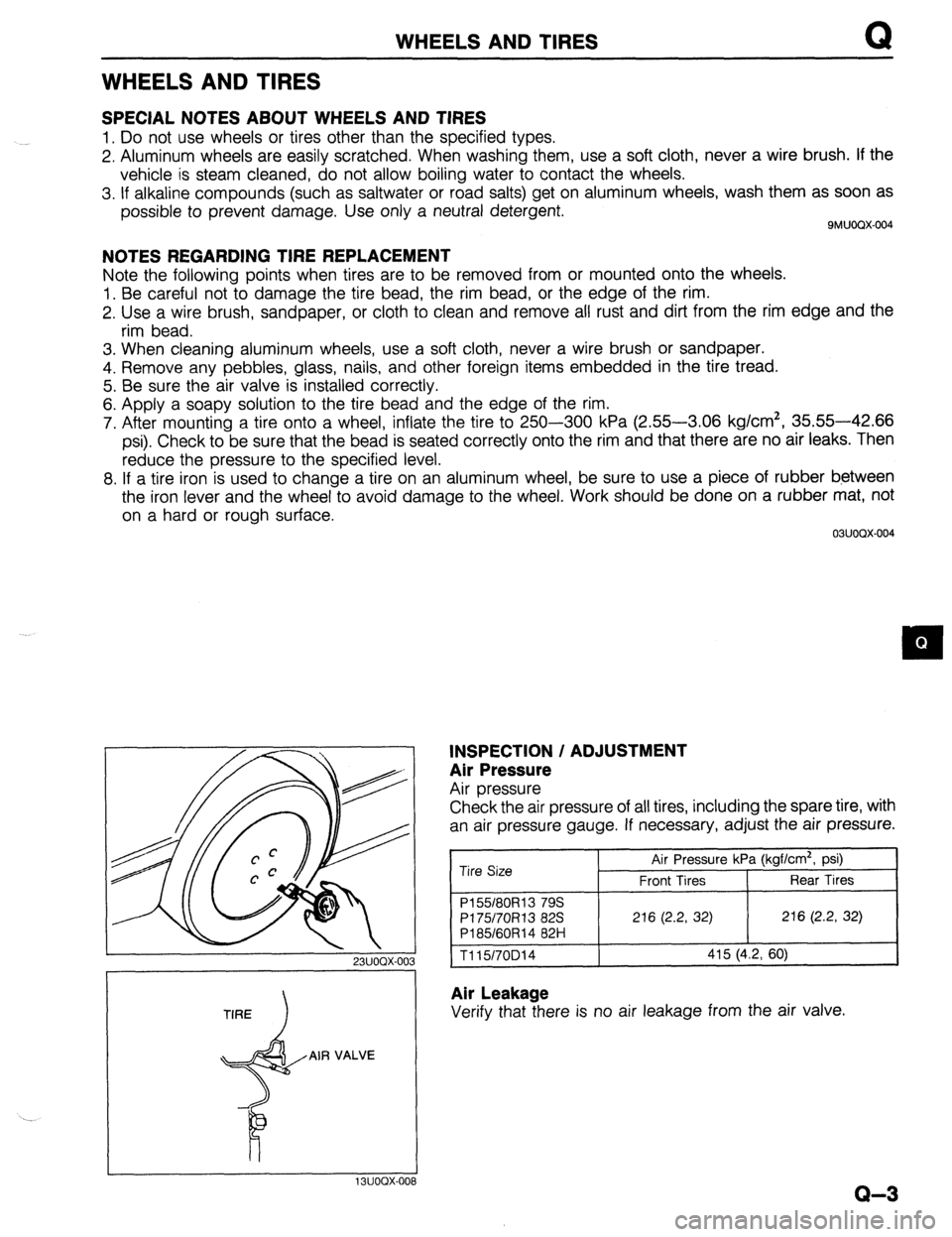

WHEELS AND TIRES

WHEELS AND TIRES

SPECIAL NOTES ABOUT WHEELS AND TIRES

1. Do not use wheels or tires other than the specified types.

2. Aluminum wheels are easily scratched. When washing them, use a soft cloth, never a wire brush. If the

vehicle is steam cleaned, do not allow boiling water to contact the wheels.

3. If alkaline compounds (such as saltwater or road salts) get on aluminum wheels, wash them as soon as

possible to prevent damage. Use only a neutral detergent.

9MUOQX-004

NOTES REGARDING TIRE REPLACEMENT

Note the following points when tires are to be removed from or mounted onto the wheels.

1. Be careful not to damage the tire bead, the rim bead, or the edge of the rim.

2. Use a wire brush, sandpaper, or cloth to clean and remove all rust and dirt from the rim edge and the

rim bead.

3. When cleaning aluminum wheels, use a soft cloth, never a wire brush or sandpaper.

4. Remove any pebbles, glass, nails, and other foreign items embedded in the tire tread.

5. Be sure the air valve is installed correctly.

6. Apply a soapy solution to the tire bead and the edge of the rim.

7. After mounting a tire onto a wheel, inflate the tire to 250-300 kPa (2.55-3.06 kg/cm2, 35.55-42.66

psi). Check to be sure that the bead is seated correctly onto the rim and that there are no air leaks. Then

reduce the pressure to the specified level.

8. If a tire iron is used to change a tire on an aluminum wheel, be sure to use a piece of rubber between

the iron lever and the wheel to avoid damage to the wheel. Work should be done on a rubber mat, not

on a hard or rough surface.

03UOQX-004

23UOOX-003

TIRE

I

AIR VALVE

INSPECTION / ADJUSTMENT

Air Pressure

Air pressure

Check the air pressure of all tires, including the spare tire, with

an air pressure gauge. If necessary, adjust the air pressure.

Tire Size Air Pressure kPa (kgf/cm2, psi)

Front Tires Rear Tires

P155180R13 79s

PI 75/70R13 82s 216 (2.2, 32) 216 (2.2, 32)

P185/60R14 82H

1115/70D14 415 (4.2, 60)

Air Leakage

Verify that there is no air leakage from the air valve.

I I 13UOOX-008

Q-3

Page 705 of 1164

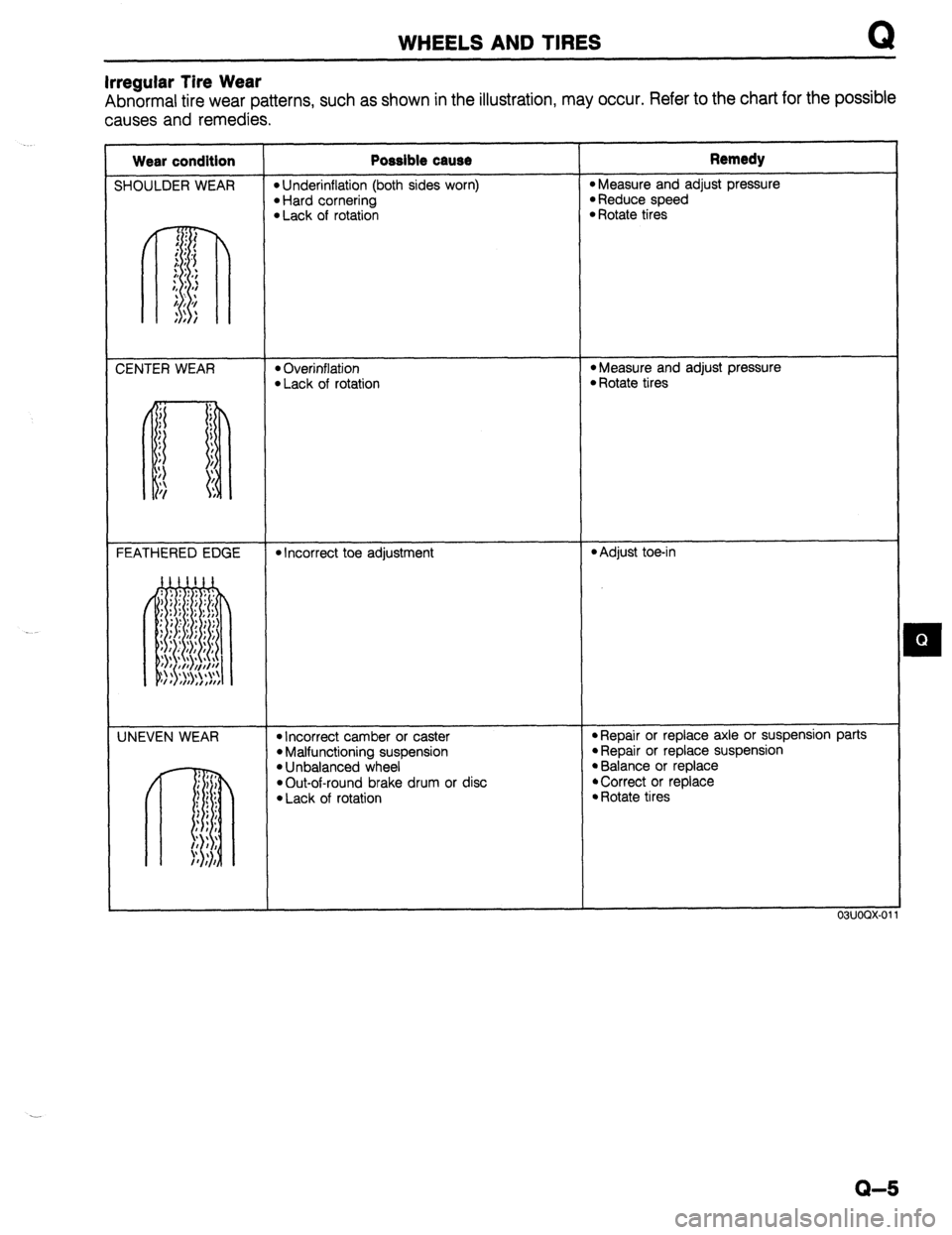

WHEELS AND TIRES

Irregular Tire Wear

Abnormal tire wear patterns, such as shown in the illustration, may occur. Refer to the chart for the possible

causes and remedies.

Wear condition

SHOULDER WEAR Possible cause l Underinflation (both sides worn) l Hard cornering l Lack of rotation Remedy

l Measure and adjust pressure l Reduce speed l Rotate tires

CENTER WEAR

l Overinflation l Lack of rotation *Measure and adjust pressure l Rotate tires

FEATHERED EDGE

l Incorrect toe adjustment l Adjust toe-in

UNEVEN WEAR

l Incorrect camber or caster l Malfunctioning suspension l Unbalanced wheel

*Out-of-round brake drum or disc

l Lack of rotation *Repair or replace axle or suspension parts

l Repair or replace suspension l Balance or replace

*Correct or replace

l Rotate tires

03UOQX-01

Q-5