wheel MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 181 of 1164

DISASSEMBLY

23UOW056

03UOB2-073

Disassembly Note

Timing belt pulley

1. Hold the flywheel or the drive plate with the SST or

equivalent.

2. Loosen the pulley lock bolt.

3. Remove the pulley lock bolt.

4. Remove the timing belt pulley.

5. Remove the pulley Woodruff key.

23UOB2-049

Flywheel (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel lock bolts.

3. Remove the flywheel.

Backing plate, drive plate, and adapter (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

Oil pan

1. Remove the oil pan mounting bolts.

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Remove the oil pan.

82-49

Page 208 of 1164

B2 ASSEMBLY

I

03UOB2-09

I

05UOBX-20 6

9

OWOBX-211 0

05uoax-21 1

03UOB2-097

Oil Pan

1. Remove all foreign material from the contact surfaces.

2. Apply silicone sealant to the shaded areas shown in the

figure.

3. install new gaskets onto the oil pump body and the rear

cover with the projections in the notches shown in the figure.

4. Apply a continuous bead of silicone sealant to the oil pan

along the inside of the bolt holes and overlap the ends.

5. Install the oil pan.

Tightening torque:

7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

End Plate

1. Install the end plate.

Tightening torque:

7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

Flywheel (MTX)

1. Remove the sealant from the flywheel bolt holes in the crank-

shaft and from the flywheel bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Set the flywheel onto the crankshaft.

3. Apply sealant to the flywheel bolts and install them.

82-76

Page 209 of 1164

--

ASSEMBLY B2

2311082-06

2311082.04

1

03UO62-09!

J 2311062-063

4. Hold the flywheel with the SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown.

Tightening torque:

96-l 03 N.m (9.6-10.5 m-kg, 71-76 ft-lb)

Clutch Disc and Clutch Cover (MTX)

1. Install the clutch disc and clutch cover using the SST or

equivalent. (Refer to Section H.)

Tightening torque:

16-26 N.m (1.8-2.7 m-kg, 13-20 ft-lb)

Drive Plate (ATX)

1. Remove the sealant from the drive plate holes in the crank-

shaft and from the drive plate lock bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Set the adapter, drive plate, and backing plate onto the

crankshaft.

3. Apply sealant to the drive plate bolts and install them.

4. Hold the drive plate with the

SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown.

Tightening torque:

96-103 N.m (9.8-10.5 m-kg, 71-76 ft-lb)

Timing Belt Pulley

1, Reverse the direction of the SST or equivalent on the

flywheel.

2311082.064

B2-77

Page 218 of 1164

I 23UOB2-044

82 ASSEMBLY

DEFLECTION CHECKING POlNT

--; 11. Measure the timing belt deflection by applying moderate

oressure (98 N, 10 kg, 22 lb) midway between the two cam-

shaft pulleys.

If the deflection is not correct, repeat from Step 7 above.

Deflection:

9.0-11.5mm (0.35-0.45 in) at 98 N (10 kg, 22 lb)

Timing Belt Cover

1. Install the lower, middle, and upper covers.

Tightening torque:

7.8-11 N.m (80- ,110 cm-kg, 69-95 in-lb)

I 13EOB2-037

82-86

Pulley lock bolt

1. Hold the flywheel (MIX) or drive plate (ATX) with the SST

and tighten the pulley lock bolt.

Tlghtening torque:

157-167 N.m (16-17 m-kg, 116-123 ft-lb)

Cankshaft pully

1. Install the crankshaft pulley.

2. Install the plate.

3. Tighten the pulley bolts.

Tightening torque:

12-17 N-m (1.25-l -75 m-kg, 9-13 ft-lb)

Water Pump Pulley

1. Install the water pump pulley.

Tightening torque:

7.8-11 N*m (80-110 cm-kg, 69-95 in-lb)

Page 283 of 1164

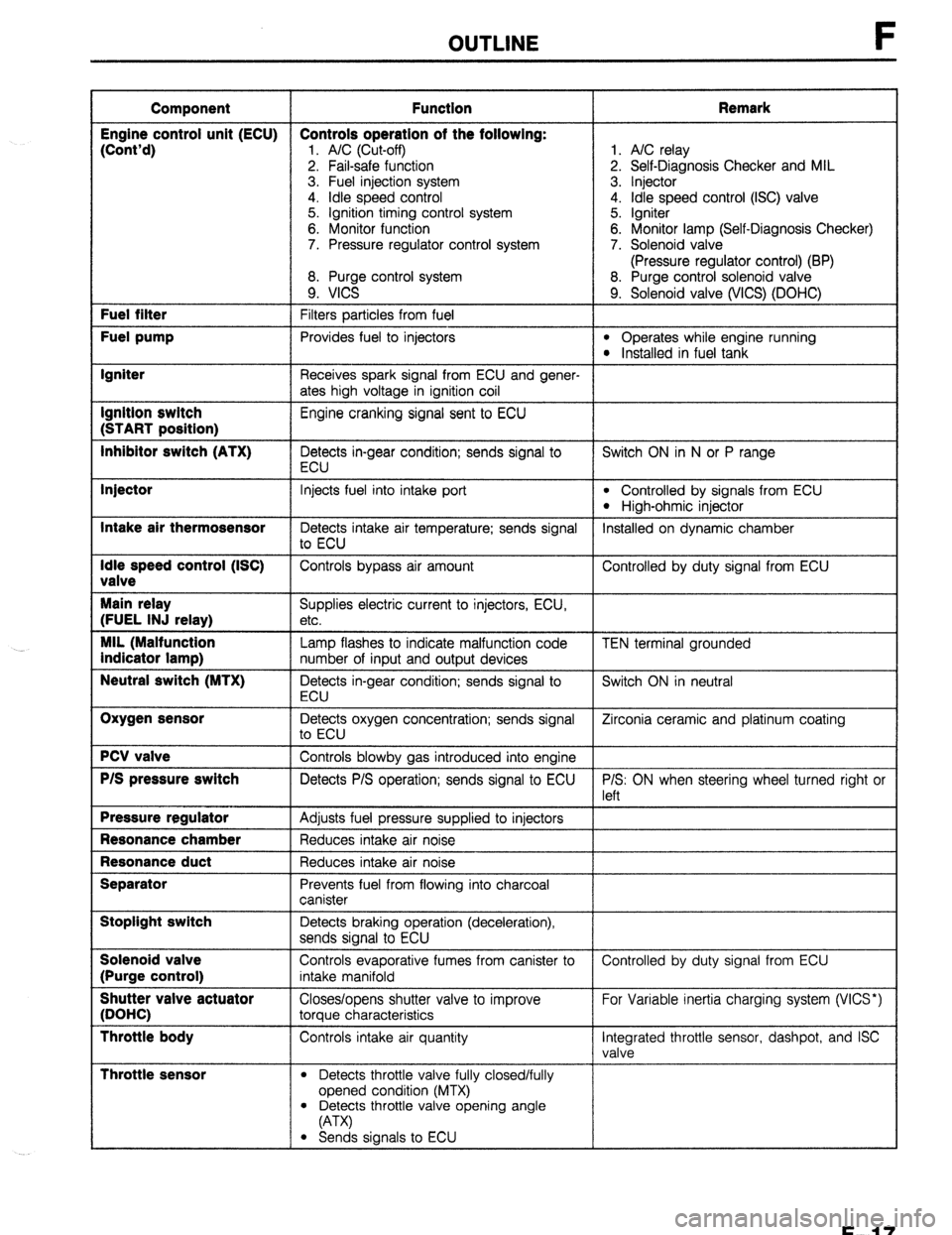

OUTLINE

Component Function Remark

Engine control unit (ECU) Controls operation of the following:

(Cont’d)

1. A/C (Cut-off) 1. A/C relay

2. Fail-safe function 2. Self-Diagnosis Checker and MIL

3. Fuel injection system 3. Injector

4. idle speed control 4. Idle speed control (ISC) valve

5. Ignition timing control system 5. Igniter

6. Monitor function 6. Monitor lamp (Self-Diagnosis Checker)

7. Pressure regulator control system 7. Solenoid valve

(Pressure regulator control) (BP)

8. Purge control system 8. Purge control solenoid valve

9. VICS 9. Solenoid valve (WCS) (DOHC) Fuel filter

Filters particles from fuel Fuel pump

Provides fuel to injectors l Operates while engine running l Installed in fuel tank Igniter

Receives spark signal from ECU and gener-

ates high voltage in ignition coil Ignition switch

Engine cranking signal sent to ECU (START position)

Inhibitor switch (ATX)

Detects in-gear condition; sends signal to Switch ON in N or P range

ECU Injector

Intake air thermosensor

Idle speed control (ISC)

valve

Main relay

(FUEL INJ relay)

MIL (Malfunction

indicator lamp)

Neutral switch (MTX)

Oxygen sensor

PCV valve

P/S pressure switch

Pressure regulator

Resonance chamber

Resonance duct

Separator

Stoplight switch

Solenoid valve

(Purge control)

Shutter valve actuator

(DOHC)

Throttle body

Throttle sensor

Injects fuel into intake port l Controlled by signals from ECU

l High-ohmic injector

Detects intake air temperature; sends signal Installed on dynamic chamber

to ECU

Controls bypass air amount Controlled by duty signal from ECU

Supplies electric current to injectors, ECU,

etc.

Lamp flashes to indicate malfunction code

number of input and output devices

Detects in-gear condition; sends signal to

ECU

Detects oxygen concentration; sends signal

to ECU

Controls blowby gas introduced into engine

Detects P/S operation; sends signal to ECU

Adjusts fuel pressure supplied to injectors

Reduces intake air noise

Reduces intake air noise

Prevents fuel from flowing into charcoal

canister

Detects braking operation (deceleration),

sends signal to ECU

Controls evaporative fumes from canister to

intake manifold

Closes/opens shutter valve to improve

torque characteristics

Controls intake air quantity

l Detects throttle valve fully closed/fully

opened condition (MTX) TEN terminal grounded

Switch ON in neutral

Zirconia ceramic and platinum coating

P/S: ON when steering wheel turned right or

left

Controlled by duty signal from ECU

For Variable inertia charging system (VICS*)

Integrated throttle sensor, dashpot, and ISC

valve

l Detects throttle valve opening angle

(A-W

l Sends signals to ECU

F-l 7

Page 439 of 1164

CONTROL SYSTEM F

23UOFX-151

WASHER,

REPLACE

9MUOF2-24

05UOFX-25

9MUOF2-24

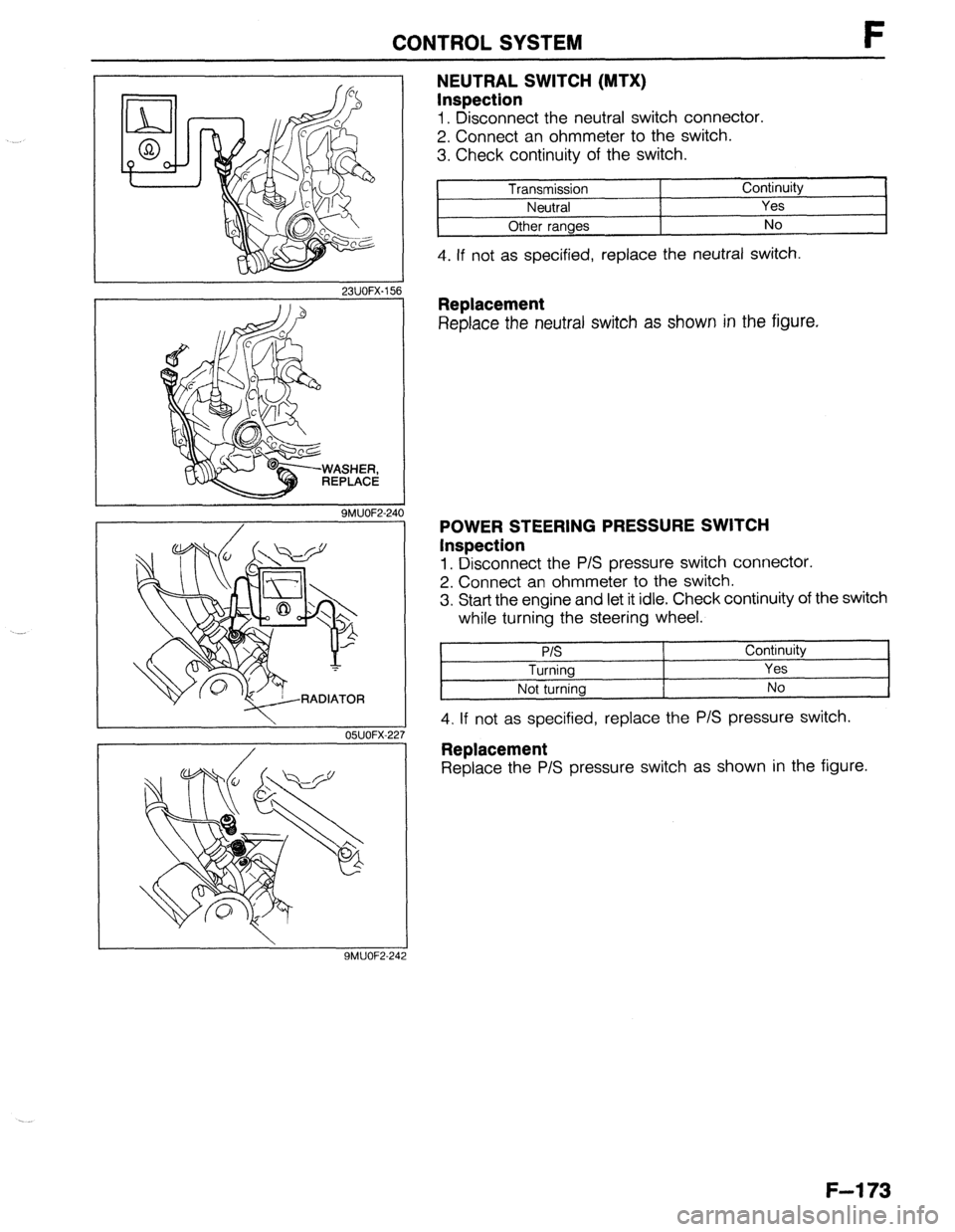

NEUTRAL SWITCH (MTX)

Inspection

1. Disconnect the neutral switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Transmission Continuity

Neutral Yes

Other ranges No

4. If not as specified, replace the neutral switch.

Replacement

Replace the neutral switch as shown in the figure.

POWER STEERING PRESSURE SWITCH

Inspection

1. Disconnect the P/S pressure switch connector.

2. Connect an ohmmeter to the switch.

3. Start the engine and let it idle. Check continuity of the switch

while turning the steering wheel.

P/S

Turning

Not turning Continuity

Yes

No

4. If not as specified, replace the P/S pressure switch.

Replacement

Replace the P/S pressure switch as shown in the figure.

F-l 73

Page 473 of 1164

H

CLUTCH

INDEX ......................................................

OUTLINE ..................................................

SPECIFICATIONS .................................... H- 3

TROUBLESHOOTING GUIDE.. .................... H- 3

CLUTCH FLUID ......................................... H- 4

PREPARATION ....................................... H- 4

REPLACEMENT ...................................... H- 4

CLUTCH PEDAL ....................................... H- 5

ADJUSTMENT ........................................ H- 5

REMOVAL / INSPECTION / INSTALLATION.. H- 6

CLUTCH MASTER CYLINDER.. ................... H- 7

PREPARATION ....................................... H- 7

REMOVAL / INSPECTION / INSTALLATION.. H- 7

AIR BLEEDING ....................................... H- 6

OVERHAUL ............................................ H-10

CLUTCH RELEASE CYLINDER ................... H-l 2

PREPARATION ....................................... H-12

REMOVAL / INSTALLATION ...................... H-l 2

AIR BLEEDING (REFER TO PAGE H-8)

OVERHAUL ............................................ H-13

CLUTCH UNIT .......................................... H-14

PREPARATION ....................................... H-14

REMOVAL I INSTALLATION.. .................... H-15

RELEASE BEARING .................................. H-17

INSPECTION .......................................... H-17

CLUTCH COVER ....................................... H-17

INSPECTION .......................................... H-17

CLUTCH DISC .......................................... H-17

INSPECTION .......................................... H-17

PILOT BEARING ....................................... H-16

INSPECTION .......................................... H-16

FLYWHEEL ............................................... H-16

INSPECTION .......................................... H-16

23UOHX-001

Page 474 of 1164

H INDEX

NDEX

CLUTCH SWITCH

SERVICE, SECTION F

23UOHX-00:

2

5. Clutch release fork

Removal / Installation . . . . . . . . . . . . . . . . . . page

H-l 5

6. Clutch cover 1. Clutch pedal

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H- 5

Removal / Inspection /

installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H- 6

2. Clutch master cylinder

Removal I Inspection I

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H- 7

Air bleeding ,............,..... I ,.,........, page H- 8

Overhaul . . . . . . . . . . . . . . . . . . . . . . . . I ,,.,........

page H-10

3. Clutch release cylinder

Removal / Installation.. . . . . . . . . . . . . . . . . page

H-l 2

Air bleeding . . . . . . . . . . . ..*..................

page H- 8

Overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page

H-l 3

4. Release bearing

Removal / installation . . . . . . . . . . . . . . . . . . page

H-l 5

Inspection ,.....,..,.,~.,..........,.,,..,,.. page H-l 7

H-2

Removal / Installation .,.......,..,..... page H-l 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H-l 7

7. Clutch disc

Removal I Installation . . . . . . . . . . . . . . . . . . page

H-l 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H-l 7

8. Pilot bearing

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H-l 8

Removal / Installation.. . . . . . . . . . . . . . . .

page H-l 5

9. Flywheel

Removal I Installation . . . . . . . . . . . . . . . . . . page

H-l 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page H-18

Page 475 of 1164

OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

-

-

Item

Clutch control Engine/Transaxle B6 SOHC BP SOHC BP DOHC

F!Wl-R GBM-R Hvdraulic

Clutch cover

Clutch disc Type

Set load Diaphragm spring

N

(kg, lb) 1 3,630 (370, 814) 1 3,826 (390, 858) 1 3,846 (392, 862)

30 17.48)

200 (7.87) 215 (8.46) Outer diameter mm (in)

Inner diameter mm (in)

Pressure plate

side mm (in)

Thickness

Flywheel side

mm lit-d

1! , I

130 (5.12) ’ ’

150 i5.91 j

3.5 (0.138) 3.8 (0.150)

3.5 (0.138)

Type Suspended

Clutch pedal

Master cylinder

Release cylinder

Clutch fluid Pedal ratio 6.55

Full stroke mm (in) 135 (5.32)

Height (With carpet)

mm (in) 196-204 (7.72-8.03)

Inner diameter mm (in) 15.87 (0.625)

Inner diameter

mm (in) 19.05 (0.750)

SAE J1703 or FMVSS116 DOT-3

23UOHX-003

TROUBLESHOOTING GUIDE Problem Possible Cause Remedy Page

Slipping

Clutch disc facing worn excessively Replace H-15, 17

Clutch disc facing surface hardened or oil on surface Repair or replace H-15

Pressure plate damaged Repair or replace H-15

Diaphragm spring damaged or weakened Replace H-15

Insufficient clutch pedal play Adjust H- 5

Clutch pedal sticking Repair or replace H- 6

Flywheel damaged Repair or replace H-15, 17 Faulty disen-

Excessive runout or damaged clutch disc Replace H-15, 17 gagement Clutch disc splines rusted or worn Remove rust or replace H-15

Oil on facing Repair or replace H-15

Diaphragm spring weakened Replace H-15

Excessive clutch pedal play Adjust H- 5

Insufficient clutch fluid

Add fluid H- 3

Leakage of clutch fluid Locate and repair or -

replace Clutch vibrates

Oil on facing Repair or replace H-15 when accelerating Torsion rubbers weakened Replace H-15

Clutch disc facing hardened or damaged Repair or replace H-15

Clutch disc facing rivets loose Replace H-15

Pressure plate damaged or excessive runout Replace H-15

Flywheel surface hardened or damaged Repair or replace H-15

Loose or worn engine mount Tighten or replace - Clutch pedal

Pedal shaft not properly lubricated Lubricate or replace H- 6 sticking

Abnormal noise

Clutch release bearing damaged Replace H-15, 17

Poor lubrication of release bearing sleeve Lubricate or replace H-15

Torsion rubbers weakened Replace H-15

Excessive crankshaft end play Repair Refer to Section E

Pilot bearing worn or damaged Replace H-15, 18

Worn pivot points of release fork Repair or replace H-15

^^. .^. I~, ^r

H-3

Page 476 of 1164

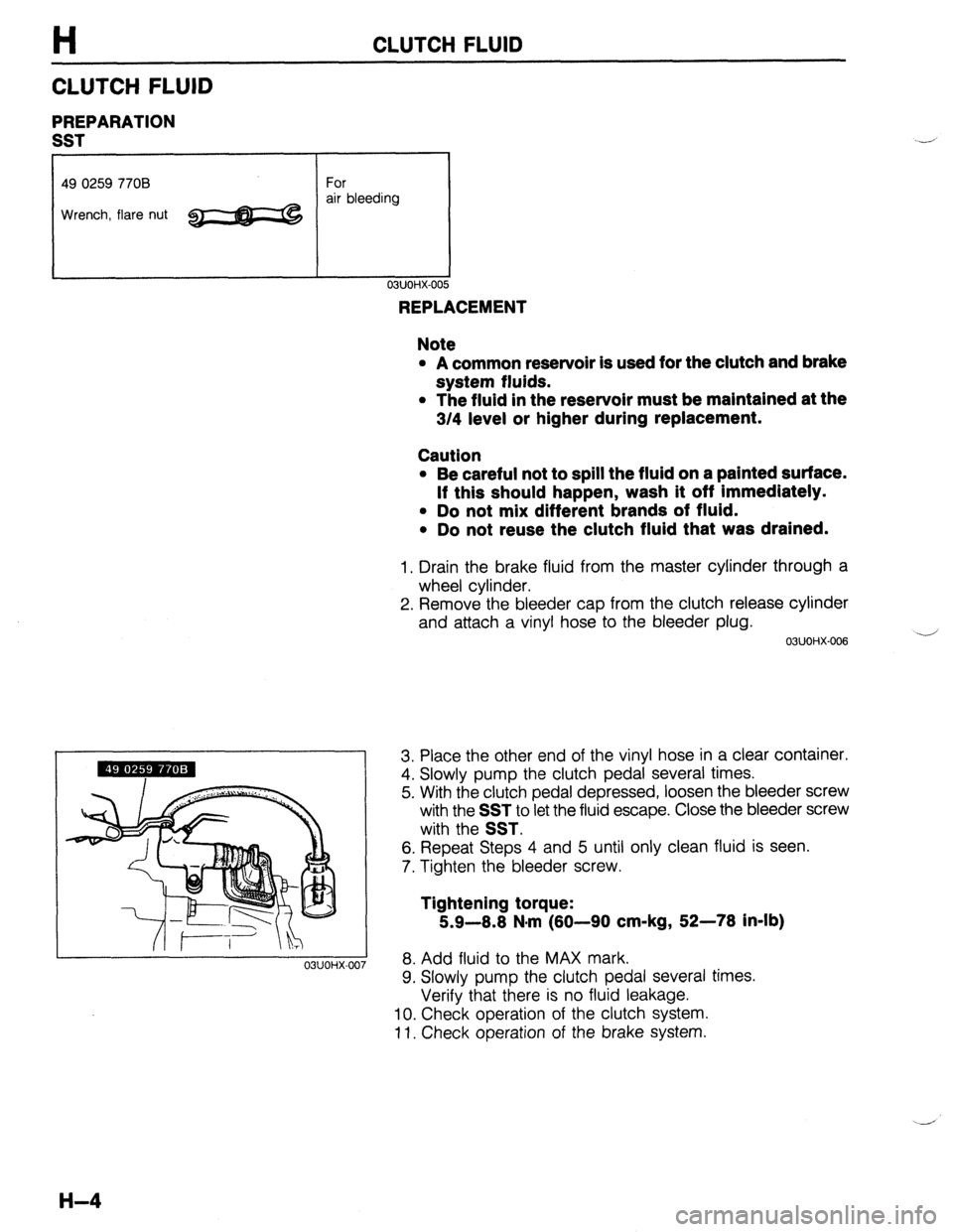

H CLUTCH FLUID

CLUTCH FLUID

PREPARATION

SST

49 0259 7708 For

Wrench, flare nut ~ air bleeding

03UOHX-007

REPLACEMENT

Note

l A common reservoir is used for the clutch and brake

system fluids.

l The fluid in the reservoir must be maintained at the

3/4 level or higher during replacement.

Caution

l Be careful not to spill the fluid on a painted surface.

If this should happen, wash it off Immediately.

l Do not mix different brands of fluid.

l Do not reuse the clutch fluid that was drained.

1. Drain the brake fluid from the master cylinder through a

wheel cylinder.

2. Remove the bleeder cap from the clutch release cylinder

and attach a vinyl hose to the bleeder plug.

03UOHX-006 -

3. Place the other end of the vinyl hose in a clear container.

4. Slowly pump the clutch pedal several times.

5. With the clutch pedal depressed, loosen the bleeder screw

with the

SST to let the fluid escape. Close the bleeder screw

with the

SST.

6. Repeat Steps 4 and 5 until only clean fluid is seen.

7. Tighten the bleeder screw.

Tightening torque:

5.9-8.8 N.m (80-90 cm-kg, 52-78 in-lb)

8. Add fluid to the MAX mark.

9. Slowly pump the clutch pedal several times.

Verify that there is no fluid leakage.

10. Check operation of the clutch system.

11. Check operation of the brake system.

H-4