coolant MAZDA PROTEGE 1992 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 379 of 1164

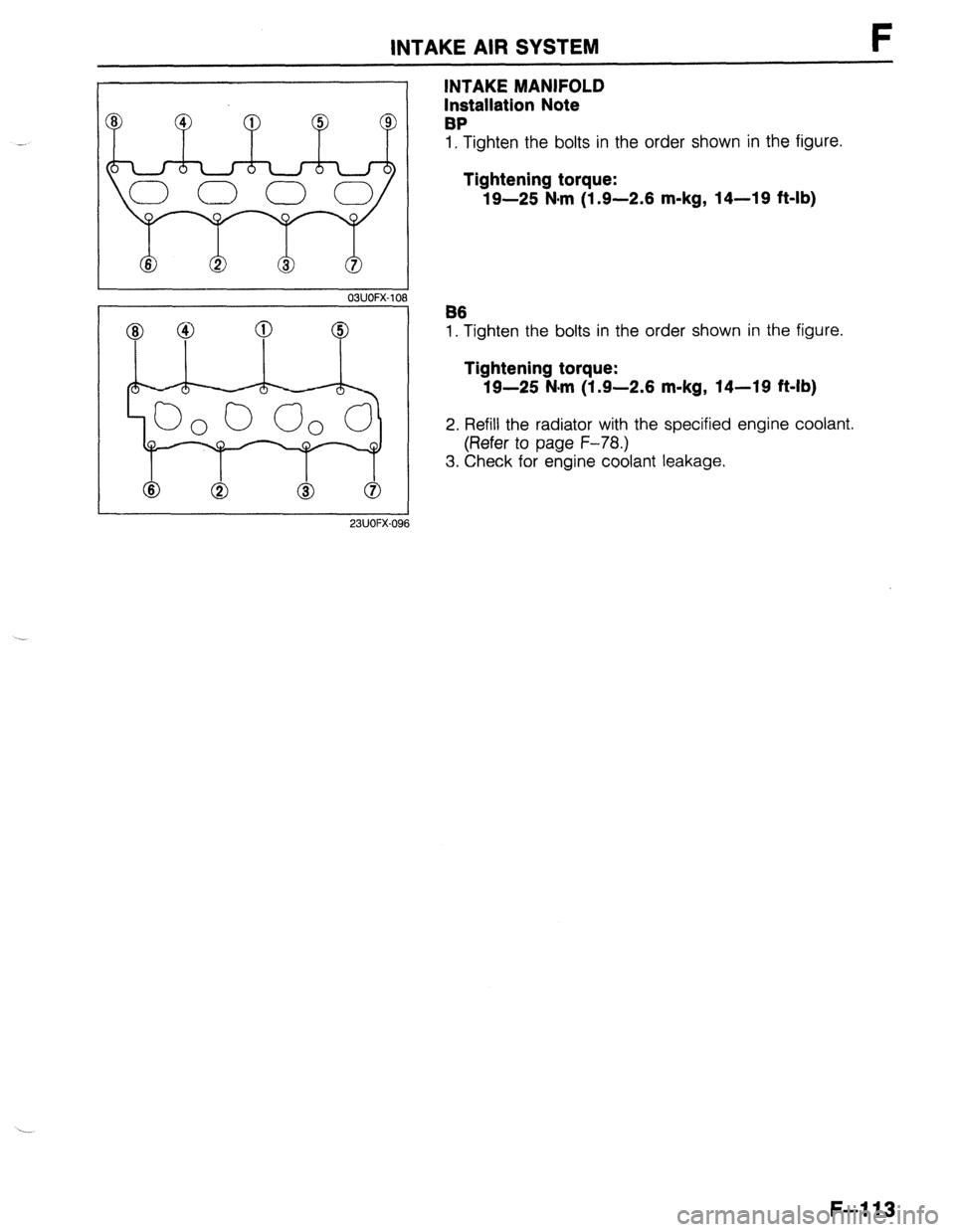

INTAKE AIR SYSTEM F

I 23UOFX-096

INTAKE MANIFOLD

Installation Note

BP

1, Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

B6

1. Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

2. Refill the radiator with the specified engine coolant.

(Refer to page F-78.)

3. Check for engine coolant leakage.

F-113

Page 382 of 1164

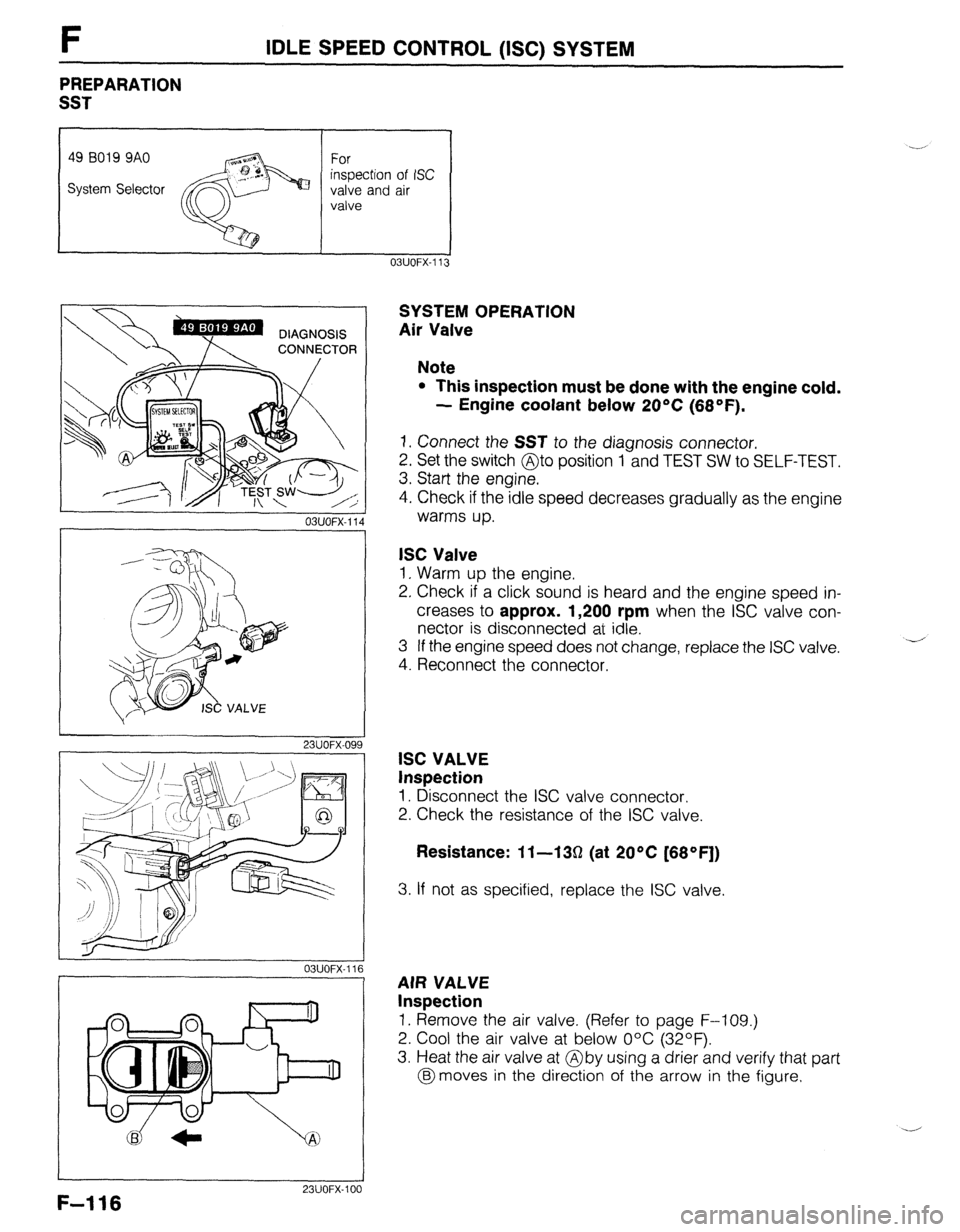

F IDLE SPEED CONTROL (ISC) SYSTEM

PREPARATION

SST

OBUOFX-113

OSUOFX-I 14

I

23UOFX-095

J 03UOFX-1 lf

23UOFX-101

F-116

SYSTEM OPERATION

Air Valve

Note

l This inspection must be done with the engine cold.

- Engine coolant below 20°C (68°F).

1. Connect the SST to the diagnosis connector.

2. Set the switch @to position 1 and TEST SW to SELF-TEST.

3. Start the engine.

4. Check if the idle speed decreases gradually as the engine

warms up.

ISC Valve

1. Warm up the engine.

2. Check if a click sound is heard and the engine speed in-

creases to approx. 1,200 rpm when the ISC valve con-

nector is disconnected at idle.

3 If the engine speed does not change, replace the ISC valve.

4. Reconnect the connector.

ISC VALVE

Inspection

1. Disconnect the ISC valve connector.

2. Check the resistance of the ISC valve.

Resistance: 11-130 (at 20°C [68*F])

3. If not as specified, replace the ISC valve.

AIR VALVE

Inspection

1. Remove the air valve. (Refer to page F-109.)

2. Cool the air valve at below O°C (32OF).

3. Heat the air valve at @by using a drier and verify that part

@moves in the direction of the arrow in the figure.

Page 400 of 1164

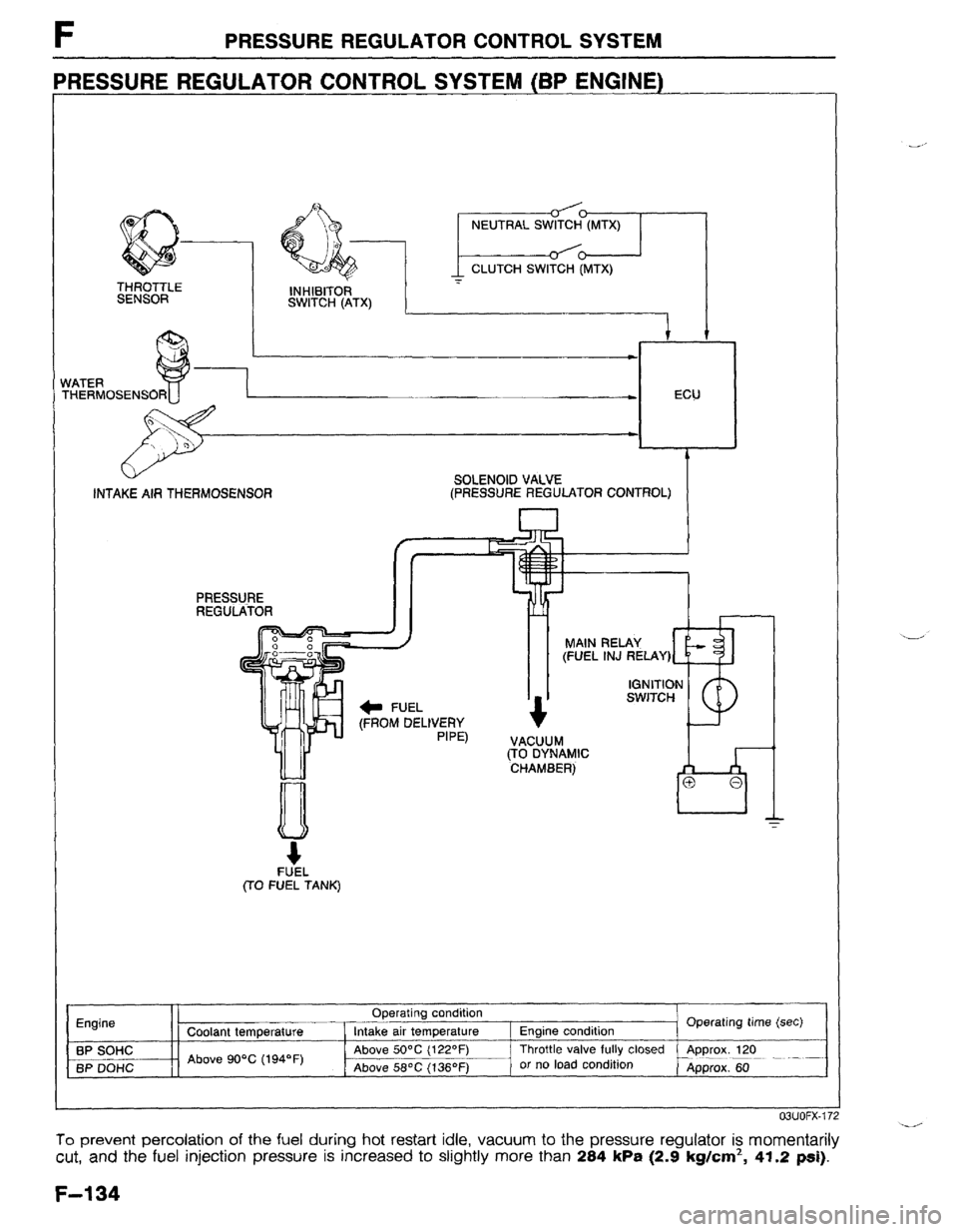

F PRESSURE REGULATOR CONTROL SYSTEM

PRESSURE REGULATOR CONTROL SYSTEM (BP ENGINE)

THERMOSEN

SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

(FROM DELIVERY

FUEL

(TO FUEL TANK)

Engine

BP SOHC

BP DOHC Coolant temperature

Above 90% (194*F) Operating condition

Intake air temperature

Above 50°C (122OF)

Above 58OC (136OF) Engine condition . Operating time (set)

Throttle valve fully closed

Approx. 120

or no load condition

Approx. 60

#.nr IAt-%/ 4 7

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator is momentarily

cut, and the fuel injection pressure is increased to slightly more than 284 kPa (2.9 kg/cm2, 41.2 psi).

F-l 34

Page 411 of 1164

DECHOKE CONTROL SYSTEM t-

DECHOKE CONTROL SYSTEM

DESCRIPTION

To facilitate starting the engine when the spark plugs become fouled, such as when the engine is flooded,

fuel injection is cut if the throttle valve is held wide open while cranking and the engine coolant temperature

is O°C (32OF) or below. This allows the spark oluas to drv and purges excess fuel from the cylinders.

f-- ECU _

. IGNITION SWITCH (START)

l ENGINE SPEED BELOW 500 rpm ’

l THROTTLE VALVE FULLY OPEN

l ENGINE COOLANT TEMPERATURE ;

BELOW

0% (32°F) I FUEL CUT

OBUOFX-19

I / / ‘ I

SYSTEM OPERATION

1.

2. Check if the engine coolant temperature is below O°C

(32OF).

If the engine coolant temperature is above O°C (32OF), dis-

connect the water thermosensor connector and connect an

approx. 10 kB resistor to the connector.

03UOFX.198 3. Turn the ignition switch to START and verify that the injec-

OBUOFX-19! 3

tor operating sound is heard.

4. Depress the accelerator pedal fully and turn the ignition

switch START. Verify that no injector operating sound is

heard.

F-l 45

Page 418 of 1164

F CONTROL SYSTEM

VB: Battery voltage

erminal Input Output Connection to Test condition Corrsct voltage Remark

1M - - - - - -

IN 0 Throttle sensor Accelerator pedal released ov Ignition switch

(Idle switch)

Accelerator pedal depressed

VB ON

10 0

1P 0 Stoplight switch

P/S pressure

switch Brake pedal released

Brake pedal depressed

Ignition switch ON

P/S ON at idle

P/S OFF at idle ov

-

VEi

Va

ov

VS -

10 0 A/C switch A/C switch ON

A/C switch OFF Below 23 Ignition switch

VS ON and blower

motor ON

1R 0

IS 0 Fan switch

Blower control

switch Fan operating (Engine coolant tempera-

ture over 97% (207OF) or diagnosis con-

nector terminal TFA grounded)

Fan not operating (Idle)

Blower control switch OFF or 1st position

Blower control switch 2nd or higher po-

sition ov

-

V0

Ve ignition switch

ov ON

IT 0 Rear window

defroster switch Rear window defroster switch OFF

Rear window defroster switch ON ov

VB

Ignition switch ON

1u 0

iv 0 Headlight switch

Neutral/Clutch

switches Headlights ON

Headlights OFF

Neutral position or clutch pedal

depressed

Others V0

-

ov

ov

VB -

1 I lr----t

r-i

ul r

2Y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2’3 2A 1lJ 1s IQ 10 1M 1K 11 1G 1E 1~ 1A

22 2x 2v 2T 2R 2P 2N 2L 2J 34 2t= 2D 28 Ii/ fT 1R 1p IN 1L 1J 1H 1F 1D 18

F-l 52

Page 420 of 1164

CONTROL SYSTEM

Ve: Battery

arminal Input Output Connection to lest condition Correct voltage Remark

2A - - Ground (Injector) Constant ov -

28 - - Ground (Output) Constant ov -

2c - - Ground (CPU) Constant ov -

2D - - Ground (Input) Constant ov -

2E 0 Distributor Ignition switch ON

Approx. OV

(Ne-signal) or 4.5-5.5V -

Idle Approx. 2V

2F - - - - - -

2G 0 Distributor Ignition switch ON Approx. OV

(G-signal) [DOHC] or 4.5-5.5V

Idle Approx. 1.5V

2H 0 Ground (California) Constant ov

-

Main relay Ignition switch ON Va

(Canada)

21 - - - - - -

2J 0 Open Constant Approx. l-29 -

2K 0 Throttle sensor Constant 4.5-5.5v

(ATX)/Airflow meter

-

2L 0 Throttle sensor

(Power switch) Accelerator pedal released

Accelerator pedal fully depressed Approx. 4.5~5%

ov -

2M 0 Throttle sensor Accelerator pedal released

Accelerator pedal fully depressed Approx. 0.5V

Approx. 4.OV -

2N 0 Oxygen sensor Ignition switch ON ov

Idle (Cold engine) ov

Idle (After warm-up) O-l .ov -

Increasing engine speed (After warm-up) 0.5-I .ov

Deceleration o-0.4v

20 0 Airflow meter Ignition switch ON Approx. 3.8V

-

Idle Approx. 3.3V

2P 0 Intake air ther- Ambient air temperature 20% (68OF) Approx. 2.5V Built in airflow

mosensor meter

2Q 0 Water thermo- Engine coolant temperature 20% (68’F) Approx. 29

_

sensor

After warm-up Below 0.5V

2R - - - - -

- 711 ICIFX-12 voltage

_““_. ,. .I 7

1 r u-

r-i Ll r

2Y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2~2 2A 1U 1s 1Q 10 lft,j ,K ,, ,G ,E ,c ,A

22 2x 2v 2T 2R 2P 2N 2L 2J 2H 2F 2D 28

IV 1T fR 1p 1N 1L 1J ,H IF ID ,B

F-l 54

Page 422 of 1164

F CONTROL SYSTEM

Ve: Battery voltage

erminal Input Output Connection to

Test condition Correct voltage Remark

2s 0 Solenoid valve

Engine speed below 5,000 rpm ov VICS: Variable In-

(VICS)

Engine speed above 5,000 rpm

VB ertia Charging

System [DOHC]

2T 0 Solenoid valve

60 [DOHC]/120 [SOHC] seconds after ov

(Pressure regula- engine started when engine coolant tem-

tor) [BP] perature above 90% (194OF) and intake

-

air temperature above 58% (136’F)

[DOHC]/50% (122OF) [SOHC]

Other condition at idle

Ve

2u

0 Injector (Nos. 1, 3) Ignition switch ON V0 *Engine Signal

idle

VB Monitor: Green

Engine speed above 2,000 rpm on de-

VB and red lamps

flash

celeration (After warm-up)

2v 0 Injector (Nos. 2, 4) Ignition switch at idle

Ve

idle

VI3

Engine speed above 2,000 rpm on de-

VB celeration (After warm-up)

2w

0 ISC valve Ignition switch ON Approx. 7V

-

Idle

Approx. QV

2x 0 Solenoid valve Ignition switch ON

VB (Purge control) -

Idle VB

2Y - - - - - -

23UOFX-1:

I r

U----l l-l

Ll I-

2y

2w 2u 2s 20 20 2M 2K 21 23 2E 2C 2.4 1U 1s 10 10 1M 1K 11 1G 1E 1~ IA

2z 2x 2’4 2T 2R 2P 2N 2L 2J 2l-i 2F 2D 28 IV 1T 1R lp IN IL 1J 1~ 1F If) 1~ -/

F-l 56

Page 428 of 1164

F CONTROL SYSTEM

VB: Battery voltage

erminal Input Output Connection to

Test condition Correct voltage Remark

28 1 0 )

1 Airflow meter Ignition switch ON Approx. 3.8V

-

2c 0 Oxygen sensor

2D 0 Fan switch Idle Approx. 3.3V

Ignition switch ON ov

Idle (Cold engine)

ov

Idle (After warm-up) O-l .ov -

increasing engine speed (After warm-up) 0.5-I .ov

Deceleration o-0.4v

Fan operating (Engine coolant tempera- ov

ture over 97OC (207°F) or diagnosis con-

nector terminal TFA grounded) -

2E 0 Water thermo-

sensor Fan not operating (Idle) VS

Engine coolant temperature 20% (68OF)

After warm-up Approx. 2.5V f&ition switch

Below 05V

2F , 0 , , Throttle sensor , Accelerator pedal released

Accelerator pedal fully depressed

2G 0

2H 0 ATF thermosensor -30°C (-20°F) -150°C (302OF) Approx. 4.9%1.12V Ignition switch

ATF

Temp 20% (68OF) Approx. 4.6V ON

130% (266OF) Approx. 1.54V

Hold switch Switch debressed ov Ignition switch

i I I

Switch released Va ON

21 0 Throttle sensor Constant 4.5-5.5v Ignition switch

ON

I , I 2J 0 Distributor Ignition switch ON Approx. OV

(G-signal) [DOHC] or 5V _-

Idle Approx. 1.5V

2K 0 Intake air ther- Ambient air temperature 20% (68’F) Approx. 2.5V Built in airflow

mosensor meter

2L - - - -

- -

2M 0 Pulse generator Engine running at idle (N range) Above 0.6V

-

(IN)

Engine stopped (Ignition switch ON) ov

2N Pulse generator Constant ov

ground

20 0 Solenoid valve ignition switch ON Va

(Purge control) -

Idle Va

2P 0 Hold indicator Hold mode Below 2V Ignition switch

ON

Normal mode VB

23UOFX-1

1 Ul Iv

I u1

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ 20)21Vi,2~]2112Gj2E)2Cj2~ iuI1s]l~lollMIlKI1IJ1~~t~l1Cj1~

32 j3X I3V 13T13R13P13N)3L13J(3H13F( 3D 13s 2P(2N\2L12J12H12F(2D126 1V IATIlRhPjlN(1 LjlJ Ilt-illFI 1 DI 16

4-

F-l 62

Page 430 of 1164

F CONTROL SYSTEM

srmina

3A

38

3c

3D

3E

3F

3G

3H

31

3J

3K

3L

3M

3N

30

3P

3Q

3R

3s

3T I input Output Connection to

Test condition Correct voltage Remark Battery voltage t

- -

Ground (Injector) Constant OU -

- -

Ground (Output) Constant OU -

- -

Ground (CPU) Constant OU -

- -

- Ground (Input) Constant ov

0 Inhibitor switch

D range VB Ignition switch

(D range) ON

Other ranges ov

0 DRL relay Parking brake pulled with ignition switch

l DRL: Daytime

(Canada) ON (DRL OFF) Va

Running Lights

Idle (DRL ON) Below 2.5V 0

Inhibitor switch

(L range) L range

Other ranges VB

ov Ignition switch

ON

0 Inhibitor switch

(S range) S range

Other ranges Va

ov Ignition switch

ON

_-__. - -. -

0 Solenoid valve Engine speed below 5,000 rpm Below 1.5V WCS: Variable In-

(VICS)

Engine speed above 5,000 rpm VB ertia Charging

System [DOHC]

- - -

- - -

- -

- - -

- - -

- - -

0 Solenoid valve 60 [DOHC]/120 [SOHC] seconds after Below 1.5v

(Pressure regula- engine started when engine coolant tem-

tor) [BP] perature above 90% (194*F) and intake

-

air temperature above 58% (136OF)

[DOHC]/50”C (122“F) [SOHC]

Other condition at idle Va

- - - - - -

- -

-

A- - -

- -

- I -

0 ISC valve Ignition switch ON VS

l Engine signal

Monitor: Green

I I Idle I

Approx. 1 OV and red lamps

flash

I

-

- - - -

-

- - - -

- - - - - -

23UOFX-1’

‘) )

U- r, )

IJ- l-1

I 1 r

3Y I3W I3U [3S13d3&M13K 31 13Gj3EI 3C

I3A 20/2M;2K( 21 12G(2E12C12A 1 U 11 Sll o]lOll MI1 K 1 I (1 G(1 E[ 1

C 11 A

32 13x [ 3V(3~(343~I3N[3~ 3~(3~(3~13~ 136 2P12N(2L[2J12H(2F(2D126 iv I~TI~RI~P(~NIIL i~(lii(l~I lo(le

.

F-l 64

Page 434 of 1164

F CONTROL SYSTEM

23UOFX-l! 51

.

r---- - --------1

I

I

i I

I

:,

m7 I

- - -.-

Fc E, Vc Ez 23UOFX-158

WATER THER@OSENSOA

I

03UOFX-21

REPLACE WASHEF

f

OYJOFX-2’

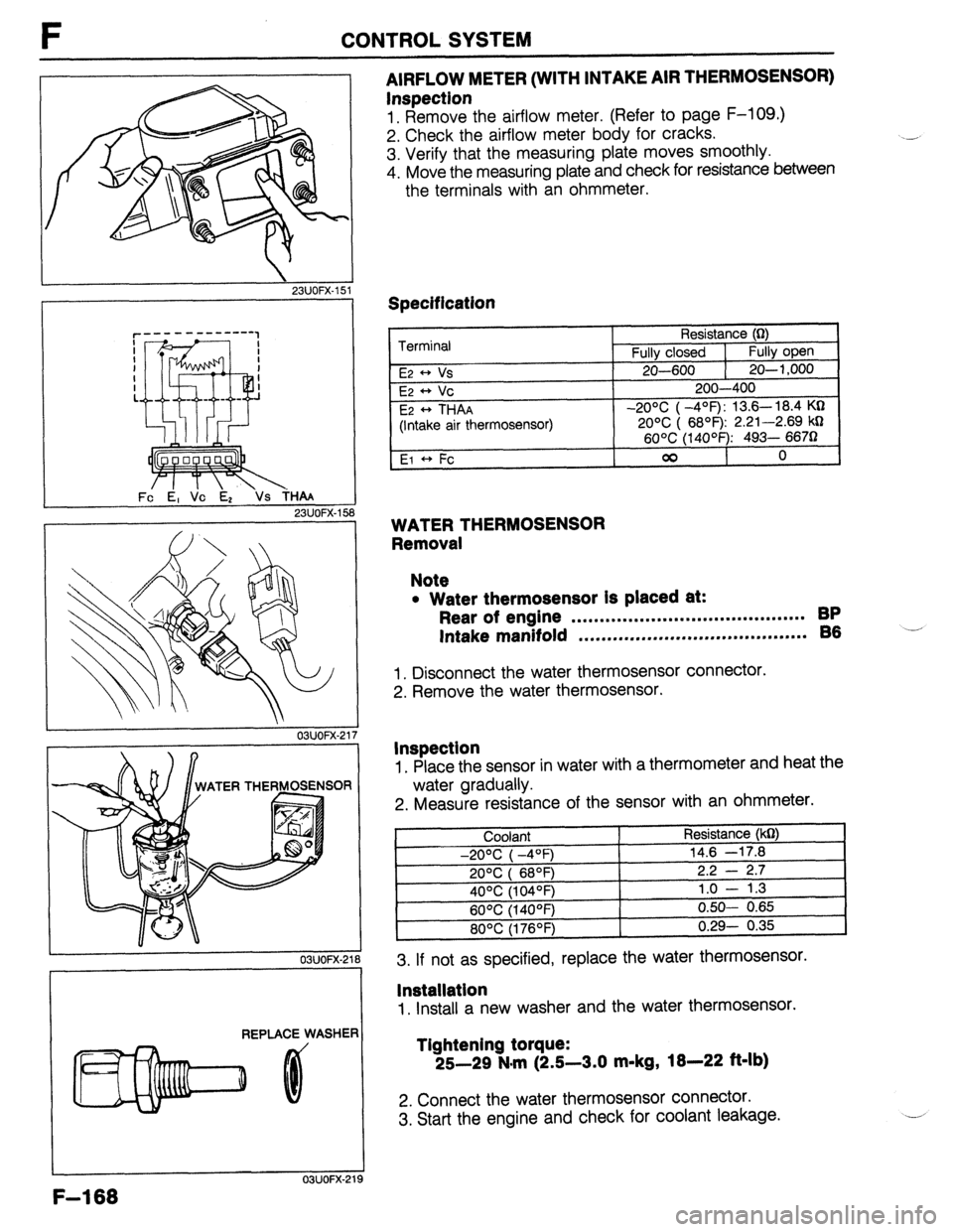

AIRFLOW METER (WITH INTAKE AIR THERMOSENSOR)

Inspection

1. Remove the airflow meter. (Refer to page F-109.)

2. Check the airflow meter body for cracks.

3. Verify that the measuring plate moves smoothly.

4. Move the measuring plate and check for resistance between

the terminals with an ohmmeter.

Specification

Terminal

E2 * Vs

E2 ++ Vc

E2

* THAA

(Intake air thermosensor)

El +, Fc Resistance (0)

Fully closed 1

Fully open

20-600 1 20-l ,000

200-400

-20% ( -4’=F): 13.6- 18.4 KQ

20% ( 6899 2.21-2.69 kD

60°C (14OOF): 493- 6670

00

0

WATER THERMOSENSOR

Removal

Note

l Water thermosensor Is placed at:

Rear of engine . . . . . . . . . . . . . . . . . . . . . . . . ..*.............. BP

Intake manifold ,.*......,..m...,..,.....*....*......... 86 -’

1. Disconnect the water thermosensor connector.

2. Remove the water thermosensor.

Inspection

1. Place the sensor in water with a thermometer and heat the

water gradually.

2. Measure resistance of the sensor with an ohmmeter.

3. If not as specified, replace the water thermosensor.

lnstallatlon

1. Install a new washer and the water thermosensor.

Tlghtening torque:

25-29 N.m (2.5-3.0 m-kg,

18-22 ft-lb)

2. Connect the water thermosensor connector.

3. Start the engine and check for coolant leakage.

F-l 68