battery location MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 46 of 1164

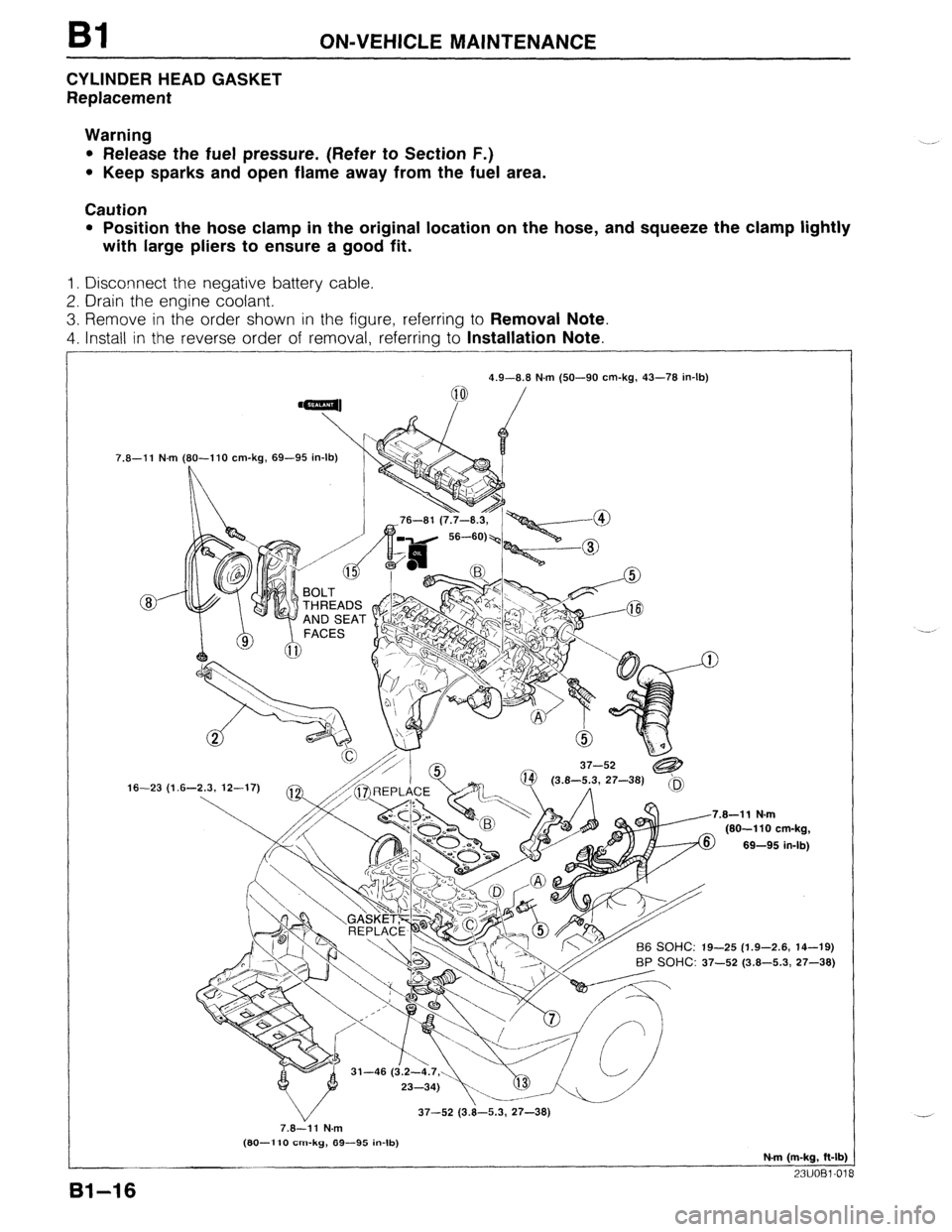

Bl ON-VEHICLE MAINTENANCE

CYLINDER HEAD GASKET

Replacement

Warning

l Release the fuel pressure. (Refer to Section F.)

l Keep sparks and open flame away from the fuel area.

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure, referring to Removal Note.

4. Install in the reverse order of removal, referring to Installation Note.

7.8-11 N.m

16-23 (1 4.9-8.8 N.m (50-90 cm-kg, 43-78 in-lb)

(80-l 10 cm-kg, 69-95 in-lb)

L

.8-11 N.m

(80-110 cm-kg,

69-95 in-lb)

-25 (1.9-2.6, 14-19)

BP SOHC: 37-52 (3.8-5.3, 27-38)

37-52 (3.8-5.3, 27-38)

7.8-11 N.m

(80-l 10 cm-kg, 89-95 in-lb)

N-m (m-kg, ft-lb)

23UOBl-01

81-16

Page 148 of 1164

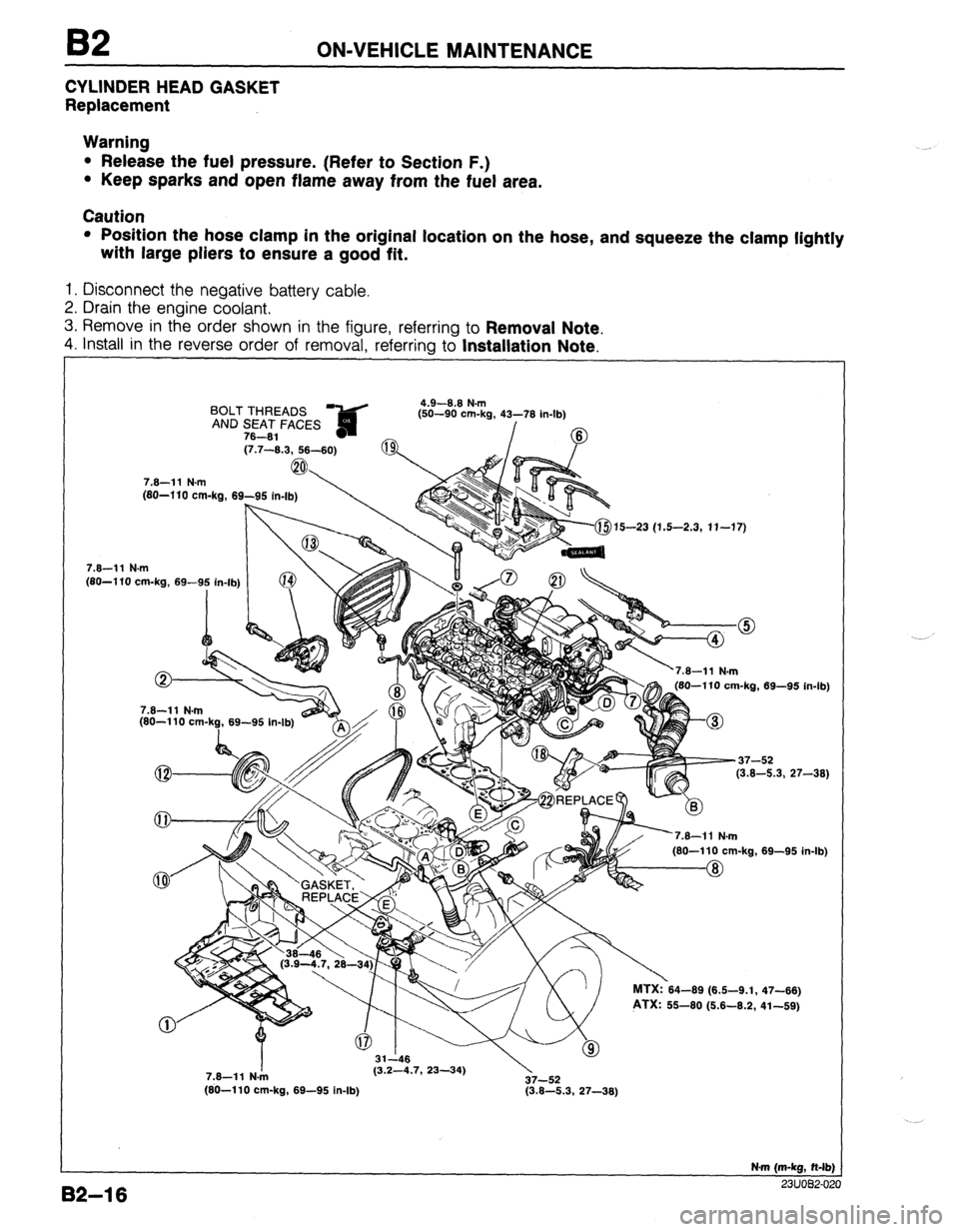

82 ON-VEHICLE MAINTENANCE

CYLINDER HEAD GASKET

Replacement

Warning

l Release the fuel pressure. (Refer to Section F.)

l Keep sparks and open flame away from the fuel area.

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. install in the reverse order of removal, referrina to Installation Note.

BOLT THREADS ?&d 4.9-8.8 N.m

fsn-an om.h 41-‘71( ir

AND SEAT FACES ,-- -- -... ..=, _” . _ ..I-lb)

78-81 - /

(7.7-8.3, 58-60)

7.8-11 N.m

(80-l 10 cm-ka, 69-95

, . . . . . . (80-l 10 cm-kg, 69-9: in-lb) (j-$15-23 (1.5-2.3, 11-17)

82-l 6

7.8-11 N.m

(80-110 cm-k?, 69-95 In-lb) 180-110 cm-ka. 69-95 in-lb

-37-52

(3.8-5.3, 27-38)

’

nl MTX:?64-69 (6.6-9.1,

PTX: 55-60 (6.6-8.2, 69-95 in. .Ib)

47-86)

41-69)

7.8-11 N./n (3.2-4.7, 23-34)

37-52

(80-110 cm-kg, 69-95 in-lb) (3.8-5.3, 27-38)

N-m (m-kg, N-lb)

^^. .^_^ __

Page 256 of 1164

E RADIATOR

RADIATOR

REMOVAL / INSTALLATION

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

7.8-11 N.m (80-110 cm-kg, 69-95 in-lb)

-...__--- --- i

771 InFu.nnc; cvyILII ..,.,..

6. Oil cooler hose (ATX)

7. Radiator bracket

8. Radiator

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page E-9

9. Cooling fan and radiator cowling assembly 1. Resonance chamber

2. Cooling fan connector

3. Radiator thermoswitch connector (BP ATX)

4. Coolant reservoir hose

5. Radiator hose i

Y’

E-8

Page 257 of 1164

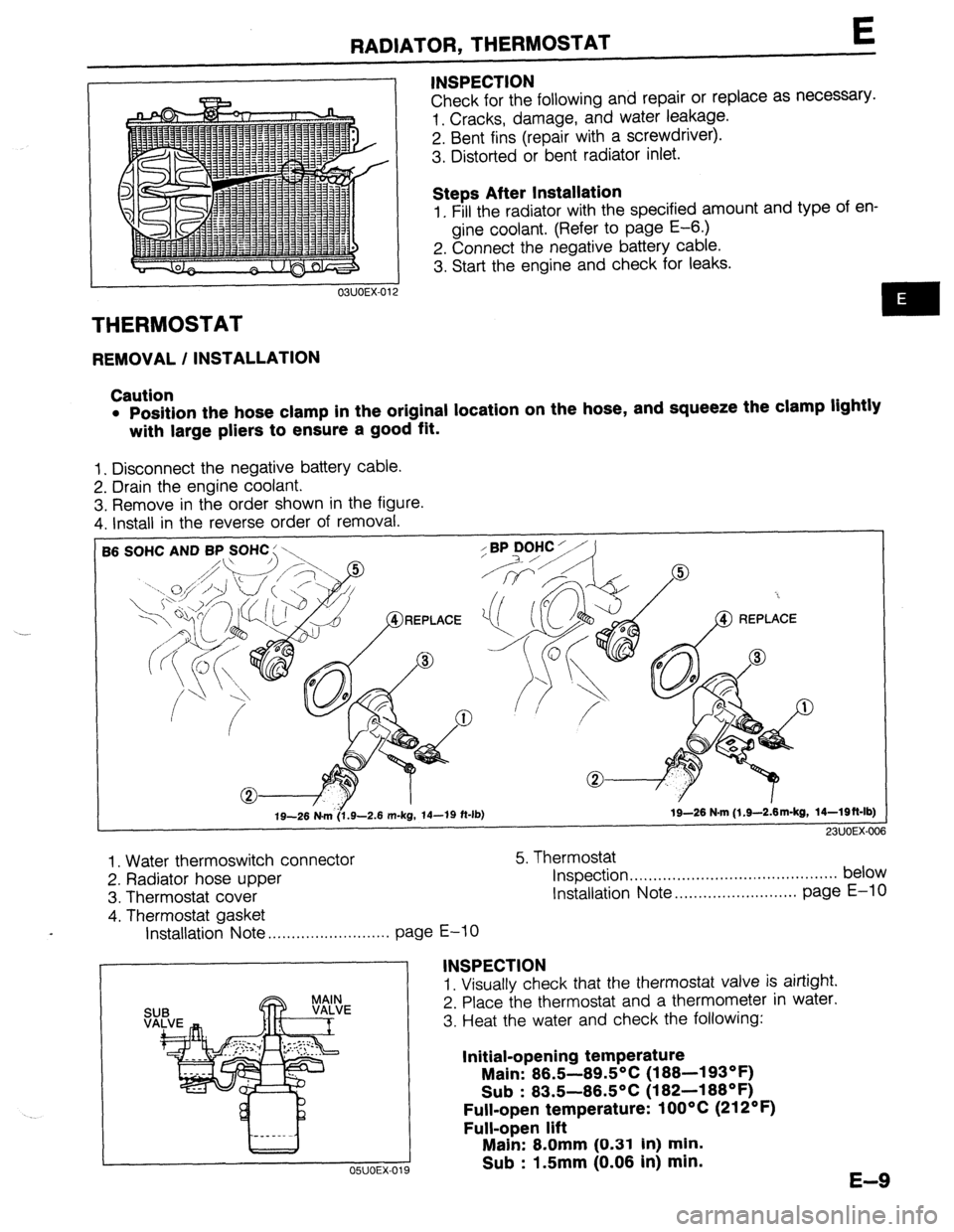

RADIATOR, THERMOSTAT t

THERMOSTAT

REMOVAL / INSTALLATION INSPECTION

Check for the following and repair or replace as necessary.

1. Cracks, damage, and water leakage.

2. Bent fins (repair with a screwdriver).

3. Distorted or bent radiator inlet.

Steps After Installation

1. Fill the radiator with the specified amount and type of en-

gine coolant. (Refer to page E-6.)

2. Connect the negative battery cable.

3. Start the engine and check for leaks.

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

SOHC AND BP SOHC : \,

19-26 N&6.9-2.6 m-kg, 14-19 ft-lb) 19-26 N-m (l.S--2&m-kg, 14-Wft-lb)

23UOEX-006

1. Water thermoswitch connector

2. Radiator hose upper

3. Thermostat cover

4. Thermostat gasket 5. Thermostat

Inspection . . . . .., .., ,.. ,.. . . . ,.. . . . . . . . . . . . . . . . . . . . . . . below

Installation Note ..,....................... page E-10

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . .

page E-10

INSPECTION

1. Visually check that the thermostat valve is airtight.

2. Place the thermostat and a thermometer in water.

3. Heat the water and check the following:

Initial-opening temperature

Main: 86.5-89.5°C (188-193OF)

Sub : 83.5-86.5OC (182-188OF)

Full-open temperature: 1 OOOC (212OF)

Full-open lift

OSUOEX-019

Main: 8.0mm (0.31 In) min.

Sub : 1.5mm (0.06 in) min.

E-9

Page 263 of 1164

FAN MOTOR E

I-

i.- 5. Connect the battery, an ammeter, and switch to the fan mo-

tor connectors for high-speed inspection.

6. Verify that the fan motor operates smoothly at the standard

current or less with the switch ON.

Current (A): 13.3 + 10% MAX

7. If the fan motor is faulty, replace it.

---“-. --

REPLACEMENT

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

7.8-11 N.m

7.8-11 N.m

(80-110 cm-kg,

1. Resonance chamber

4. Radiator cowling

2. Cooling fan connector

5.

Cooling fan

3. Radiator hose upper

6. Fan motor

E-l 5

Page 351 of 1164

SELF-DIAGNOSIS FUNCTION F

:ODE LOCATION OF

NO.

MALFUNCTION

26 Solenoid valve ON

(purge control)

OFF OUTPUT SIGNAL PATTERN nnnnnll 1 SELF4IAGNOSIS

Open or

short circuit FAIL-SAFE

-

ON

34

ISC valve

OFF u 1 llllJlll r -

41 Solenoid valve ON

(WCS)

[DOHC]

OFF -

Pulse ON No input signal Shifting performed in

55*

i nnnnn

from pulse accordance with signals

generator

OFF generator from vehicle speed

sensor

Open or Solenoid valve(s)

60* 1-2 shift ON

short circuit

solenoid valve

uuuuul performs the shifting with

as little interference as

OFF

possible with driving

performance

2-3 shift ON Lockup not provided

61*

solenoid valve

OFF

UUUI n

3-4 shift ON

62’

solenoid valve

OFF u u u u inn

1.6 sec. 4 sec.

63* Lockup solenoid

valve

u u&m I- Shifting performed

normally

Lockup not provided

0.4 sec.

0.4 sec.

*If the marked code numbers appeor, refer to Section K

Note

l The HOLD indicator does not flash the service code numbers.

l If there is more than one failure present, the code numbers will be indicated in numerical or-

der, lowest number first.

* After repairing a problem, turn the ignition switch OFF and disconnect the negative battery

cable at least 20 seconds to erase the service code numbers from the engine control unit (ECU)

memory.

23UOFX-051

F-85

Page 962 of 1164

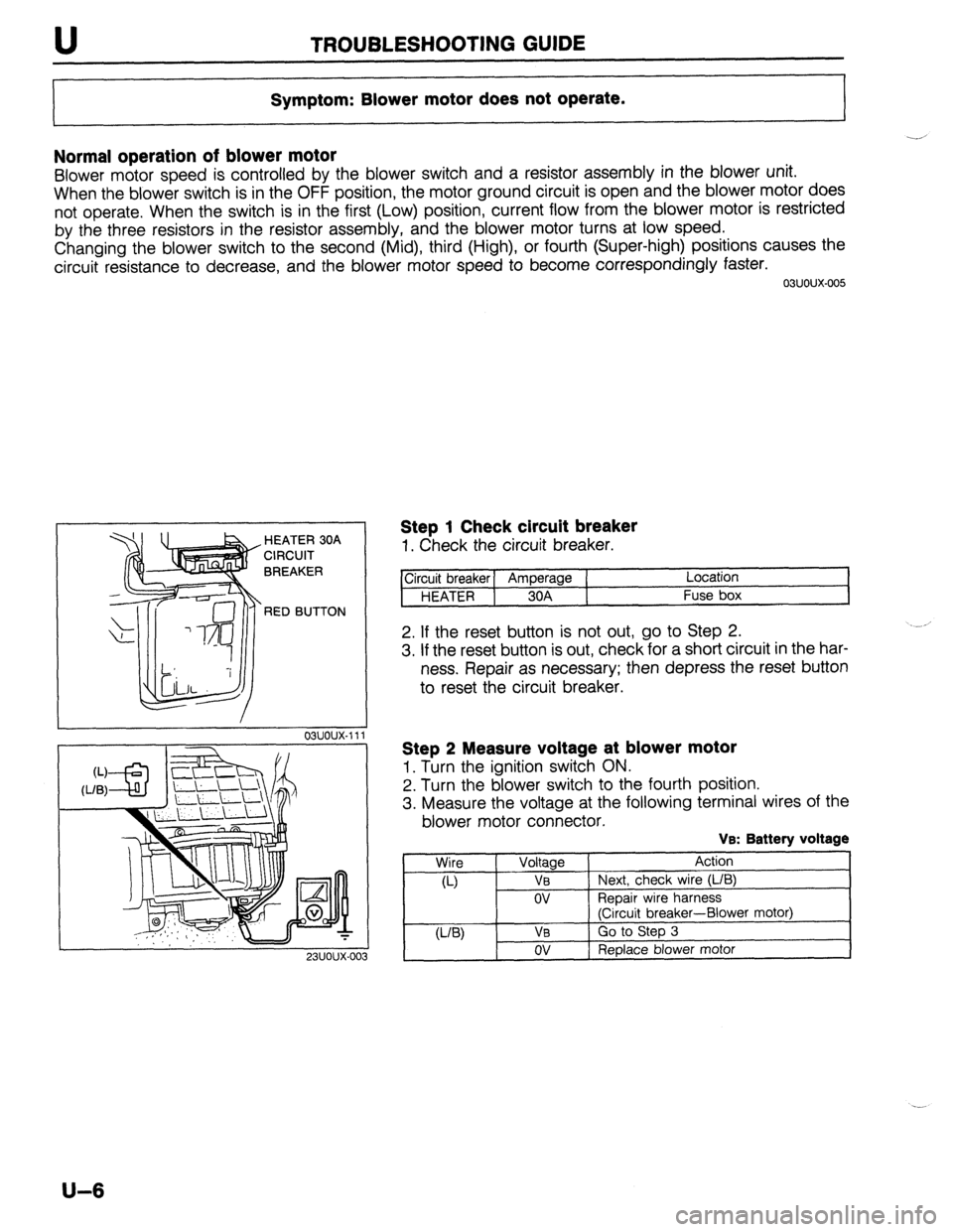

U TROUBLESHOOTING GUIDE

Symptom: Blower motor does not operate.

Normal operation of blower motor

Blower motor speed is controlled by the blower switch and a resistor assembly in the blower unit.

When the blower switch is in the OFF position, the motor ground circuit is open and the blower motor does

not operate. When the switch is in the first (Low) position, current flow from the blower motor is restricted

by the three resistors in the resistor assembly, and the blower motor turns at low speed.

Changing the blower switch to the second (Mid), third (High), or fourth (Super-high) positions causes the

circuit resistance to decrease, and the blower motor speed to become correspondingly faster.

03uoux-005

. HEATER 30A

CIRCUIT

BREAKER

RED BUTTON

23UOUX-01

Step 1 Check circuit breaker

1. Check the circuit breaker.

ircuit breaker] Amperage ( Location

HEATER 1 30A Fuse box

2. If the reset button is not out, go to Step 2.

3. If the reset button is out, check for a short circuit in the har-

ness. Repair as necessary; then depress the reset button

to reset the circuit breaker.

Step 2 Measure voltage at blower motor

1. Turn the ignition switch ON.

2. Turn the blower switch to the fourth position.

3. Measure the voltage at the following terminal wires of the

blower motor connector.

VB: Battery voltage

Wire

Voltage Action

a-) VB Next, check wire (L/B)

ov ReDair wire harness

(Ciicuit breaker-Blower motor)

U-W VB Go to Step 3

ov Replace blower motor

U-6

Page 968 of 1164

TROUBLESHOOTING GUIDE

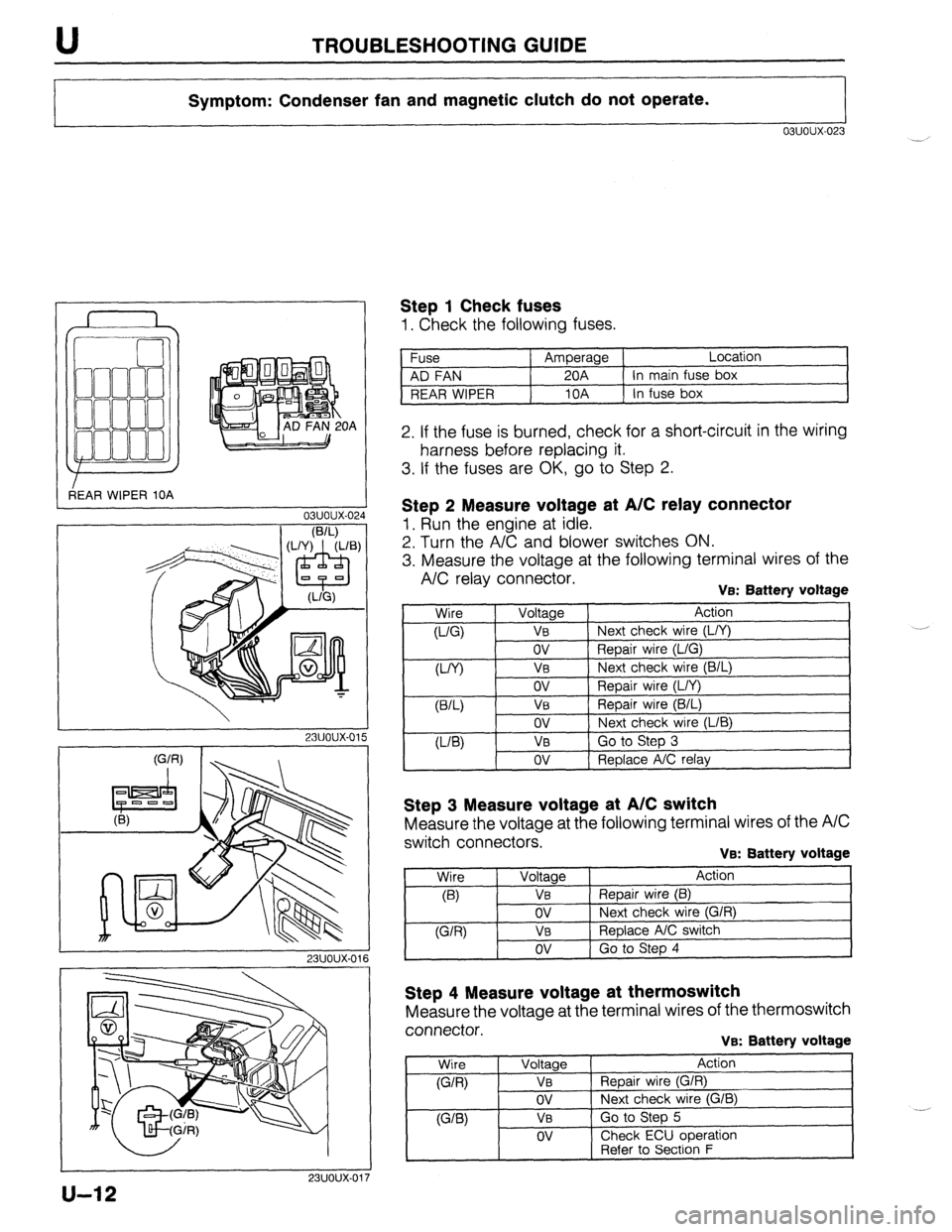

Symptom: Condenser fan and magnetic clutch do not operate.

03uoux-023

r

3EAR WIPER 10A OA

L

03uoux-02.

I

1 Step 1 Check fuses

1. Check the following fuses.

Fuse Amperage Location

AD FAN 20A In main fuse box

REAR WIPER 10A In fuse box

2. If the fuse is burned, check for a short-circuit in the wiring

harness before replacing it.

3. If the fuses are OK, go to Step 2.

I

23uoux-011

Step 2 Measure voltage at A/C relay connector

1. Run the engine at idle.

2. Turn the A/C and blower switches ON.

3. Measure the voltage at the following terminal wires of the

A/C relay connector. VEX Battery voltage

,

Wire

0-Q

W) Voltage Action

VB Next check wire (L/Y)

ov Repair wire (L/G)

V0 Next check wire (B/L)

ov

VB

ov

VB

ov Repair wire (L/Y)

Repair wire (B/L)

Next check wire (LIB)

Go to Step 3

Replace A/C relay

Step 3 Measure voltage at A/C switch

Measure the voltage at the following terminal wires of the A/C

switch connectors.

VB: Battery voltage

Step 4 Measure voltage at thermoswitch

Measure the voltage at the terminal wires of the thermoswitch

connector.

VB: Battery voltage

Wire

(G/R)

WB)

Voltage

VB

ov

VB

OV

Action

Repair wire (G/R)

Next check wire (G/B)

Go to Step 5

Check ECU ooeration

1 -. [ Refer to Secti6n F

u-12

Page 1058 of 1164

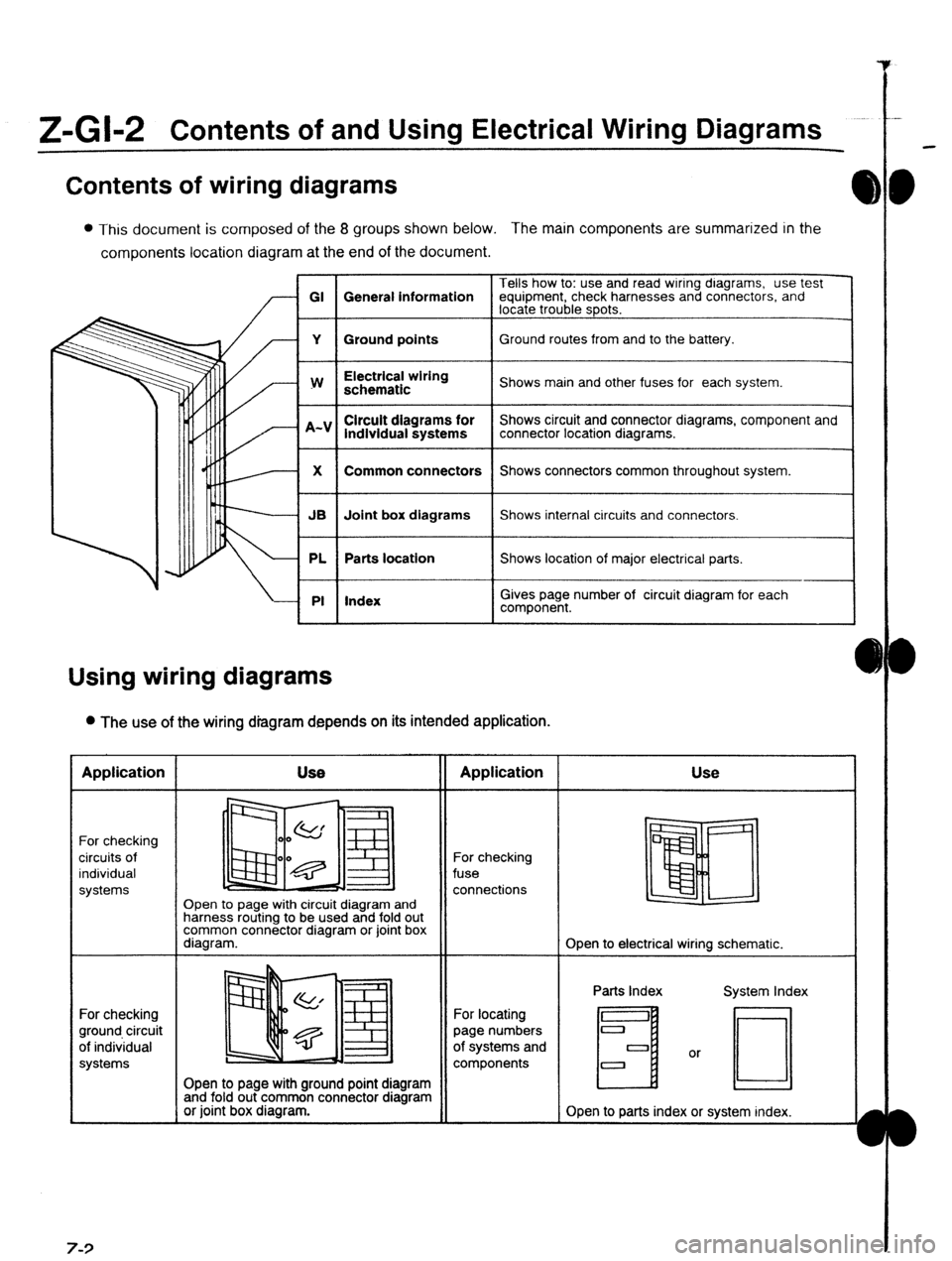

Z-Gl-2 Contents of and Using Electrical Wiring Diagrams

Contents of wiring diagrams

l This document is composed of the 8 groups shown below. The main components are summarized in the

components location diagram at the end of the document.

Tells how to: use and read wiring dragrams, use test

GI General information equipment, check harnesses and connectors, and

locate trouble spots.

Y Ground points Ground routes from and to the battery.

I

w

I Electrical wiring

schematic

I Shows main and other fuses for each system.

lndlvidual systems

I Shows circuit and connector diagrams, component and

connector location diagrams.

1

X

I Common connectors

I Shows connectors common throughout system.

I

JB Joint box diagrams Shows internal circuits and connectors.

PL Parts location Shows location of major electrical parts.

PI Index

I

I

Gives page number of circuit diagram for each

component.

Using wiring diagrams

l The use of the wiring diagram depends on its intended application. Application

For checking

circuits of

individual

systems

For checking

ground circuit

of individual

systems 7-3 Use

II Application

Open to page with circuit diagram and

harness routing to be used and fold out

common connector diagram or joint box

diagram. For checking

fuse

connections Use

Open to electrical wiring schematic.

Open to page with ground point diagram

and fold out common connector diagram

or joint box diagram. For locating

page numbers

of systems and

components Parts Index

H

Open to parts index or system index.

Page 1072 of 1164

II-GM6 Troubleshooting

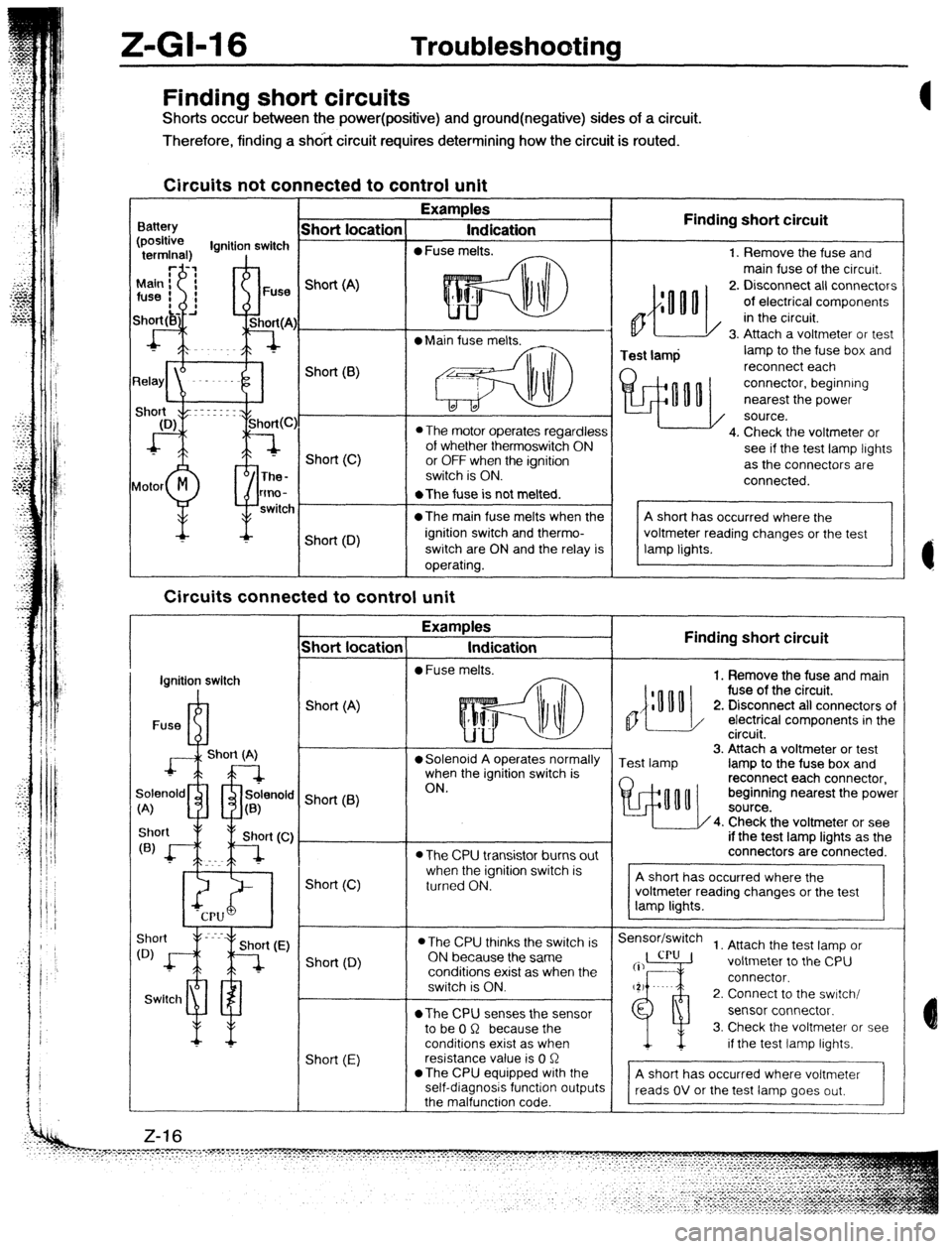

Finding short circuits

Shorts occur between the power(positive) and ground(negative) sides of a circuit.

Therefore, finding a shdit circuit requires determining how the circuit is routed.

Circuits not connected to control unit

Examples

Indication

0 Fuse melts. Finding short circuit

0

Test lamp 1. Remove the fuse and

main fuse of the circurt.

2. Disconnect all connectors

of electrical components

in the circuit.

3. Attach a voltmeter or test

lamp to the fuse box and

reconnect each

connector, beginning

nearest the power

source.

4. Check the voltmeter or

see if the test lamp lights

as the connectors are

connected. Finding short circuit

,,{:““o

1. Remove the fuse and main

fuse of the circuit.

2. Disconnect all connectors of

/ electrical components in the

circuit.

Test lamp 3. Attach a voltmeter or test

lamp to the fuse box and

reconnect each connector,

beginning nearest the power

4. Check the voltmeter or see

if the test lamp lights as the

connectors are connected.

Sensor/switch

1. Attach the test lamp or

voltmeter to the CPU

connector.

2. Connect to the swrtch/

sensor connector.

3. Check the voltmeter or see

if the test lamp lights.

A short has occurred where voltmeter

reads OV or the test lamp goes out,

- Short location

Battery Short (A)

l Main fuse melts.

L* Short(B)

0 The motor operates regardless

of whether thermoswitch ON

or OFF when the ignition

switch is ON. Short (C)

lotor

M

P The-

tmo-

switc *The fuse is not melted.

@The main fuse melts when the

ignition switch and thermo-

switch are ON and the relay is

operating. Short (D)

Circuits connected to control unit

-T Examples

Indication

l Fuse melts.

- Short locatior

I

ignition switch

I

Fuse R-l Short (A)

J+L--l

Short (A) l Solenoid A operates normally

when the ignition switch is

ON.

9enold m rfr solenok

;<

A) u a(B) ’ Short (6)

l The CPU transistor burns out

when the ignition switch is

turned ON. Short (C)

l The CPU thinks the switch is

ON because the same

conditions exist as when the

switch is ON.

*The CPU senses the sensor

to be 0 R because the

conditions exist as when

resistance value is 0 R

*The CPU equipped with the

self-diagnosis function output

the malfunctron code. Short (0)

Swltcl1 ml

Short (E) Z-16