engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 1 of 1164

1992

Mazda

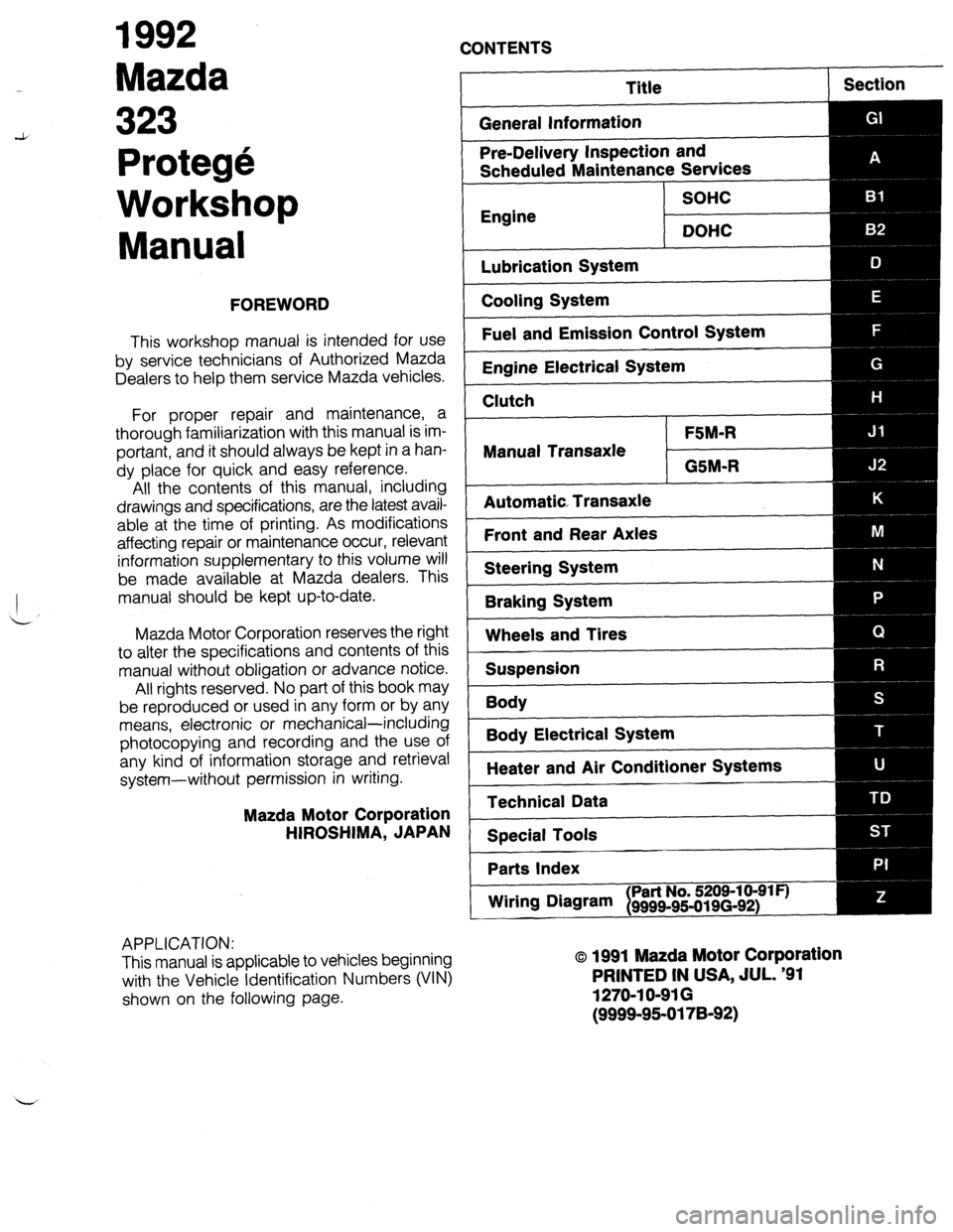

CONTENTS

Protege

Workshop

Manual

FOREWORD

This workshop manual is intended for use

by service technicians of Authorized Mazda

Dealers to help them service Mazda vehicles.

For proper repair and maintenance, a

thorough familiarization with this manual is im-

portant, and it should always be kept in a han-

dy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest avail-

able at the time of printing. As modifications

affecting repair or maintenance occur, relevant

information supplementary to this volume will

be made available at Mazda dealers. This

manual should be kept up-to-date.

Mazda Motor Corporation reserves the right

to alter the specifications and contents of this

manual without obligation or advance notice.

All rights reserved. No part of this book may

be reproduced or used in any form or by any

means, electronic or mechanical-including

photocopying and recording and the use of

any kind of information storage and retrieval

system-without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN)

shown on the following page.

Title

General Information Section

Pre-Delivery Inspection and

Scheduled Maintenance Services

SOHC

Engine

DOHC

Lubrication System

Cooling System

Fuel and Emission Control System

Engine Electrical System

Clutch

FSM-R

Manual Transaxle

GSM-R

Automatic Transaxle

Front and Rear Axles

Steering System

Braking System

Wheels and Tires

Suspension

Body

--

Body Electrical System

Heater and Air Conditioner Systems

Technical Data

Special Tools

Parts Index

Wiring DNvam

I Part No. 5209-10-91 F)

9999~95-019(3-92)

o 1991 Mazda Motor Corporation

PRINTED IN USA, JUL. ‘91

1270-l O-91 G

(9999-95-0178-92)

Page 4 of 1164

IMPORTANT INFORMATION

IMPORTANT INFORMATION

BASIC ASSUMPTIONS

This workshop manual assumes that you have certain special tools that are necessary for the safe and effi-

cient performance of service operations on Mazda vehicles and that you know how to use them properly.

It also assumes that you are familiar with automobile systems and basic service and repair procedures. You

should not attempt to use this manual unless these assumptions are correct and you understand the conse-

quences described below.

SAFETY RISK

This manual contains certain notes, warnings, and other precautionary information that you should carefully

read and follow to reduce the risk of personal injury to yourself or others and the risk of improper service

that may damage the vehicle or render it unsafe. If there is no such information in regard to any specific

service method, this does not mean there is no possibility that personal safety or vehicle safety will be

jeopardized by the use of incorrect methods or tools.

POSSIBLE LOSS OF WARRANTY

The manufacturer’s warranty on Mazda vehicles and engines can be voided if improper service or repairs

are performed by persons other than those at an Authorized Mazda Dealer.

WARNING ON LUBRICANTS AND GREASES

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used oils contaminated

during service (e.g., engine sump oils) are more irritating and more likely to cause serious effects, including

skin cancer, in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving oil.

Protective hand cleaners may be of value provided they can be removed from the skin with water. Do not

use gasoline, paraffin, or other solvents to remove oil from the skin.

Lubricants and greases may be slightly irritating to the eyes.

Repeated or prolonged skin contact should be avoided by wearing protective clothing if necessary. Particu-

lar care should be taken with used oils and greases containing lead. Do not allow work clothing to be con-

taminated with oil. Dry clean or launder such clothing at regular intervals.

9MUGIX-002

GI-2

Page 6 of 1164

HOW TO USE THIS MANUAL/FUNDAMENTAL PROCEDURES

SYMBOLS

There are six symbols indicating oil, grease, and sealant. These symbols show the points of applying such

materials during service.

Symbol Meaning Kind

Apply oil New engine oil or gear oil as appropriate

aI i . Apply brake fluid Only brake fluid

Apply automatic transaxle fluid Only ATF

Apply grease Appropriate grease

amal Apply sealant Appropriate sealant

0 Apply petroleum jelly Appropriate petroleum jelly

23UGIX-001

Note

l When special oil or grease is needed, this is shown in the illustration.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each

one is there for a specific purpose.

NOTES give you added information that will help you to complete a

particular procedure.

CAUTIONS are given to prevent you from making an error that could damage the

vehicle. WARNINGS

remind you to be especially careful in those areas where carelessness can cause per-

sonal injury.

The following list contains some general WARNINGS you should follow when you work on

a vehicle.

9MUGIX-036

SMUGIX-037

a-4 FUNDAMENTAL PROCEDURES

PROTECTION OF THE VEHICLE

Always be sure to cover fenders, seats, and floor areas be-

fore starting work.

Page 7 of 1164

FUNDAMENTALPROCEDURES GI

SMUGIX-0: B

47UOGX-00 5 ‘3

16

A WORD ABOUT SAFETY

The following precautions must be followed when jacking up

the vehicle.

1. Block the wheels.

2. Use only the specified jacking positions.

3. Support the vehicle with safety stands.

Start the engine only after making certain the engine compart-

ment is clear of tools and people.

PREPARATION OF TOOLS AND MEASURING

EQUIPMENT

Be sure that all necessary tools and measuring equipment are

available before starting any work.

SPECIAL TOOLS

Use special tools when they are required.

REMOVAL OF PARTS

While correcting a problem, try also to determine its cause.

Begin work only after first learning which parts and subassem-

blies must be removed and disassembled for replacement or

repair.

DISASSEMBLY

If the disassembly procedure is complex, requiring many parts

to be disassembled, all parts should be disassembled in a way

that will not affect their performance or external appearance

and identified so that reassembly can be performed easily and

efficiently.

GI-5

Page 12 of 1164

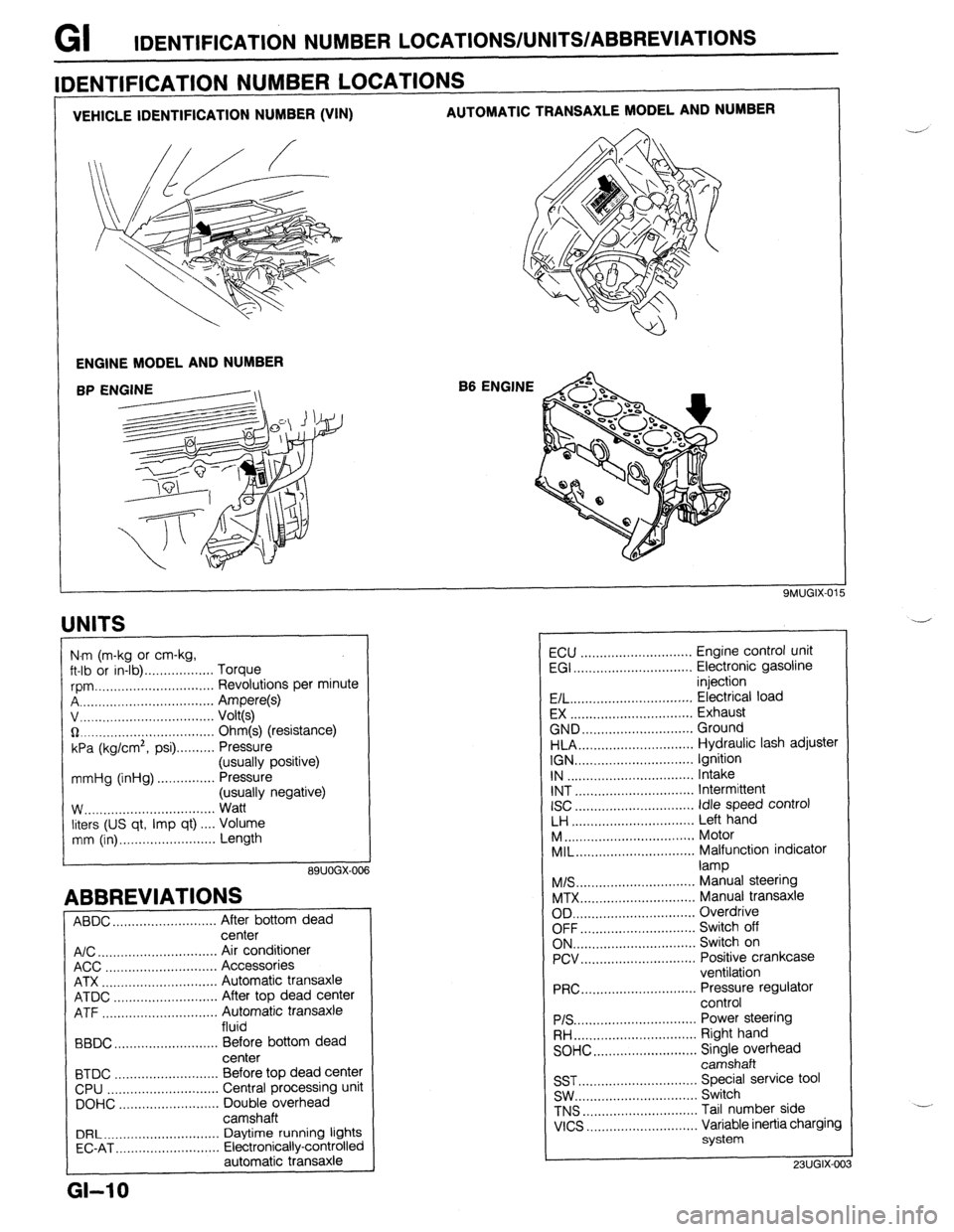

GI IDENTIFICATION NUMBER LOCATIONS/UNITS/ABBREVlATlONS

VEHICLE IDENTIFICATION NUMBER (VIN) AUTOMATIC TRANSAXLE MODEL AND NUMBER

ENGINE MODEL AND NUMBER

B6 ENGINE

IDENTIFICATION NUMBER LOCATIONS

UNITS

I

N.m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . . . . . . . . . . . . . . Torque

rpm ._..,,,.............,.......... Revolutions per minute

A . . . . . . . . . . . . . . . . . Ampere(s)

v, . . . . . . . . . . . . . .

Volt(s)

$2 _....._..,......................... Ohm(s) (resistance)

kPa (kg/cm2,

psi) . . . . . . . . . . Pressure

(usually positive)

mmHg (inHg) . . . . . . . . . . . . . . . Pressure

(usually negative)

W.. . . . . . . . . . . .

Watt

liters (US qt, Imp qt) ,... Volume

mm (in) ..,......,...,........... Length

89UOGX-00

ABBREVIATIONS

ABDC . . . . . . . . . . . . . . . . . . . . .

After bottom dead

center

A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air conditioner

ACC ..,.,...... 3 . . . . . . . . . . . . . . . . . Accessories

ATX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic transaxle

ATDC ..,,...,...,............... After top dead center

ATF . . . . . . . . . . . . . . . . . Automatic transaxle

fluid

BBDC ,,..,.......,...,......,... Before bottom dead

center

BTDC .,......,...............,.. Before top dead center

CPU ..,,.......,...,..........,.. Central processing unit

DOHC ..,...,..,............,,.. Double overhead

camshaft

DRL ____.......................... Daytime running lights

EC-AT .,_.......,............,,.. Electronically-controlled

automatic transaxle

L

GI-10

ECU ............................. Engine control unit

EGI ............................... Electronic gasoline

injection

E/L.. .............................. Electrical load

EX ................................ Exhaust

GND.. ........................... Ground

HLA.. ............................ Hydraulic lash adjuster

IGN ............................... Ignition

IN ................................. Intake

INT ............................... Intermittent

ISC

............................... idle speed control

LH ................................ Left hand

M..

................................ Motor

MIL..

............................. Malfunction indicator

lamp

M/S..

............................. Manual steering

MTX.. ............................ Manual transaxle

OD ................................ Overdrive

OFF.. ............................ Switch off

ON.. .............................. Switch on

PCV.. ............................ Positive crankcase

ventilation

PRC..

............................ Pressure regulator

control

PIS ................................ Power steering

RH..

.............................. Right hand

SOHC.. .........................

z;;kiprhead

SST ............................... Special service tool

SW.. .............................. Switch

TNS

.............................. Tail number side

VICS

............................. Variable inertia charging

system

23UGIX-00

Page 13 of 1164

CAUTION GI

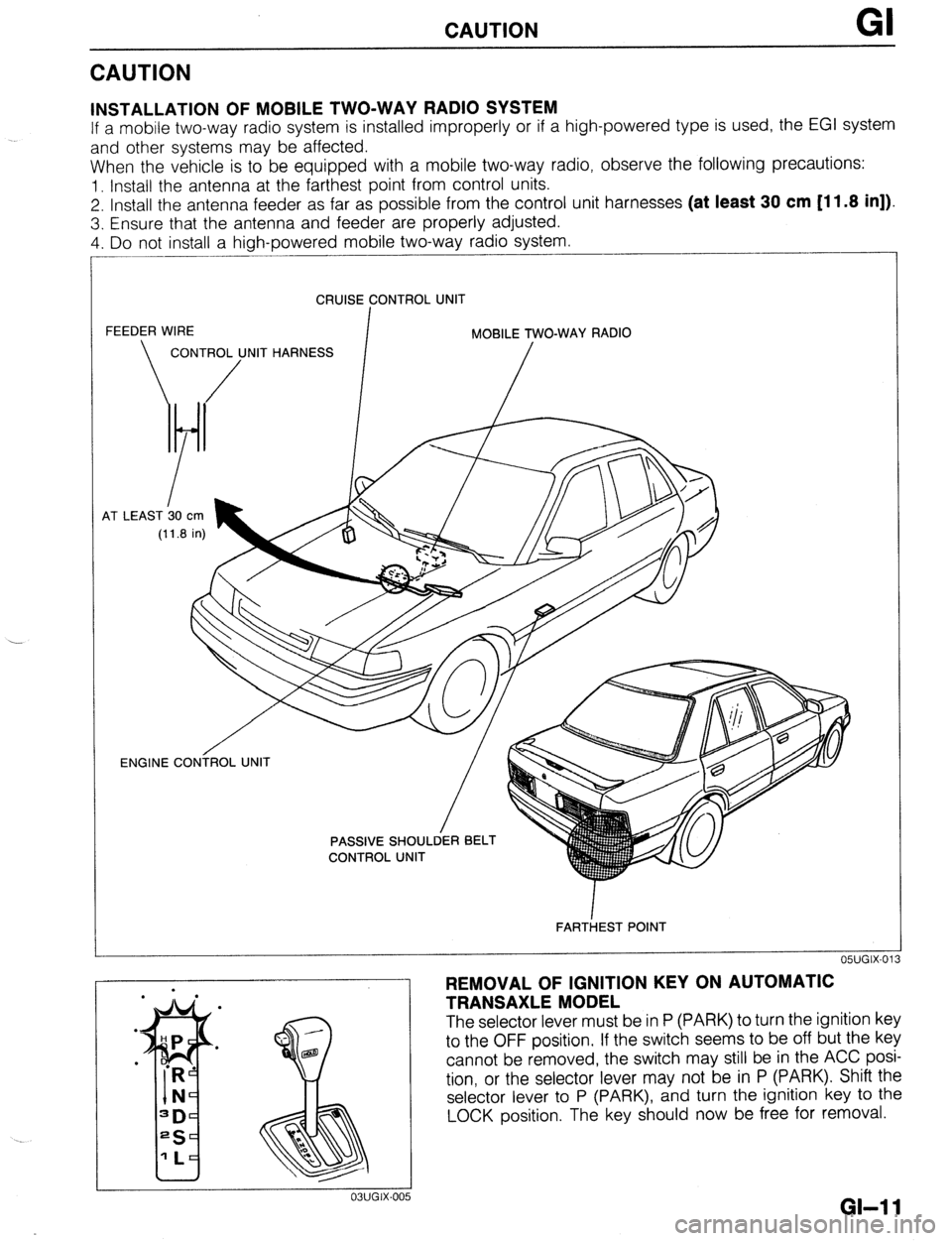

CAUTION

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a mobile two-way radio system is installed improperly or if a high-powered type is used, the EGI system

and other systems may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

1. Install the antenna at the farthest point from control units.

2. Install the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [11.8 in]).

3. Ensure that the antenna and feeder are properly adjusted.

4. Do not install a high-powered mobile two-way radio system.

CRUISE CONTROL UNIT

FEEDER WIRE

I MOBILE TWO-WAY RADIO

CONTROL UNIT HARNESS

/ /

4T LEAST b0

cm

(11.8 in)

OWGIX-013 ENGINE CONiROL UNIT

/

FARTiEST POINT

REMOVAL OF IGNITION KEY ON AUTOMATIC

TRANSAXLE MODEL

The selector lever must be in P (PARK) to turn the ignition key

to the OFF position. If the switch seems to be off but the key

cannot be removed, the switch may still be in the ACC posi-

tion, or the selector lever may not be in P (PARK). Shift the

selector lever to P (PARK), and turn the ignition key to the

LOCK position. The key should now be free for removal.

GI-1 1

Page 20 of 1164

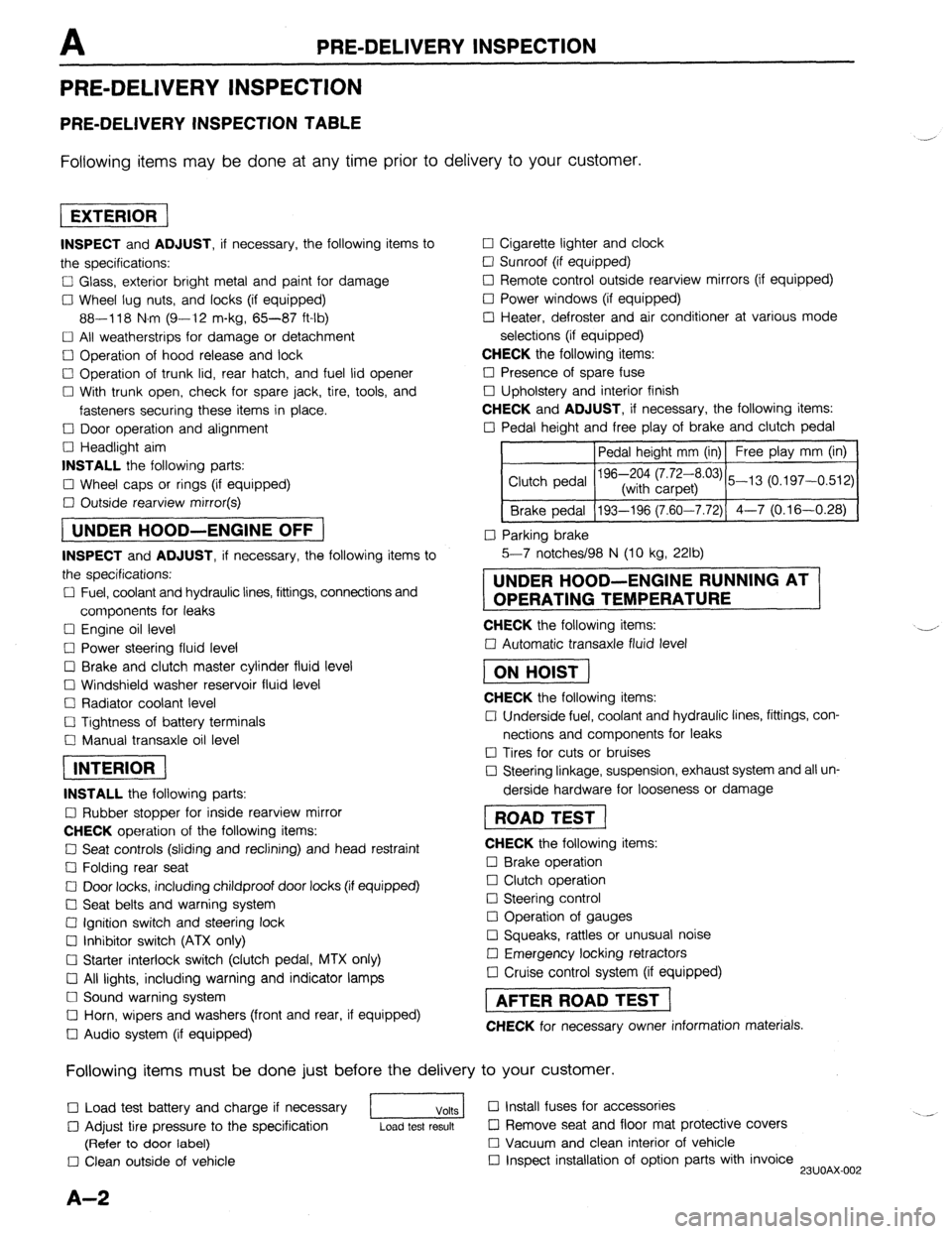

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 21 of 1164

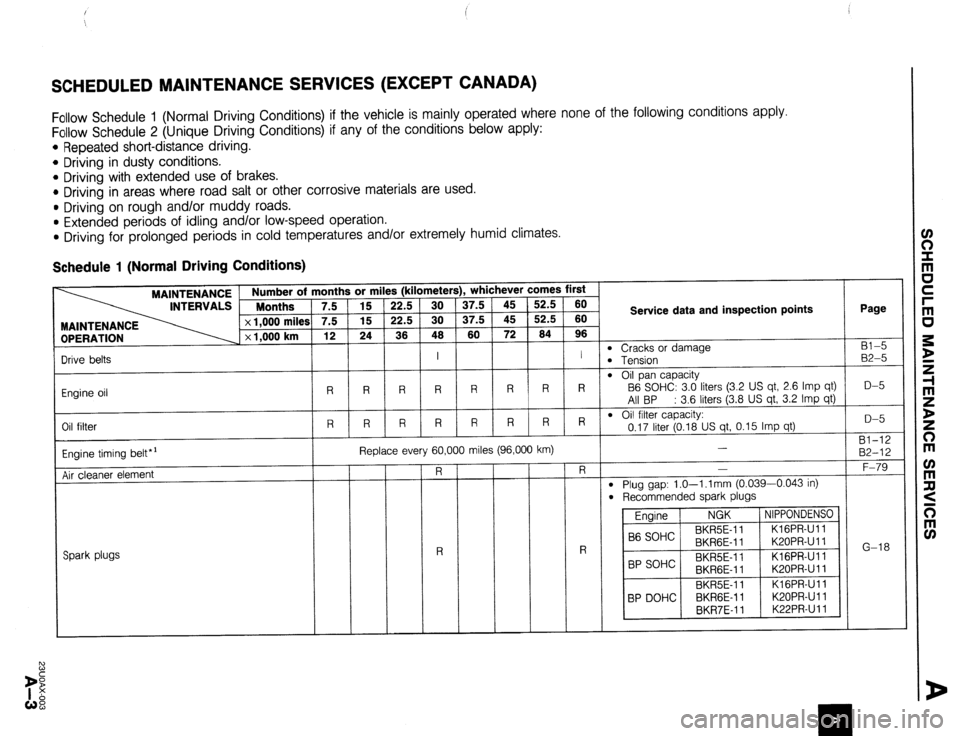

SCHEDULED MAINTENANCE SERVICES (EXCEPT CANADA)

Follow Schedule 1 (Normal Driving Conditions) if the vehicle is mainly operated where none of the following conditions apply.

Follow Schedule 2 (Unique Driving Conditions) if any of the conditions below apply:

l Repeated short-distance driving.

l Driving in dusty conditions.

* Driving with extended use of brakes.

* Driving in areas where road salt or other corrosive materials are used.

l Driving on rough and/or muddy roads.

l Extended periods of idling and/or low-speed operation.

l Driving for prolonged periods in cold temperatures and/or extremely humid climates.

Schedule 1 (Normal Driving Conditions)

Number of months or miles (kilometers), whichever comes first

Months 7.5 15 22.5 30 37.5 45 52.5 60

7.5 15 22.5 30 37.5 45 52.5 60

12 24 36 46 60 72 64 96 Service data and inspection points Page

Bl-5

B2-5

D-5

D-5

Bl-12

B2-12

F-79

G-18 MAINTENANCE

OPERATION

m Cracks or damage

B Tension

m Oil pan capacity

B6 SOHC: 3.0 liters (3.2 US qt, 2.6 Imp qt)

All BP : 3.6 liters (3.8 US qt, 3.2 Imp qt)

l Oil filter capacity:

0.17 liter (0.18 US qt, 0.15 Imp qt)

-

l Plug gap: 1.0-l .l mm (0.039-0.043 in)

l Recommended spark plugs

Engine NGK NIPPONDENSO

B6 SOHC BKR5E-11 KIGPR-Ull

BKRGE-11 K20PR-U 11

BP SOHC BKR5E-11 KlGPR-Ull

BKRGE-11 K20PR-U 11

BKR5E-11 KlGPR-Ull

BP DOHC BKRGE-11 K20PR-U 11

BKR7E-11 K22PR-Ull I I

R R R R R R R R

R R R R R R R R Drive belts

Engine oil

Oil filter

Engine timing belt*’

Air cleaner element Replace every 60,000 miles (96,000 km)

I

Spark plugs

Page 22 of 1164

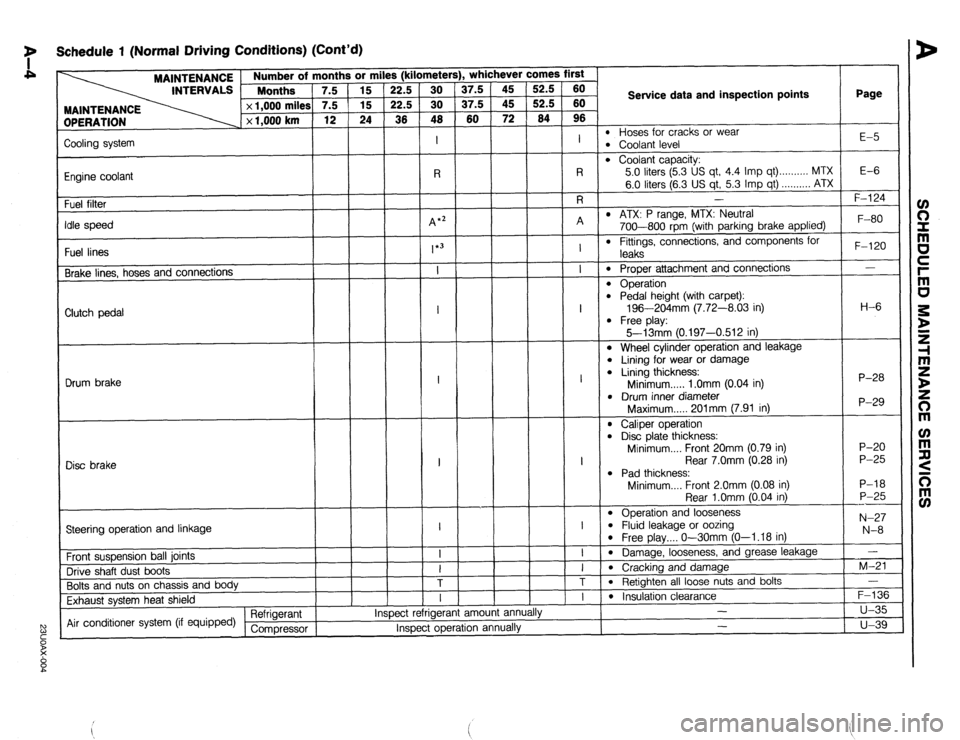

7 Schedule 1 (Normal Driving Conditions) (Cont’d)

MAINTENANCE

INTERVALS 1 ::::“’ rths ’ 7.5

DPERATION x 1,000 miles

x 1,000 km 3r mi

15

15

24

1

Page

l- . whichever comes first s (kilometer!

37.5

37.5

60 52.5

52.5

64 60

60

96

I

l-7

Service data and inspection points

l Hoses for cracks or wear l Coolant level E-5

Zooling system

Engine coolant

Fuel filter

‘die speed

Fuel lines

Brake lines, hoses and connections

l Coolant capacity:

5.0 liters (5.3 US qt, 4.4 Imp qt) . . . . . . . . . . MTX

6.0 liters (6.3 US qt, 5.3 Imp qt) . . . . . . . . . . ATX

I E-6 -

F-l 24

l ATX: P range, MTX: Neutral

700-800 rpm (with parking brake applied)

l Fittings, connections, and components for F-80

F-120

-

H-6

P-28

P-29

P-20

P-25

P-18

P-25

---

N-27

N-8

-

M-21

-

F-136

u-35

u-39 leaks

0 Proper attachment and connections

l Operation l Pedal height (with carpet):

196-204mm (7.72-8.03 in)

l Free play:

5--13mm 10.197-0.512 in) Clutch pedal

l Wheel cylinder operation and leakage

l Lining for wear or damage l Lining thickness:

Minimum . . . . . 1 .Omm (0.04 in)

l Drum inner diameter

Maximum..... 201mm (7.91 in) Drum brake

l Caliper operation l Disc plate thickness:

Minimum.... Front 20mm (0.79 in)

Rear 7.0mm (0.28 in)

l Pad thickness:

Minimum.... Front 2.0mm (0.08 in)

Rear l.Omm (0.04 in)

l Operation and looseness l Fluid leakage or oozing l Free play.... O-30mm (O-l .18 in)

l Damage, looseness, and grease leakage

l Cracking and damage

l Retighten all loose nuts and bolts I

1

Disc brake

I

---l-T

Steering operation and linkage

Front suspension ball joints

Drive shaft dust boots

Bolts and nuts on chassis and body

Exhaust system heat shield

Air conditioner system (if equipped) Refrigerant

Compressor am01 anni I

l Insulation clearance

- ,.

Inspect rerrlgerar

Inspect operation annually -

Page 23 of 1164

Note

I .*.* Inspect, and if necessary correct, clean, or replace

A.... Adjust

R.... Replace or change

T.... Tighten

After 60 months or 60,000 miles (96,000 km), continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points:

* 1 Replacement of the timing belt is required every 60,000 miles (96,000 km). Failure to replace the timing belt may result in damage to the engine.

*2 This maintenance is required for all states except California. However, we recommend that it also be performed on California vehicles.

*3 This maintenance is recommended by Mazda. However, it is not necessary for emission warranty coverage or manufacturer recall liability.