alternator MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 34 of 1164

Bl TROUBLESHOOTING GUIDE

Problem

Insufficient power

Abnormal

combustion

Engine noise Possible Cause

Insufficient compression

Malfunction of HLA*

Compression leakage from valve seat

Seized valve stem

Weak or broken valve spring

Failed cylinder head gasket

Cracked or distorted cylinder head

Sticking, damaged, or worn piston ring

Cracked or worn piston Malfunction of fuel system

Malfunction of ignition system

Others

Slipping clutch

Dragging brakes

Wrong size tires Malfunction of engine-related components

Malfunction of HLA’

Sticking or burned valve

Weak or broken valve spring

Carbon accumulation in combustion chamber Malfunction of fuel system

Malfunction of ignition system

Crankshaft- or bearing-related parts

Excessive main bearing oil clearance

Main bearing seized or heat-damaged

Excessive crankshaft end play

Excessive connecting rod bearing oil clearance

Connecting rod bearing seized or heat-damaged Piston-related parts

Worn cylinder

Worn piston or piston pin

Seized piston

Damaged piston ring

Bent connecting rod Valves or timing-related parts

Malfunction of HLA*

Broken valve spring

Excessive valve guide clearance Malfunction of cooling system

Malfunction of fuel system

Others

Malfunction of water pump bearing

Improper drive belt tension

Malfunction of alternator bearing

Exhaust gas leakage

Malfunction of timing belt tensioner Action

Replace

Repair

Replace

Replace

Replace

Replace

Replace

Replace

Refer to Section F

Refer to Section G

Refer to Section H

Refer to Section P

Refer to Section Q

Replace

Replace

Replace

Eliminate carbon

Refer to Section F

Refer to Section G

Replace or repair

Replace

Replace or repair

Replace or repair

Replace

Replace or repair

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Refer to Section E

Refer to Section F

Refer to Section E

Adjust

Refer to Section G

Refer to Section F

Replace Page 81-20

Bl-57

81-55

81-58

81-16

81-54

81-62

al-62

81-20

81-55

81-58

-

61-71

Bl-64

81-72

81-73 8-i-64

Bl-60

81-63

81-62

81-62

El-63

Bl-20

El-58

81-55

Bl- 5

81-12

911 IORI .N)J LI.,“l. --

* Tappet noise may occur if the engine has set idle for an extended period. The noise should

normal operating temperature. (HLA troubleshooting: Refer to page Bl-7) dissipate after the engine has reached

81-4

Page 36 of 1164

Bl ENGINE TUNE-UP PROCEDURE

iLTERNATOR

ALTERNATOR

I

I I I

IDLER

h ANKSHAFT /A/C

-LEY %OMPRESSC

PULLEY

AIC P/S AND A/C

23UOBl-006

WHEN MEASURED

WHEN SET

23UOBl.00

1 /

23UOBl-001

Bl-6

6

4. Check the drive belt deflection by applying moderate pres-

sure (98 N,

10 kg, 22 lb) midway between the pulleys.

Note

l Measure the belt deflection between the specified

pulleys.

l A belt is considered “New” if it has been used on

a running engine for less than five minutes.

Set the deflection specified below accordingly.

l Check the belt deflection when the engine is cold,

or at least 30 minutes after the engine has stopped.

Deflection

mm (in)

Drive

belt New Used Limit

Alternator 8.0-9.0

9.0-10.0 12.5

(0.31-0.35) (0.35-0.39) (0.49)

P/S, P/S + A/C 8.0-9.0

9.0-10.0 11.5

(0.31-0.35) (0.35-0.39) (0.45) A/C 8.0-9.0 9.0-l 0.0

11.5

(0.31-0.35) (0.35-0.39) (0.45)

5. If the deflection is not within specification, adjust it.

6. Install the air intake pipe.

Drive belt tension check

Note

l Belt tension can be checked in place of belt

deflection.

l Belt tension can be measured between any two

pulleys.

1. Removal the air intake pipe.

2. Using the

SST, check the belt tension.

Tension

N (kg, lb)

Drive belt New Used Limit

Alternator

383-461 304-383 167 (39-47, 85.8-103.4) (31-39, 68.2-85.8) (17, 37) PIS, P/S + AIC

491-589 422-491 245

(50-60, 110-132) (43~-50,95--110) (25, 55)

245 A/C 491-589 422-491

(50-60,110-132) (43-50,95-l 10) (25, 55)

3. If the tension is not within specification, adjust it.

4. Install the air intake pipe.

Adjustment

Caution

l If a new belt is used, adjust the belt deflection at

the midpoint of new belt specification.

l A belt is considered “New” if it has been used on

a running engine for less than five minutes.

Alternator belt

1. If necessary, loosen the alternator mounting bolts @and

adjusting bolt @I.

2. Lever the alternator outward and apply tension to the belt.

Page 42 of 1164

Bl ON-VEHICLE MAINTENANCE

TIMING BELT

Removal / Installation

1. Disconnect the negative battery cable.

2. Raise the vehicle on a lift and remove the right front wheel.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal, referrina to Installation Note.

7.6-11 N.m

[SO-110 cm-kg, 69-95 in-lb)

7.6-11 N.m

(60-l 10 cm-kg,

0 69-95 in-lb)

, .v- I . (60-110 cm-kg, 69-95 in-lb)

157-167 (16-17, 116-123) /@ 7.i11 N.m

(60-110 cm-kg,

69-95 in-lb)

N.m (m-kg, ft-lb]

23UOBl-01

1. Under cover and side cover 10. Timing belt cover, lower

2. P/S and/or A/C drive belt 11. High-tension leads

3. Alternator drive belt 12. Spark plugs

4. Water pump pulley 13. Timing belt

5. Plate Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-13

6. Pulley lock bolt Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Bl-13

Removal Note ..,.,,.,....,....,...,...,, page Bl-13 14. Tensioner

installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Bl-14 Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 81-13

7. Crankshaft pulley 15. Tensioner spring .__

8. Pulley boss Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 61-13

9. Timing belt cover, upper

131-12

Page 59 of 1164

REMOVAL I31

Step 2

2311081-O: ii

1.

Disconnect the harness connectors shown in the figure.

Removal note

P/S oil pump

Caution

l Do not damage the hoses.

1. Remove the P/S oil pump with the hoses still connected.

2. Position the pump away from the engine and affix it with wire.

A/C compressor (if equipped)

Caution

l Do not damage the hoses.

1, Remove the A/C compressor with the hoses still connected.

2. Position the compressor away from the engine and affix it

with wire.

ALTERNATOR

OIL PRESSURE SWITCH

GROUND THROTTLE SENSOR

------- I

INJECTOR

NEUTRAL SWITCH (MTX)

Page 70 of 1164

Bl DISASSEMBLY

AUXILIARY PARTS

1. Drain the engine oil.

2. Disassemble in the order shown in the figure.

- REPLACE - ’ ,/ I’

1. Distributor and high-tension lead

2. Intake manifold assembly

3, Alternator and drive belt

4. Alternator bracket

5. No.3 engine mount bracket 6. Oil filter

7. Oil pressure switch

8. Spark plug

9. Oil level gauge and pipe 10. Engine hanger

61-40

Page 120 of 1164

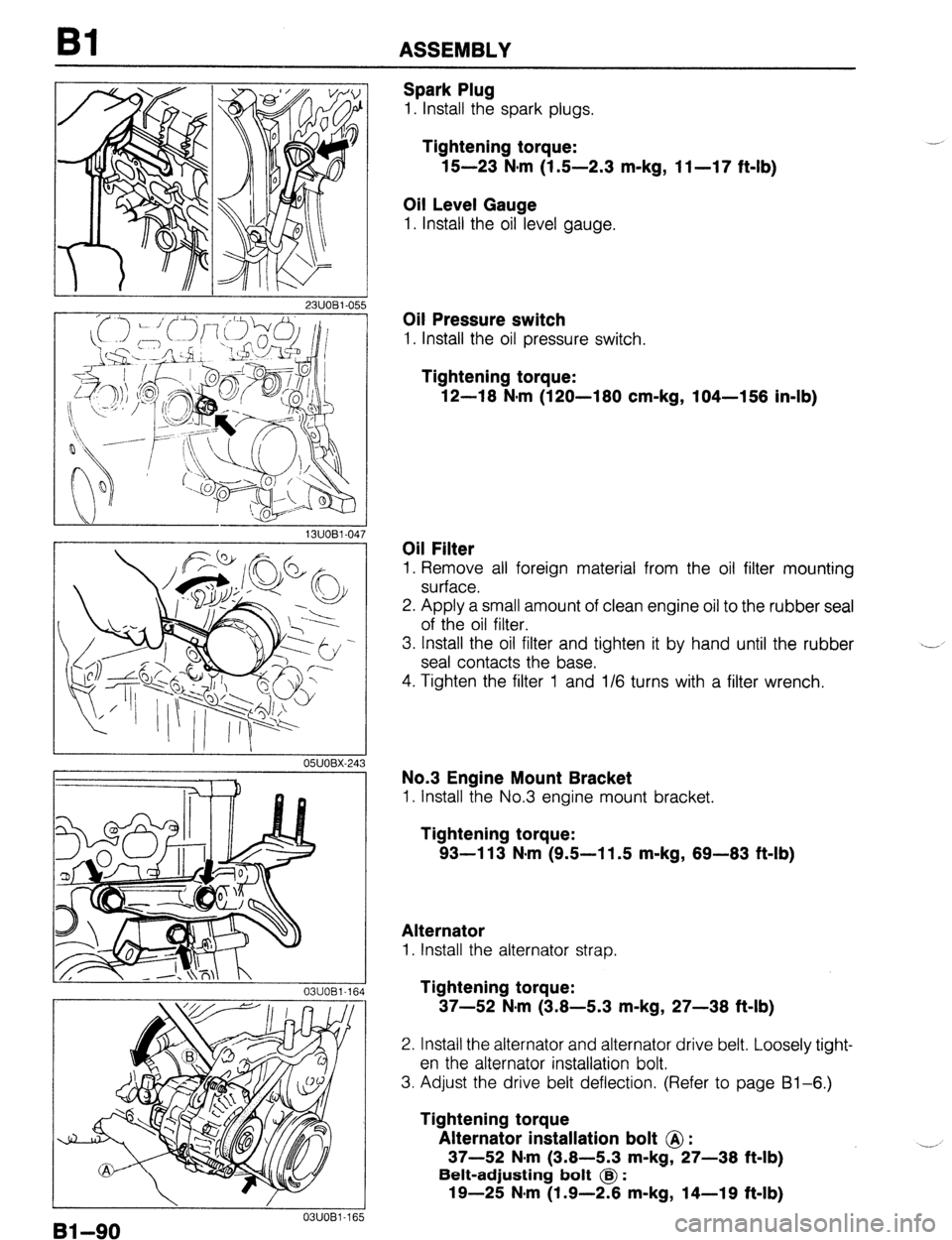

Bl ASSEMBLY

05UOBX-24:

Spark Plug

1. Install the spark plugs.

Tightening torque:

15-23 N*m (1.5-2.3 m-kg, 1 I-17 ft-lb)

Oil Level Gauge

1. Install the oil level gauge.

Oil Pressure switch

1. Install the oil pressure switch.

Tightening torque:

12-18 N-m (120-180 cm-kg, 104-158 in-lb)

Oil Filter

1. Remove all foreign material from the oil filter mounting

surface.

2. Apply a small amount of clean engine oil to the rubber seal

of the oil filter.

3. Install the oil filter and tighten it by hand until the rubber

seal contacts the base.

4. Tighten the filter 1 and l/6 turns with a filter wrench.

No.3 Engine Mount Bracket

1. Install the No.3 engine mount bracket.

Tightening torque:

93-l 13 N-m (9.5-l 1.5 m-kg, 89-83 ft-lb)

Alternator

1. Install the alternator strap.

Tightening torque:

37-52 N#m (3.8-5.3 m-kg, 27-38 ft-lb)

2. Install the alternator and alternator drive belt. Loosely tight-

en the alternator installation bolt.

3. Adjust the drive belt deflection. (Refer to page Bl-6.)

Tightening torque

Alternator installation bolt @ :

37-52 N-m (3.8-5.3 m-kg, 27-38 ft-lb)

Belt-adjusting bolt @ :

19-25 N#m (1.9-2.8 m-kg, 14-19 f&lb) --’ I

I 0311081-165

Bl-90

Page 130 of 1164

Bl INSTALLATION

Step 5

1. Connect the harness connectors shown in the figure.

GROUND ALTERNATOR

OIL PRESSURE SWITCH

I- THFOTTLE SENSOR

NEUTRAL SWITCH (MTX)

IGNITION COIL

$A_c_K;u_p LIGHT SWITCH

____------- ;

Step 6

Torque Specifications

7.8-11 N.m (80-110 cm-kg, 89-95 in-lb)

19-25 (1.9-2.6, 14-19)

2.9-5.9 N.m

(30-60 cm-kg, 26-52 in-lb)

7.8-11 N.m

(80-l 10 cm-kg,

6.4-9.3 N.m 37-52

(3.8-5.3, 27-38)

24-35

(2.4-3.6, 17-26)

7.8-11 N.m 160-110 cmika, 69-95 in-lb) ‘-- -- -..’ ‘-=’ -’ / 166-96 r?m.ka.

66-82 in-lb) 69-95 in-lb)

N.m (m-kg, ft-lb -- OBUOBl-1E

Bl-100

Page 134 of 1164

82 INDEX

NDEX

COMPRESSION INSPECTION, PAGE 92-10

STANDARD: 1,256 kPa (12.8 kg/cm2, 182 psi)-300 rpm

MINIMUM: 883 kPa (9.0 kg/cm2, 128 psi)-300 rpm

INTAKE MANIFOLD

TIGHTENING TORQUE

*(I-I)* hl.m I, (I-0 c m.h.

DRIVE BELT

ADJUSTMENT, PAGE 82-6 TIGHTENIF

36-46 N.m (3.9-4.7 rlG TORQUE

m-kg, 26-34 ft-lb)

JEFLECTION

mm (in)

DRIVE BELT

New Used Limit

ALTERNATOR

8.0-9.0 (0.31-0.35) 9.0-10.0 (0.35-0.39)

12.5 (0.49)

PIS, PIS + AIC 8.0-9.0 (0.31-0.35) 9.0-10.0 (0.35-0.39)

11.5 (0.45)

23UOB2-00:

1. Timing belt

6. Engine

Removal I Installation..

..............

page 62-l 2 Removal ...................................

page 82-31

2. Cylinder head gasket

Engine stand mounting..

.......... page 82-38

Replacement ............................

page B2-16 Disassembly

.............................

page 82-41

3. HLA

Inspection / Repair.. ..................

page B2-54

Removal / Installation

................ page

82-22 Assembly ..................................

page B2-66

4. Front oil seal

Engine stand dismounting

....... page 62-91

Replacement

page 82-26 Installation..

.-- ............................

............................... page 62-93

5. Rear oil seal

Replacement ............................

page 82-28

82-2

Page 136 of 1164

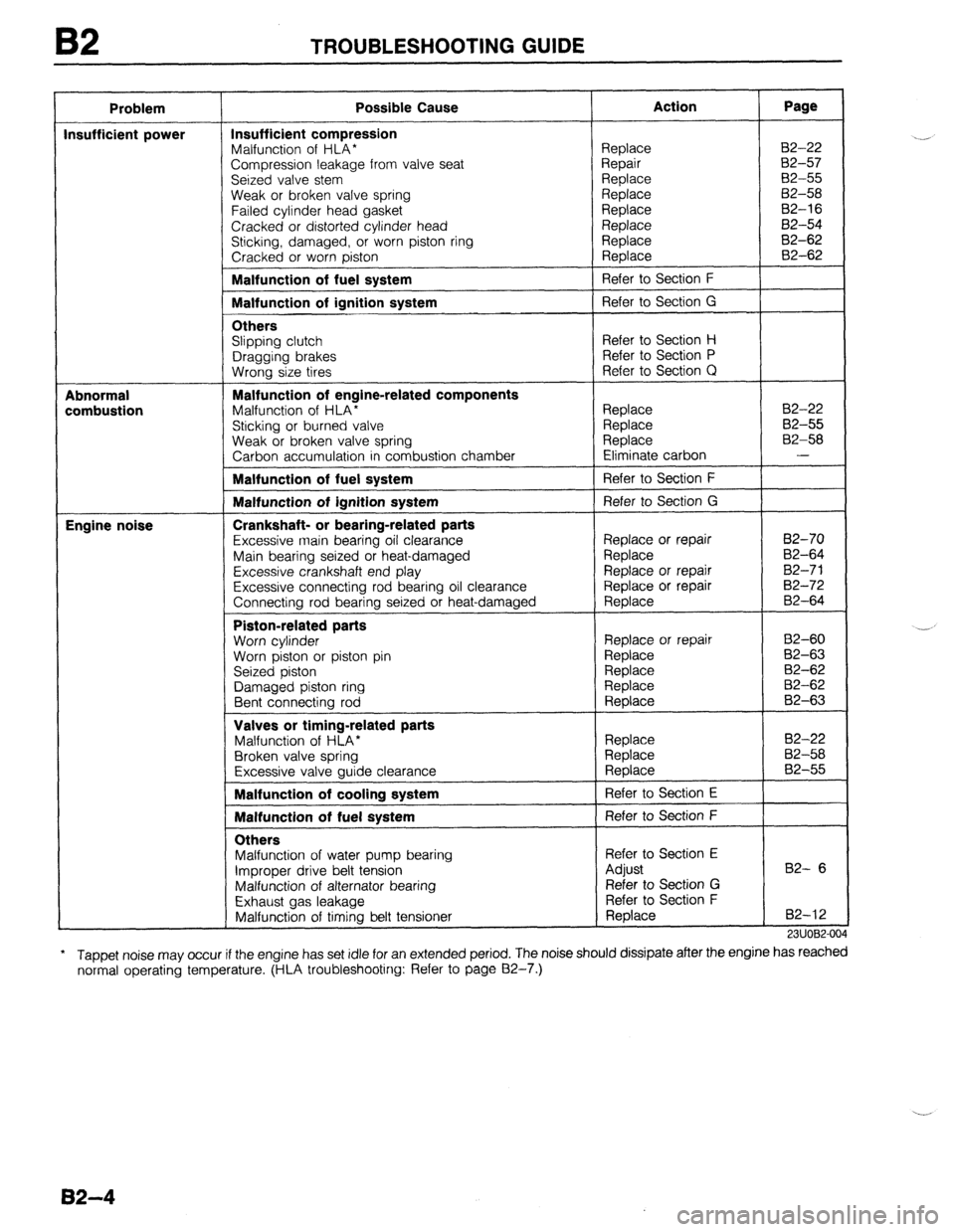

B2 TROUBLESHOOTING GUIDE

Problem

Insufficient power

Abnormal

combustion

Engine noise -

I

I

f

,

I

I

,

I

I Possible Cause Action Page

Insufficient compression

Malfunction of HLA*

Compression leakage from valve seat

Seized valve stem

Ueak or broken valve spring

Failed cylinder head

gasket Cracked or distorted cylinder head

Sticking, damaged, or worn piston ring

Cracked or worn piston Replace

Repair

Replace

Replace

Replace

Replace

Replace

Replace

Refer to Section F 82-22

82-57

02-55

B2-58

82-16

82-54

82-62

82-62 Malfunction of fuel system

Malfunction of ianition svstem

Others

Slipping clutch

Dragging brakes

Wrong size tires Malfunction of engine-related components

Malfunction of HLA*

Sticking or burned valve

Weak or broken valve spring

Carbon accumulation in combustion chamber Malfunction of fuel system

Malfunction of ignition system

Crankshaft- or bearing-related parts

Excessive main bearing oil clearance

Main bearing seized or heat-damaged

Excessive crankshaft end play

Excessive connecting rod bearing oil clearance

Connecting rod bearing seized or heat-damaged Piston-related parts

Worn cylinder

Worn piston or piston pin

Seized piston

Damaged piston ring

Bent connecting rod Valves or timing-related parts

Malfunction of HLA*

Broken valve spring

Excessive valve guide clearance Malfunction of cooling system

Malfunction of fuel svstem

Others

Malfunction of water pump bearing Refer to Section E

Improper drive belt tension Adjust

Malfunction of alternator bearing Refer to Section G

Exhaust gas leakage Refer to Section F

Malfunction of timing belt tensioner Replace Refer to Section G

Refer to Section H

Refer to Section P

Refer to Section C!

Replace B2-22

Replace 82-55

Replace 82-58

Eliminate carbon -

Refer to Section F

Refer to Section G

Replace or repair B2-70

Replace 82-64

Replace or repair 82-7 1

Replace or repair B2-72

Replace B2-64

Replace or repair

82-60

Replace 82-63

Replace 82-62

Replace 82-62

Replace 82-63

Replace

Replace

Replace

Refer to Section E

Refer to Section F 82-22

82-58

82-55

B2- 6

82-12

23UOB2-00,

..J

.-,

l

Tappet noise may occur if the engine has set idle for an extended period. The noise should dissipate after the engine has reached

normal operating temperature. (HLA troubleshooting: Refer to page 82-7.)

82-4

Page 138 of 1164

B2 ENGINE TUNE-UP PROCEDURE

ALTERNATOR DRIVE BELT

2311082-00

P/S OIL PUMP

DRIVE BELT

-

A/C AND P/S OIL

PUMP DRIVE BELT

23UOB2-001

1

23UOB2-00

23UOB2-OC

3. Check the drive belt deflection by applying moderate pres-

sure (98 N,

10 kg, 22 lb) midway between the pulleys.

Note

l Measure the belt deflection between the specified

pulleys.

l A belt is considered “New” if it has been used on

a running engine for less than five minutes.

Set the deflection specified below accordingly.

l Check the belt deflectlon when the engine is cold,

or at least 30 minutes after the engine has stopped.

Deflectlon

Drive belt

Alternator

P/S, PAS + A/C New Used

8.0-9.0 9.0-10.0

(0.31-0.35) (0.35-0.39)

8.0-9.0 9.0-I 0.0

(0.31-0.35) (0.35-0.39) mm (in)

Limit

12.5

(0.49)

11.5

(0.45)

4. If the deflection is not within specification, adjust it.

5. Install the air intake pipe.

Drive belt tension check

Note

l Belt tension can be checked in place of belt

deflection.

l Belt tension can be measured between any two

pulleys.

1. Removal the air intake pipe.

2. Using the

SST, check the belt tension.

_-

Tenslon

N (kg, lb)

Drive belt

Alternator New

383-461 Used

304-383 Limit

167

(39-47, 85.8-103.4) (31-39, 68.2-85.8) (17, 37)

P/S, P/S + AIC 491-589 422-491 245

(5040, 110-132) (43-50,95-l 10) (25, 55)

3. If the tension is not within specification, adjust it.

4. Install the air intake pipe.

Adjustment

Cautlon

l If a new belt is used, adjust the belt deflection at

the midpoint of new belt specification.

l A belt is considered “New” If it has been used on

a runnlng engine for less than five minutes.

1. Alternator belt

(1) Loosen the alternator mounting bolt @ and adjusting

lock bolt @.

(2) Lever the alternator outward and apply tension to the

belt.

(3) Tighten adjusting lock bolt @I.

82-6