differential MAZDA PROTEGE 1992 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 591 of 1164

DIFFERENTIAL J2

DIFFERENTIAL

PREPARATION

SST

49 GO17 1AO

Bearing remover

set

49 8092 375

Attachment J

(Part of

49

GO17 1AO)

49 GO30 338

Attachment E For

removal of

bearing

For

removal of side

bearing inner

race

For

installation of side

bearing inner

race 49 F401 366A

Plate

(Part of

49 GO17 1AO) For

removal of side

bearing inner

race

49 0839 425C

Puller set,

bearing For

removal of side

bearing inner

race I

23UOJ2-01

J2-43

Page 592 of 1164

J2 DIFFERENTIAL

DISASSEMBLY / INSPECTION / ASSEMBLY

Caution

l Do not remove inner race if not necessary.

1. Before disassembly, inspect the backlash of side gear and pinion gear, referring to Pre-inspection.

2. Disassemble in the order shown in the figure, referring to Disassembly Note.

3. inspect all parts and repair or replace as necessary.

4. Assemble in the reverse order of disassembly, referring to

Assembly Note.

5 Mwn~lre the backlash after assembly, referring to Backlash of Side Gear and Pinion Gear.

1. Roll pin

2. Pinion shaft

3. Pinion gear

Inspection for wear and cracks

Pre-inspection .,...,........,............ page J2-44

Inspection of backlash. . . . ,.,.,..,,. page J2-45

4. Thrust washer

5. Side gear

Inspect for wear and cracks

Pre-inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-44

Inspection of backlash . . . . . . . . . . . . . . page J2-45

6. Thrust washer

1

J ______ Ji

7. Side bearing inner race

Inspect for wear and rough rotation

Disassembly Note . . . . . . . . . . . . . . . . . . . . . page J2-45

Assembly Note, .., ,.,..,,,,....,...,..,. page J2-45

8. Speedometer drive gear

9. Side bearing inner race

Inspect for wear and rough rotation

Disassembly Note .., ..,...., . ,. . . . . . . . page J2-45

Assembly

Note.. . . . . . . ,.. . . . ..,.. . . . . . . . page J2-45

10. Ring gear and gear case assembly

Inspect ring gear for wear or damage

Pre-inspection

Backlash of side gear and pinion gear

Measure the backlash by the following procedure.

1. Install the left and right driveshafts in the differential as-

sembly.

2. Support the driveshafts on V-blocks as shown in the figure.

3. Measure the backlash of both pinion gears.

Backlash: O-O. 1 mm (O-0.004 in)

J2-44

Page 593 of 1164

DIFFERENTIAL

03UOJ2-10

03UOJ2-10

03UOJ2-10

03UOJ2-

03UOJ2-

Disassembly Note

Side bearing inner race (side opposite ring gear)

Caution

l Hold the gear case with one hand so that it does

not fall.

1. Remove the bearing inner race with the SST.

Side bearing inner race (ring gear side)

Caution

l Use pads in the vise to prevent damaging the

differential assembly.

1. Remove the bearing inner race with the SST.

Assembly Note

Side bearing inner race (Side opposite rlng gear)

1. install the speedometer drive gear.

2. Install the new side bearing inner race with the

SST.

Side bearing inner race (ring gear side)

1. Install the new bearing inner race with the SST.

Backlash of Side Gear and Pinion Gear

Measure the backlash by the following procedure.

1. Install the left and right driveshafts in the differential as-

sembly.

2. Support the driveshafts on V-blocks as shown in the figure.

3. Measure the backlash of both pinion gears.

Backlash: O-O.1 mm (O-0.004 in)

4. If not as specified, replace the differential assembly.

--I

107

52-45

Page 623 of 1164

DRIVE SHAFT M

I

I 03UOMX-053

DIFFERENTIAL SIDE WHEEL SIDE

23UOMX-03 1

03UOMX.05

23UOMX :-032

23UOMX

Caution

l Do not remove the wheel side boot if not necessary.

12. Pry up the locking clips of the wheel-side boot bands with

a screwdriver.

13. Remove both bands with pliers. Remove the boot.

Assembly procedure

Caution

l The wheel-side and transaxle-side boots are

different.

mm (in)

I c3

80.8

I 89.0 85.2

(3.18) (3.50)

I I 94.1

(3.35) (3.70)

1. Wrap the splines of the transaxle-side shaft, and install the

wheel-side boot.

Caution

l Always use new bands.

l The bands should be mounted in the direction op-

posite the forward revolving direction of the drive

shaft.

2. Install the dynamic damper and new band.

3. Fold the band back by pulling on the end of it with pliers.

4. Lock the end of the band by bending the locking clip.

5. Install the wheel-side boot.

Caution

l Do not damage the bearing.

6. Align the marks and install the tripod joint with a bar and

a hammer.

7. Install the new snap ring with snap-ring pliers.

M-27

Page 1022 of 1164

TECHNICAL DATA

D. LUBRICATION SYSTEM

Item I I bhricatinn mothnd

Engine

B6 SOHC BP SOHC

Force-fed BP DOHC 1

Requlated pressure kPa (kg/Cm”, p

Inner rotor tooth tip to outer rotor Standard

I-‘---- -.----,

clearance mm (in) Maximum 0.20 (0.0078)

Outer rotor to body clearance mm (in) Standard 0.09-0.18 (0.0035-0.0071)

Maximum 0.22 (0.0087)

Side clearance mm (in) Standard 0.03-0.11 (O.pniq n nnn=’

Maximum n4rl ‘-

“” I r-“.““+..I,

I “. I ‘t (U.0055)

I

1

Oil filter

_ Type

Relief pressure differential

Engine oil

I

Capacity

liters (US qt, Imp qt)

Grade

I Viscosity Full-flow, paper element

kPa (kg/cm’, psi) 1 78-l 18 (0.8-I .2, 1 l-l 7) Tntal /An, nnr*inol 3.4 (3.6, 3.0) 1 4.0 (4.2, 3.5)

3.0 (3.2, 2.6) 1 3.6 (3.8, 3.2)

VII 111Lb1 0.17 (0.18, 0.15)

API Service SG Energy Conserving II (ECQ

1

SA!f InW-Xl 1~ Above -25% (-13OF _ .-.. --

I

I

number

1 Below O’C (32OF) SAE 5W-30

1

E. COOLING SYSTEM

Cooling method EnginelTransaxle

MTX ] ATX 1 MTXl

Water-cooled, forced circulation

J B6 SOHC BP SOHC BP DOHC

, ATX 1 MTX ) ATX

LThermostat

Type Opening temperature

Full-open temperature

Full-open lift

Radiator

_ Type

Cap valve opening pressure

Cooling circuit checking pressure Wax, two-stage

“C (OF) Sub: 83.5-86.5 (182--188), Main: 86.5-89.5 (188-193)

OC (OF) 100 (212)

mm (in) Sub: 1.5 (0.06) min., Main: 8.0 (0.31) min.

Corrugated fin

kPa (kg/cm2, psi) 74-103 (0.75-1.05, 11-15)

kPa (kg/cm’, psi) 103 (1.05, 15)

~..

Cooling fan

Type Electric .-

Number of blades 4

_.---- _I___-

Outer diameter mm (in) 320 (12.6)

--_ ~~-

Capacity w-v 80-12 - 160-12 80-l 2 160-12

6.6 Hi : 13.3

6.6 Hi : 13.3

Current A

Low : 8.8 Low : 8.8

_------ ._____

Water thermoswitch

“c (OF) 1

OFF-ON 97 (207)

I--.

Radiator thermoswitch

__-I____-

OFF+ON “C (OF) 1 1105 (221)( - (105 (221)

TD-8

Page 1026 of 1164

TD TECHNICAL DATA

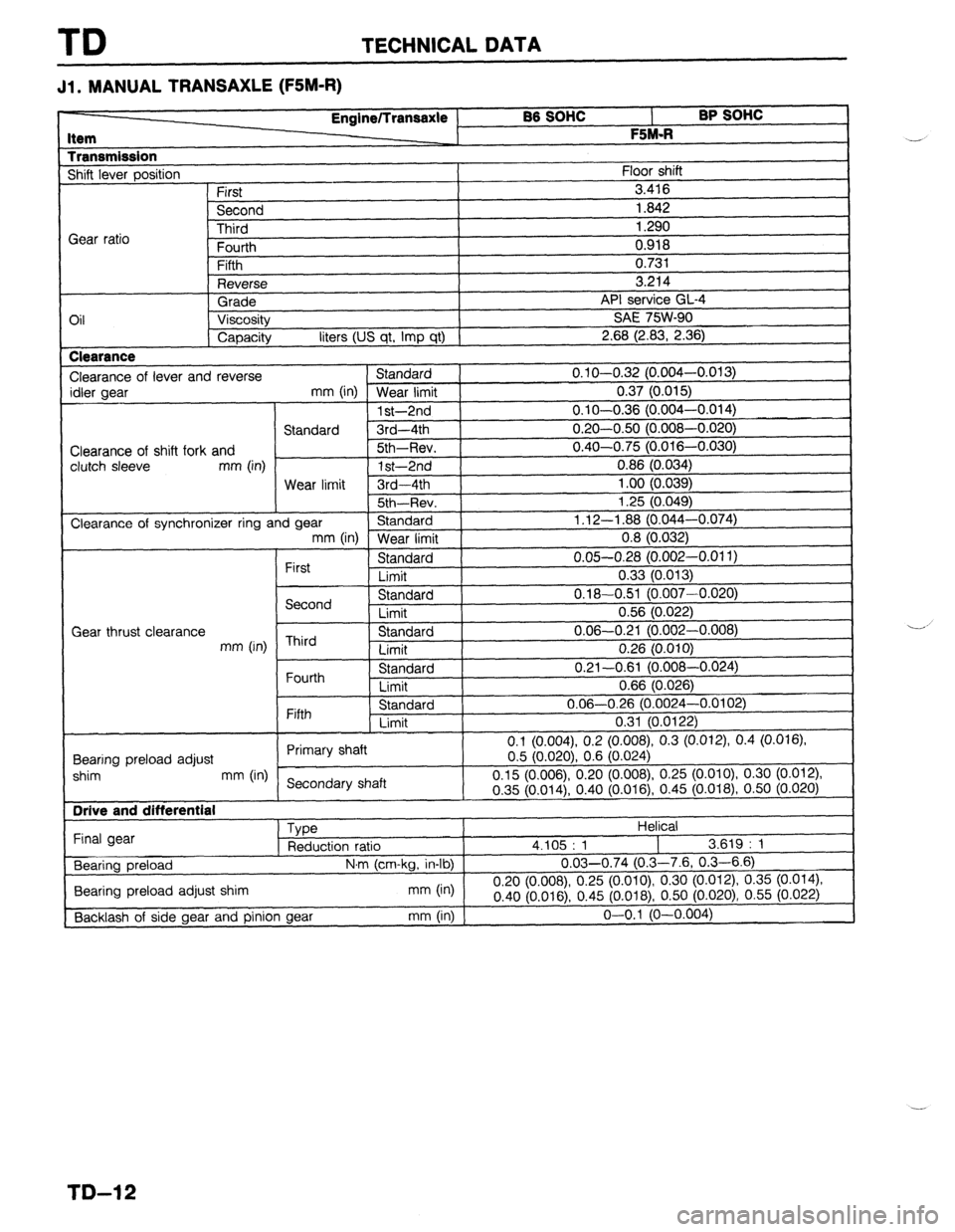

Jl l MANUAL TRANSAXLE (FSM-R)

BB SOHC

l- BP SOHC I

F %M.R

I

1

Floor shift Item

Transmission Shift lever oosition Engine/lransaxle

First

Second

-I?-:-.4

I 0.918

I

n ‘31

I Gear ratio lllll”

Fourth

Fifth

Reverse

Grade

Oil Viscosity

Capacity liters (US qt, Imp qt) Clearance

Clearance of lever and reverse Standard

idler gear

mm (in) Wear limit

1 st-2nd

Standard 3rd-4th

Clearance of shift fork and Sth-Rev.

clutch sleeve mm (in)

1 st-2nd

Wear limit 3rd-4th

I 5th~Rev. j

Clearance of synchronizer ring and gear Standard ) mm (in)

Wear limit 3.416

1.842

1.290

ce GL-4

SW-90

I

V.I.

3.214

API servil

SAE 7t

2.68 (2.83, 2.36)

0.1 O-O.32 (0.004-o.

0.37 (0.015)

0.1 O-O.36 (0.004-o.

0.20-0.50 (0.008-O.

0.40-0.75 (0.016-O.

0.86 (0.034)

1 .oo (0.039)

i 3c /n n/la

I .L” \“.“T”,

1.12-l .88 (0,044-O.

0.8 (0.032)

0.05-0.28 (0.002-0.011)

0.33 (0.013)

0.18-0.51 (0.007-0.020)

0.56 (0.022)

0.06-0.21 (0.002-0.008)

0.26 (0.010)

0.21-0.61 (0.008-0.024)

0.66 (0.026)

0.06-0.26 (0.0024-0.0102)

0.31 (0.0122)

(0.008), 0.3 (0.012), 0.4 (0.016) Fifth Standard

Limit

0.1 (0.004) 0.2

Rnnrinn nrdnari adjust Primary shaft

0.5 (0.020) 0.6

I shim mm (in)

Secondary shaft 0.15 (0.006) 0.20 (0.008) 0.25 (0.

~-~?r;liln

I Final gear

Bearing preload

I Bearing preload adjust shim

[Backlash of side gear and pinion gear

I

I

030)

,074)

I

First Standard

Limit

Second Standard

Limit

Gear thrust clearance

mm (in) Third Standard

Limit

Fourth Standard

Limit

(0.024j

OlO), 0.30 (0.012)

I

I V.“” \“‘V I .,, “.~lV \Y... VW,? “I ,-

\... 018j, 0.50 (0.020)

Helical

4.105 : 1

I 3.619 : 1

N,m (cm-kg, in-lb) 0.03-0.74 (0.3-7.6, 0.3-6.6)

n qn

mm (in)

“.L” ,“.“U mnr78), 0.25 (o.oio), 0.30 (0.012) 0.35

(0.014)

0.40 (0.01 6) 0.45 (0.018),

0.50 (0.020) 0.55 (0.022)

-~ -1

mm (in) j o-o.1 (O-0.004 --

--’

TD-12

Page 1027 of 1164

TECHNICAL DATA TD

J2. MANUAL TRANSAXLE (G5M-R)

tern EnginelTransaxle BP DoHc

-__-

G BM-R

hansmission

shift lever position

First

Second

Third

;ear ratio

Fnt rrth Floor shift

3.307

1.833

1.310

1.030

3il Reverse

Viscosity

Capacity All-season

Above -18OC (OOF)

liters (US qt, imp qt) a. IOD

ATF Dexron@II, M2C33-F or SAE 75W-80

API service GL-4 SAE 8OW-90

3.35 (3.55, 2.96)

Clearance

Clearance of

idler gear

Clearance of

clutch sleeve

Clearance of lever and reverse Standard 0.1-0.32 (0.004-0.013)

mm (in) Wear limit 0.5 (0.020)

-

1 st-2nd 0.08-0.228 (0.003-0.009)

Standard 3rd-4th 0.1-0.5 (0.004-0.020)

shift fork and 5th~Rev. 0.15-0.458 (0.059-0.018)

mm (in)

1 st-2nd 0.728 (0.029)

Wear limit 3rd-4th 1.000 (0.039)

5th~Rev.

0.958 (0.03

synchronizer ring and gear Standard

mm (in) Wear limit I

First Standard

Limit

I I I 8) 1.5 (0.059)

0.8 (0.032)

0.05-0.28 (0.002’-0.011)

0.33 (0.013)

Gear thrust clearance

mm (in) Second

Third

Fourth

Fifth Standard

Limit

Standard

Limit

Standard

Limit

nr- --,_-..I

3tariuaru

Limit 0.175-0.455 (0.0069-0.0179)

0.505 (0.0199)

0.05-0.20 (0.002-0.008)

0.25 (0.010)

0.165-0.365 (0.0065-0.0144)

0.415 (0.0163)

al-O.22 (0.0039-0.0087)

0.27 (0.0106)

Bearing preload of primary shaf t gear

N.m (cm-kg, in-lb) 0.1-0.25 (1.0-2.5, 0.87-2.18)

Bearing preload of secondary shaft gear

N.m (cm-kg, in-lb)

Bearing preload adjust shim mm (in)

Drive and differential

Type

Final gear

Reduction ratio

Bearing preload N.m (cm-kg, in-lb)

Bearing

preload adjust

shim (in) mm

Backlash of side gear and pinion gear mm (in) 0.2-0.4 (2.0-4.0, 1.7-3.5)

0.20 (0.008) 0.30 (0.012) 0.40 (0.016) 0.50 (0.020)

0.25 (O.OlO), 0.35 (0.014) 0.45 (0.020) 0.55 (0.022)

0.60 (0.023) 0.65 (0.025) 0.70 (0.028)

Helical

4.105

1.4-2.0 (14-20, 12.2---17)

0.10 (0.004) 0.20 (0.008) 0.25 (0.010) 0.30 (0.012)

0.35 (0.014) 0.40 (0.016) 0.45 (0.018) 0.50 (0.020)

0.55

(0.022) 0.60

(0.024) 0.65 (0.026) 0.70 (0.028)

0.75 (0.030) 0.80 (0.031) 0.85 (0.033) 0.90 (0.035)

0.95 (0.037) 1.00 (0.039), 1.05 (0.041) 1.10 (0.043)

1 ,15 (0.045) 1.20

(0.047)

o-o.1 (O-0.004)

TD-13

Page 1029 of 1164

TECHNICAL DATA TD

Item

Carrier hub

Sun gear drum

Small sun gear TransaxlelEngine

Clearance between pinion washer

and planet carrier mm (in) Maximum

Bushing inner diameter

mm (in) Maximum

Bushing inner diameter

mm (in) Maximum F4A-EL

B6 SOHC BP SOHC BP DOHC

0.2-0.7 (0.008-0.028)

30.425 (1.198)

21.021 (0.828)

Gear assembly

Total end play

End play adjust race

Idle gear bearing preload

Preload

adjust shims

Output gear bearing preload

Preload adjust shims

Differential

Bearing preload

Preload

adjust shims

Backlash of side gear and pinion mm (in)

mm (in)

N.m (cm-kg, in-lb)

mm (in)

N.m (cm-kg, in-lb)

mm (in)

N.m (cm-kg, in-lb)

mm (in)

mm (in) Standard

Maximum 0.25-0.50 (0.010-0.020)

1.2 (0.047) 1.4 (0.055), 1.6 (0.063)

1.8 (0.071) 2.0 (0.079) 2.2 (0.087)

-

0.03-0.9 (0.3-9.0, 0.26-7.8)

3.80 (0.150) 3.85 (0.152) 3.90 (0.154) 3.95

(0.156)

4.00 (0.158) 4.05 (0.159) 4.10 (0.161) 4.15 (0.163)

4.20 (0.165) 4.25 (0.167) 4.30 (0.169) 4.35 (0.171)

4.40 (0.173), 4.45 (0.175) 4.50 (0.177) 4.55

(0.179)

4.60 (0.181) 4.65 (0.183) 4.70 (0.185) 4.75 (0.187)

0.03-0.9 (0.3-9.0, 0.26-7.8)

0.50 (0.020) 0.55 (0.022) 0.60 (0.024) 0.65

(0.026).

0.70 (0.028) 0.75 (0.030) 0.80 (0.032) 0.85

(0.034)

0.90 (0.035) 0.95 (0.037) 1.00 (0.039) 1.05 (0.041)

1.10 (0.043) 1.15 (0.045) 1.20 (0.047) 1.25 (0.049)

1.30 (0.051), 1.35 (0.053) 1.40 (0.055) 1.45

(0.057)

2.9-3.9 (30-40, 26-35)

0.50 (0.020) 0.55 (0.022) 0.60 (0.024) 0.65

(0.026)

0.70 (0.028) 0.75 (0.030) 0.80 (0.032) 0.85 (0.034)

0.90 (0.035) 0.95 (0.037) 1.00 (0.039), 1.05 (0.041)

1.10 (0.043) 1.15 (0.045) 1.20 (0.047). 1.25 (0.049)

1.30 (0.051) 1.35 (0.053) 1.40 (0.055), 1.45 (0.057)

0.025-0.1 (0.001-0.004)

0.5 (0.020)

Torque converter

Bushing inner diameter mm (in) Standard 1 53.030-53.075 (2.088-2.090)

Maximum 1 53.075 (2.090)

Spring Specification

Spring name Outer diameter Free length

No. of coil Wire diameter

mm (in) mm (in) mm (in)

Throttle modulator 8.1 I I--.._ ^^^1-^1 1 spring 1 (0.319)

1 43.4 (1.709) 1 10.5 1 0.8 (0.031)

1

” cJIJtz:I li”I IL, “I

valve body Throttle spring

Throttle assist spring 1 5.4 (0.213) 46.2 (1.819) 1 29.0

0.88 (0.035)

1 5.15 (0.203)

26.88 (1.058) 1 16.2 0.6 (0.024)

,

^ -- ,^ ^^^

Mnin contrnl I Low reducina sprina I 7.9 (0.311) .._... __.._. -

valve body

-. .- \“---I 29.98 (1.180) 10.0

0.8 (0.03lj

1 3-4

shift spring / 7.4 (0.291) I 36.6 (1.441)

12.0 0.8 (0.031)

B6 SOHC

23.0

Bypass spring BP

SOHC 4.9 (0.193) 27.6 (1.087) 0.55 (0.022)

Premain control BP

DOHC 4.9 (0.193) 30.5 (1.201) 23.0

0.55 (0.022)

valve body

2-3 shift spring 7.4 (0.291) 36.6 (1.441)

12.0 0.8 (0.031)

Converter relief spring

8.6 (0.339) 68.4 (2.693) 27.5

1.2 (0.057)

Lockup control spring

5.0 (0.197) 30.1 (1.185) 21.5 0.55 (0.022)

Control valve body Throttle relief spring

6.6 (0.260) 21.6 (0.850) 11.5

0.8 (0.031)

Oil

pump Spring

13.0 (0.512) 53.0 (2.087)

12.0 1.2 (0.047)

TD-15

Page 1040 of 1164

ST SPECIAL TOOLS

ENGINE (CONT’D)

TOOL NUMBER

& DESCRIPTION PRIORITY

49 E301 144

Removing plate A ILLUSTRATION

CLUTCH AND MANUAL TRANSAXLE

TOOL NUMBER

8, DESCRIPTION

49 GO17 5AO

Support, engine

49 SE01 310A

Clutch disc

centering tool

49 1285 071

Puller, bearing

49 GO19 OAO

Hanger, transaxle

49 8017 001

Bolt set

(Except

BP DOHC)

49 GO30 370

Removing plate

ST-4

PRIORITY

A

A

A

A ILLUSTRATION

I

=-a==-=

TOOL NUMBER

81 DESCRIPTION PRIORITY ILLUSTRATION -

- -

TOOL NUMBER

!I DESCRIPTION PRIORITY ILLUSTRATION

19 0636 145

Uler, fan A

oulley boss

49 GO30 440

Holder, primary A

shaft (BP DOHC)

T

49 F401 440

Holder, primary

shaft (Except

BP DOHC) A

49 0187 520

Bearing puller,

rear axle shaft

(Except

BP DOHC) A

49 GO30 455

Holder,

differential

side gear A

49 0259 770B

Wrench, flare nut A

Page 1049 of 1164

PARTS INDEX

‘I

A

ACCELERATOR CABLE ............................. F-l 14

ACCELERATOR PEDAL ............................. F-l 14

AIR CONDITIONER ...................................... u-30

A/C RELAY.. ........................................... U-56

A/C SWITCH ...........................................

U-57

COMPRESSOR.. ..................................... U-41

CONDENSER.. ....................................... U-53

CONDENSER FAN ................................. u-57

CONDENSER FAN RELAY .................... U-56

COOLING UNIT ..................................... U-38

MAGNETIC CLUTCH ............................. u-51

RECEIVER/DRIER .................................. U-52

REFRIGERANT PRESSURE SWITCH.. .. U-55

AIR FLOW METER ..................................... F-l 68

AIR VALVE.. ................................................ F-l 16

ALTERNATOR .............................................. G-10

ANTENNA FEEDER

AUDIO

....... .......................................................................................... T-i;

AUTOMATIC TRANSAXLE ............................. K-l

2-4 BRAKE BAND ................................ K-l 97

3-4 CLUTCH.. ....................................... K-l 87

ACCUMULATORS ................................ K-l 67

ATF ....................................................... K-135

ATF THERMOSENSOR ........................ K-142

BEARING COVER ASSEMBLY ............ K-208

CLUTCH ASSEMBLY ........................... K-l 72

CONTROL VALVE BODY.. .....

K-21 0,224,234

DIFFERENTIAL ..................................... K-236

DRIVE PLATE.. ..................................... K-267

EC-AT CONTROL UNIT ....................... K-144

HOLD SWITCH ..................................... K-140

HYDRAULIC CIRCUIT .......................... K-278

IDLER GEAR ........................................ K-203

INHIBITOR SWITCH ............................. K-l 41

LOW AND REVERSE BRAKE .............. K-192

MAIN CONTROL VALVE BODY .......... K-220

OIL COOLER.. ...................................... K-265

OIL PUMP ............................................

K-169

OIL SEAL ..............................................

K-209

ONE-WAY CLUTCH 2

CARRIER HUB ASSEMBLY ............... K-185

OUTPUT GEAR .................................... K-206

P RANGE SWITCH.. ............................. K-271

PREMAIN CONTROL VALVE BODY .a. K-218

PULSE GENERATOR ........................... K-142

SELECTOR LEVER ............................... K-272

SHIFT MECHANISM ............................. K-269

SHIFT-LOCK ACTUATOR

..................... K-271

SMALL SUN GEAR AND

ONE-WAY CLUTCH 1 ........................ K-l 82

SOLENOID VALVE.. ............................. K-l 43

SPEEDSENSOR .................................. K-l 43

THROTTLE CABLE .............................. K-l 37

TORQlJE CONVERTER.. ...................... K-l 66

TRANSAXLE UNIT. ......... K-149,153,246,261 UPPER CONTROL VALVE BODY.. ..... K-215

BACK-UP LIGHT SWITCH..

..........................

BATTERY T;4;

- .......................................................

BLOWER UNIT ............................................

U-23

BRAKE FLUID.. .............................................. P-8

BRAKE MASTER CYLINDER. ...................... P-10

BRAKE PEDAL ...............................................

P-8

C

CALIPER .................................................. P-21,26

CARGO COMPARTMENT LAMP ................. T-54

CENTRAL PROCESSING UNIT..

.................. T-55

CHARCOAL CANISTER ............................. F-l 41

CHECK VALVE (TWO-WAY) .......................

CHECK-AND-CUT VALVE - .......................... ;-;b$

CIRCUIT OPENING RELAY.. ...................... F-129

CLUTCH COVER ......................................... H-l 7

CLUTCH DISC ............................................. H-l 7

CLUTCH FLUID ............................................. H-4

CLUTCH MASTER CYLINDER.. .................... H-7

CLUTCH PEDAL ............................................ H-5

CLUTCH RELEASE CYLINDER..

................. H-12

CLUTCH SWITCH (MTX) ............................ F-l 72

COMBINATION SWITCH .............................. T-23

COWL GRILLE ............................................. S-53

CRUISE CONTROL UNIT.. ...................... T-78,85

D

DASHBOARD ............................................... S-94

DASHPOT ................................................... F-l 42

DISTRIBUTOR .............................................. G-20

DOOR LOCK TIMER UNIT ........................... T-17

DOOR MIRROR ............................................ S-54

REMOTE CONTROL MIRROR ............... S-56

REMOTE CONTROL MIRROR SWITCH. S-55

DOOR SPEAKER .......................................... T-98

DRIVE SHAFT.. ....................................... M-l 7,21

DRL RELAY.. ................................................ T-18

DRL RESISTOR ............................................ T-46

DUAL PROPORTIONING VALVE..

............... P-l 6

DYNAMIC CHAMBER ................................ F-l 12

E

ELECTRIC COOLING FAN SYSTEM ........... E-13

ENGINE (B6 & BP SOHC) ........................... Bl-2

CAMSHAFT ..........................................

Bl-58

CAMSHAFT PULLEY ...........................

Bl-65

CONNECTING ROD ............................. 81-63

PI-I