charging MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 12 of 1164

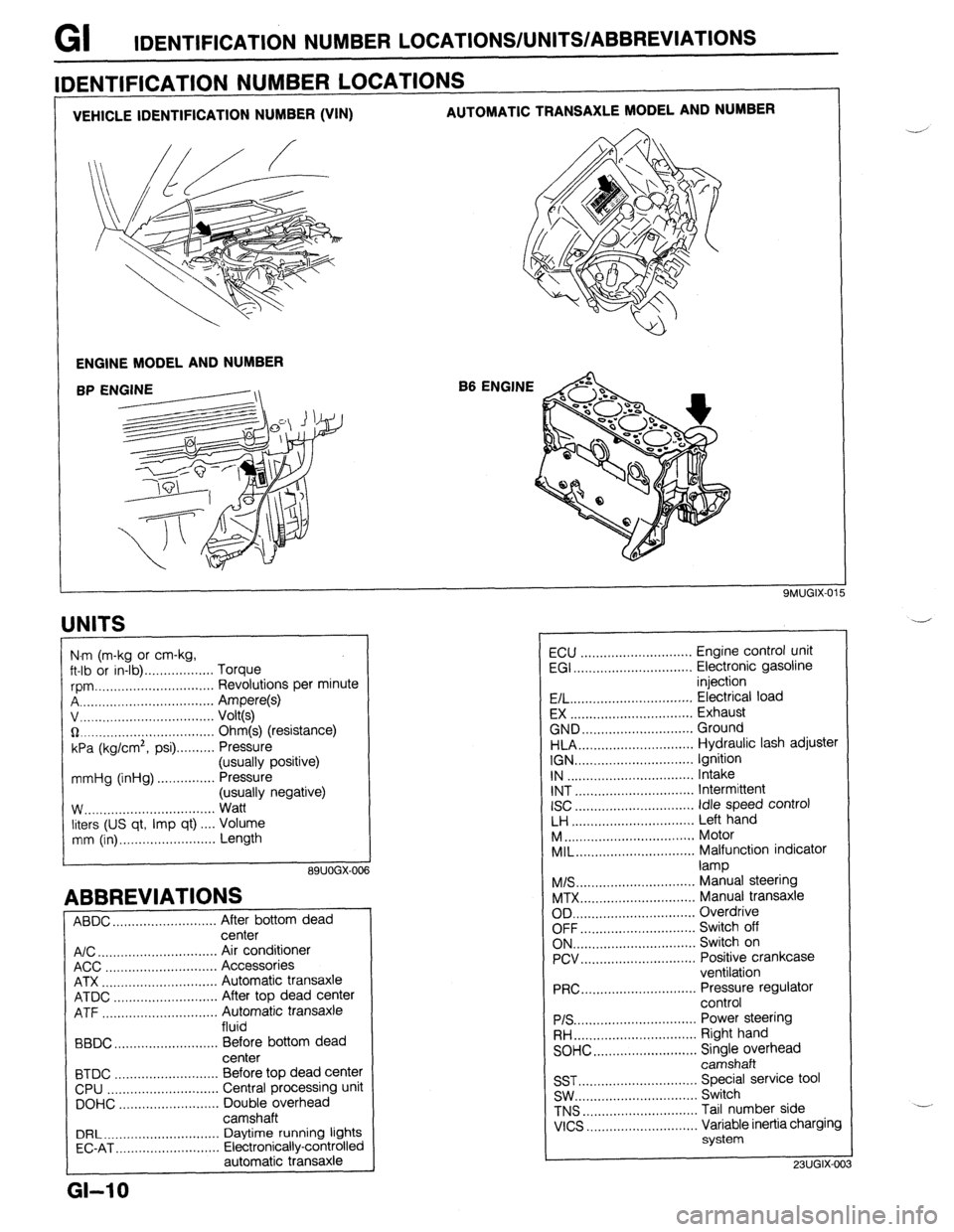

GI IDENTIFICATION NUMBER LOCATIONS/UNITS/ABBREVlATlONS

VEHICLE IDENTIFICATION NUMBER (VIN) AUTOMATIC TRANSAXLE MODEL AND NUMBER

ENGINE MODEL AND NUMBER

B6 ENGINE

IDENTIFICATION NUMBER LOCATIONS

UNITS

I

N.m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . . . . . . . . . . . . . . Torque

rpm ._..,,,.............,.......... Revolutions per minute

A . . . . . . . . . . . . . . . . . Ampere(s)

v, . . . . . . . . . . . . . .

Volt(s)

$2 _....._..,......................... Ohm(s) (resistance)

kPa (kg/cm2,

psi) . . . . . . . . . . Pressure

(usually positive)

mmHg (inHg) . . . . . . . . . . . . . . . Pressure

(usually negative)

W.. . . . . . . . . . . .

Watt

liters (US qt, Imp qt) ,... Volume

mm (in) ..,......,...,........... Length

89UOGX-00

ABBREVIATIONS

ABDC . . . . . . . . . . . . . . . . . . . . .

After bottom dead

center

A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air conditioner

ACC ..,.,...... 3 . . . . . . . . . . . . . . . . . Accessories

ATX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic transaxle

ATDC ..,,...,...,............... After top dead center

ATF . . . . . . . . . . . . . . . . . Automatic transaxle

fluid

BBDC ,,..,.......,...,......,... Before bottom dead

center

BTDC .,......,...............,.. Before top dead center

CPU ..,,.......,...,..........,.. Central processing unit

DOHC ..,...,..,............,,.. Double overhead

camshaft

DRL ____.......................... Daytime running lights

EC-AT .,_.......,............,,.. Electronically-controlled

automatic transaxle

L

GI-10

ECU ............................. Engine control unit

EGI ............................... Electronic gasoline

injection

E/L.. .............................. Electrical load

EX ................................ Exhaust

GND.. ........................... Ground

HLA.. ............................ Hydraulic lash adjuster

IGN ............................... Ignition

IN ................................. Intake

INT ............................... Intermittent

ISC

............................... idle speed control

LH ................................ Left hand

M..

................................ Motor

MIL..

............................. Malfunction indicator

lamp

M/S..

............................. Manual steering

MTX.. ............................ Manual transaxle

OD ................................ Overdrive

OFF.. ............................ Switch off

ON.. .............................. Switch on

PCV.. ............................ Positive crankcase

ventilation

PRC..

............................ Pressure regulator

control

PIS ................................ Power steering

RH..

.............................. Right hand

SOHC.. .........................

z;;kiprhead

SST ............................... Special service tool

SW.. .............................. Switch

TNS

.............................. Tail number side

VICS

............................. Variable inertia charging

system

23UGIX-00

Page 267 of 1164

F

FUEL AND EMISSION

CONTROL SYSTEM

INDEX ...........................................

OUTLINE ...................................... ;: 2

SYSTEM DIAGRAM ...................... F-

:

VACUUM HOSE ROUTING

DIAGRAM .................................

WIRING DIAGRAM ....................... F- 6

- 7

ENGINE CONTROL UNIT (ATX) ...... F- 13

SPECIFICATIONS.. ....................... F- 15

COMPONENT DESCRIPTIONS.

...... F- 16

TROUBLESHOOTING GUIDE.. ......... F- 20

ENGINE CONTROL OPERATION

CHART

..................................... F- 20

RELATIONSHIP CHART.. .............. F- 24

USING THIS SECTION .................. F- 25

DIAGNOSTIC INDEX .................... F- 27

PRECAUTION ............................. F- 29

SYMPTOM TROUBLESHOOTING .... F- 30

ENGINE TUNE-UP

.......................... F- 76

PREPARATION ............................

F- 76

BASIC INSPECTION ..................... F- 78

ADJUSTMENT .............................

F- 79

SELF-DIAGNOSIS FUNCTION .......... F- 82

DESCRIPTION .............................

F- 82

PREPARATION

............................

F- 83

SERVISE CODE NUMBER.. ........... F- 83

SWITCH MONITOR FUNCTION ...... F-105

INTAKE AIR SYSTEM.. ................... F-109

COMPONENT PARTS.. ................. F-109

THROTTLE BODY ........................ F-l 12

DYNAMIC CHAMBER ................... F-l 12

INTAKE MANIFOLD ..................... F-l 13

ACCELERATOR PEDAL ................ F-l 14

ACCELERATOR CABLE ................ F-l 14

IDLE SPEED CONTROL (ISC)

SYSTEM ......................................

F-115

DESCRIPTION ............................. F-115

PREPARATION

............................ F-116

SYSTEM OPERATION.. ................. F-l 16

ISC VALVE ................................. F-116

AIR VALVE

................................. F-116

VARIABLE INERTIA CHARGING

SYSTEM (VICS) [DOHC] ................ F-l 17

DESCRIPTION ............................. F-117

SYSTEM OPERATION ................... F-l 18

SHUTTER VALVE ACTUATOR.. ...... F-l 18

SOLENOID VALVE (VICS). ............. F-118

VACUUM CHAMBER.. .................. F-119

FUELSYSTEM .............................. F-l 20

DESCRIPTION

............................. F-l 20

PRECAUTION ............................. F-121

SYSTEM OPERATION.. ................. F-121

FUEL TANK ................................

F-l 23

FUEL FILTER .............................. F-l 24 FUEL PUMP ............................... F-l 25

CIRCUIT OPENING RELAY.. .......... F-129

PRESSURE REGULATOR.. ............ F-129

INJECTOR .................................. F-l 31

PRESSURE REGULATOR

CONTROL SYSTEM.. .................... F-l 34

SOLENOID VALVE (PRESSURE

REGULATOR CONTROL). ............ F-l 35

EXHAUST SYSTEM ........................ F-l 36

COMPONENT PARTS.. ................. F-136

OUTLINE OF EMISSION

CONTROL SYSTEM.. .................... F-l 37

STRUCTURAL VIEW.. ................... F-l 37

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM.. ..... F-138

DESCRIPTION .............................

F-l 38

PCV VALVE ................................ F-l 38

EVAPORATIVE EMISSION

CONTROL SYSTEM.. .................... F-l 39

DESCRIPTION ............................. F-l 39

SYSTEM OPERATION.. ................. F-140

SOLENOID VALVE

(PURGE CONTROL) ................... F-140

SEPARATOR ............................... F-l 40

CHECK VALVE (TWO-WAY) ........... F-140

CHECK-AND-CUT VALVE.. ............ F-141

CHARCOAL CANISTER.. ............... F-141

DECELERATION CONTROL

SYSTEM ...................................... F-l 42

DESCRIPTION ............................. F-l 42

DASHPOT .................................. F-142

FUEL CUT CONTROL SYSTEM ....... F-143

DESCRIPTION ............................. F-l 43

PREPARATION ............................ F-l 43

SYSTEM OPERATION.. ................. F-143

DECHOKE CONTROL SYSTEM.. ...... F-145

DESCRIPTION ............................. F-l 45

SYSTEM OPERATION ................... F-l 45

CONTROL SYSTEM ....................... F-l 47

PREPARATION ............................ F-147

STRUCTURAL VIEW.. ................... F-l 48

ENGINE CONTROL UNIT (ECU) ..... F-149

AIRFLOW METER (WITH INTAKE AIR

THERMOSENSOR) ..................... F-168

WATER THERMOSENSOR.. ........... F-168

THROTTLE SENSOR .................... F-l 69

OXYGEN SENSOR.. ..................... F-171

MAIN RELAY (FUEL INJ RELAY) .... F-172

CLUTCH SWITCH (MTX) ............... F-172

NEUTRAL SWITCH (MTX). ............. F-173

POWER STEERING PRESSURE

SWITCH .................................... F-173

WJOFX-001

Page 283 of 1164

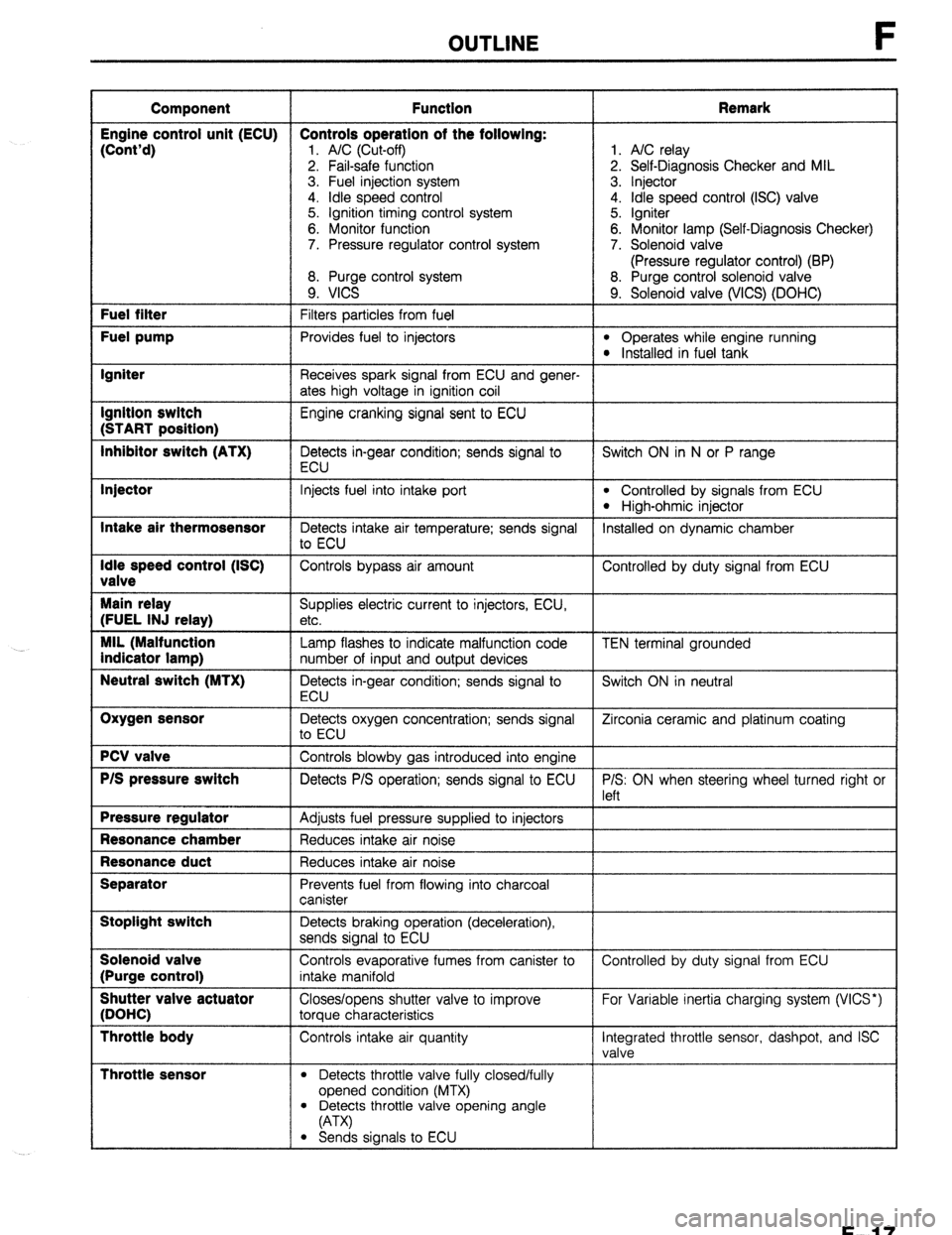

OUTLINE

Component Function Remark

Engine control unit (ECU) Controls operation of the following:

(Cont’d)

1. A/C (Cut-off) 1. A/C relay

2. Fail-safe function 2. Self-Diagnosis Checker and MIL

3. Fuel injection system 3. Injector

4. idle speed control 4. Idle speed control (ISC) valve

5. Ignition timing control system 5. Igniter

6. Monitor function 6. Monitor lamp (Self-Diagnosis Checker)

7. Pressure regulator control system 7. Solenoid valve

(Pressure regulator control) (BP)

8. Purge control system 8. Purge control solenoid valve

9. VICS 9. Solenoid valve (WCS) (DOHC) Fuel filter

Filters particles from fuel Fuel pump

Provides fuel to injectors l Operates while engine running l Installed in fuel tank Igniter

Receives spark signal from ECU and gener-

ates high voltage in ignition coil Ignition switch

Engine cranking signal sent to ECU (START position)

Inhibitor switch (ATX)

Detects in-gear condition; sends signal to Switch ON in N or P range

ECU Injector

Intake air thermosensor

Idle speed control (ISC)

valve

Main relay

(FUEL INJ relay)

MIL (Malfunction

indicator lamp)

Neutral switch (MTX)

Oxygen sensor

PCV valve

P/S pressure switch

Pressure regulator

Resonance chamber

Resonance duct

Separator

Stoplight switch

Solenoid valve

(Purge control)

Shutter valve actuator

(DOHC)

Throttle body

Throttle sensor

Injects fuel into intake port l Controlled by signals from ECU

l High-ohmic injector

Detects intake air temperature; sends signal Installed on dynamic chamber

to ECU

Controls bypass air amount Controlled by duty signal from ECU

Supplies electric current to injectors, ECU,

etc.

Lamp flashes to indicate malfunction code

number of input and output devices

Detects in-gear condition; sends signal to

ECU

Detects oxygen concentration; sends signal

to ECU

Controls blowby gas introduced into engine

Detects P/S operation; sends signal to ECU

Adjusts fuel pressure supplied to injectors

Reduces intake air noise

Reduces intake air noise

Prevents fuel from flowing into charcoal

canister

Detects braking operation (deceleration),

sends signal to ECU

Controls evaporative fumes from canister to

intake manifold

Closes/opens shutter valve to improve

torque characteristics

Controls intake air quantity

l Detects throttle valve fully closed/fully

opened condition (MTX) TEN terminal grounded

Switch ON in neutral

Zirconia ceramic and platinum coating

P/S: ON when steering wheel turned right or

left

Controlled by duty signal from ECU

For Variable inertia charging system (VICS*)

Integrated throttle sensor, dashpot, and ISC

valve

l Detects throttle valve opening angle

(A-W

l Sends signals to ECU

F-l 7

Page 284 of 1164

F OUTLINE

I Component

I Function

I Remark

I

Three-way

solenoid

valve vIcs*

Pressure

regulator

control

Controls vacuum to shutter valve actuator

Controls vacuum to pressure regulator Cuts vacuum when engine speed above

5.000 ram

Cuts vacuum just after starting when engine

hot starting Vacuum chamber

(DOHC)

Water thermosensor

Stores vacuum for use during wide open For WCS*

throttle

Detects coolant temperature; sends signal to

ECU

l WCS: Variable Inertia Charging System 23UOFX-013

F-l 8

Page 330 of 1164

TROUBLESHOOTING GUIDE

ISTEP 1 INSPECTION

15 Check if variable inertia charging system (WCS)

is OK (BPD) CT page F-l 18

16 Try known good ECU and check if condition

improves w page F-149

1

23UOFX-035

F-64

Page 334 of 1164

F TROUBLESHOOTING GUIDE

iTEF

___

13

14

-

15

__

16 INSPECTION

Change fuel and check if acceleration improves

Check if A/C cut-off control system is OK

Check if variable inertia charging system (WCS)

is OK (BPD)

w page F-l 18

Try known good ECU and check if condition

improves

w page F-149 ACTION

Yes Change fuel to another brand

No Go to next step

Yes SOHC

Go to Step 16

DOHC

Go to next step

No Repair or replace

Yes Go to next step

I

No 1 Repair or replace /

F-68

Page 383 of 1164

![MAZDA PROTEGE 1992 Workshop Manual VARIABLE INERTIA CHARGING SYSTEM (VI-)

VARIABLE INERTIA

CHARGING SYSTEM (VICS) [DOHC]

DESCRIPTION

VACUUM CHAMBER

SHUTTER VALVE ACTUATOR

F

THREE-WAY VALVE CLOSED

5,000 rpm

SHUTTER VALVE

BELOW MAZDA PROTEGE 1992 Workshop Manual VARIABLE INERTIA CHARGING SYSTEM (VI-)

VARIABLE INERTIA

CHARGING SYSTEM (VICS) [DOHC]

DESCRIPTION

VACUUM CHAMBER

SHUTTER VALVE ACTUATOR

F

THREE-WAY VALVE CLOSED

5,000 rpm

SHUTTER VALVE

BELOW](/img/28/57077/w960_57077-382.png)

VARIABLE INERTIA CHARGING SYSTEM (VI-)

VARIABLE INERTIA

CHARGING SYSTEM (VICS) [DOHC]

DESCRIPTION

VACUUM CHAMBER

SHUTTER VALVE ACTUATOR

F

THREE-WAY VALVE CLOSED

5,000 rpm

SHUTTER VALVE

BELOW 5,000 rpm ABOVE 5,000 rpm

SHUTTER VALVE CLOSED SHUTTER VALVE OPEN

By varying the length of the intake air path in the intake manifold and dynamic chamber, the resonance

induced inertia charging effect is improved, yielding higher torque and a wider torque band.

The length of the intake track is controlled within the intake manifold and dynamic chamber by opening and

closing the shutter valve at 5,000 rpm.

l-R; FCZz consists of the shutter valves, shutter valve actuator, three-way solenoid valve, vacuum chamber,

F-117

Page 384 of 1164

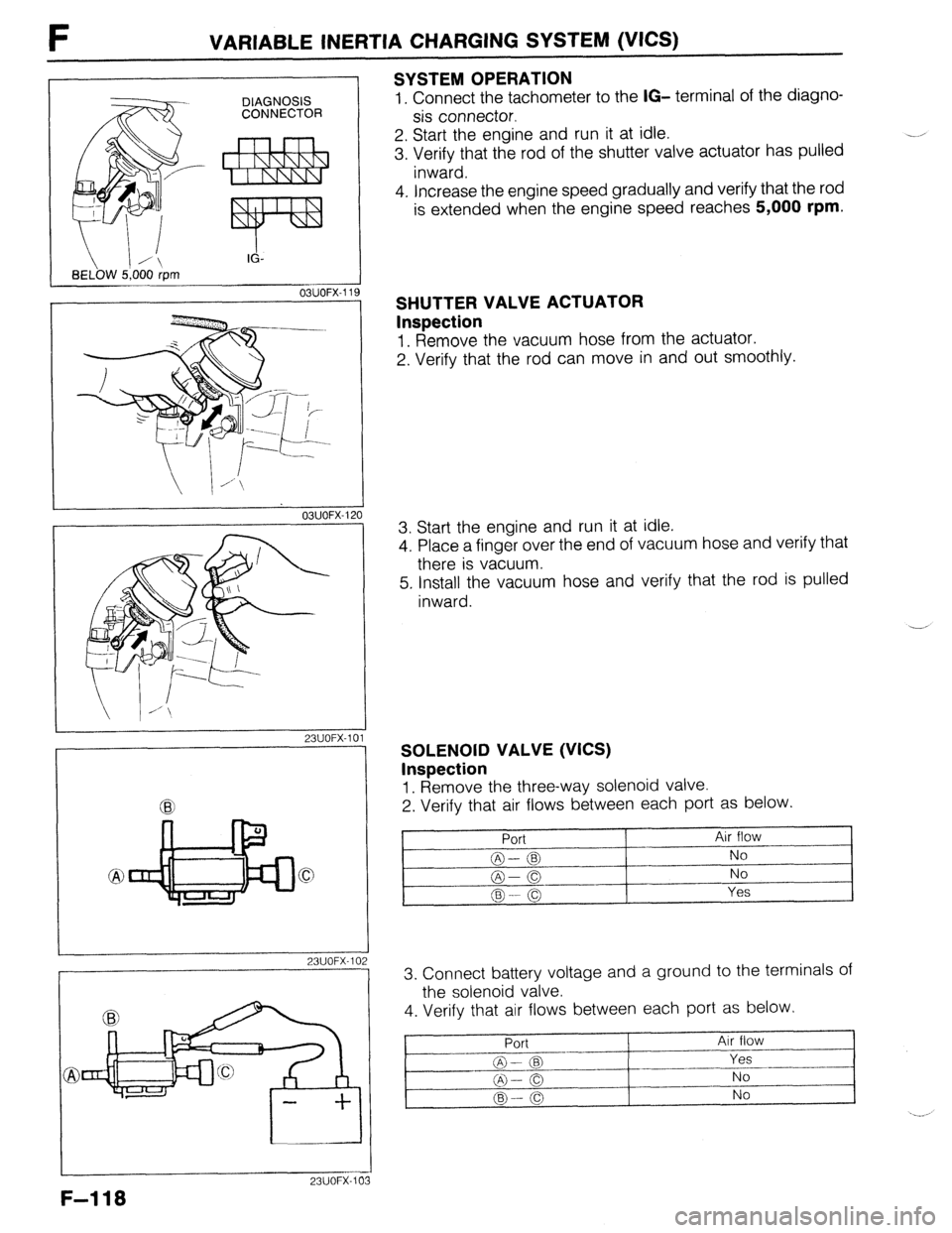

VARIABLE INERTIA CHARGING SYSTEM (VICS)

SYSTEM OPERATION

DIAGNOSIS 1. Connect the tachometer to the IG- terminal of the diagno- CONNECTOR sis connector.

2. Start the engine and run it at idle.

3. Verify that the rod of the shutter valve actuator has pulled -

inward.

OSUOFX-I 19

F-118

i-..

1”

03UOFX-I 2

23UOFX-1 C

23UOFX-1 C

23UOFX-IC

4. increase the engine speed gradually and verify that the rod

is extended when the engine speed reaches 5,000 rpm.

SHUTTER VALVE ACTUATOR

Inspection

1. Remove the vacuum hose from the actuator.

2. Verify that the rod can move in and out smoothly.

3. Start the engine and run it at idle.

4. Place a finger over the end of vacuum hose and verify that

there is vacuum.

5. Install the vacuum hose and verify that the rod is pulled

inward.

SOLENOID VALVE (VICS)

Inspection

1. Remove the three-way solenoid valve.

2. Verify that air flows between each port as below.

Port

@--@ - -

@-0

@ --- (g Air flow

No

No

Yes

3. Connect battery voltage and a ground to the terminals of

the solenoid valve.

4. Verify that air flows between each port as below.

Port Air flow

-_I

-I_

@- 03 Yes

@l-o No

@--0 No

Page 385 of 1164

VARIABLE INERTIA CHARGING SYSTEM (VICS) F

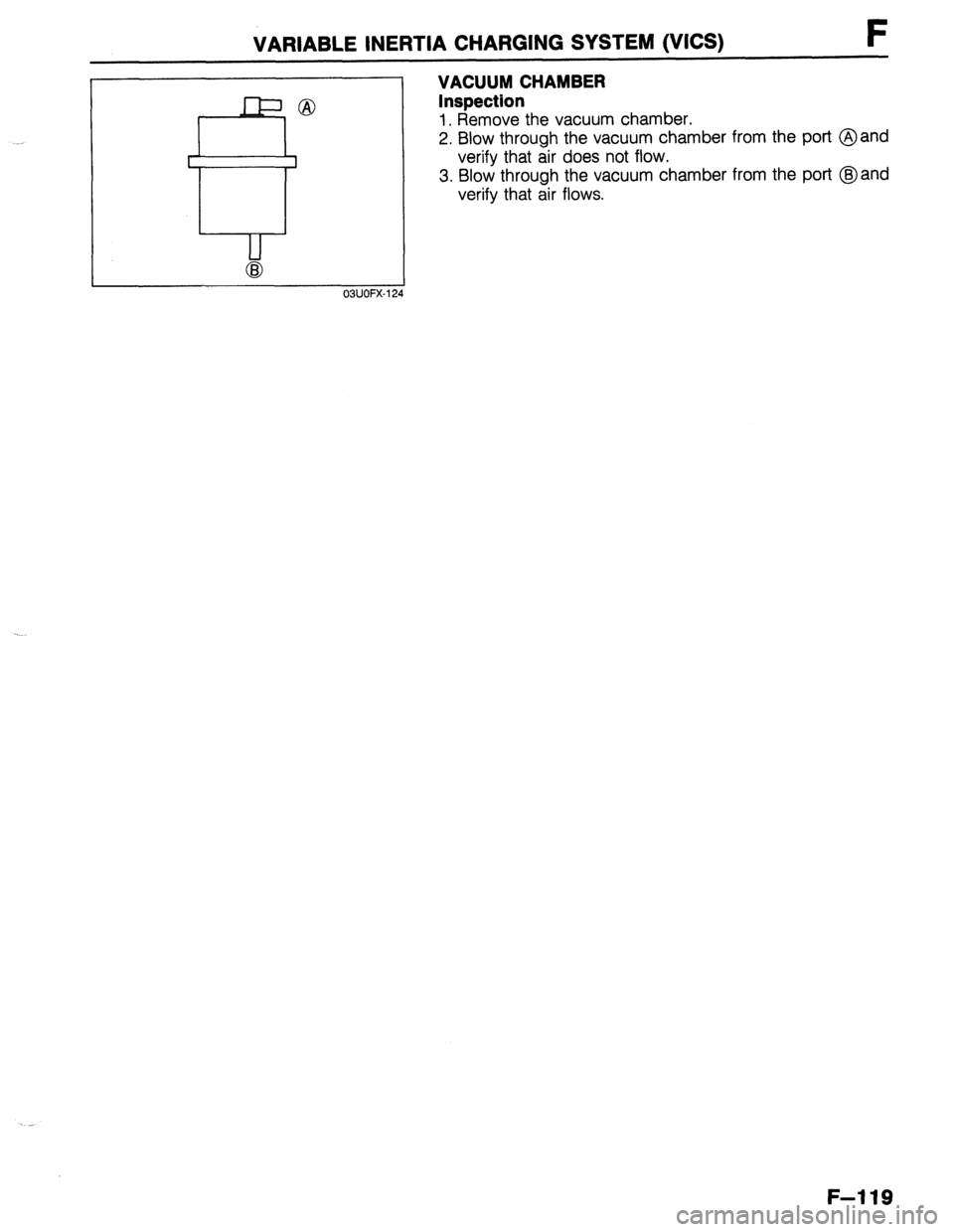

VACUUM CHAMBER

Inspection

1. Remove the vacuum chamber.

2. Blow through the vacuum chamber from the port @and

verify that air does not flow.

3. Blow through the vacuum chamber from the port @and

verify that air flows.

03UOFX-12

F-119

Page 422 of 1164

F CONTROL SYSTEM

Ve: Battery voltage

erminal Input Output Connection to

Test condition Correct voltage Remark

2s 0 Solenoid valve

Engine speed below 5,000 rpm ov VICS: Variable In-

(VICS)

Engine speed above 5,000 rpm

VB ertia Charging

System [DOHC]

2T 0 Solenoid valve

60 [DOHC]/120 [SOHC] seconds after ov

(Pressure regula- engine started when engine coolant tem-

tor) [BP] perature above 90% (194OF) and intake

-

air temperature above 58% (136’F)

[DOHC]/50% (122OF) [SOHC]

Other condition at idle

Ve

2u

0 Injector (Nos. 1, 3) Ignition switch ON V0 *Engine Signal

idle

VB Monitor: Green

Engine speed above 2,000 rpm on de-

VB and red lamps

flash

celeration (After warm-up)

2v 0 Injector (Nos. 2, 4) Ignition switch at idle

Ve

idle

VI3

Engine speed above 2,000 rpm on de-

VB celeration (After warm-up)

2w

0 ISC valve Ignition switch ON Approx. 7V

-

Idle

Approx. QV

2x 0 Solenoid valve Ignition switch ON

VB (Purge control) -

Idle VB

2Y - - - - - -

23UOFX-1:

I r

U----l l-l

Ll I-

2y

2w 2u 2s 20 20 2M 2K 21 23 2E 2C 2.4 1U 1s 10 10 1M 1K 11 1G 1E 1~ IA

2z 2x 2’4 2T 2R 2P 2N 2L 2J 2l-i 2F 2D 28 IV 1T 1R lp IN IL 1J 1~ 1F If) 1~ -/

F-l 56